Feeding and discharging device for digital controlled lathe

A CNC lathe and swing mechanism technology, applied in the field of loading and unloading, can solve the problems of unsafe manual loading and unloading, troublesome workpiece loading and unloading, and increased control process, so as to reduce the difficulty of cable laying, facilitate loading and unloading operations, and improve processing efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

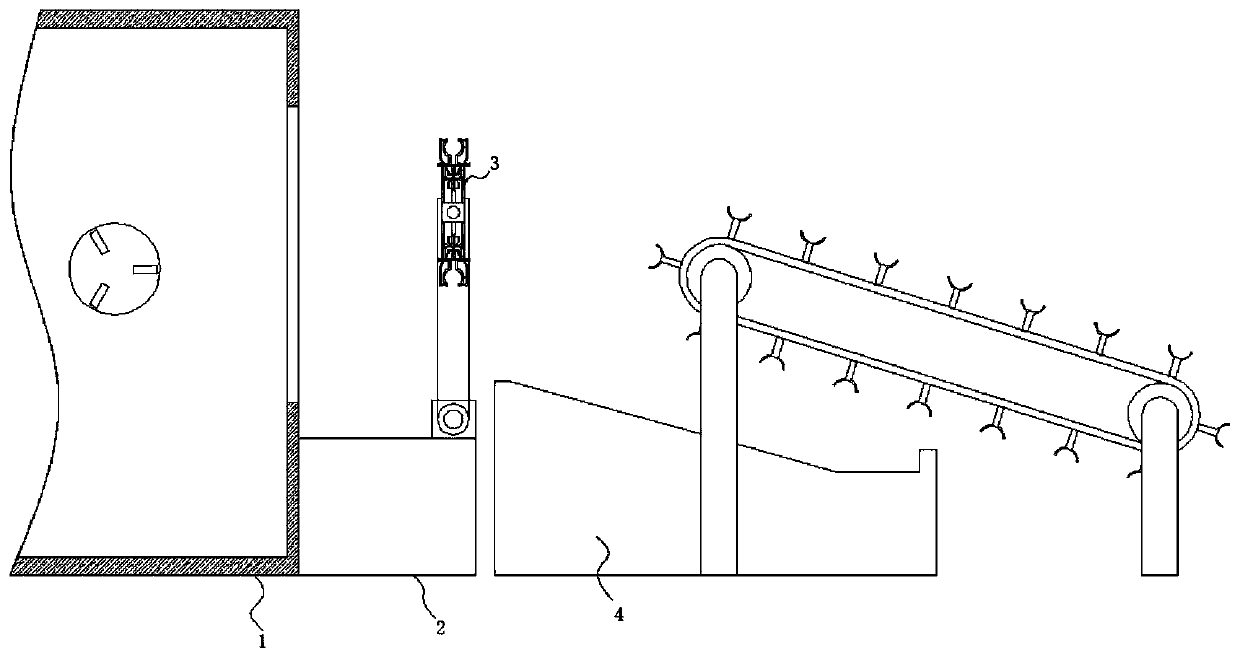

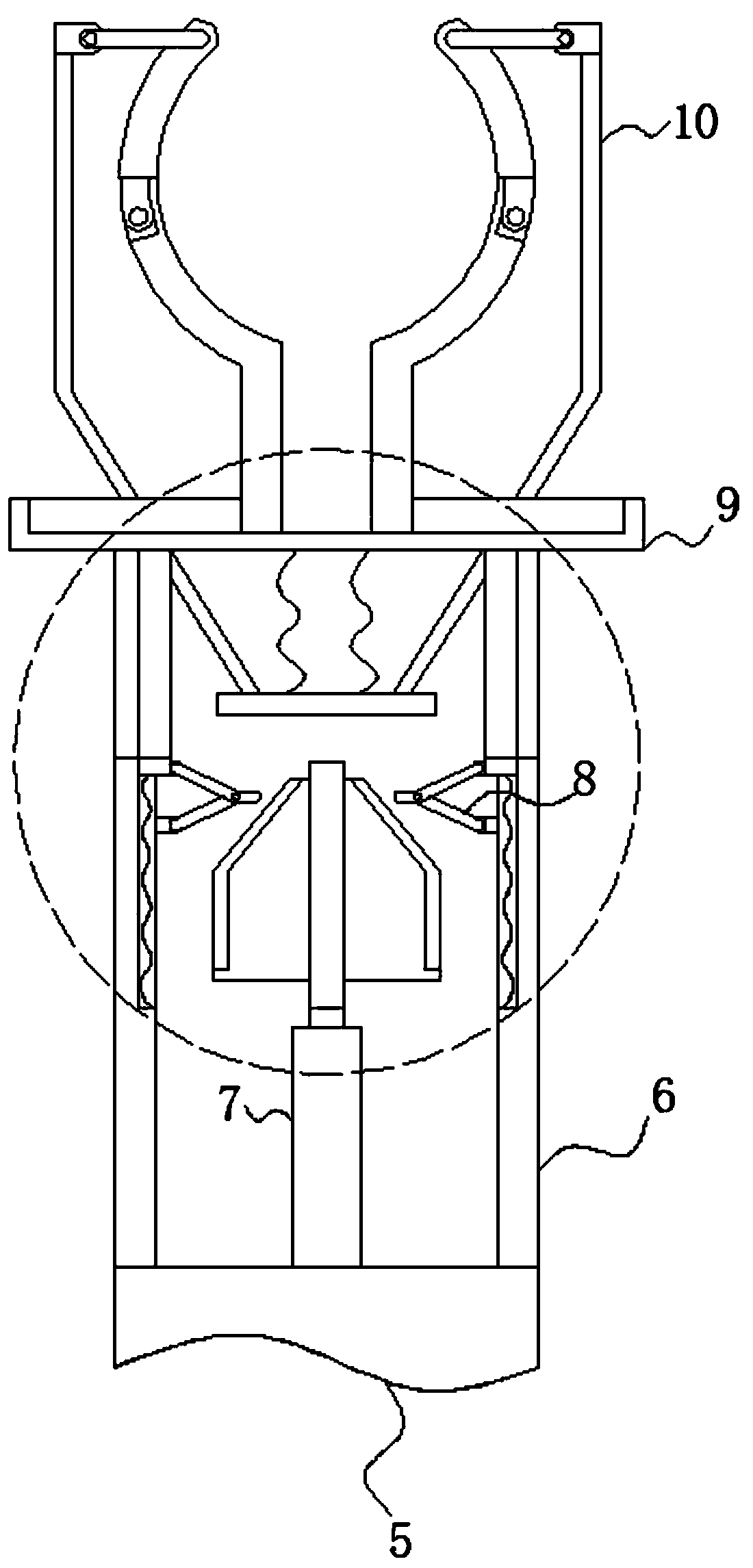

[0034] The swing mechanism 2 comprises a base arranged below the opening of the CNC lathe 1, the top of the base is provided with a rotating rod arranged along the length direction of the CNC lathe 1 through a bearing seat, and one end of the rotating rod is equipped with a first motor affixed to the top of the base, The outer ring of the rotating rod is fixedly sleeved with a swing plate, and the end of the swing plate away from the rotating rod is provided with an inner groove arranged along its length direction, and the opening of the inner groove is movably socketed with a rotating shaft fixedly socketed with the base plate 5, A second motor is installed at one end of the rotating shaft protruding from the swing plate.

Embodiment 2

[0036] The conveying mechanism 4 includes a support frame arranged on the side of the swing mechanism 2 away from the CNC lathe 1. Two groups of side baffles arranged in parallel are installed on the top of the support frame, and the side baffles are arranged obliquely. It is connected to the roller equidistantly arranged along its length direction. The outer ring of the roller is fixedly sleeved with a sprocket arranged along its length direction. The sprocket is connected with a ring-shaped chain. At least three sets of parallel For the provided chain, the outer ring of the chain is fixedly connected with a supporting plate of Y-shaped structure equidistantly arranged along its length direction, and a third motor is installed at one end where the roller protrudes from the side baffle.

