Side-sweeping polishing method

One kind of edge sweeping and another group of technologies, applied in the field of edge sweeping and polishing, can solve the problems of difficult clamping, discontinuous polishing, and high overall quality requirements of workers, and achieve the advantages of adjustable pressurization pressure, improved polishing trajectory, and improved polishing efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

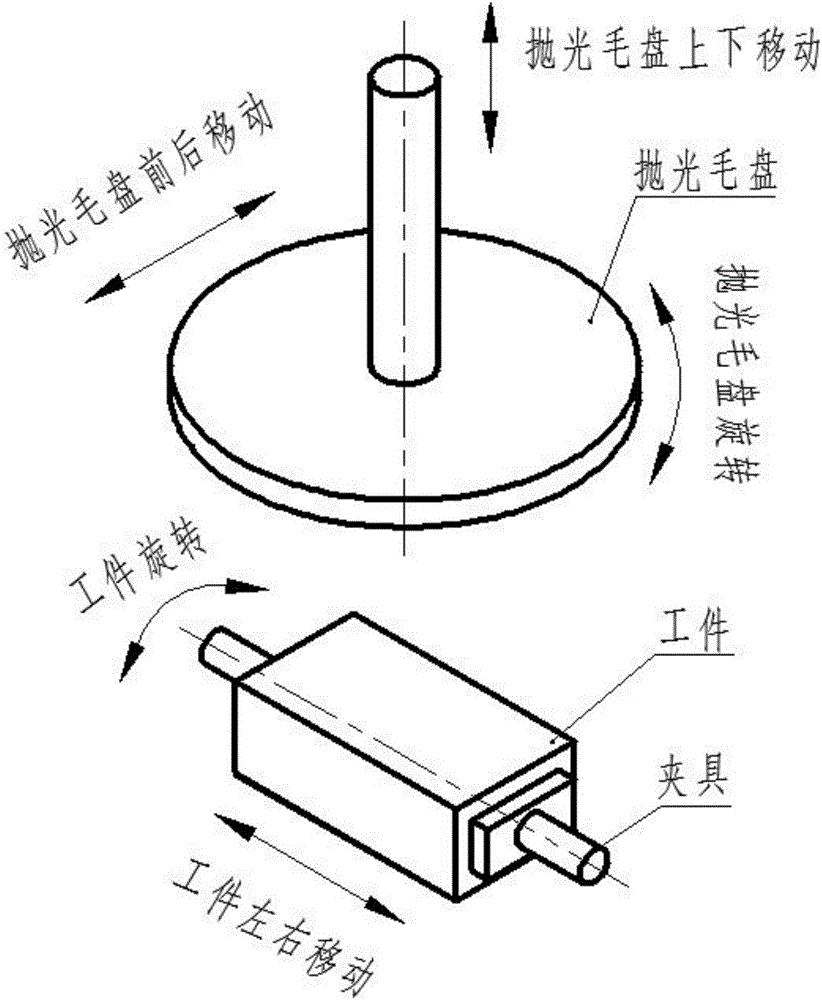

[0015] refer to figure 1 , the edge-sweeping polishing method of the present embodiment is: the polishing pad drives the belt through an independent motor to realize the rotation of the polishing pad, realizes the up and down movement of the polishing pad through the servo motor and the screw rod transmission, and then passes another set of servo motor and wire The rod drive realizes the forward and backward movement of the polishing disc; the workpiece is clamped by the fixture and the cylinder, and the workpiece is driven by the servo motor to realize the rotation of the workpiece (it can make the workpiece stay at any position to prolong the polishing time and increase the controllability of the polishing process), and then through another A set of servo motor and screw drive can realize the left and right movement of the workpiece, so as to realize the polishing movement at any position in the effective three-dimensional space of the polishing disc, and improve the polishin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com