Patents

Literature

39results about How to "High motion positioning accuracy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

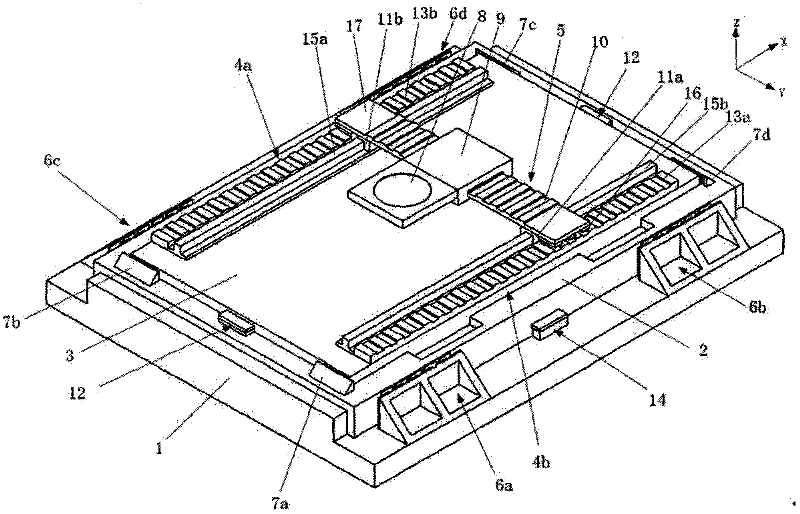

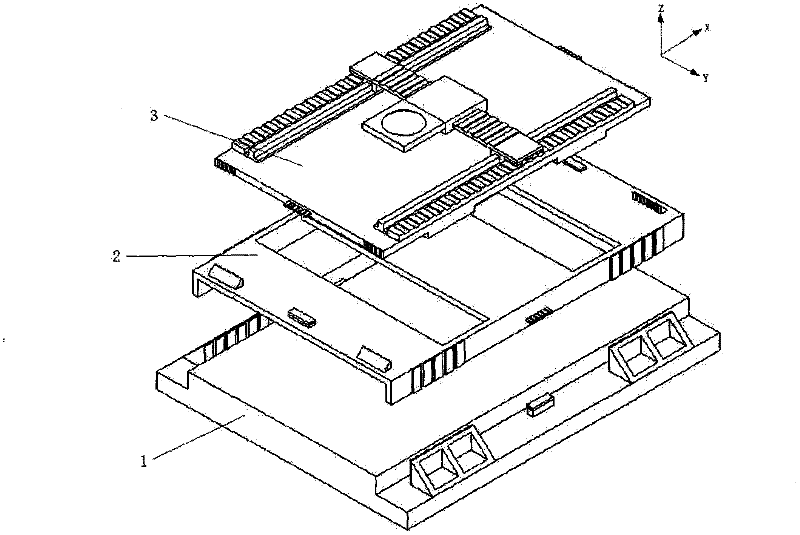

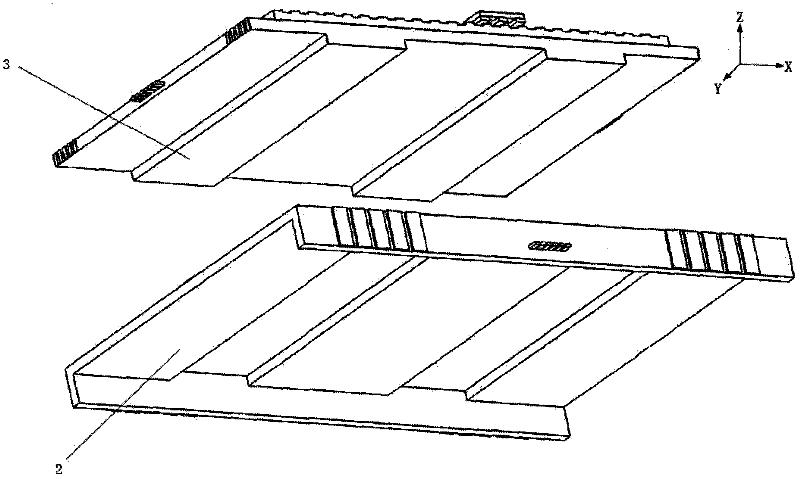

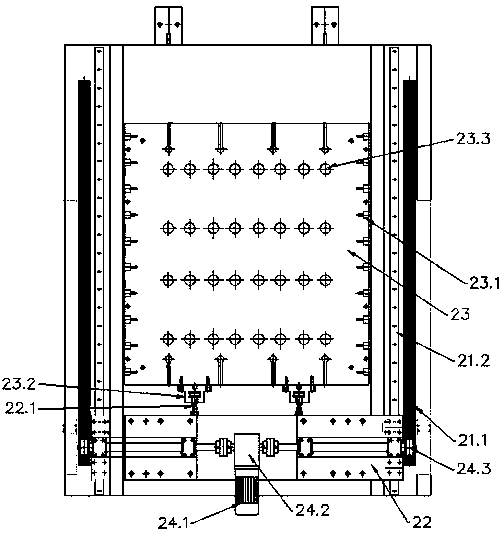

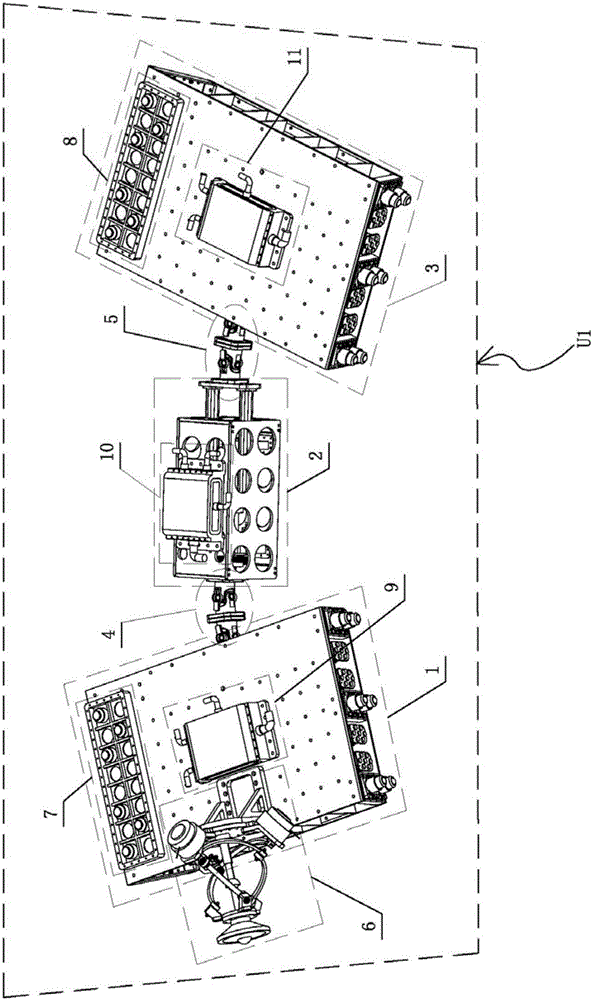

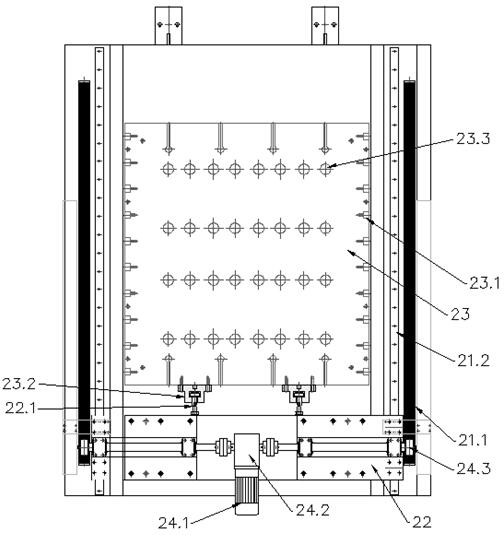

Photoetching machine workpiece stage magnetic preloading balance positioning system

InactiveCN102393611AHigh motion positioning accuracyGood real-time compensationPhotomechanical exposure apparatusMicrolithography exposure apparatusEngineeringPositioning system

