A kind of lutein ester extraction process

A technology of lutein ester and extraction process, which is applied in the field of effervescent tablet processing, can solve the problems of fine filter blockage, slow filtration efficiency, uneven filtration, etc., and achieve the effect of close connection and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

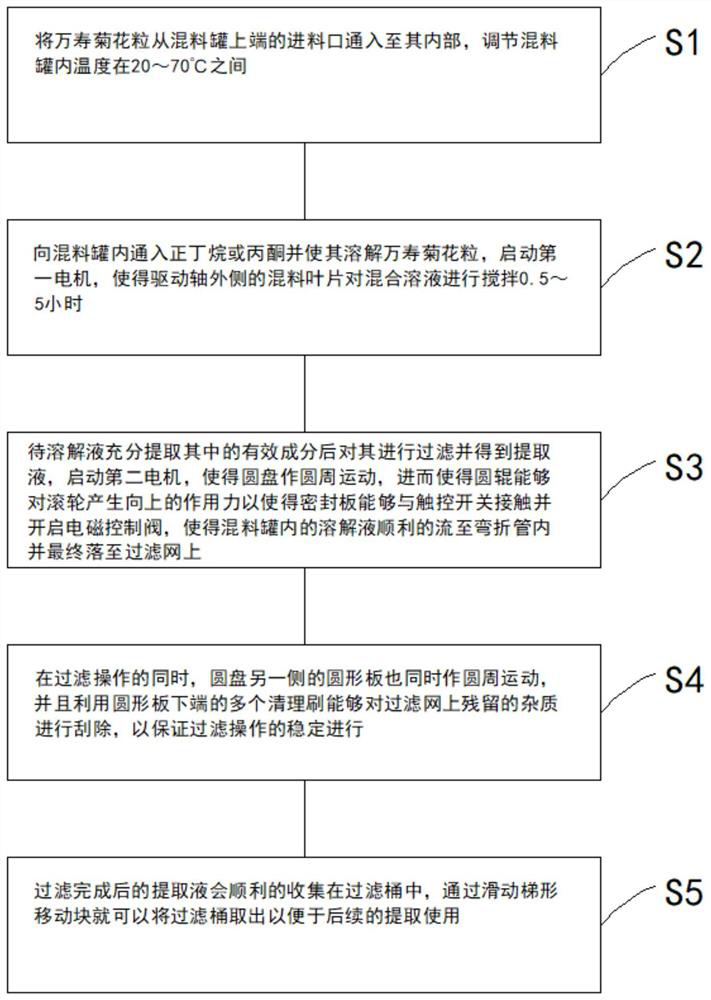

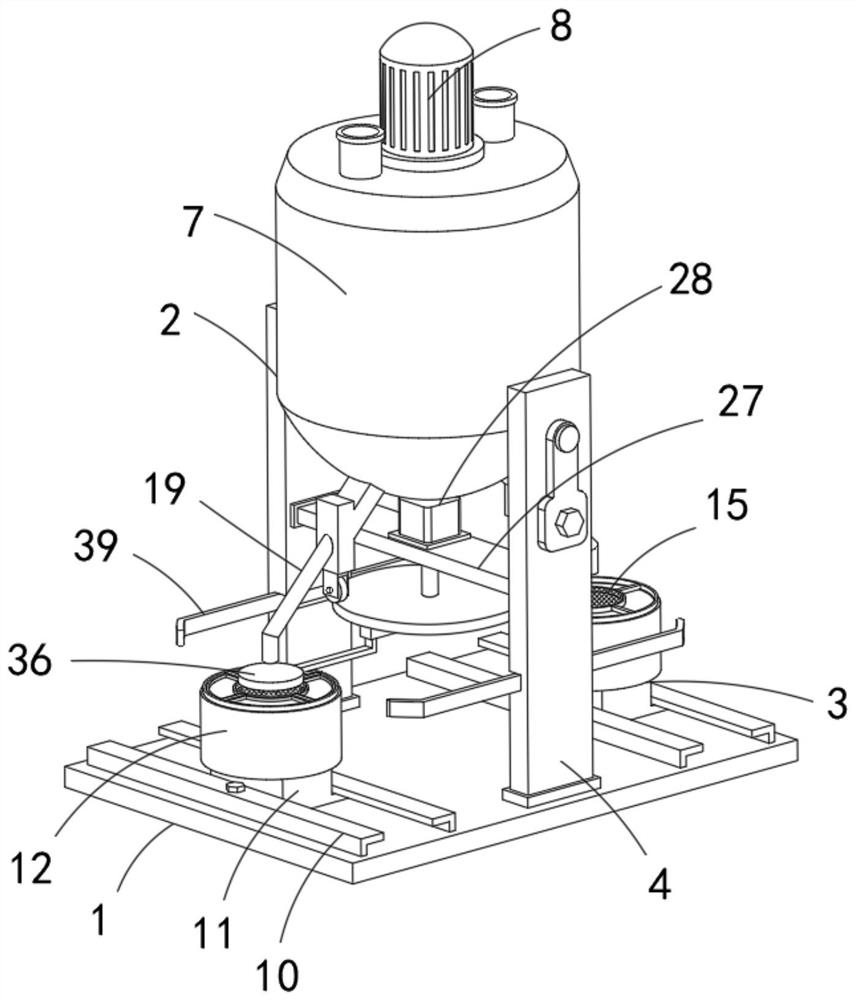

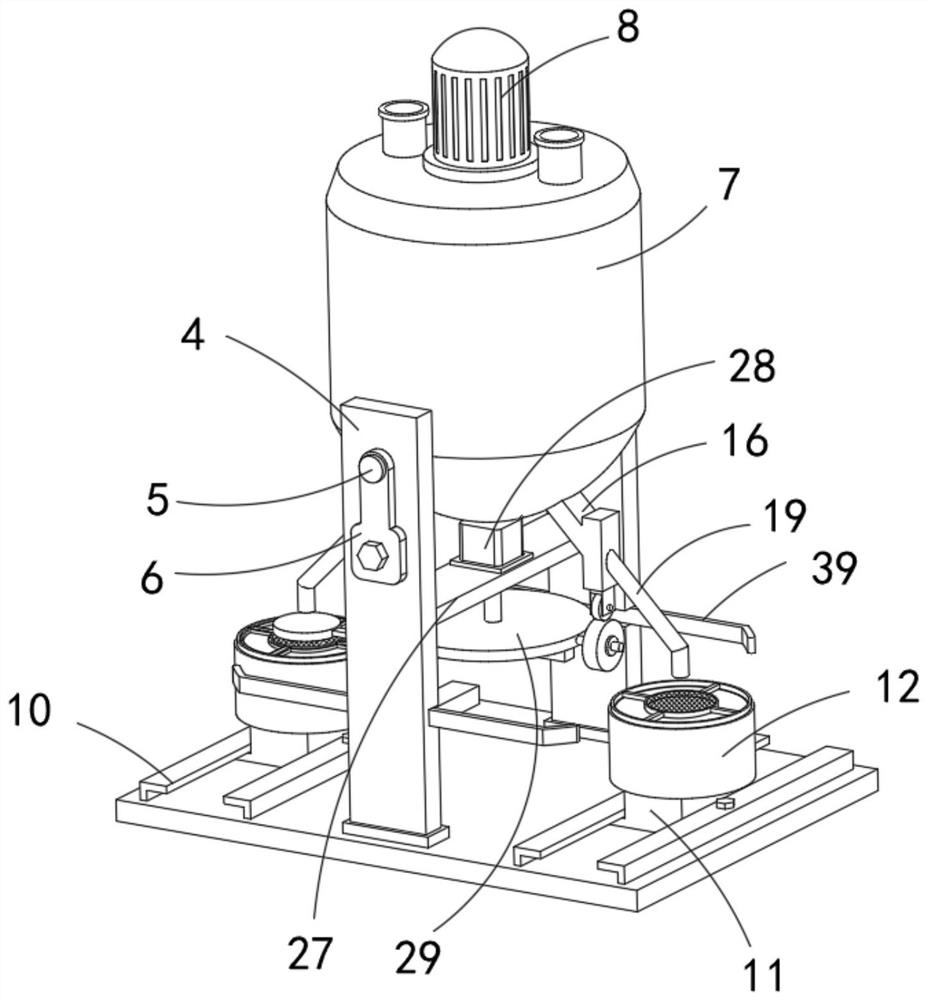

[0040] refer to Figure 1-8, a lutein ester extraction process, which uses a lutein ester extraction device, the lutein ester extraction device includes a workbench 1, a mixing mechanism 2 and a filter mechanism 3, using the above-mentioned lutein ester extraction The specific process of the device when extracting lutein esters is as follows:

[0041] S1. Pass the marigold flower grains into the interior of the mixing tank 7 from the feed inlet at the upper end, and adjust the temperature in the mixing tank 7 to be between 20°C and 70°C;

[0042] S2. Pass n-butane or acetone into the mixing tank 7 to dissolve the marigold flower grains, start the first motor 8, and make the mixing blade 9 on the outside of the drive shaft stir the mixed solution for 0.5 to 5 hours;

[0043] S3. After the effective components are fully extracted from the solution, it is filtered to obtain the extract, and the second motor 28 is started to make the disc 29 move in a circle, so that the round ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com