Embodiment 3

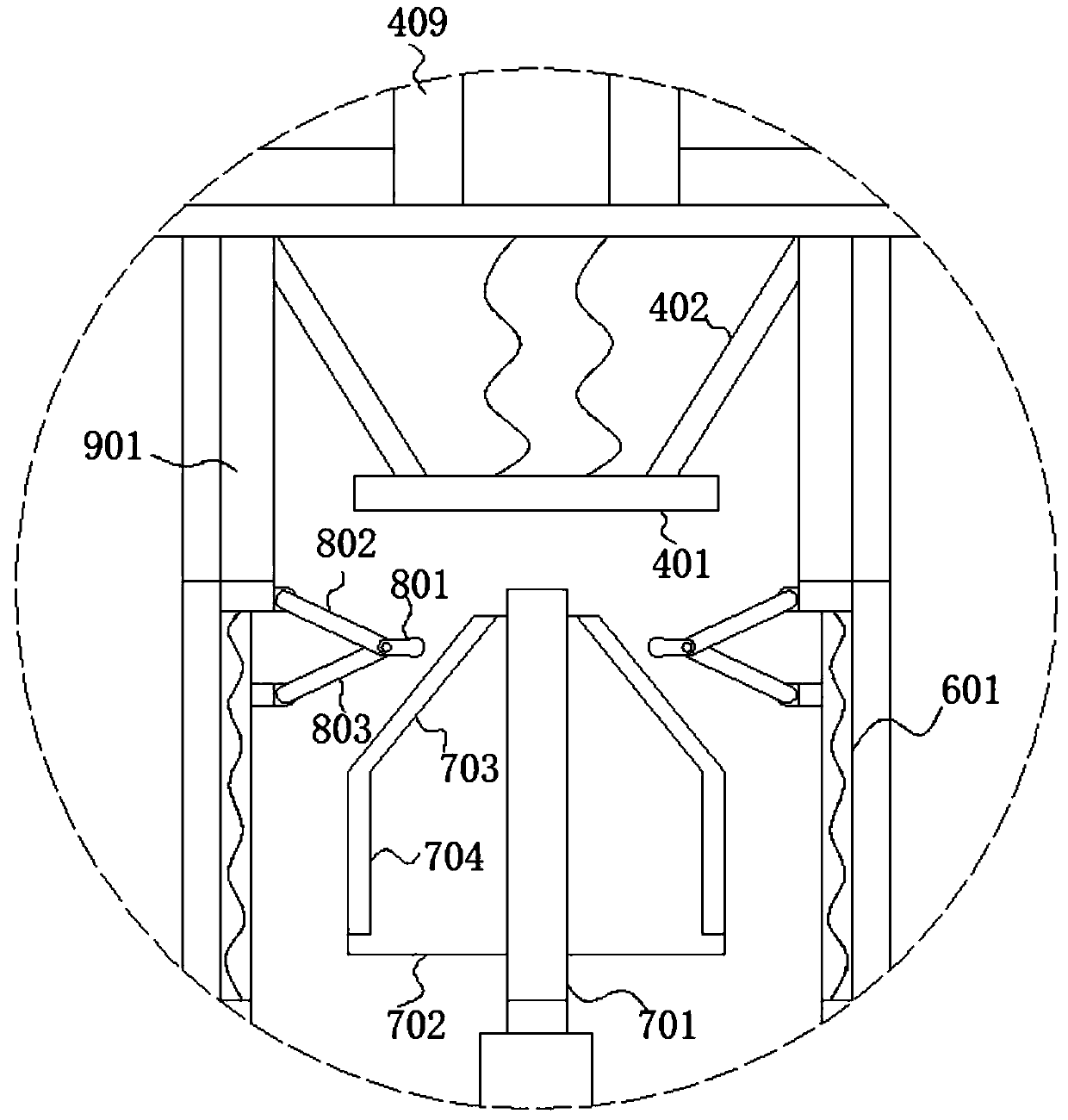

[0038] The pull rod 402 includes a sleeve fixedly connected to the bottom of the cross bar 403. One end of the sleeve away from the cross bar 403 is movably sleeved with a telescopic rod affixed to the top of the push plate 401, and the outer ring of the end close to the telescopic rod is movably socketed with a A second spring fixed to the bottom of the cover plate 9 is installed on the top of the push plate 401 as the rotating collar threadedly connected with the outer ring of the telescopic rod.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com