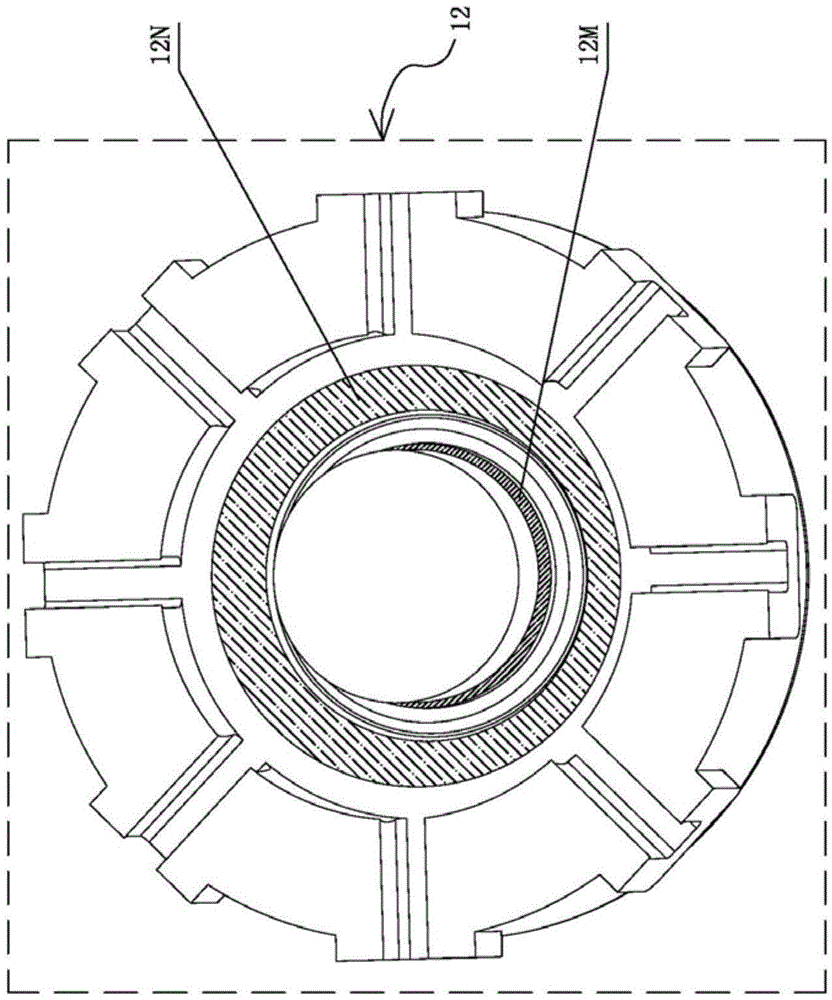

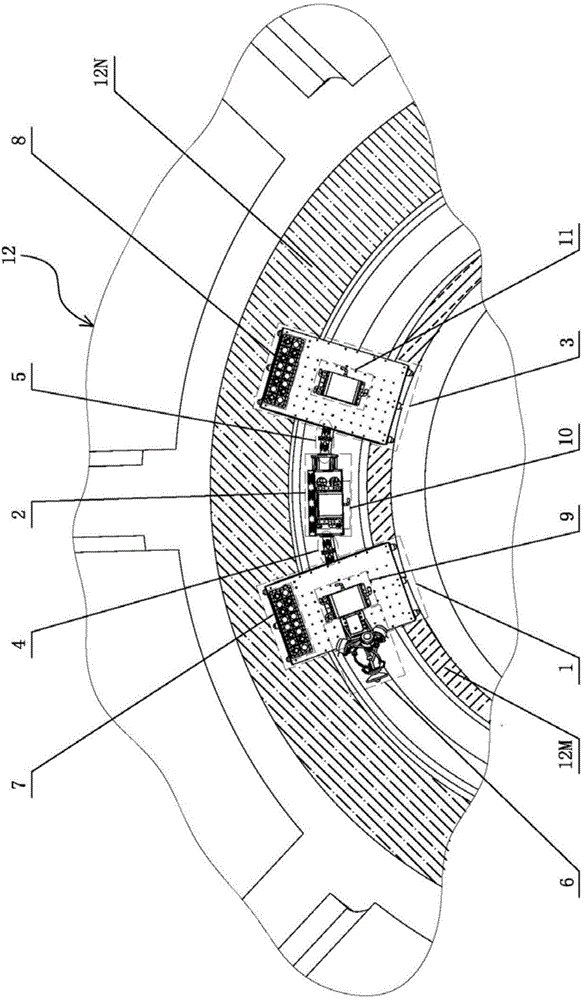

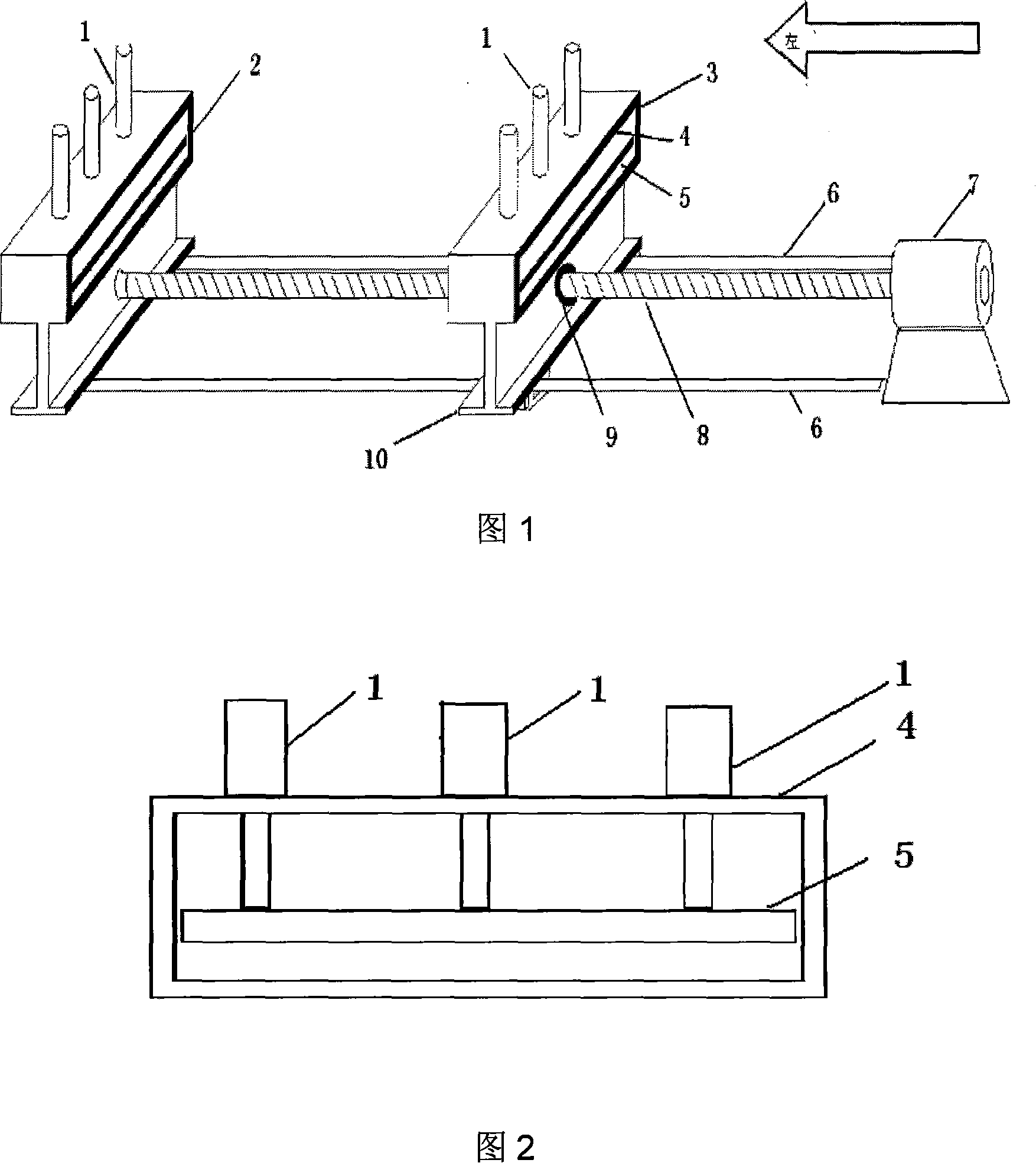

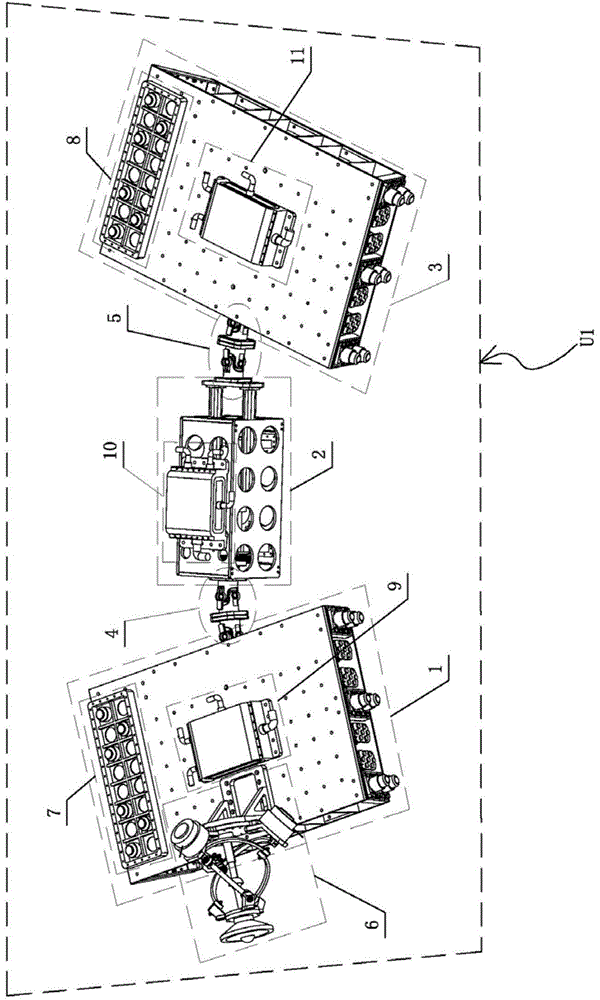

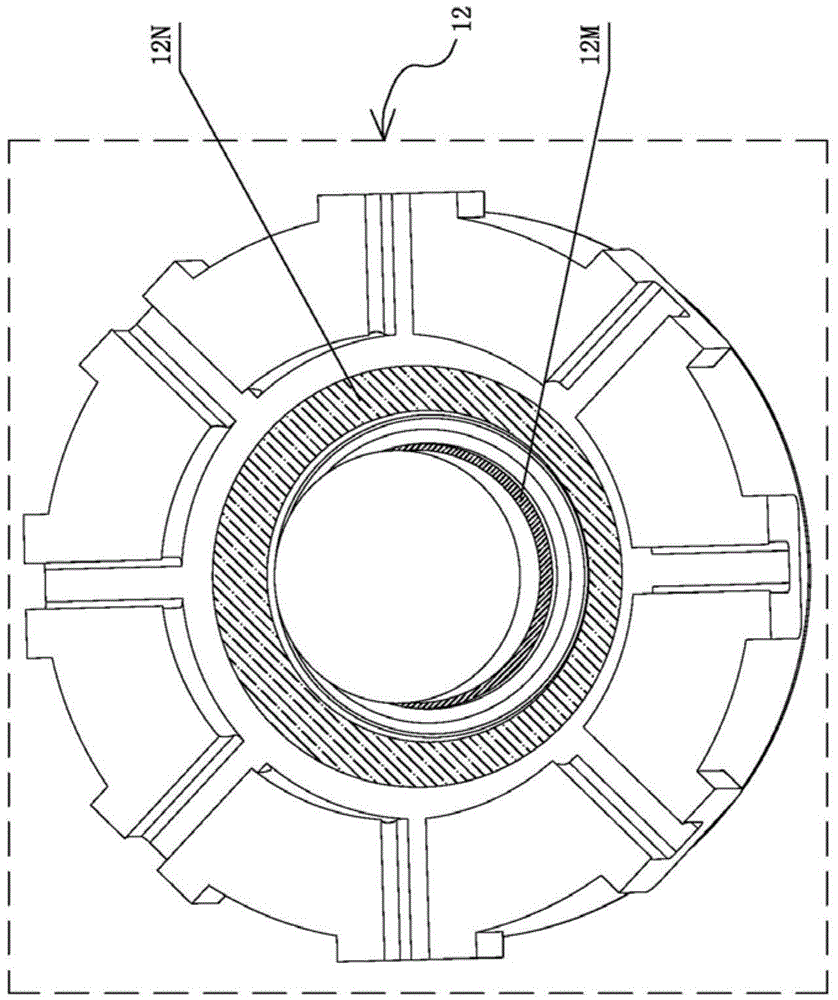

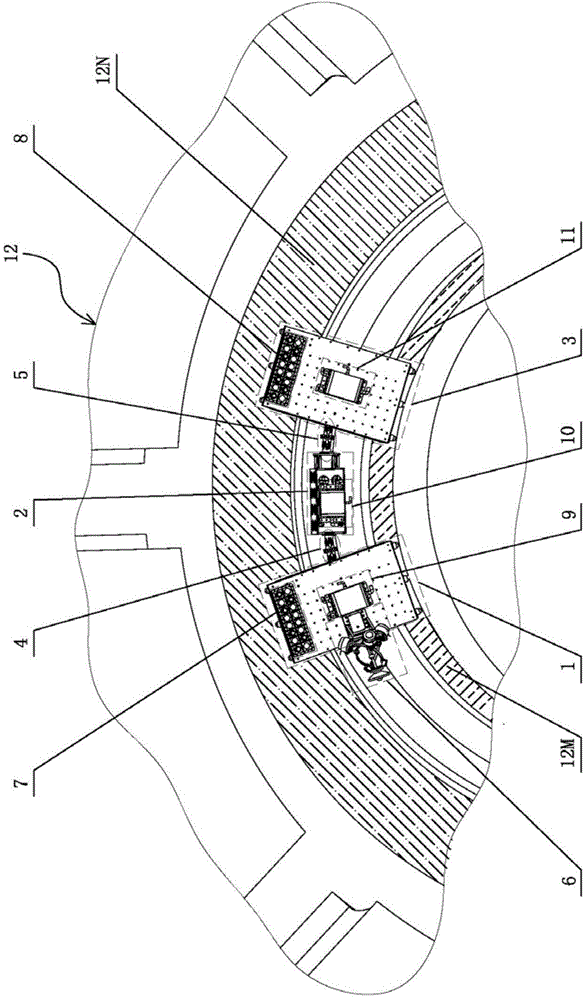

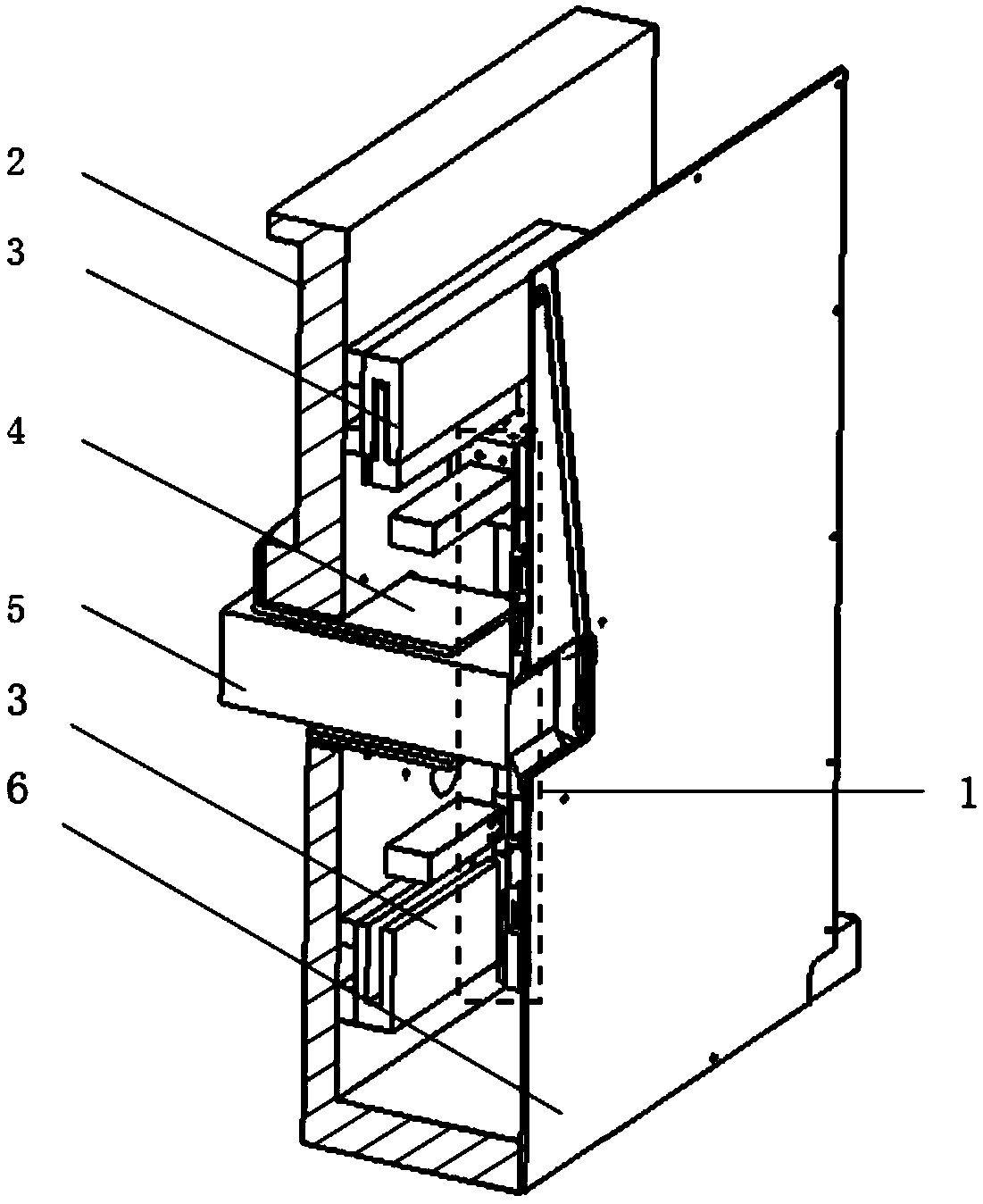

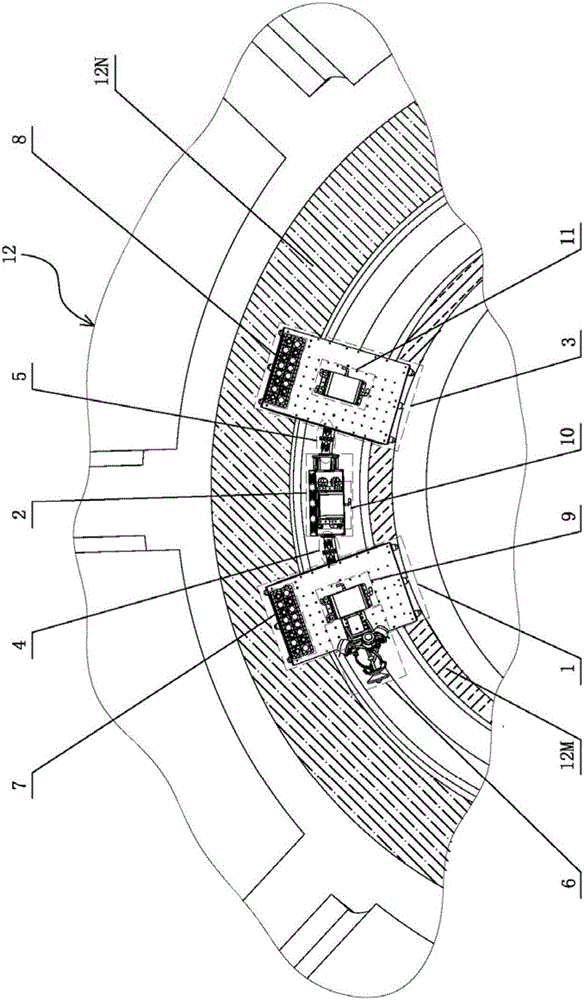

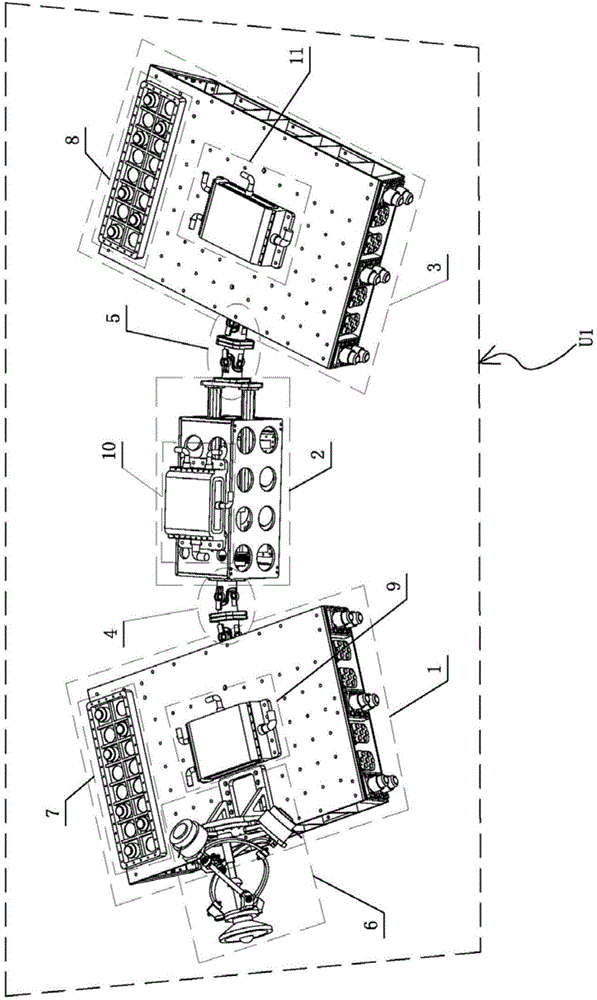

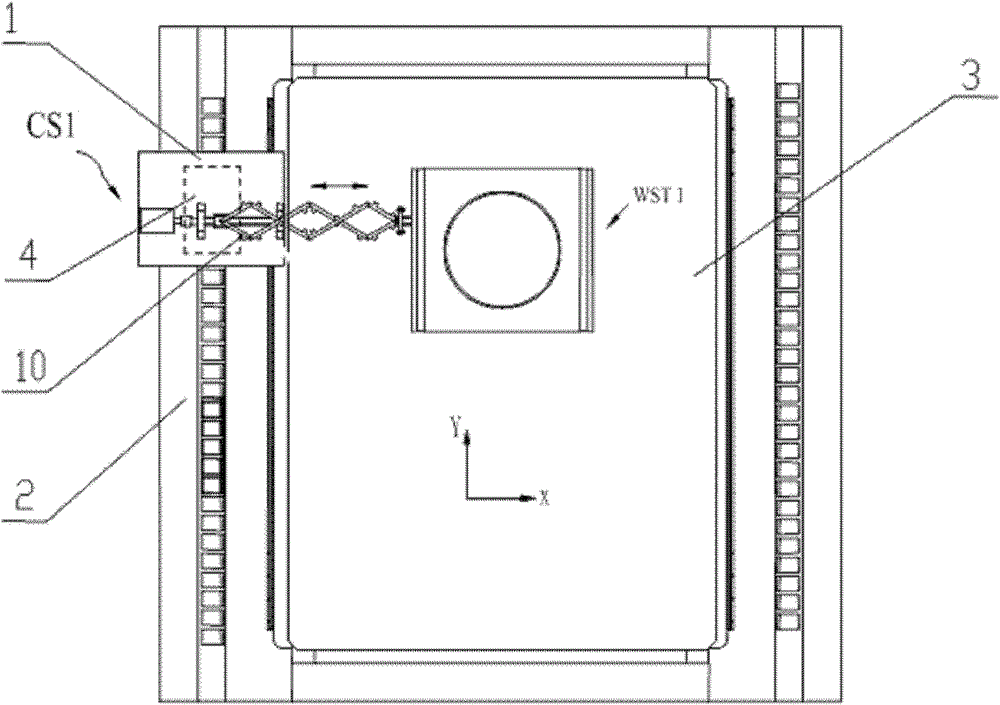

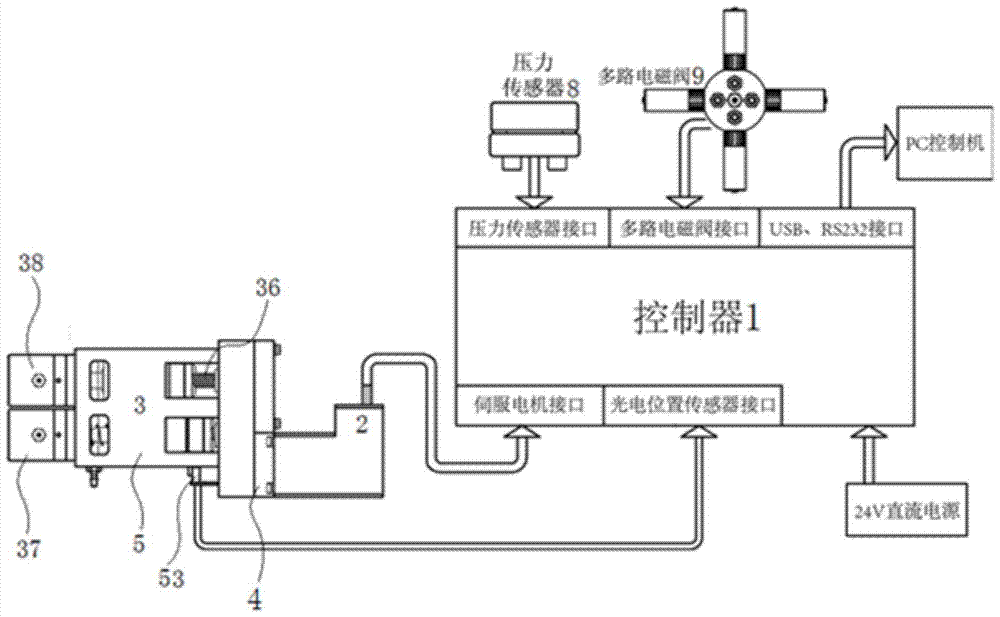

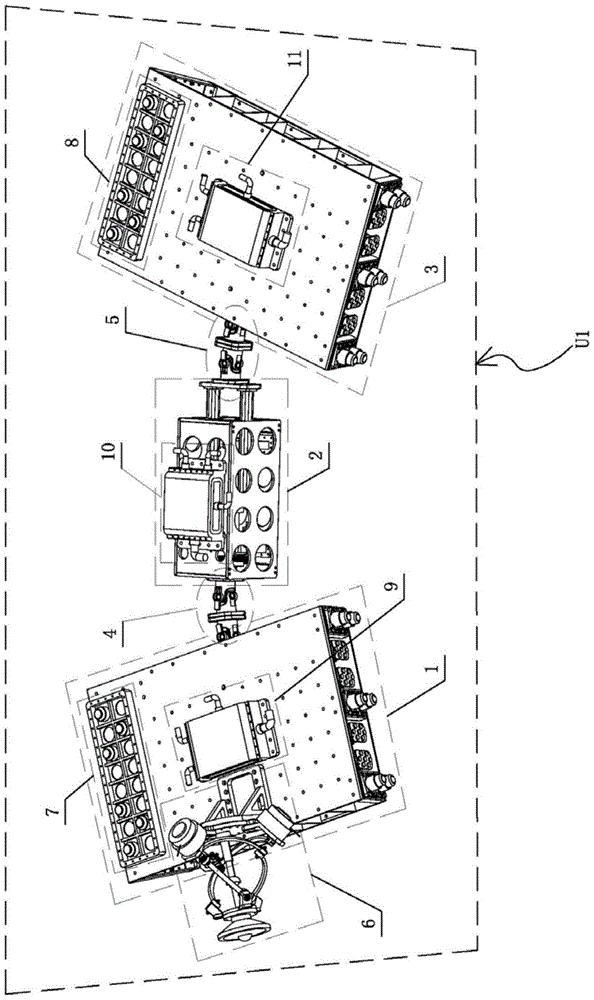

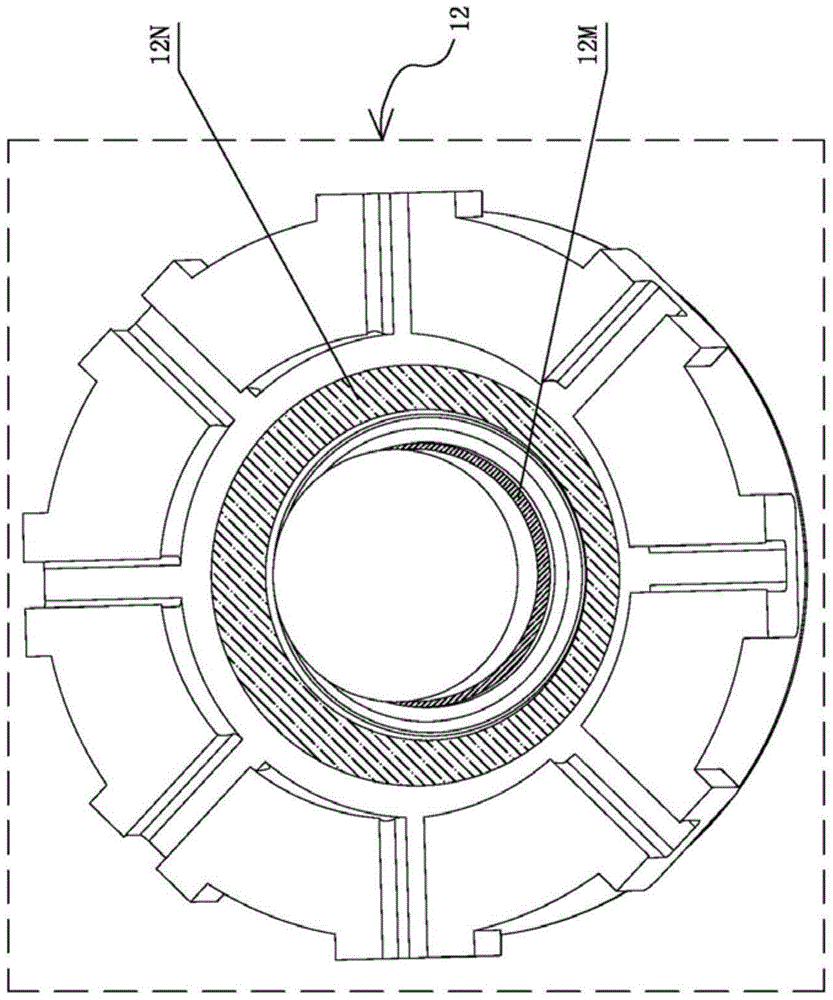

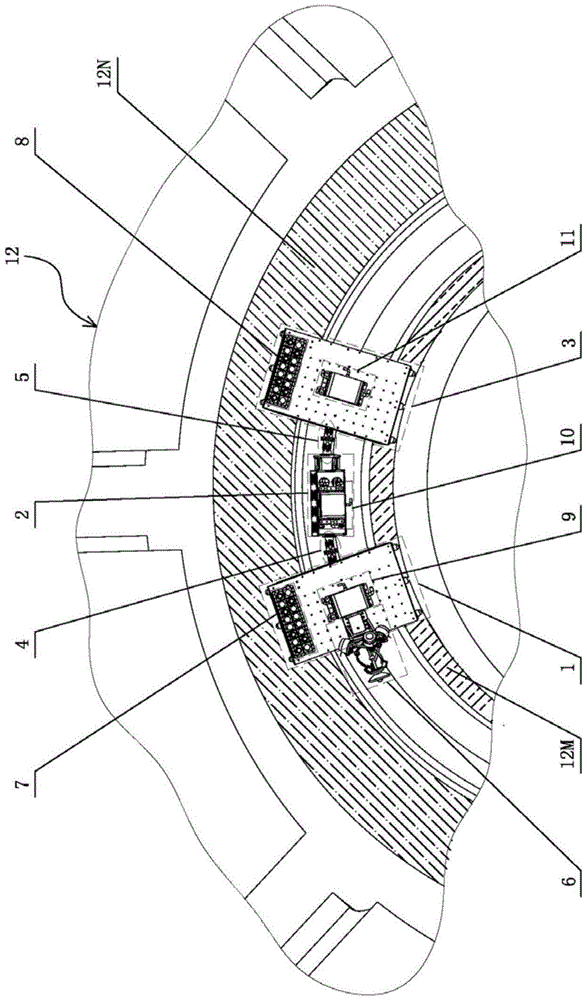

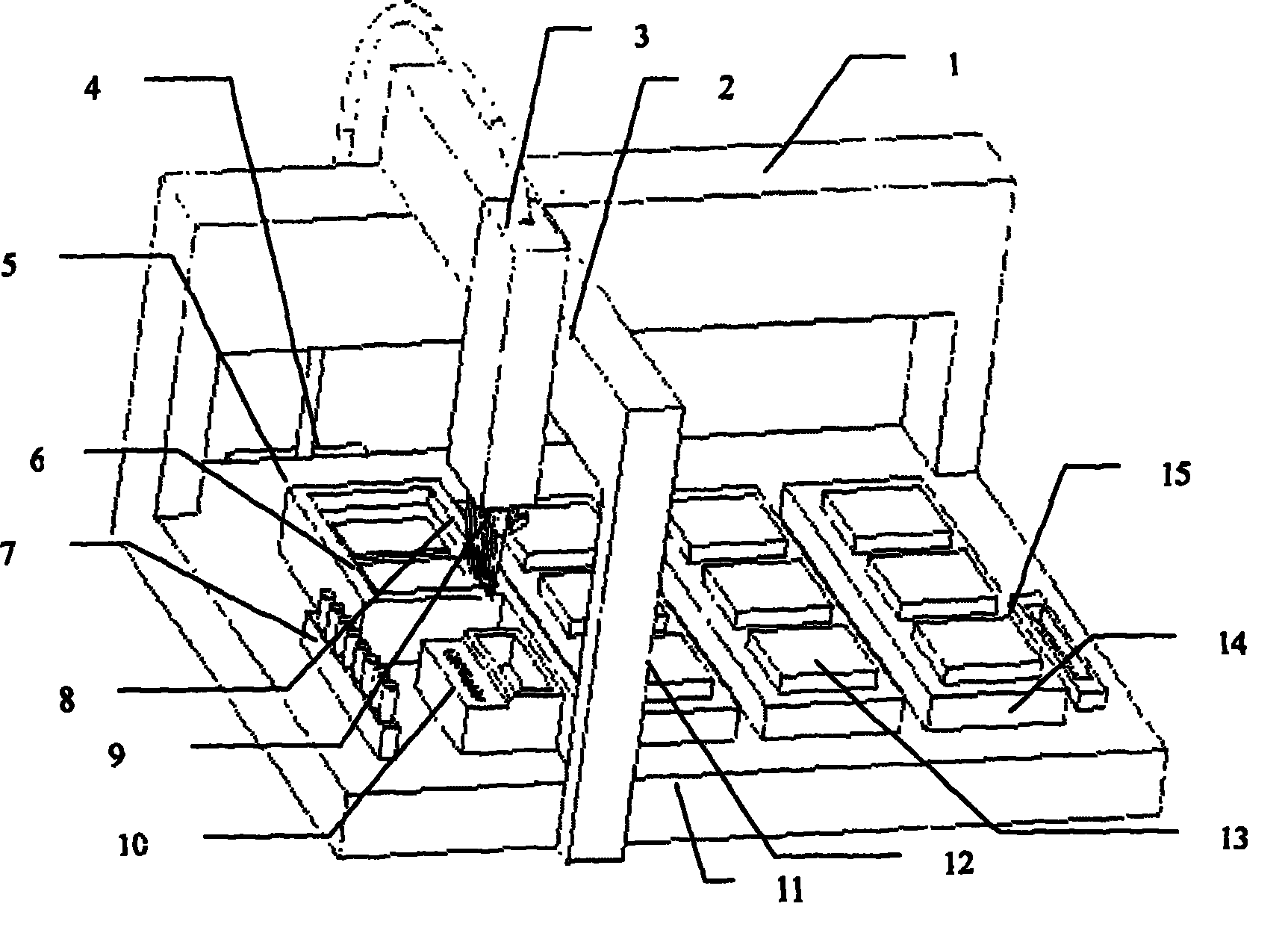

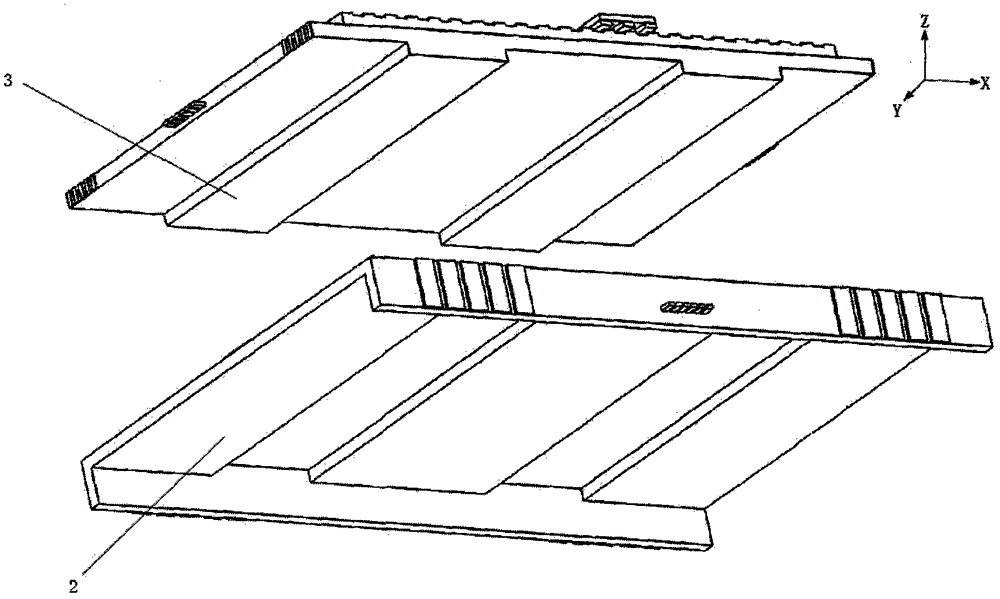

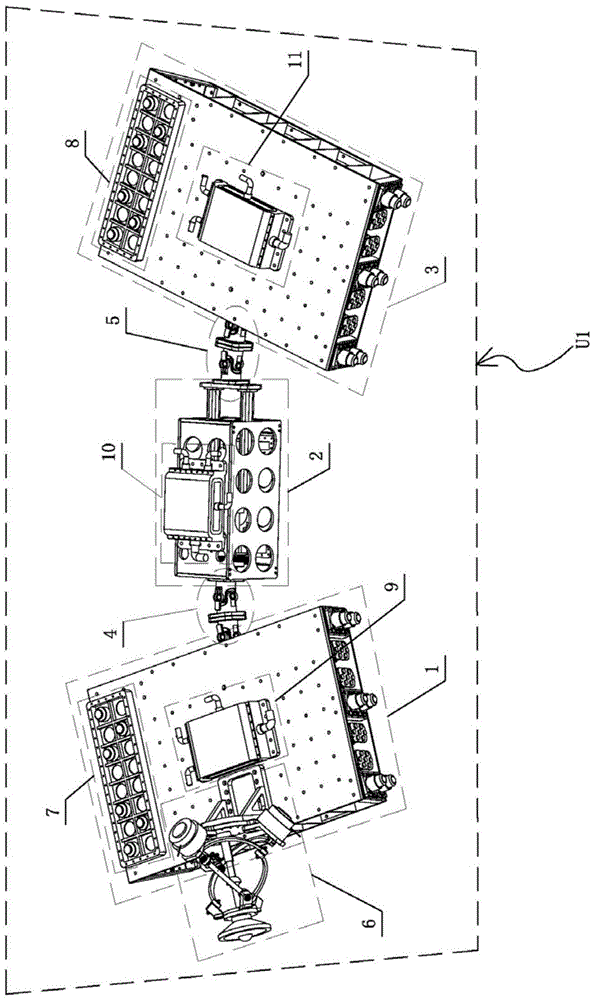

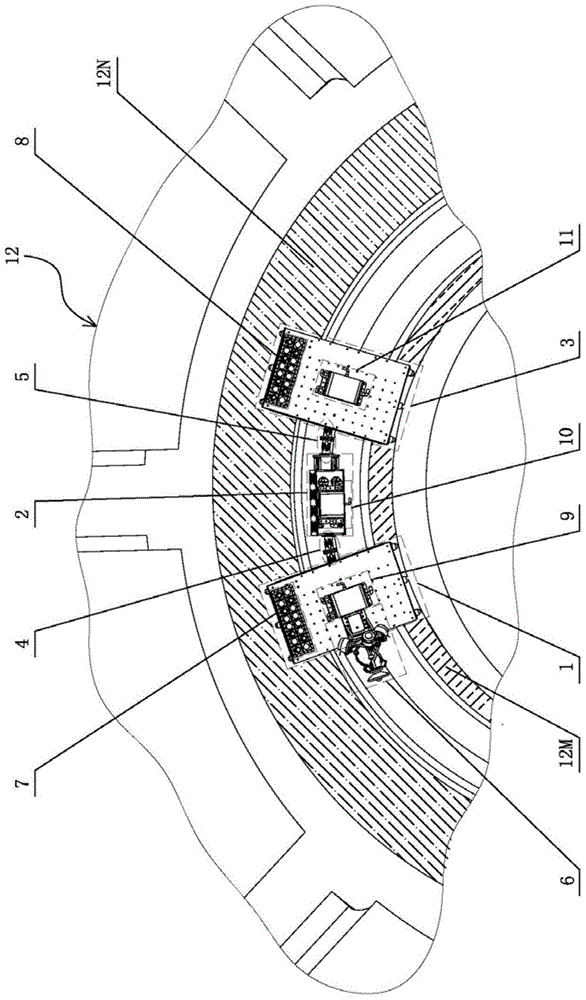

