Loading and unloading system and loading and unloading method

A material tray and material area technology, which is applied to the loading and unloading system and the field of loading and unloading, can solve the problems of high labor cost and low work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

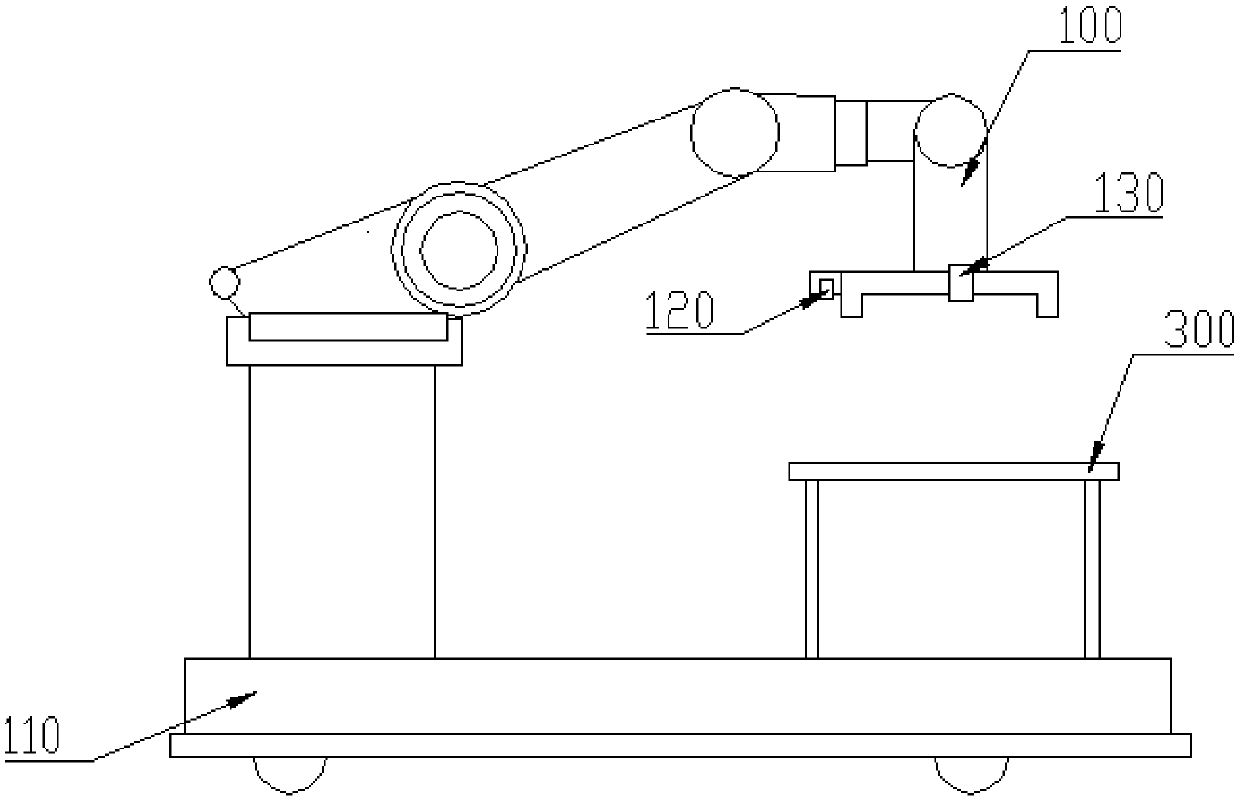

[0089] This embodiment is a loading and unloading system for loading and unloading functional devices. The loading and unloading system includes: a feeding tray, a loading and unloading area, a storage area, and a manipulator device. The material tray is used to load materials, and functional devices such as testing devices, machining devices, and assembly devices will pass through a material tray pushing mechanism or be placed directly in the loading and unloading area after processing materials; and the storage area stores materials in a stacked manner. The function of the manipulator device is to grab the tray and make it transfer between the loading and unloading area and the storage area. On the one hand, the material to be processed in the storage area is placed in the loading and unloading area for the functional device to remove and then processed. material action. Material is a general name, which generally refers to the processing object of the functional device. It...

