A polishing machine adsorption and transmission system

A transmission system and polishing machine technology, which is applied in the field of polishing machine adsorption and transmission system, can solve the problems of low polishing efficiency and poor adsorption effect of workpieces, and achieve the effects of improving polishing efficiency, improving polishing trajectory, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

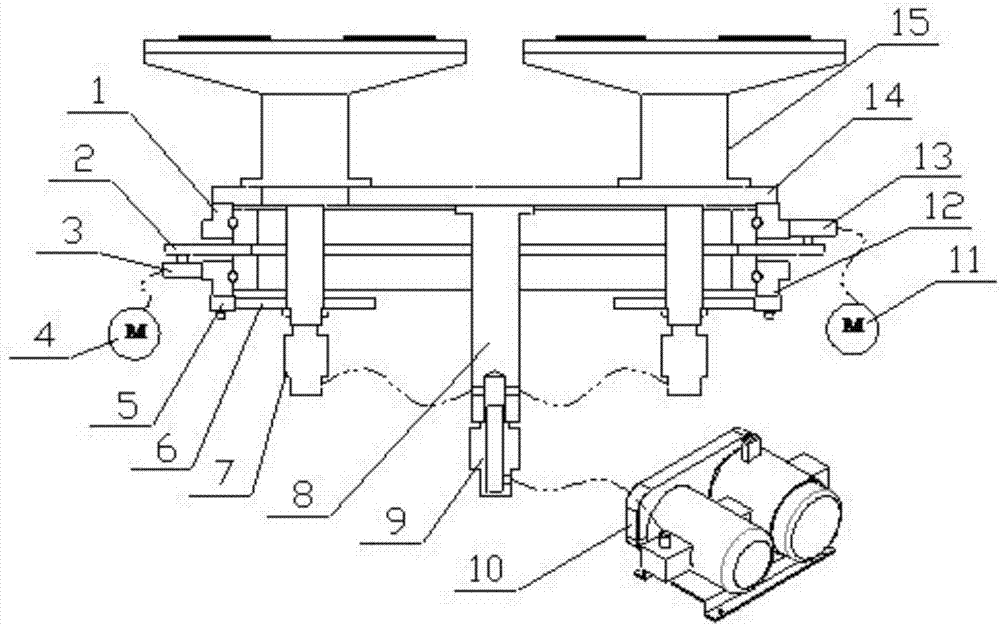

[0022] refer to figure 1 , this embodiment includes turntable bearing I1, support plate 2, gear I3, driving device I4, ring gear I5, gear II6, rotary joint I7, central shaft 8, rotary joint II9, vacuum pump 10, driving device II11, turntable bearing II12, Gear III 13, mounting plate 14 and rotary assembly 15; the turntable bearing I1 is installed on the upper part of the support plate 2, the mounting plate 14 is fixed on the turntable bearing I1, and the central shaft 8 and rotary assembly 15 are fixed on the mounting plate 14 The gear III13 is meshed with the turntable bearing I1, and the gear III13 is connected with the driving device II11; the turntable bearing II12 is installed on the lower part of the support plate 2, the gear I3 is meshed with the turntable bearing II12, and the gear I3 is connected with the The driving device I4 is connected, the ring gear I5 is located on the turntable bearing II12, the gear II6 is installed on the rotary assembly 15, and meshes with t...

Embodiment 2

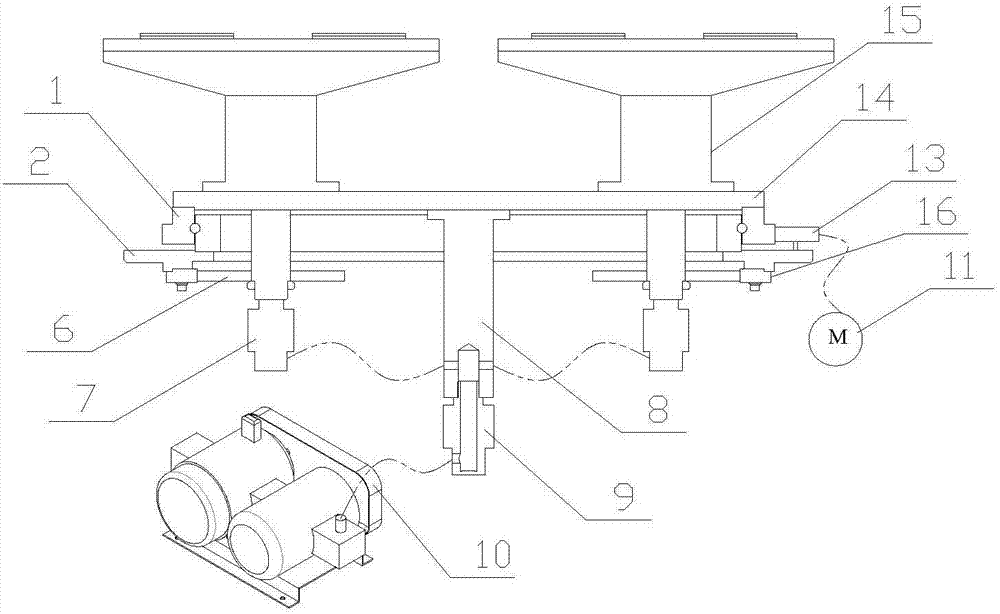

[0026] refer to figure 2 , this embodiment includes a turntable bearing I1, a support plate 2, a gear II6, a rotary joint I7, a central shaft 8, a rotary joint II9, a vacuum pump 10, a driving device II11, a gear III13, a mounting plate 14, a rotary assembly 15 and a ring gear II16; The turntable bearing I1 is installed on the upper part of the support plate 2, the installation plate 14 is fixed on the turntable bearing I1, the central shaft 8 and the rotary assembly 15 are fixed on the installation plate 14; the gear III13 is meshed with the turntable bearing I1 , the gear III13 is connected with the driving device II11; the ring gear II16 is located at the lower part of the support plate 2, and the gear II6 is installed on the rotary assembly 15 and meshed with the ring gear II16; the rotary assembly 15 is provided with an adsorption channel , the rotary joint I7 is installed at the bottom of the rotary assembly 15 and communicates with the adsorption channel, the central s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com