A photoetching machine workpiece stage magnetic preloading balance positioning system belongs to the field of semiconductor photoetching technology; the system mainly comprises a base stage, a balance mass system, a magnetic preloading system, a motion unit, a silicon wafer stage, and a balance mass drift-resistant system; the balance mass system comprises two frames which nest each other, and has freedom degrees in the X and Y directions; the motion unit is disposed at the upper part; the impact force caused by the motion part to the base stage is weakened by momentum conservation principle;the balance mass drift-resistant system is used to compensate the position displacement of the balance mass system caused by external resistance during working; the magnetic preloading system is usedfor real-time compensation of the torsion of the workpiece stage along a Z axis; the invention can effectively reduce internal vibration, compensate the torsion of the workpiece stage along the Z axis, and thus greatly improve the motion positioning precision of the silicon wafer stage.

Owner:HARBIN INST OF TECH

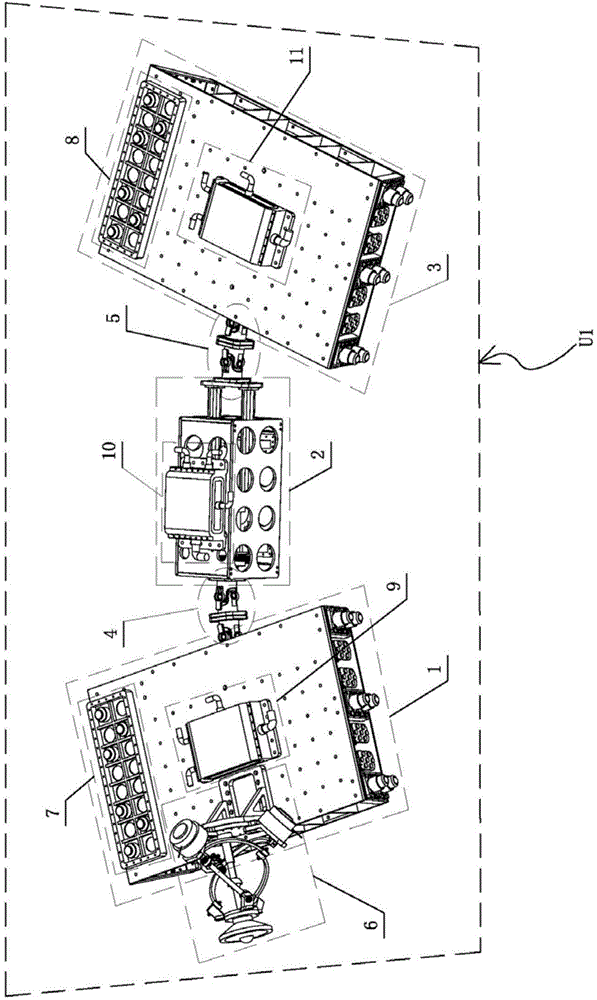

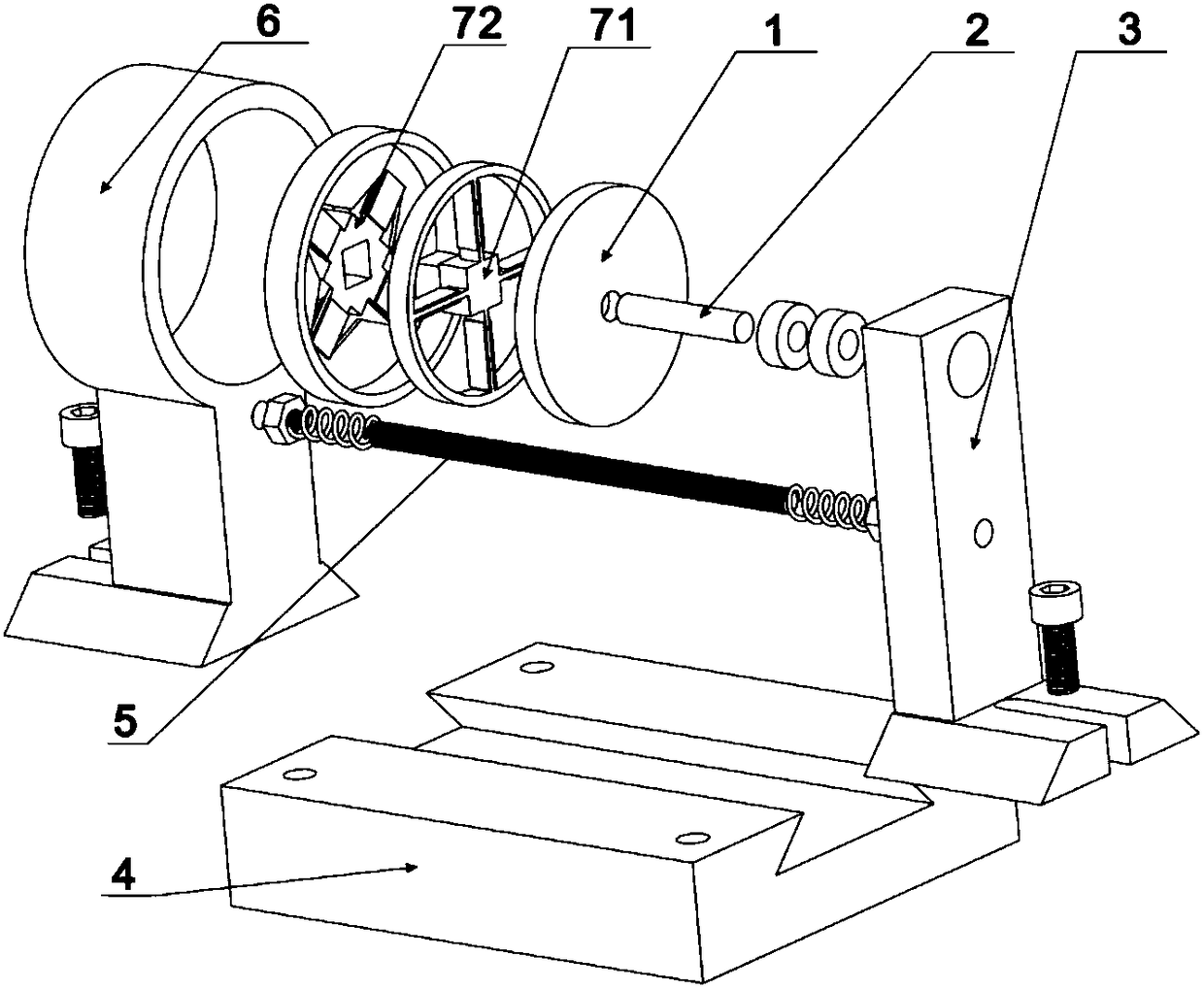

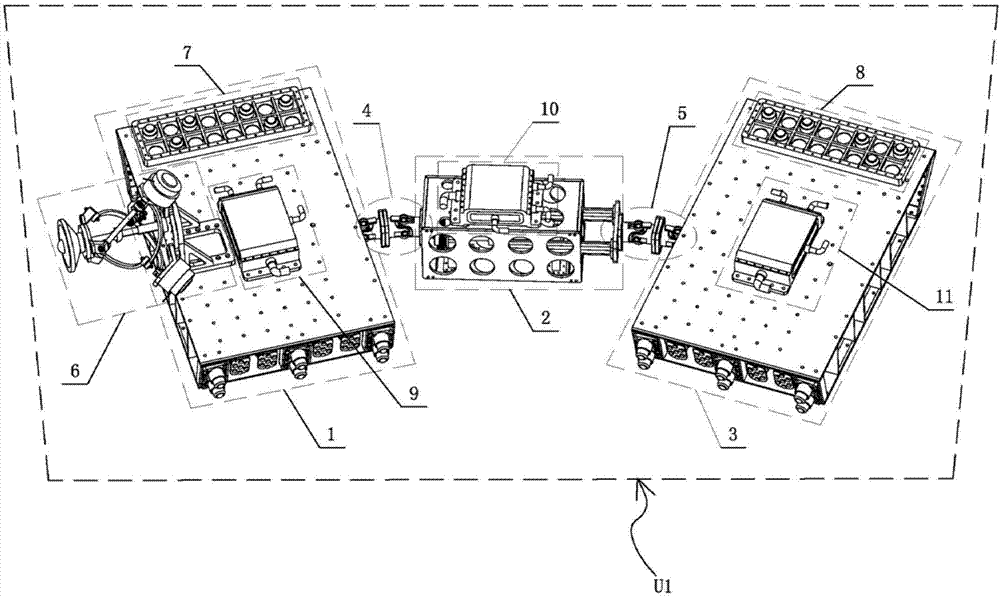

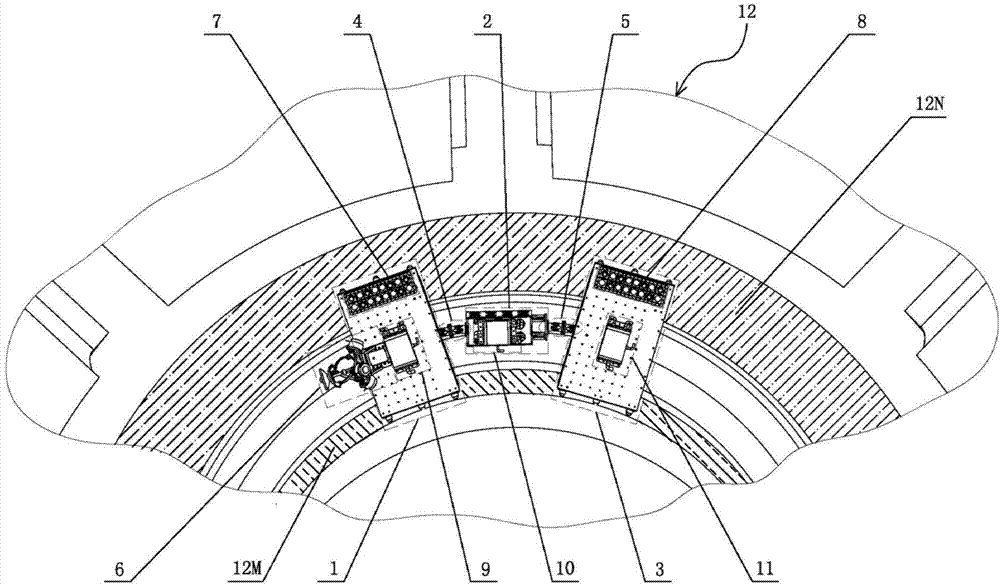

Control method of multi-section peristaltic snake-like robot running in nuclear fusion cabin

InactiveCN104627266ALarge range of motionMeet the overall technical requirements for depth of involvementVehiclesInterior spaceEngineering

