A high-generation flat panel display glass polishing machine and method for processing glass thereof

A technology of generation flat and polishing machine, applied in surface polishing machine tools, metal processing equipment, grinding/polishing equipment, etc., can solve the problems of small operating space, increased machine cost, cost increase, etc., to achieve convenient operation, up and down The effect of easy operation and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

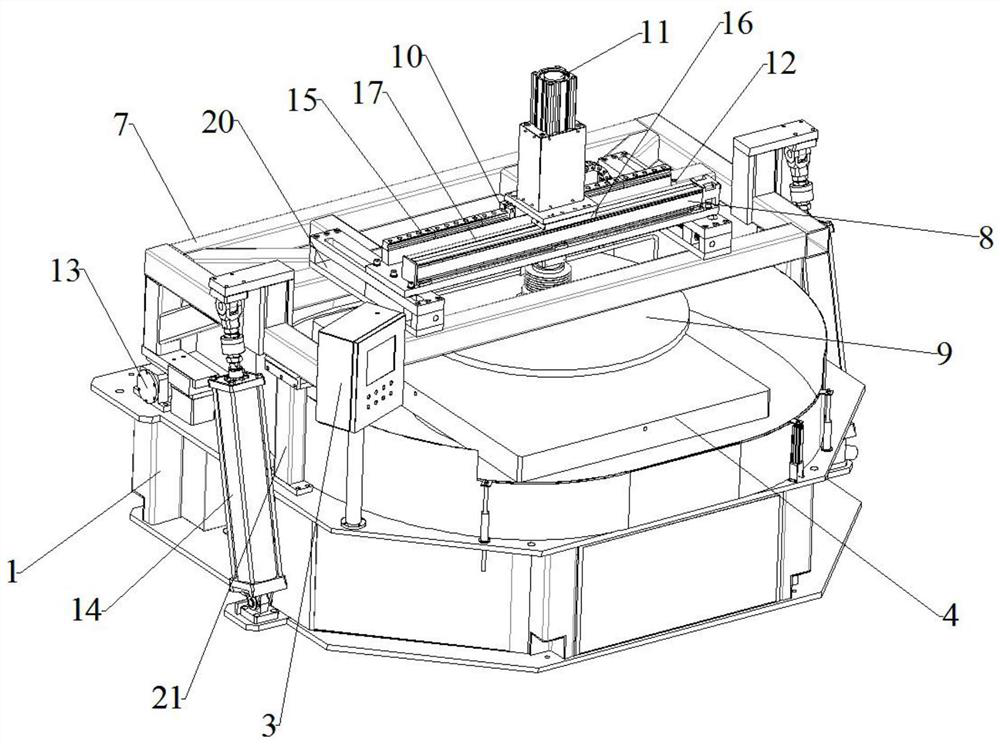

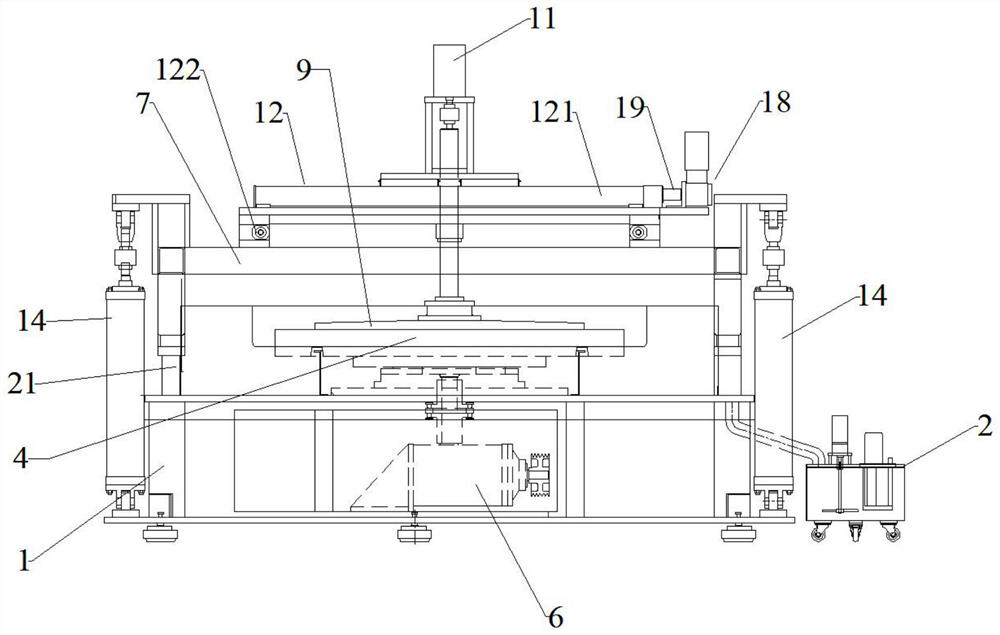

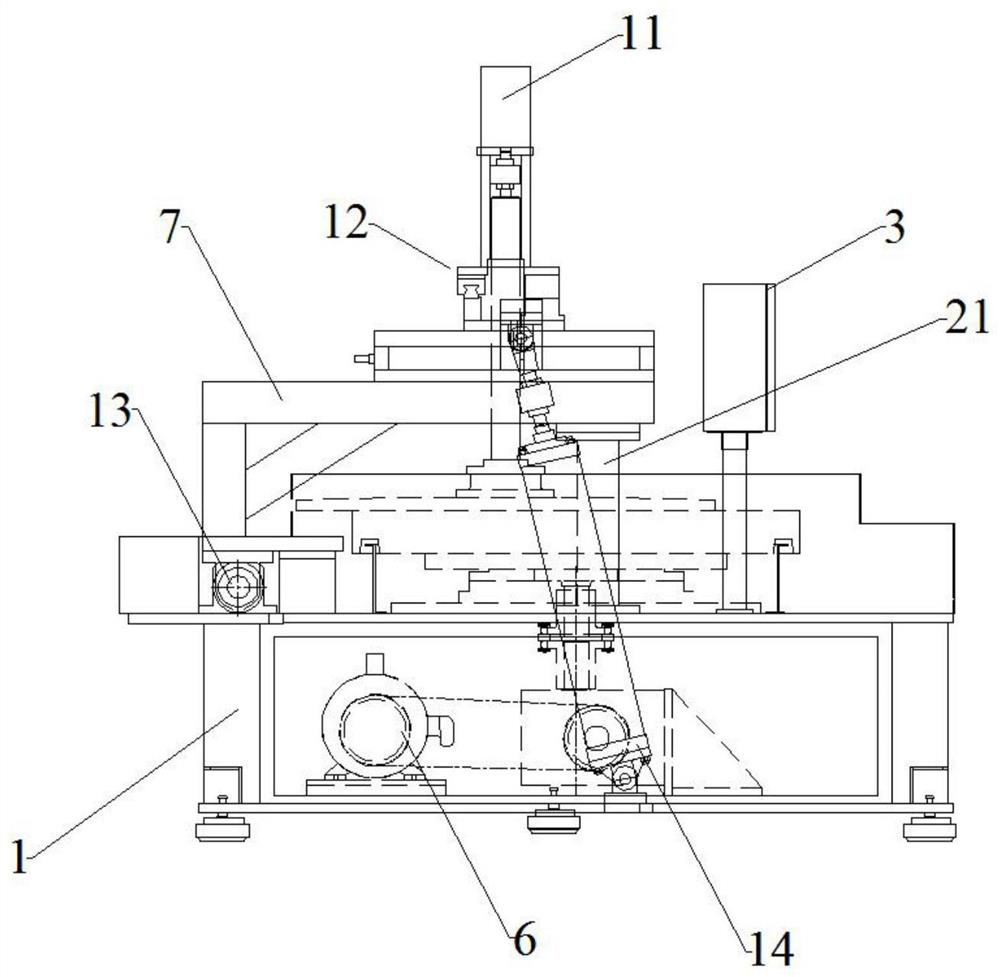

[0031] Such as Figure 1-3 As shown, the high-generation flat panel display glass polishing machine of this embodiment includes a machine base 1, a lower fixed plate component, an upper fixed plate component, a polishing liquid supply system 2, and an automatic control system 3 for controlling the polishing process. The lower fixed plate component is set On the machine base 1, the lower fixed plate parts include the lower fixed plate 4, the adsorption pad arranged on the upper surface of the lower fixed plate 4 and the first driving device 6 that drives the lower fixed plate 4 to rotate, and the upper fixed plate parts include the upper fixed plate bracket 7 and the upper fixed plate. Disk system, the upper fixed disk system includes an upper fixed disk 9, a polishing pad arranged on the lower surface of the upper fixed disk 9, and a second drive device 11 for driving the vertical movement of the upper fixed disk 9, and the upper fixed disk system passes through the horizontal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com