Movable type loading and positioning mechanism for glass product machining

A positioning mechanism and mobile technology, applied in glass manufacturing equipment, stone processing tools, glass transportation equipment, etc., can solve the problems of reduced processing efficiency and processing quality, non-adjustable processing platform size, non-movable processing base, etc. Quality, improve processing efficiency and processing quality, the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

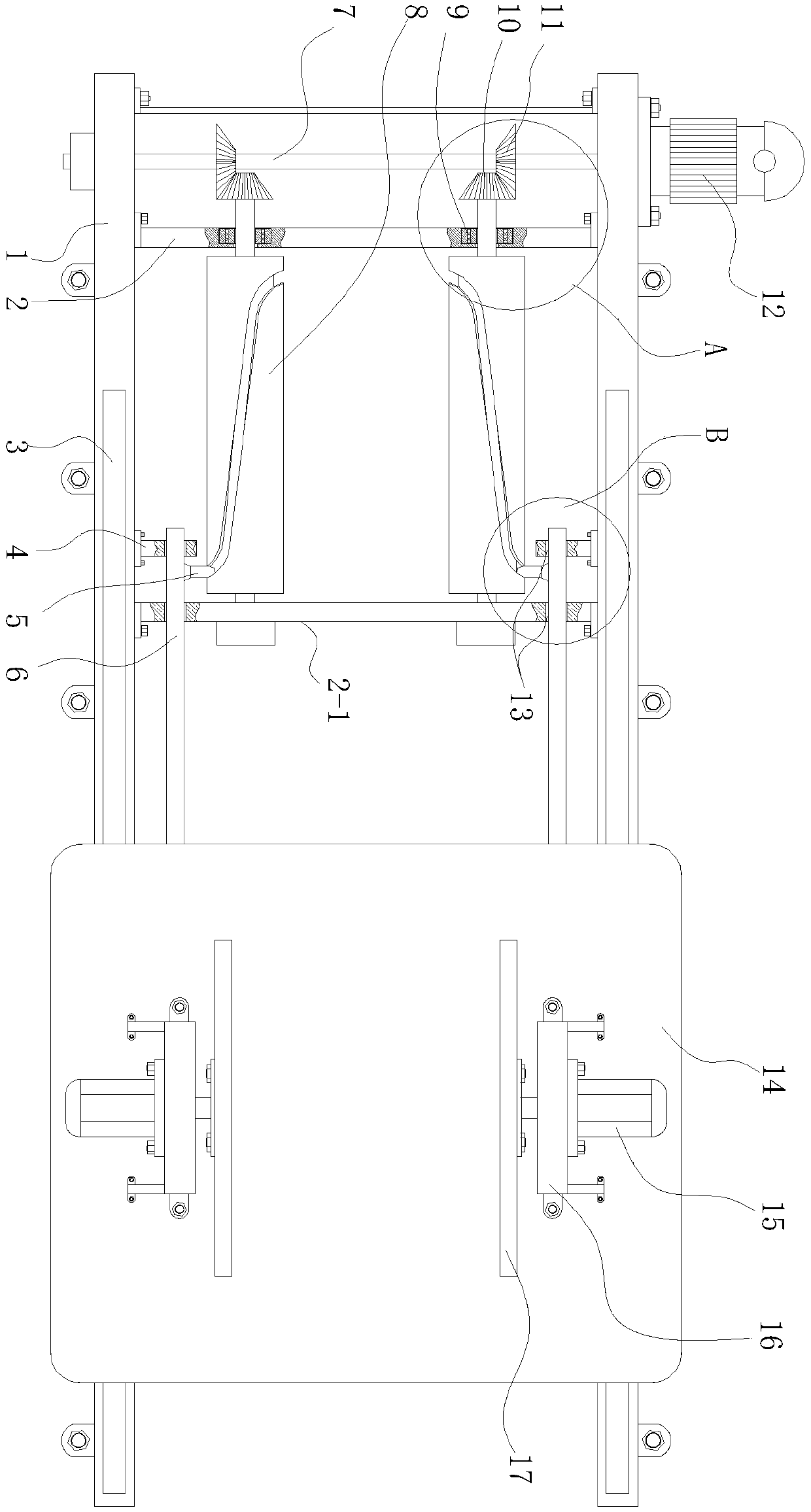