Embodiment 2

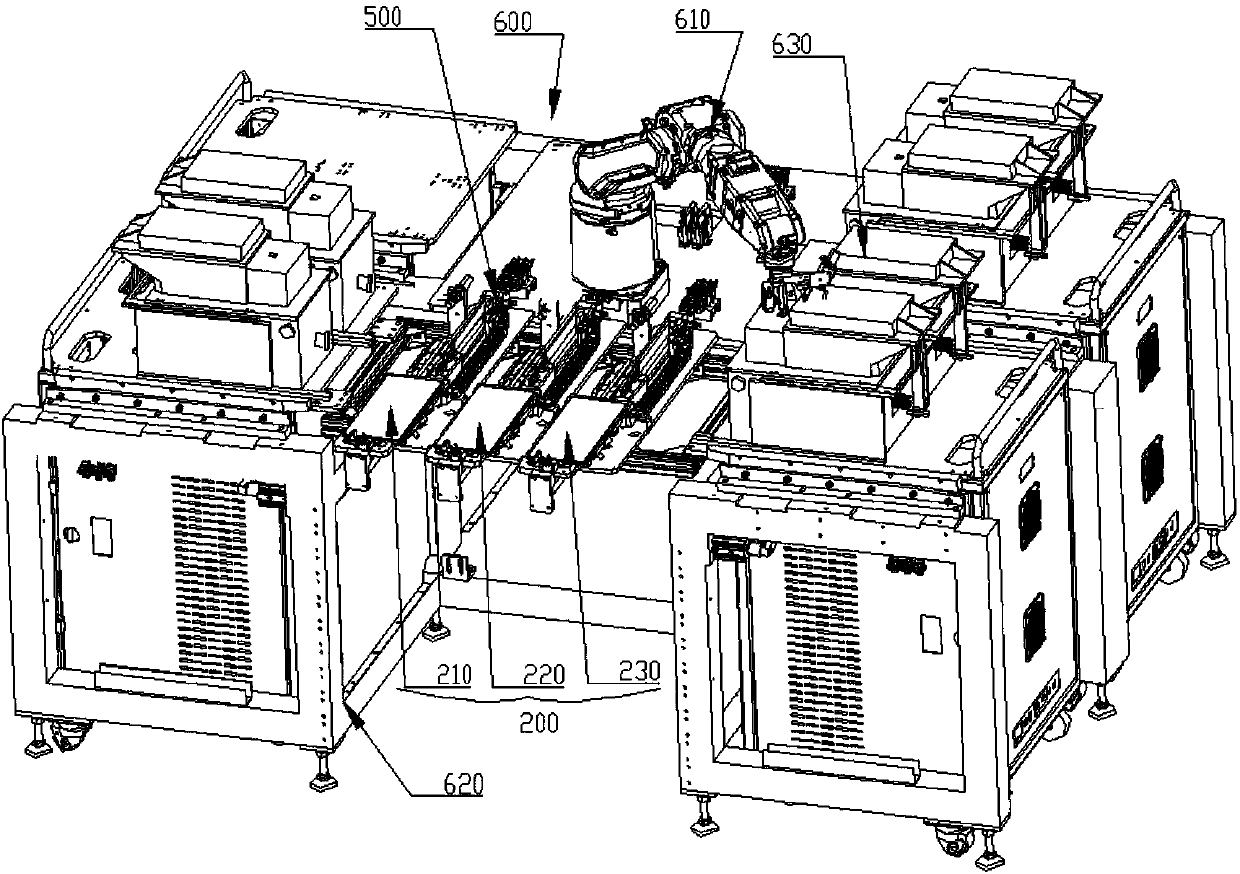

[0097] On the basis of Embodiment 1, if this loading and unloading system is used to supply materials to more than one functional device, the functional device is still taken as the test device 600 as an example, as Image 6 As shown, it is necessary to set the storage area 300 and the manipulator device 100 on the unmanned self-propelled vehicle 110. The loading and unloading system should also include a control device for regulating the walking of the unmanned self-propelled vehicle 110. The control device regulates the unmanned self-propelled vehicle 110. 110 walks to the loading and unloading area 200 of the test device 600 that needs loading, such as Image 6 As shown in , it is the test device in the upper left corner, so that the loading and unloading area 200 is located within the working radius of the manipulator device 100 . Then complete a group of loading and unloading actions according to the actions of Step2-Step5 in the above-mentioned embodiment. For the loadi...