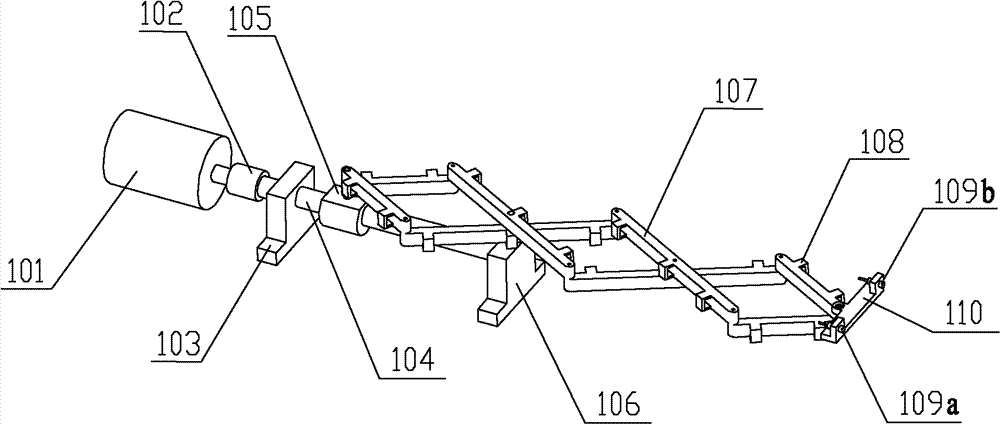

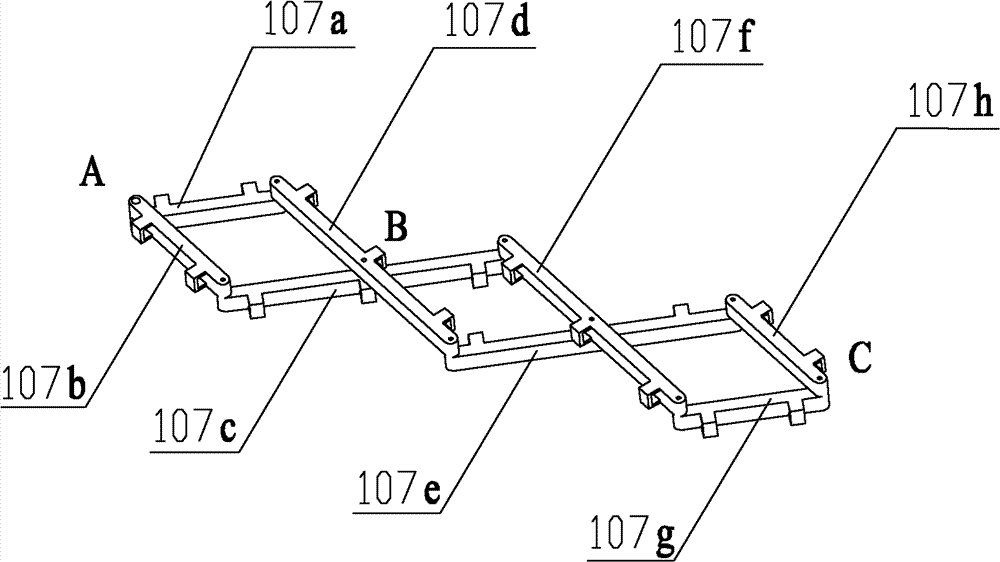

The invention discloses a control method of a multi-section peristaltic snake-like robot running in a nuclear fusion cabin. The control method is characterized in that a front section side positioning module and a rear section side positioning module are symmetrically arranged at two ends of a middle section axial moving module to form a walking mechanism, the walking mechanism is used as at least two creeping units, the at least two creeping units are serially connected to form the multi-section peristaltic snake-like robot, and adjacent creeping units are connected by using two telescopic elastic universal joints. By using the control method disclosed by the invention, a locomotion gait similar to multi-section worm walking can be realized, the running stability is good, the control is simple; a movement locus can be across a large dual-ring groove at the bottom of the whole nuclear fusion cabin, and the all-dimensional vision information acquisition of a space inside the nuclear fusion cabin is realized by carrying a vision observing cloud deck.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

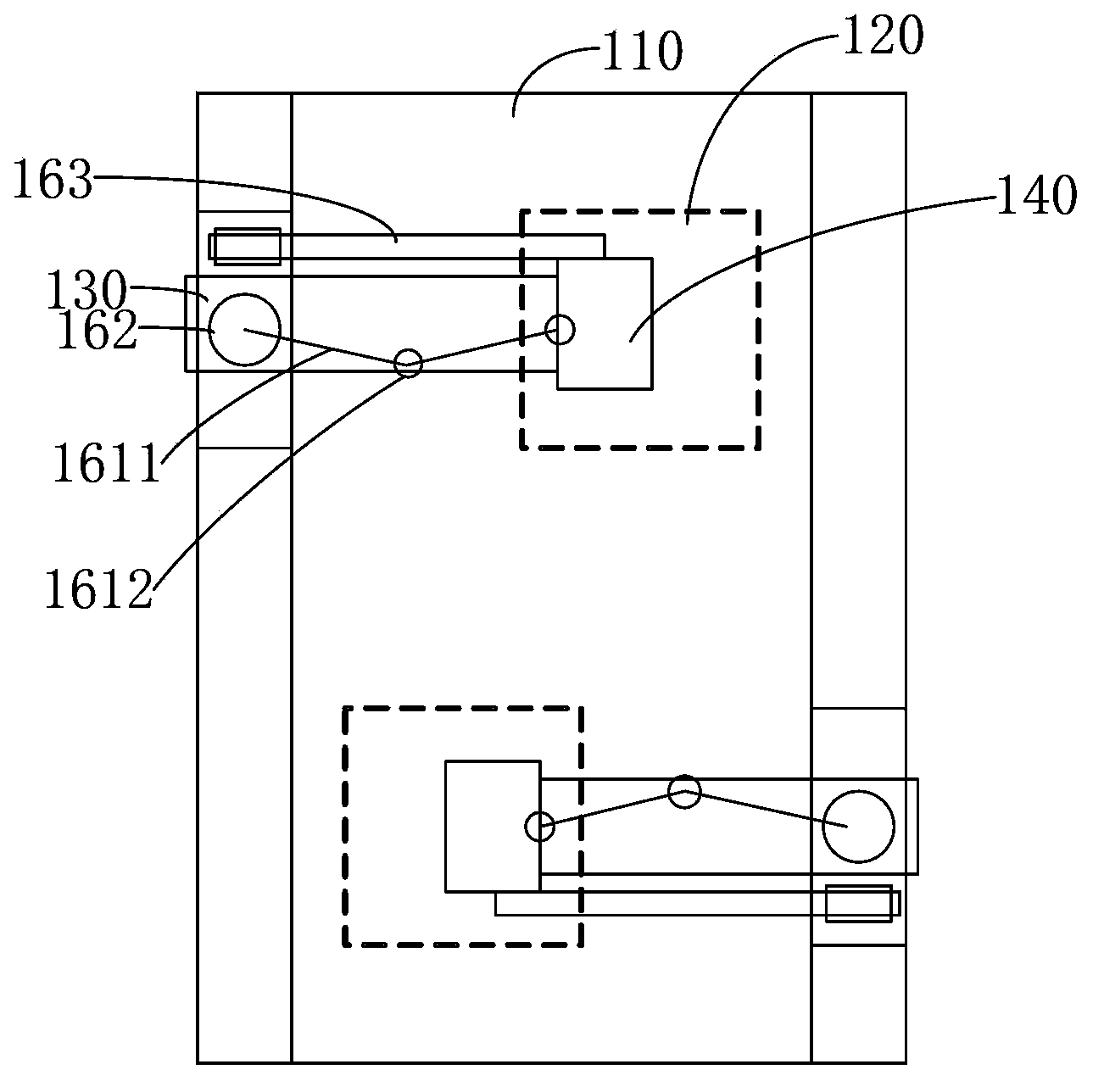

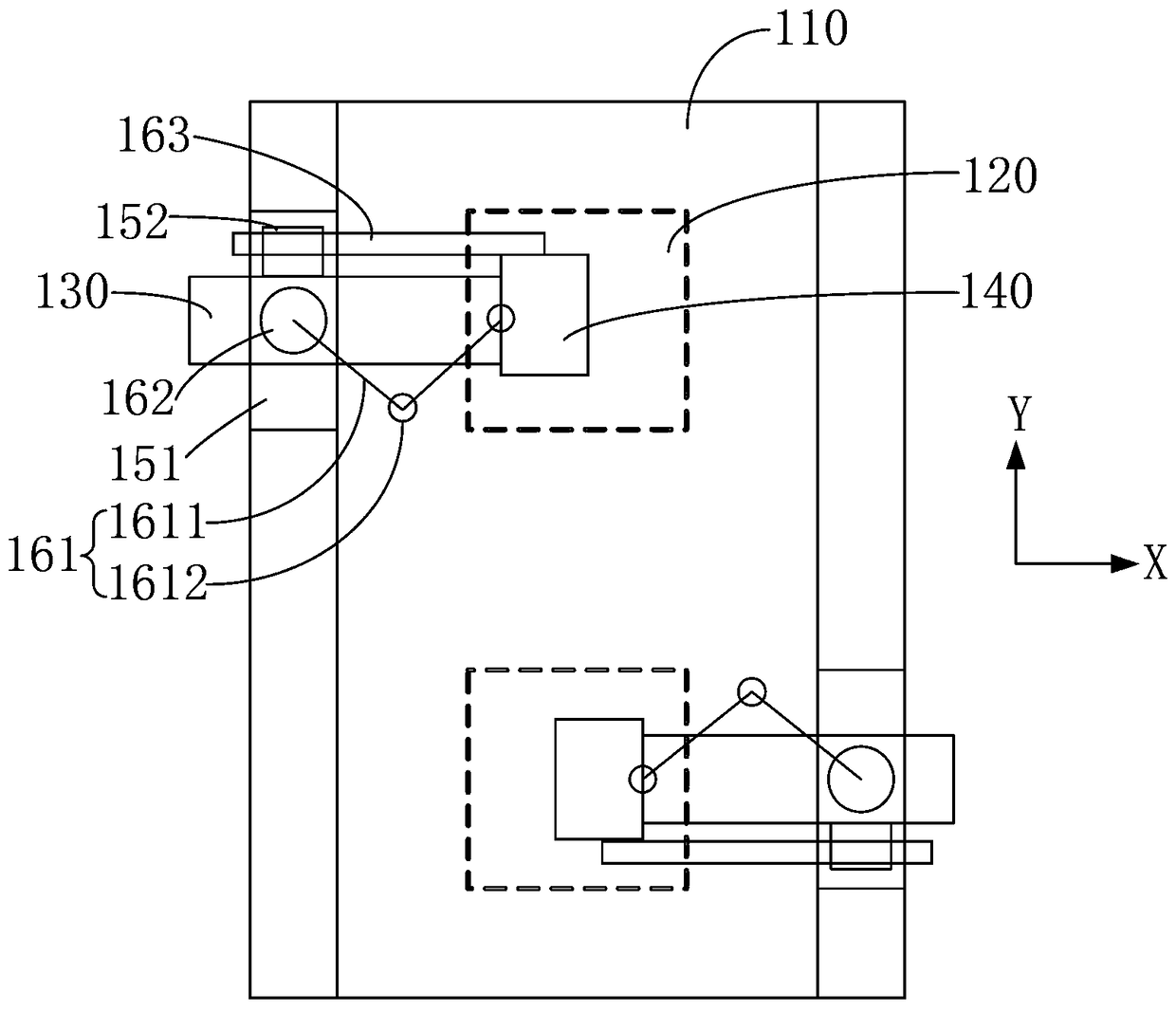

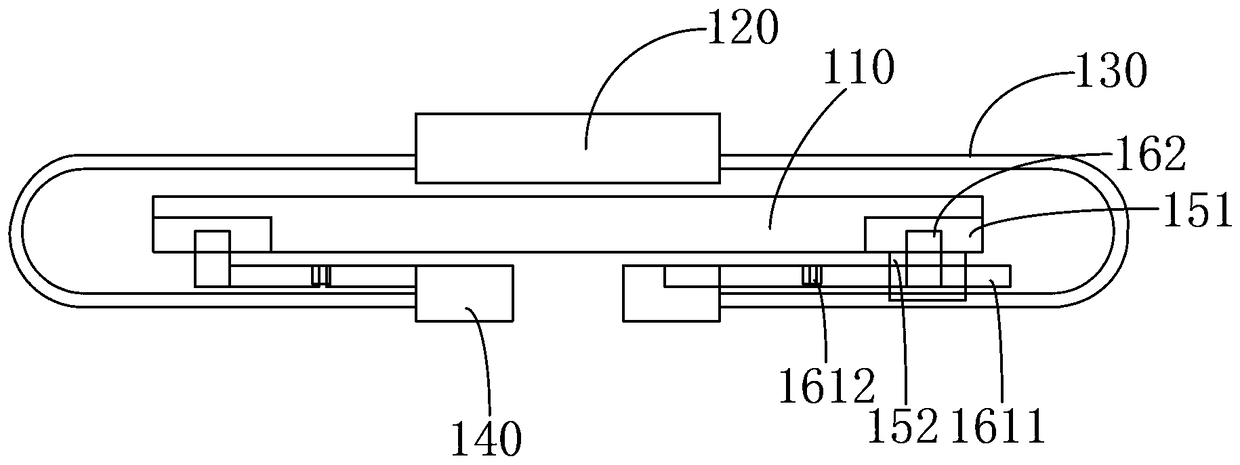

Workbench cable device

ActiveCN103901734AIncrease stiffnessHigh elastic modulusSemiconductor/solid-state device manufacturingPhotomechanical exposure apparatusPower stationEngineering