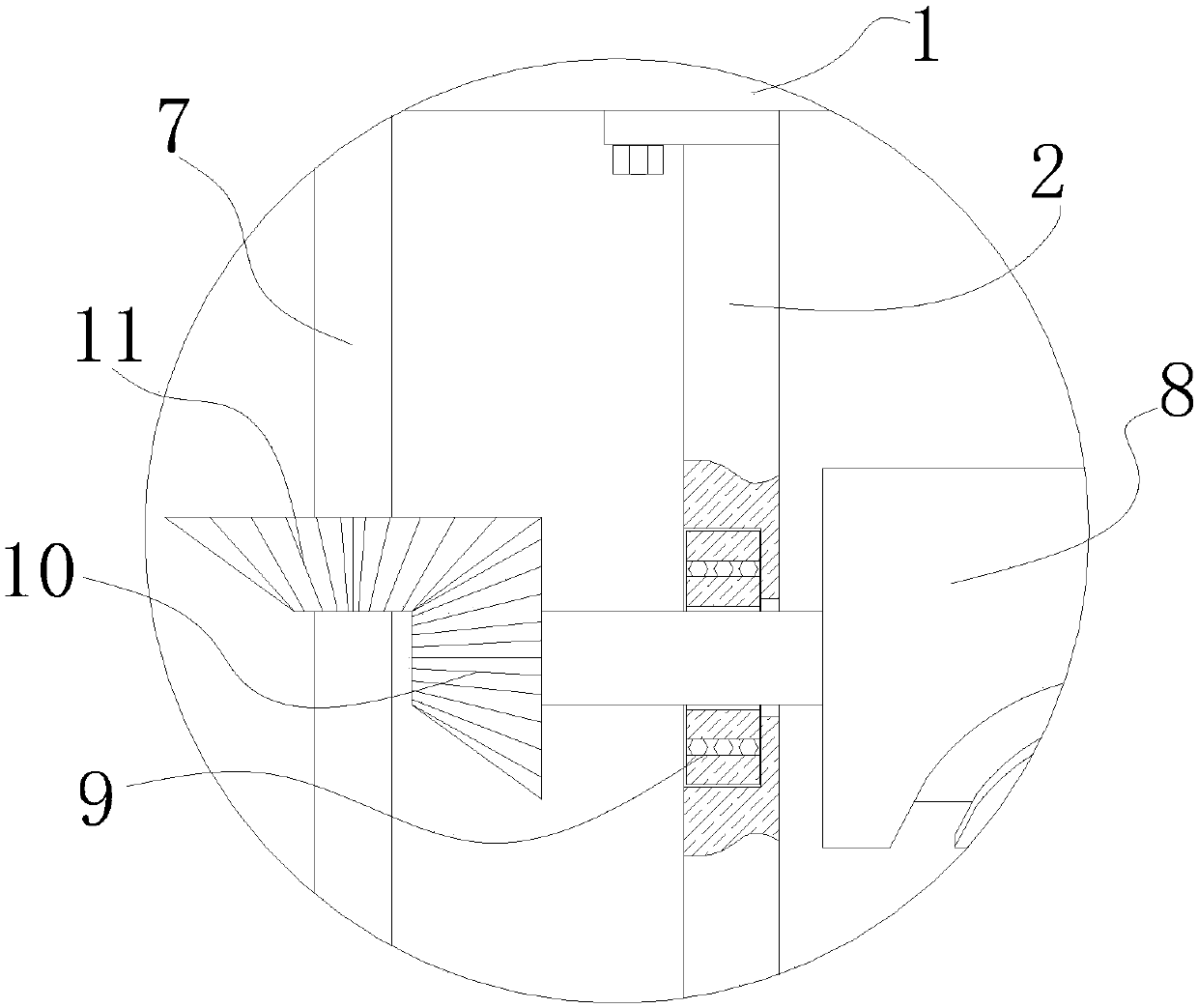

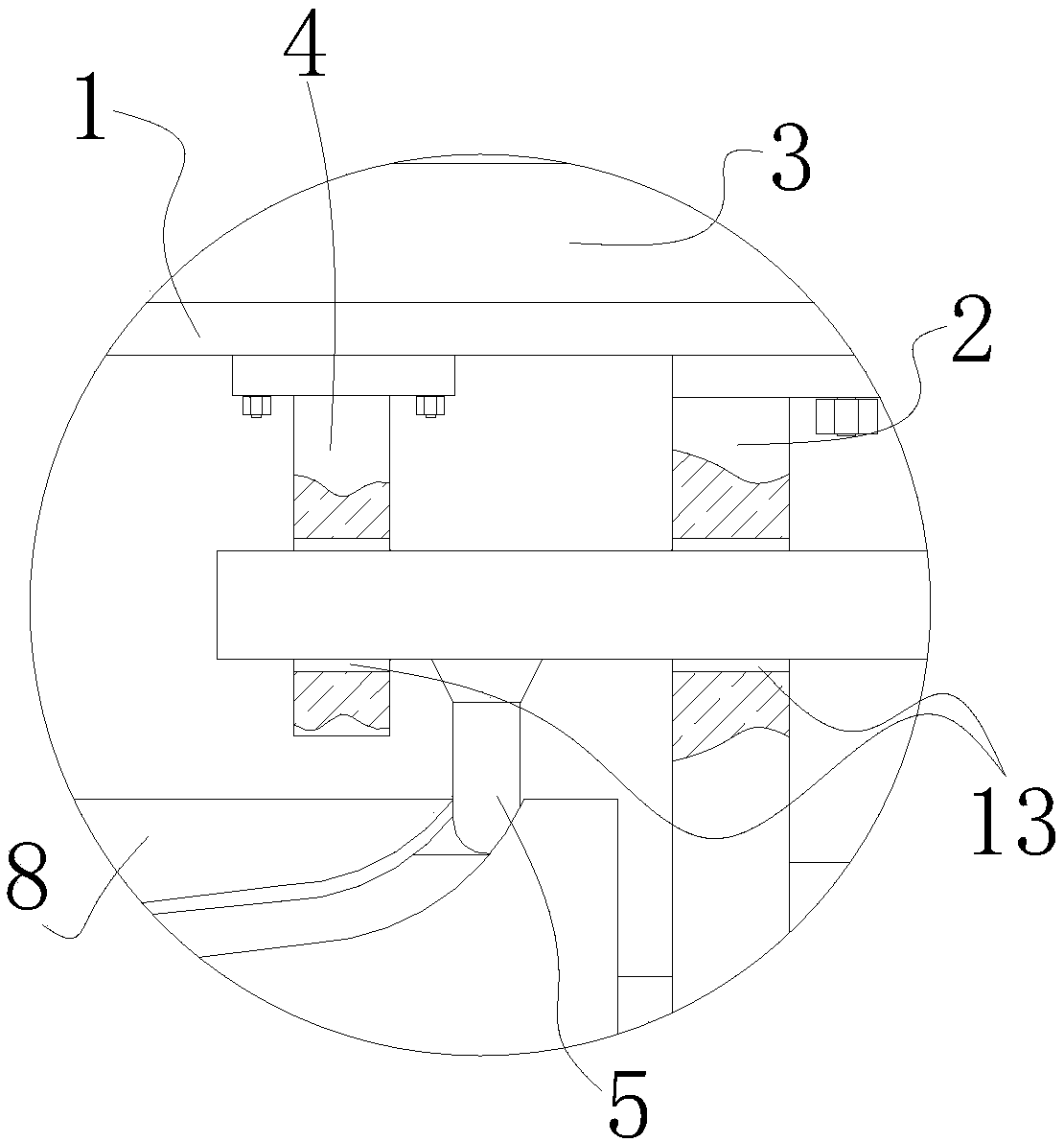

[0021] like Figure 1 to Figure 5As shown, a mobile load positioning mechanism for glass product processing includes two supporting vertical plates 1 distributed in parallel, and a positioning seat is provided on the outer wall of the lower end of the supporting vertical plate 1, and the positioning seat can be fastened and installed by expansion bolts. On the horizontal plane, the end of the supporting vertical board 1 extends into the glass plate processing room provided with a processing manipulator. The supporting vertical board 1 is provided with a linear drive mechanism and a loading platform 14. The upper ends of the two supporting vertical boards 1 There is a walking guide rail 4, and the lower end of the loading platform 4 is provided with a roller 18 that rolls and cooperates with the walking guide rail 3. The linear drive mechanism is driven by a stepping motor 12 and two sets of mirror images installed on the inner side of the support vertical plate 1. Composed of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com