Diesel engine cover machining feeding and discharging lifting table

A diesel engine and bottom plate technology, applied in metal processing and other directions, can solve the problems of single function, increased operation process, unfavorable production efficiency, etc., and achieve the effect of convenient transportation, convenient operation, and convenient loading and unloading operations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

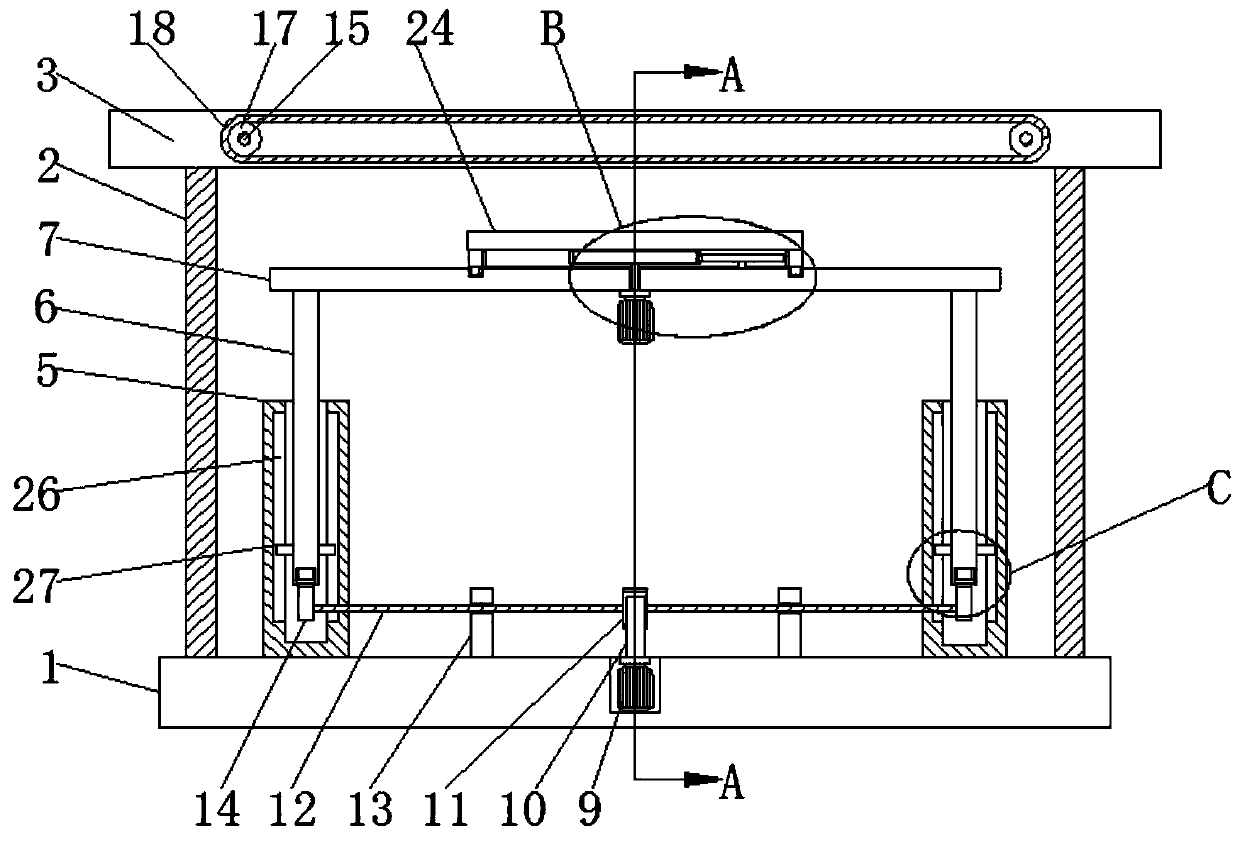

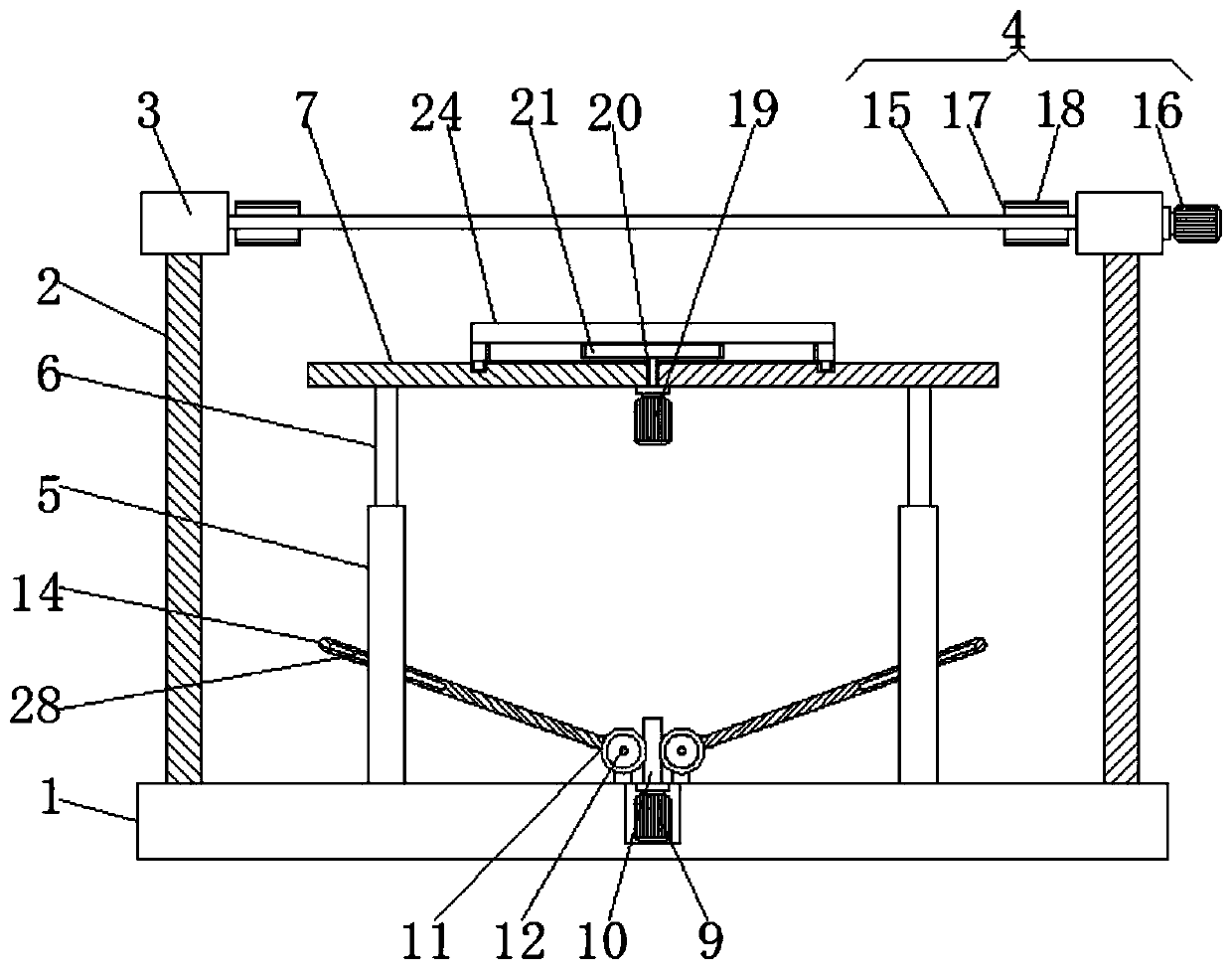

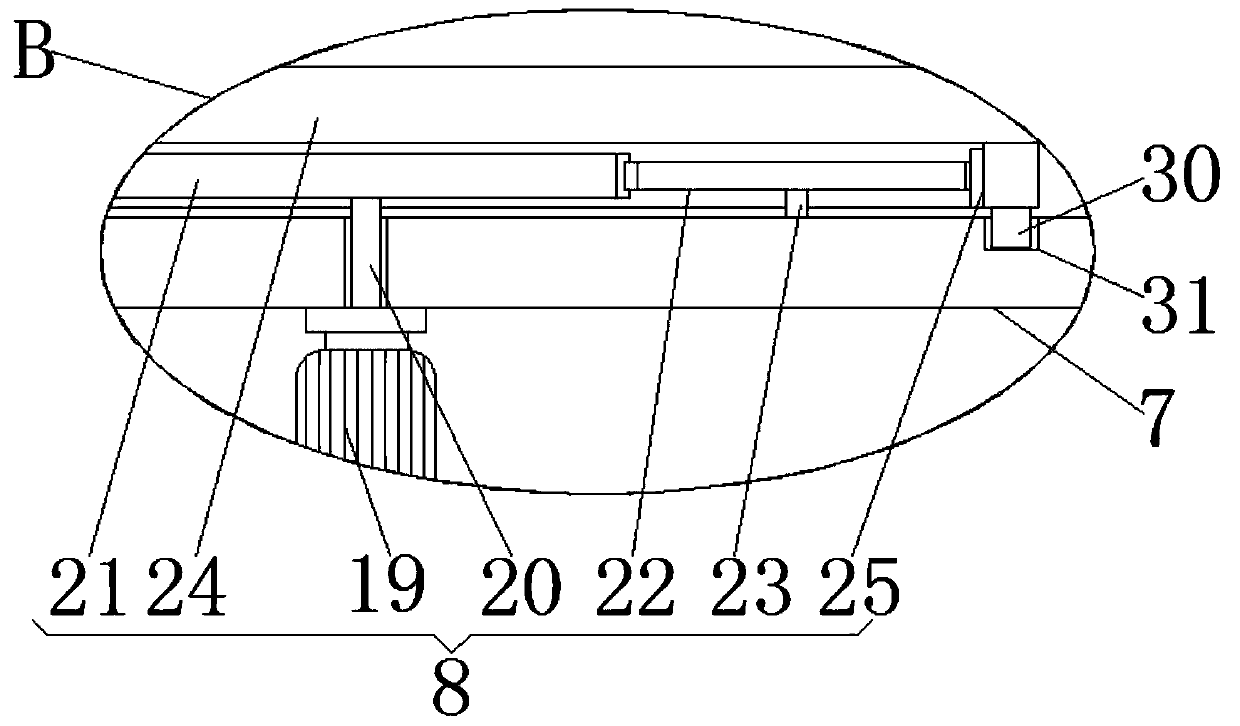

[0021] Example 1, such as Figure 1-4 Shown:

[0022] A lifting platform for loading and unloading materials used for diesel engine cover processing, including a bottom plate 1, the bottom plate 1 is arranged in a rectangular shape, vertical rods 2 are fixedly connected to the top surface of the bottom plate 1 near the four corners, and the two vertical rods 2 on the front and rear sides are far away from the bottom plate 1 One end is fixedly connected with the same fixed plate 3, the fixed plate 3 is provided with a conveying mechanism 4, the conveying mechanism 4 includes a main shaft 15, two main shafts 15 are arranged symmetrically between the two fixed plates 3, and the two ends of the two main shafts 15 All are movably connected on the side wall of the fixed plate 3, wherein a main shaft 15 runs through the fixed plate 3 and is fixedly connected with the rotor of the second motor 16, and the second motor 16 is fixedly connected on the side wall of the fixed plate 3, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com