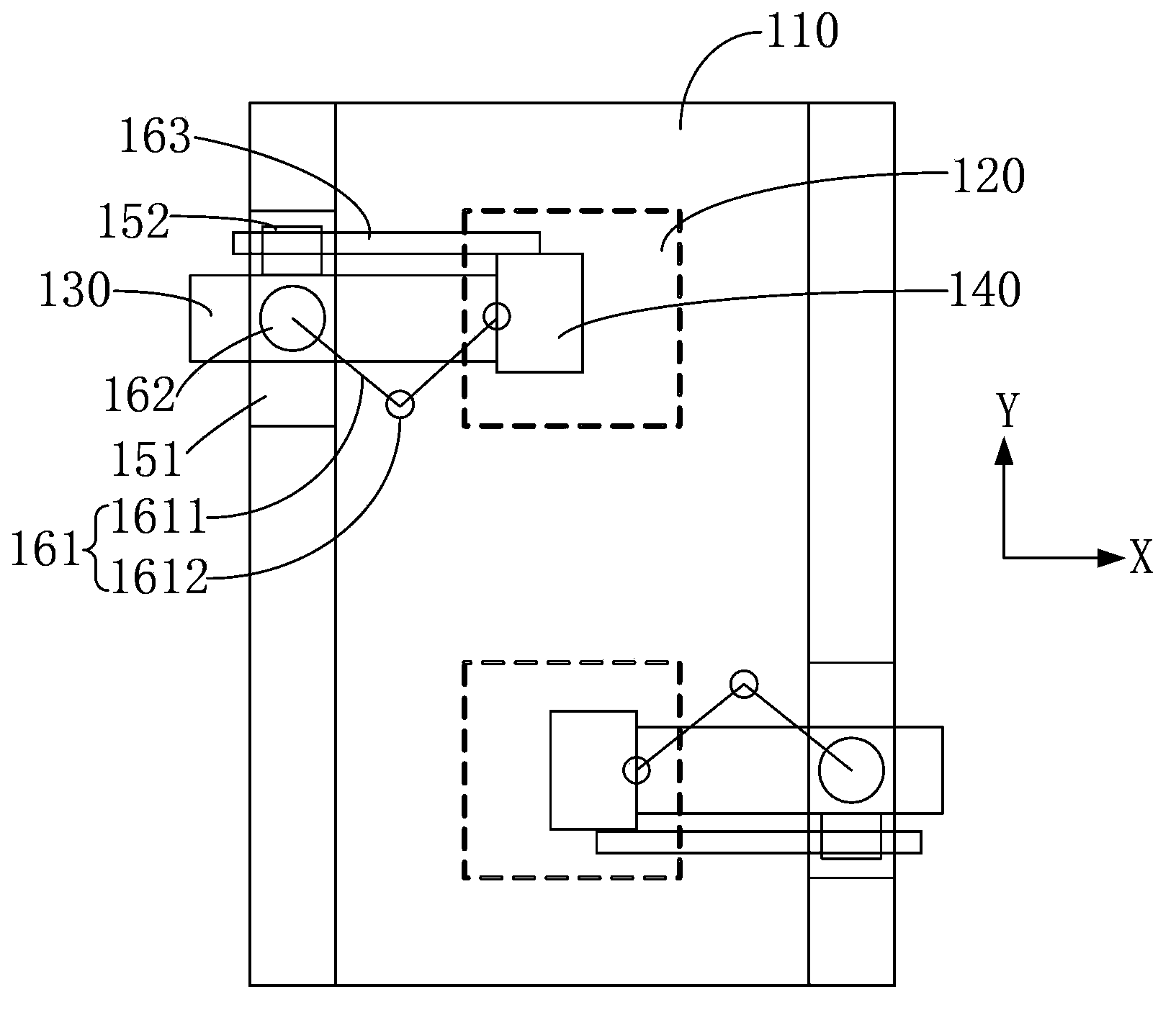

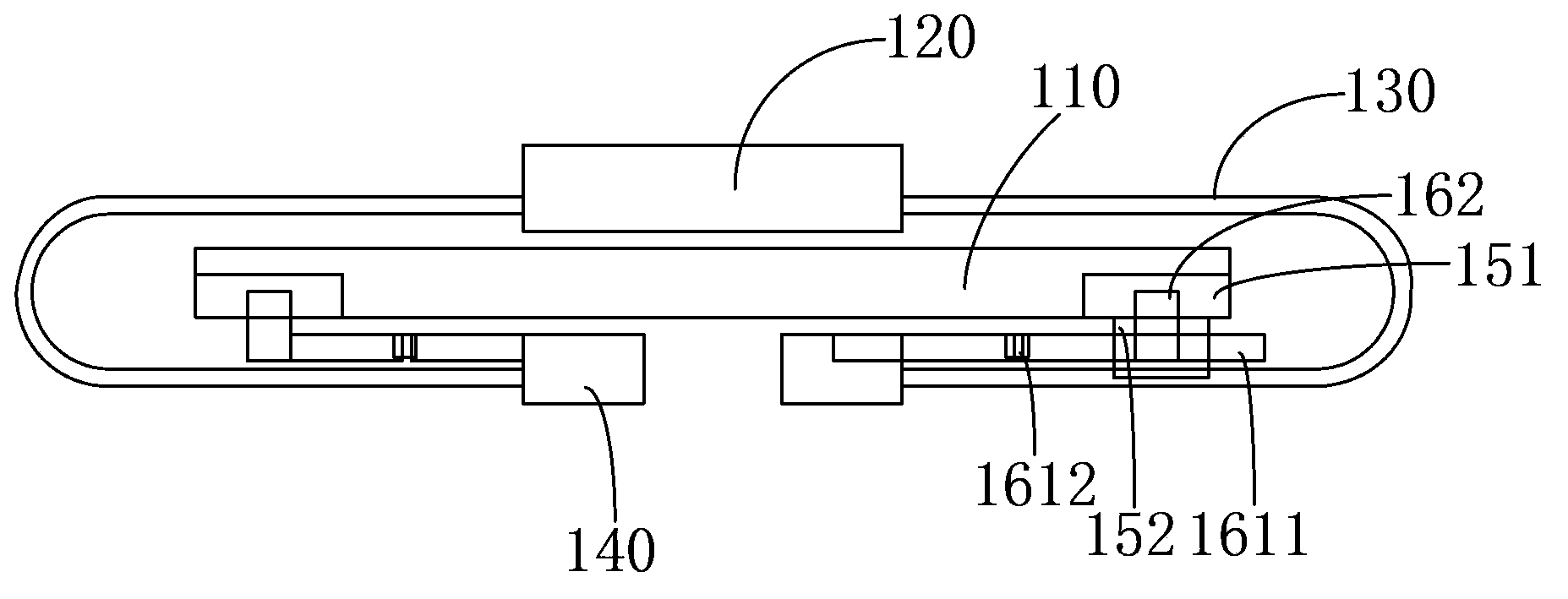

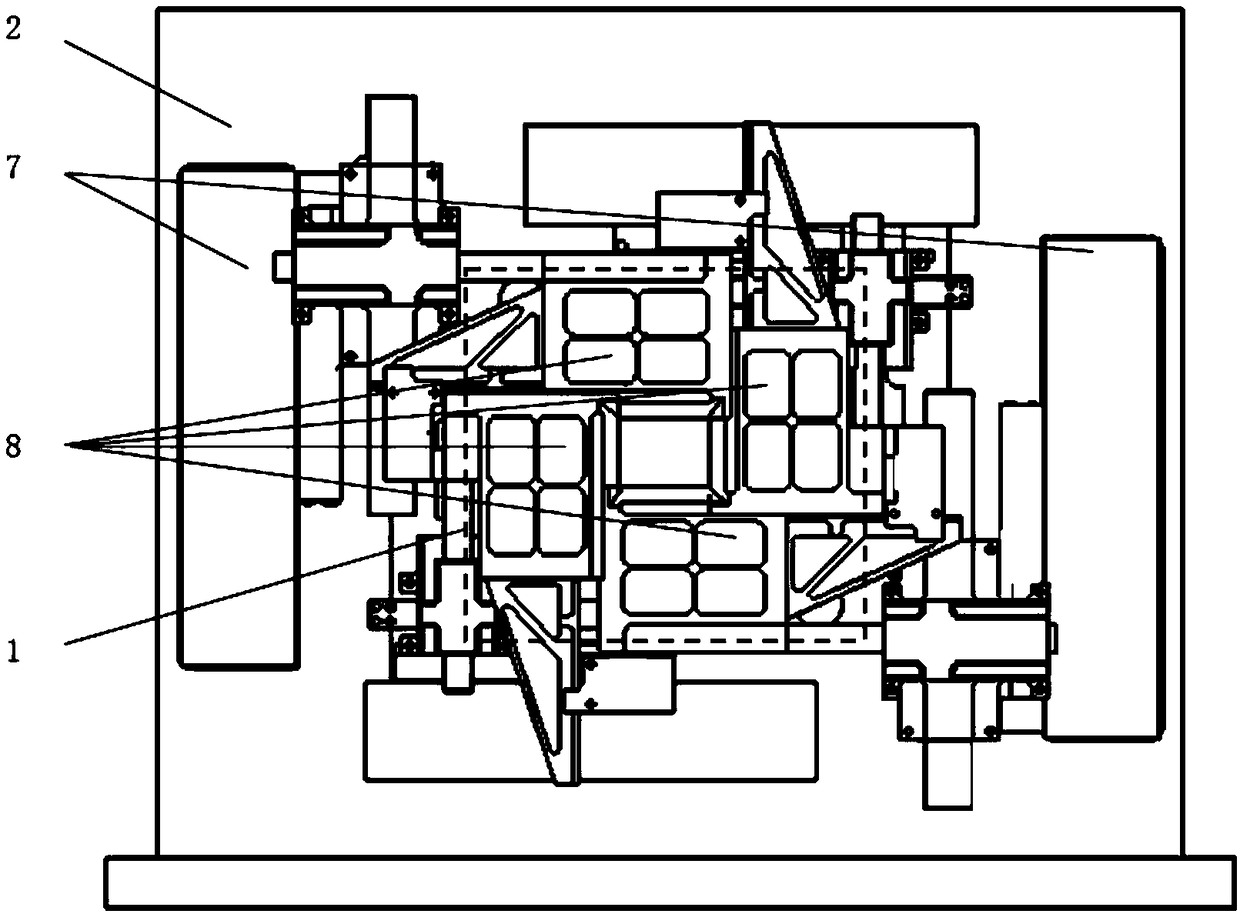

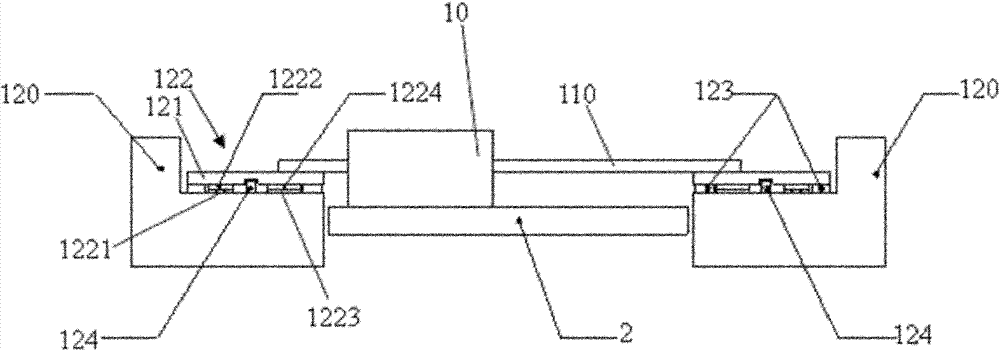

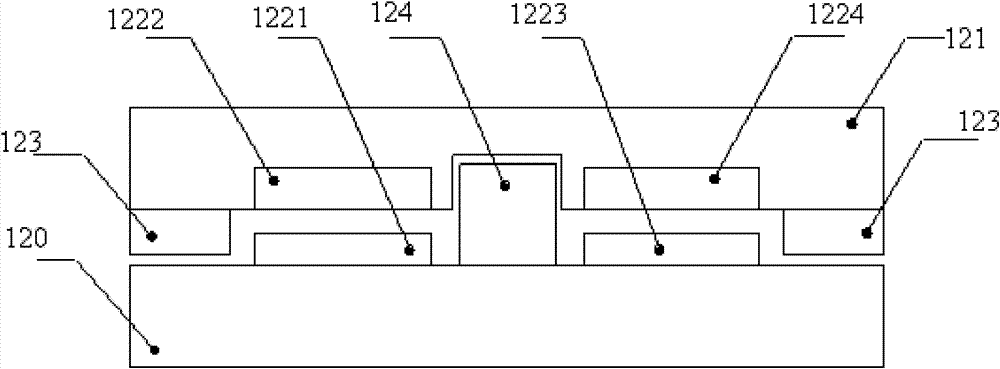

A work station cable apparatus comprises a work station (110), a silicon wafer station (120), a cable device (130), a cable connection station (140), an X-direction moving device and a Y-direction moving device. The silicon wafer station (120) and the cable connection station (140) are respectively mounted on the upper side and the lower side of the work station (110). The two ends of the cable device (130) are connected to the silicon wafer station (120) and the cable connection station (140) respectively. The X-direction and Y-direction moving devices are both connected to the cable connection station (140) and respectively drive the cable connection station (140) to move following the silicon wafer station (120) along the X-direction and the Y-direction. The cable connection station (140) drives the cable device (130) to synchronously move following the silicon wafer station (120) along the X-direction and the Y-direction, thus being able to reduce disturbance of the cable device (130) to the motion of the silicon wafer station (120), reduce the bending times of the cable device (130) and prolong the service life of the cable device.