Embodiment 3

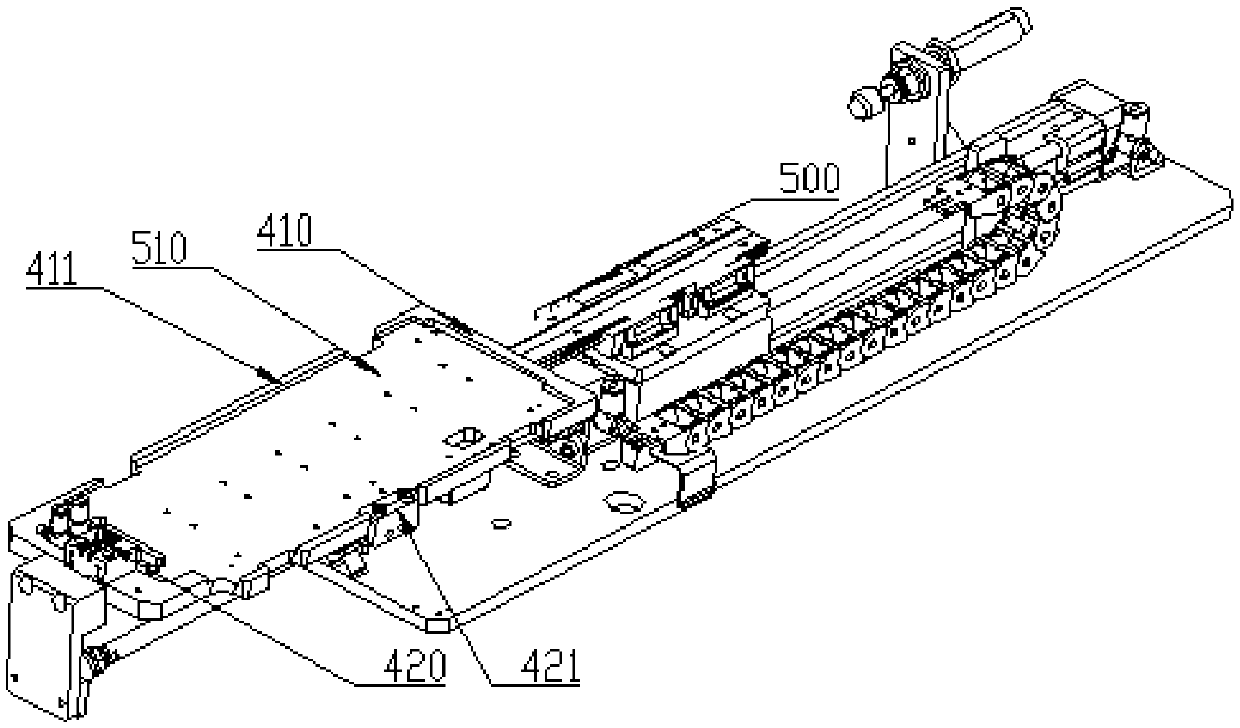

[0101] On the basis of Embodiment 1 and Embodiment 2, if the loading and unloading system supplies materials for the testing device of the electronic module, such as Figure 5 As shown, several electronic modules are laid on the tray 700 . The storage area 300 further includes a reject station 330 and an empty tray station 340, the empty tray station 340 is used for stacking several empty trays.

[0102] Then the loading and unloading system can complete the unloading action for the unqualified products tested by the test device, such as Figure 1-Figure 6 As shown, the manipulator device 100 transfers the empty tray from the empty tray station 340 to the loading and unloading area 200, and the testing device 600 puts the unqualified electronic modules after the test into the empty tray, and waits for it to be placed in the tray. After filling the tray that failed the test. The testing device 600 places the unqualified material tray in the loading and unloading area 200 thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com