Laser cutting machine for water gaps of battery cover plates

A laser cutting machine and battery cover technology, applied in laser welding equipment, manufacturing tools, welding equipment, etc., can solve the problems of inability to identify product quality and cutting quality, inability to guarantee the quality of injection molded products, and inability to guarantee processing accuracy, etc., to achieve savings The effect of manpower, reducing labor costs and saving loading and unloading time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

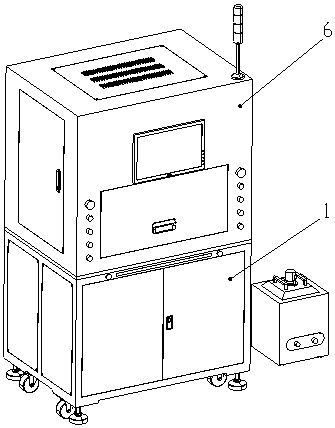

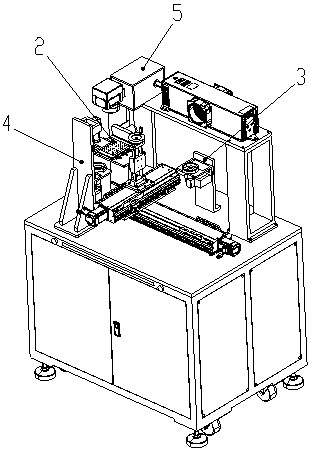

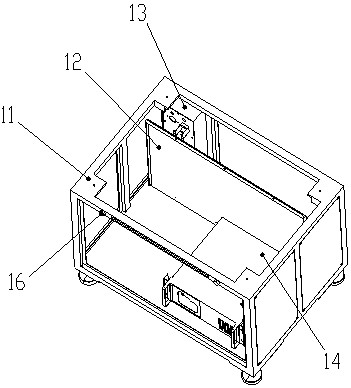

[0038] see figure 1 , figure 2 , the embodiment of the present invention provides a battery cover nozzle laser cutting machine, including a lower frame assembly 1, a clamp movement assembly 2 arranged on the lower frame assembly 1, a CCD good product detection assembly 3, a CCD positioning assembly 4 and an optical path assembly 5, and An upper cover assembly 6 is arranged on the top of the lower frame assembly 1 to cover the clamp movement assembly 2 , the CCD good product detection assembly 3 , the CCD positioning assembly 4 , and the optical path assembly 5 . Among them, the lower frame component 1 plays a supporting role for the entire machine, the fixture movement component 2 is used to control the movement of the fixture, the CCD good product detection component 3 is used to detect good products and non-good products, and the CCD positioning component 4 is used to automatically position the product for laser cutting And detect the cutting quality of the front incision ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com