Owner:SHANGHAI MICRO ELECTRONICS EQUIP (GRP) CO LTD

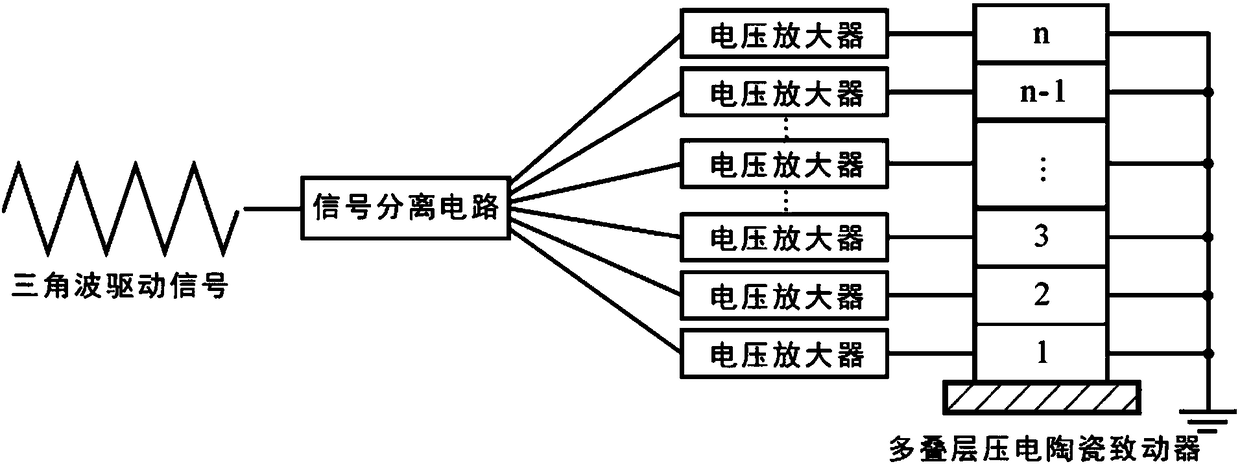

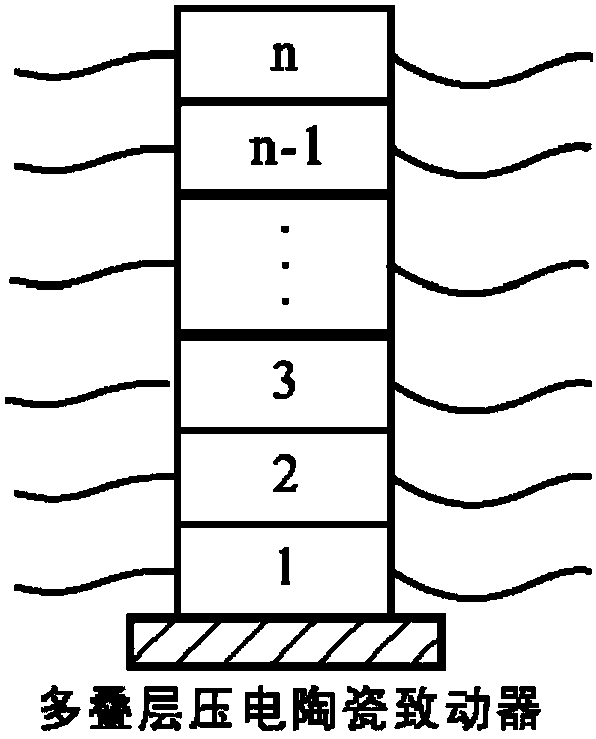

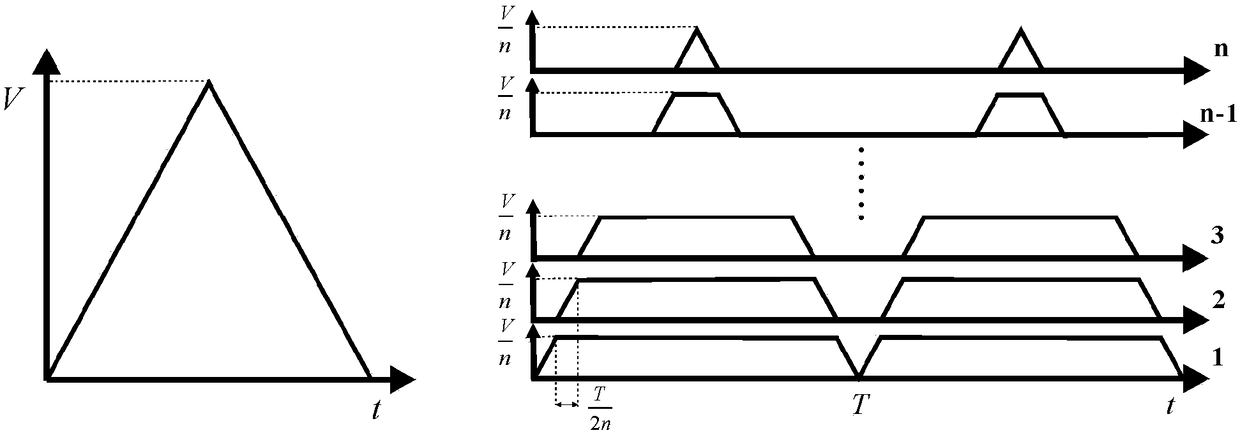

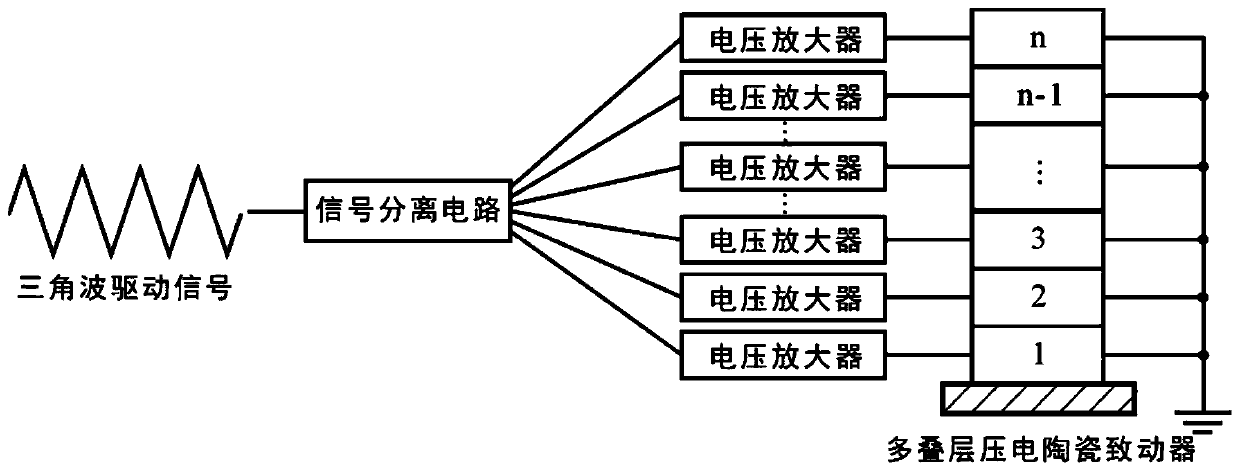

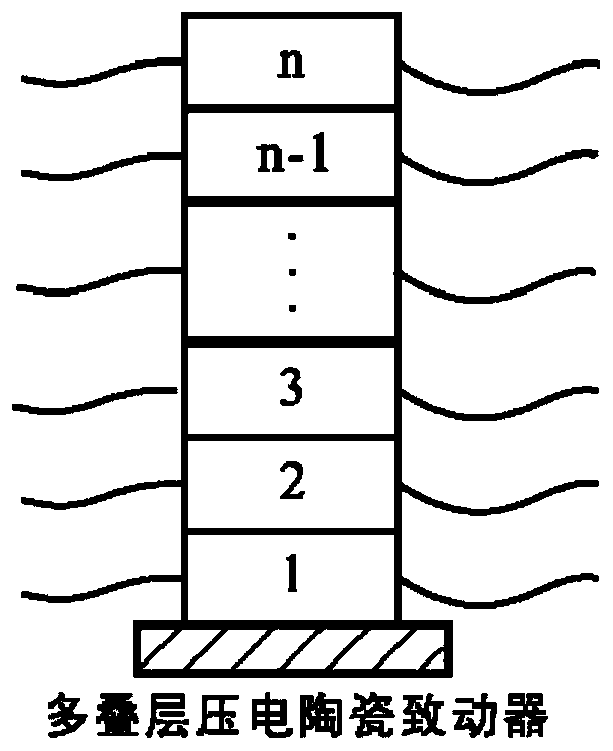

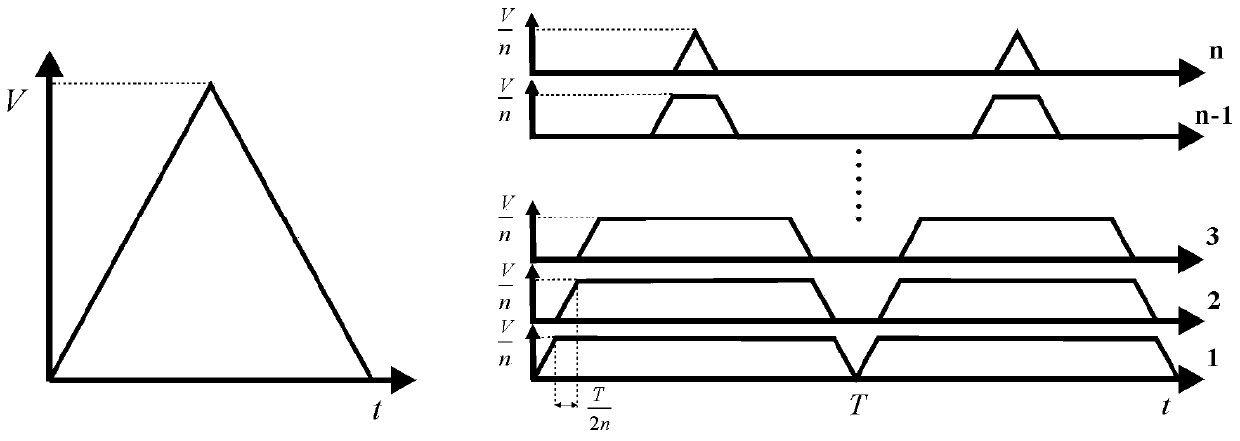

Multi-stack piezoelectric actuator independent time-sharing driving device and method

InactiveCN108448928AHigh motion positioning accuracyEasy to operatePiezoelectric/electrostriction/magnetostriction machinesElectricityHysteresis

The invention provides a multi-stack piezoelectric actuator independent time-sharing driving device and method and relates to the application in the field of a precision displacement platform. Each layer of piezoelectric actuators is independently driven. A driving signal is separated into sub signals in time series connection according to a voltage evenly-spaced rule. A signal applied to an independent piezoelectric actuator of each layer is an amplified sub signal. The voltage evenly-spaced rule is achieved by a signal separating circuit. The driving signal may be any desired signal. Compared with the piezoelectric stack with the parallel connection of multiple layers of piezoelectric actuators, according to the driving device of the invention, the hysteresis accumulation due to paralleldriving can be effectively eliminated, only the hysteresis of a piezoelectric actuator of one layer exists at the same moment, the hysteresis in the displacement process of the multiple layers of piezoelectric actuators is effectively reduced, the motion positioning accuracy is improved, the operation is simple, and the cost is low.

Owner:HEFEI UNIV OF TECH

Reeling mechanism for weave hard ultra-thick textile

Owner:DONGHUA UNIV

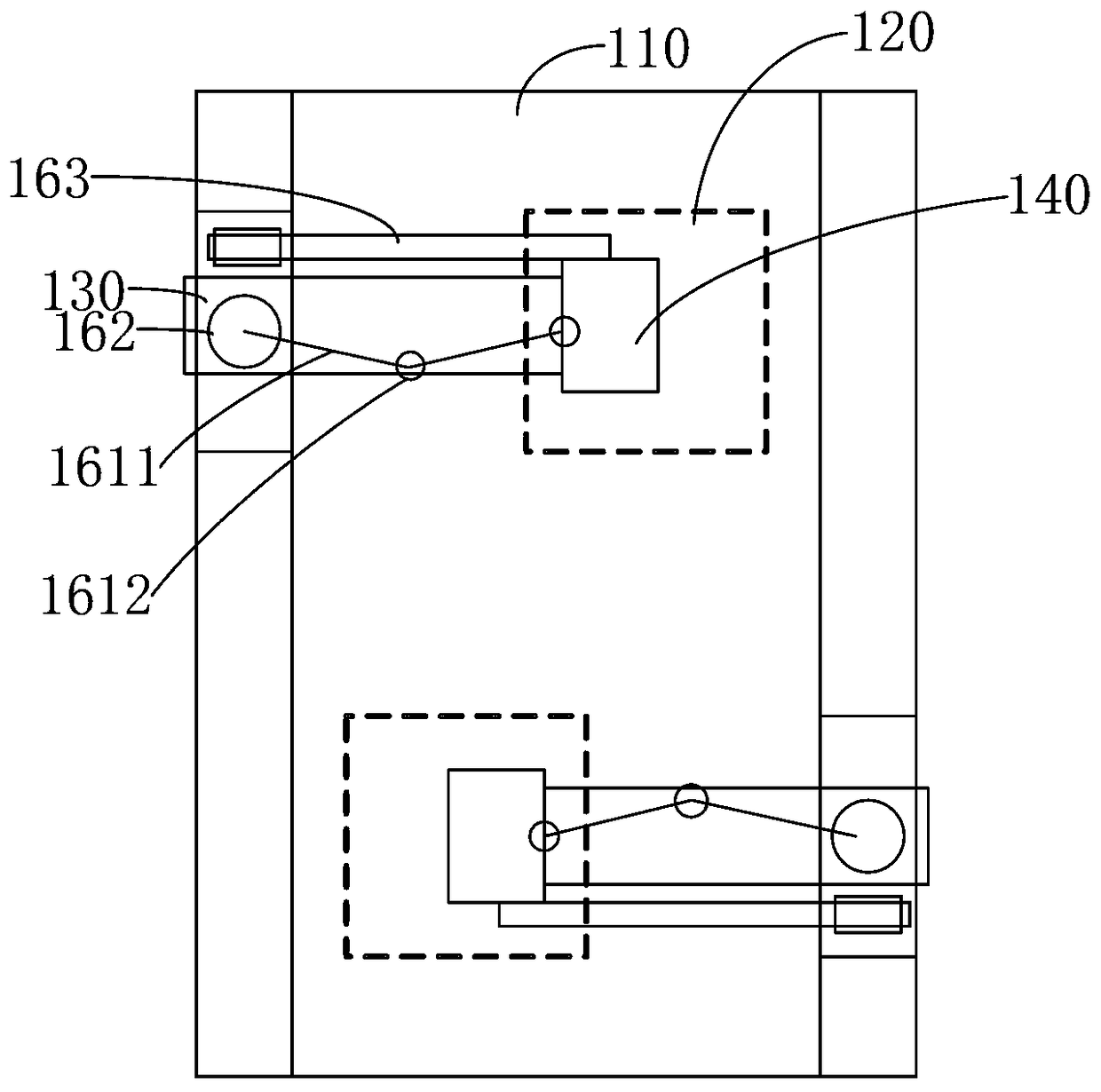

Active driving wire cable table of silicon wafer stage of lithography machine

ActiveCN103246168ASimple structureHigh motion positioning accuracyPhotomechanical exposure apparatusMicrolithography exposure apparatusStepperEngineering

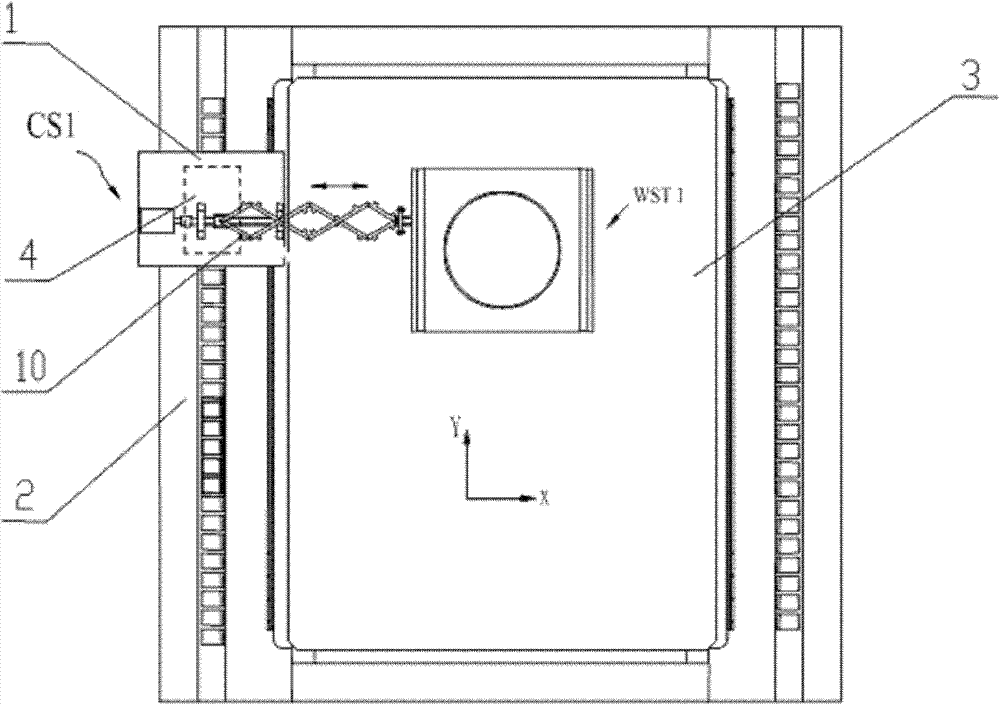

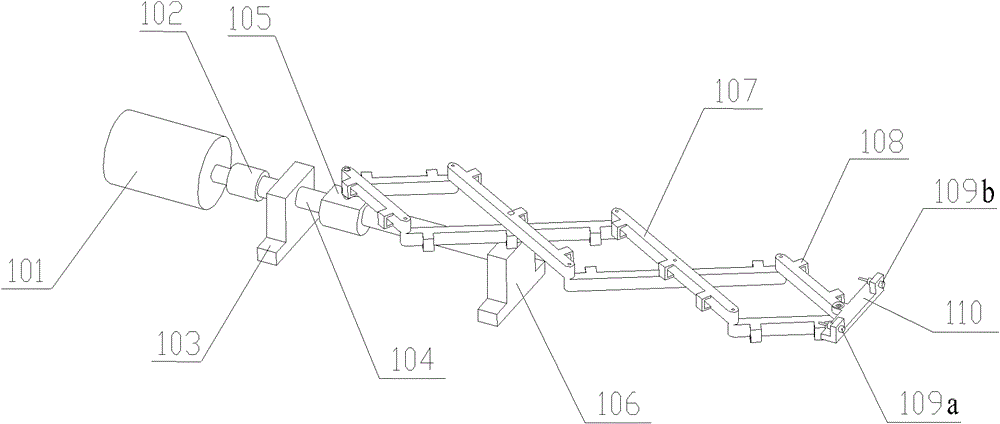

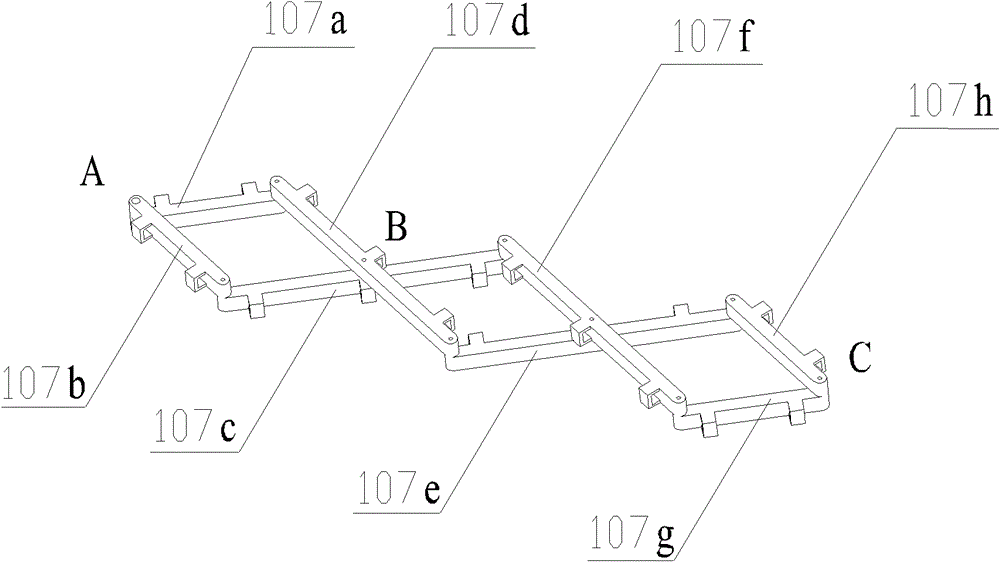

The invention provides an active driving wire cable table of a silicon wafer stage of a lithography machine. The active driving wire cable table comprises a Y-direction sliding table, a Y-direction guide rail and a cross-telescopic linkage mechanism, wherein the Y-direction sliding table is disposed on the Y-direction guide rail through an air bearing; the Y-direction sliding table is driven by a sliding table motor and moves synchronously in the Y direction and on the silicon wafer stage; wire cable instrument is conveyed to the silicon wafer stage along the cross-telescopic linkage mechanism through the Y-direction sliding table; the cross-telescopic linkage mechanism comprises a cross telescopic connecting rod and a driver; one end of the cross telescopic connecting rod is connected with the Y-direction sliding table; the other end of the cross telescopic connecting rod is connected with the silicon wafer stage through the wire cable instrument; and the driver is used for driving the cross telescopic connecting rod to move along with an X direction, so that the wire cable is driven to move along the X direction. The active driving wire cable table of the silicon wafer stage of the lithography machine can realize active control of the wire cable table and follow motion of the wire cable table to the silicon wafer stage in an X-Y plane.

Owner:SHANGHAI MICRO ELECTRONICS EQUIP (GRP) CO LTD

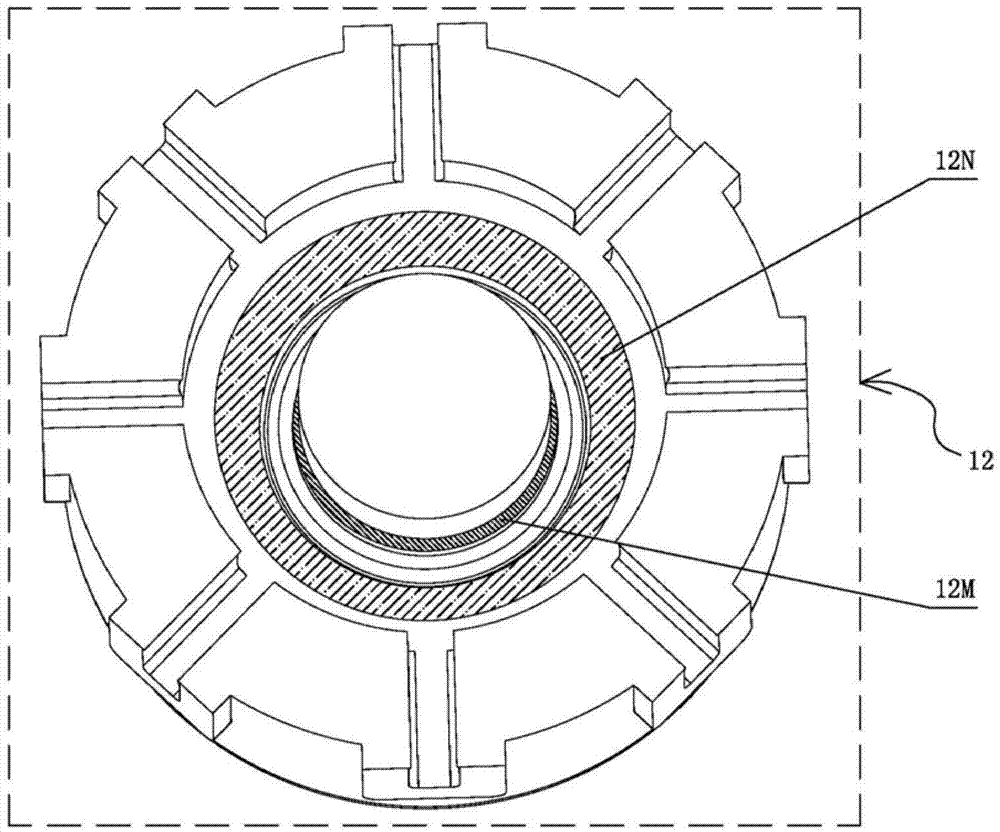

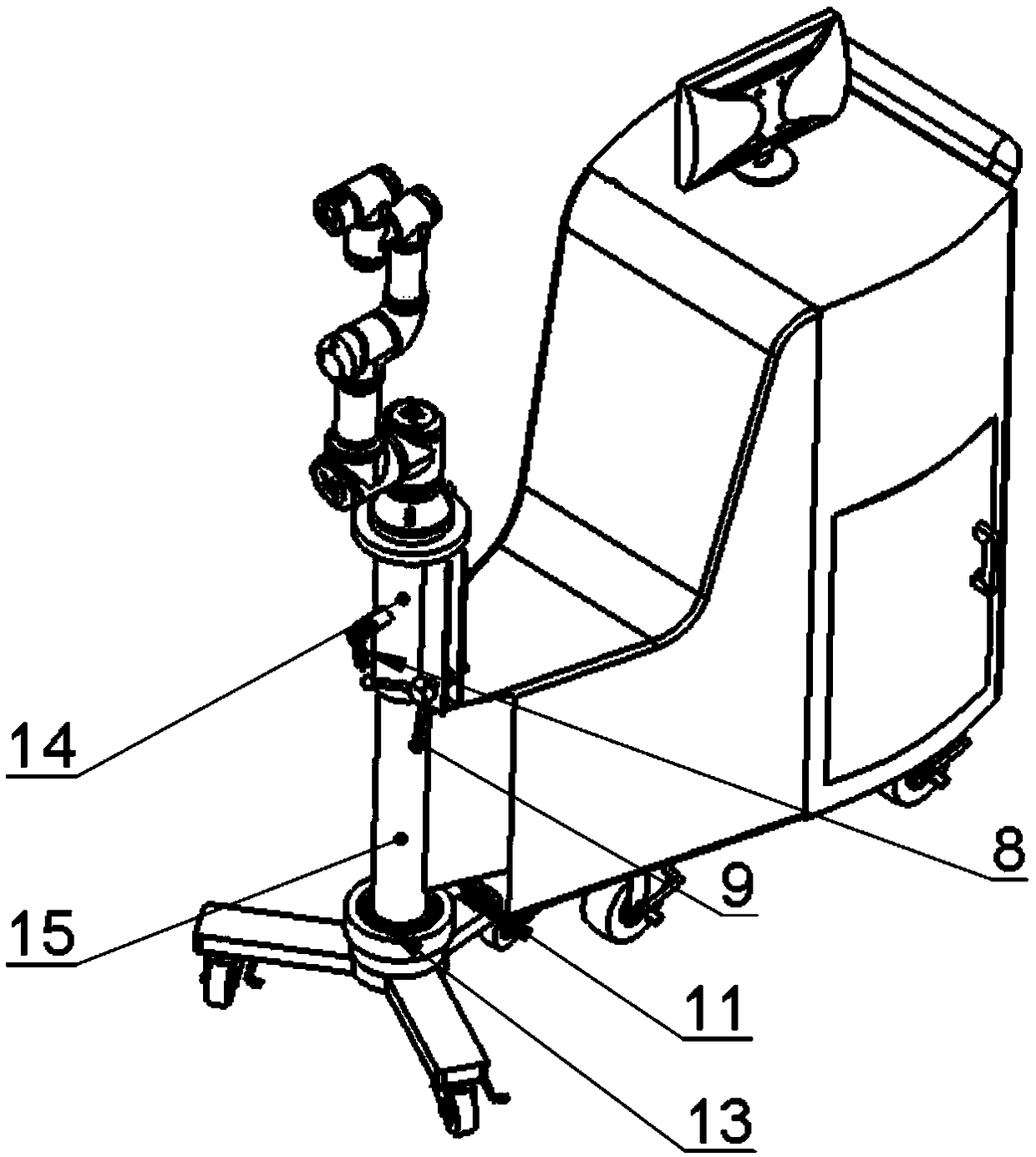

Visual observation mechanism working in nuclear fusion chamber and control method thereof

InactiveCN104637550ALarge range of motionMeet the technical requirements for depth of involvementNuclear energy generationThermonuclear fusion reactorVisual observationNuclear fusion

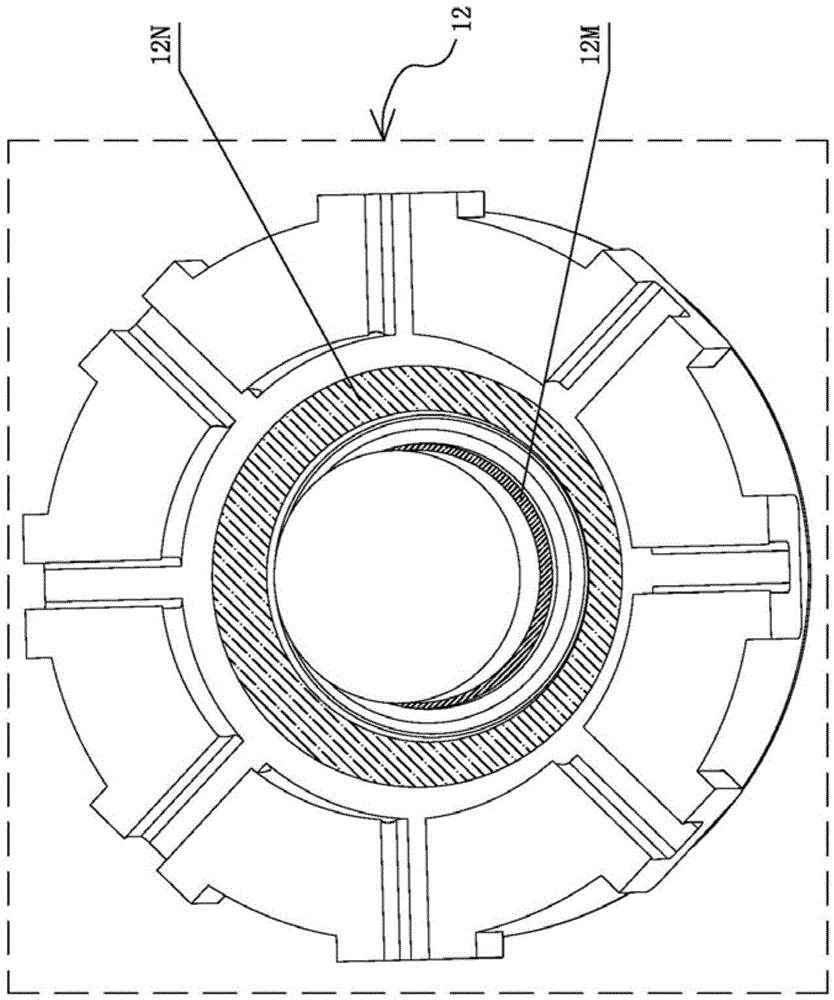

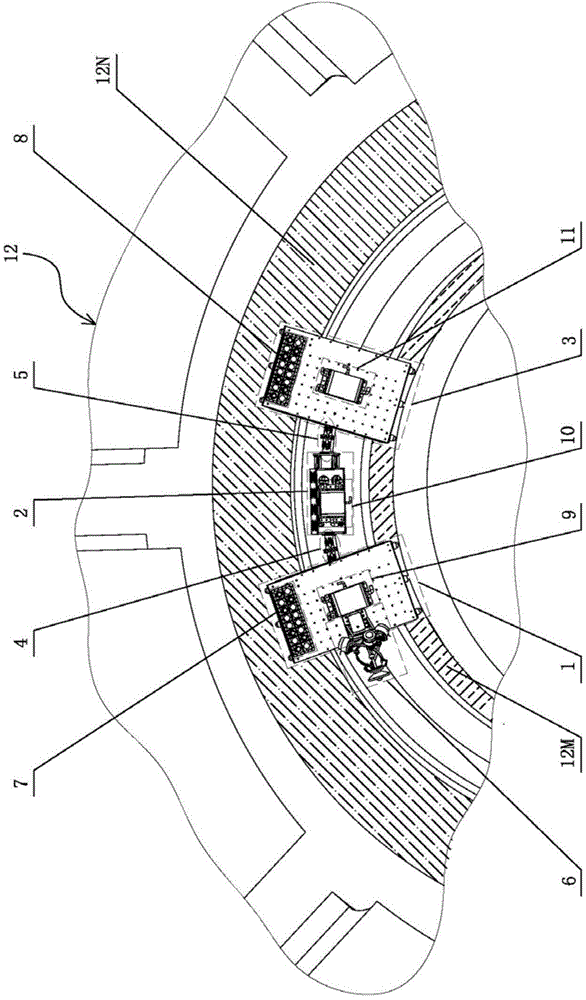

The invention discloses a visual observation mechanism working in a nuclear fusion chamber and a control method thereof. The visual observation mechanism is characterized in that a front body segment lateral positioning module and a rear body segment lateral positioning module are symmetrically arranged at two ends of a middle body segment axial motion module to form a traveling mechanism; a visual observation cloud deck is arranged at the front part of the front body segment lateral positioning module; the front body segment lateral positioning module and the middle body segment axial motion module are connected by a front double universal joint; the rear body segment lateral positioning module and the middle body segment axial motion module are connected by a rear double universal joint. According to the visual observation mechanism disclosed by the invention, the traveling mechanism is wide in motion range; the traveling track of the traveling mechanism can extend all over the complete cycle of a large-double circular channel at the bottom of the nuclear fusion chamber; the visual observation cloud deck is arranged in a matching way, so that all-round visual information acquisition of an annular space with a D-shaped section inside the nuclear fusion chamber can be finished.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

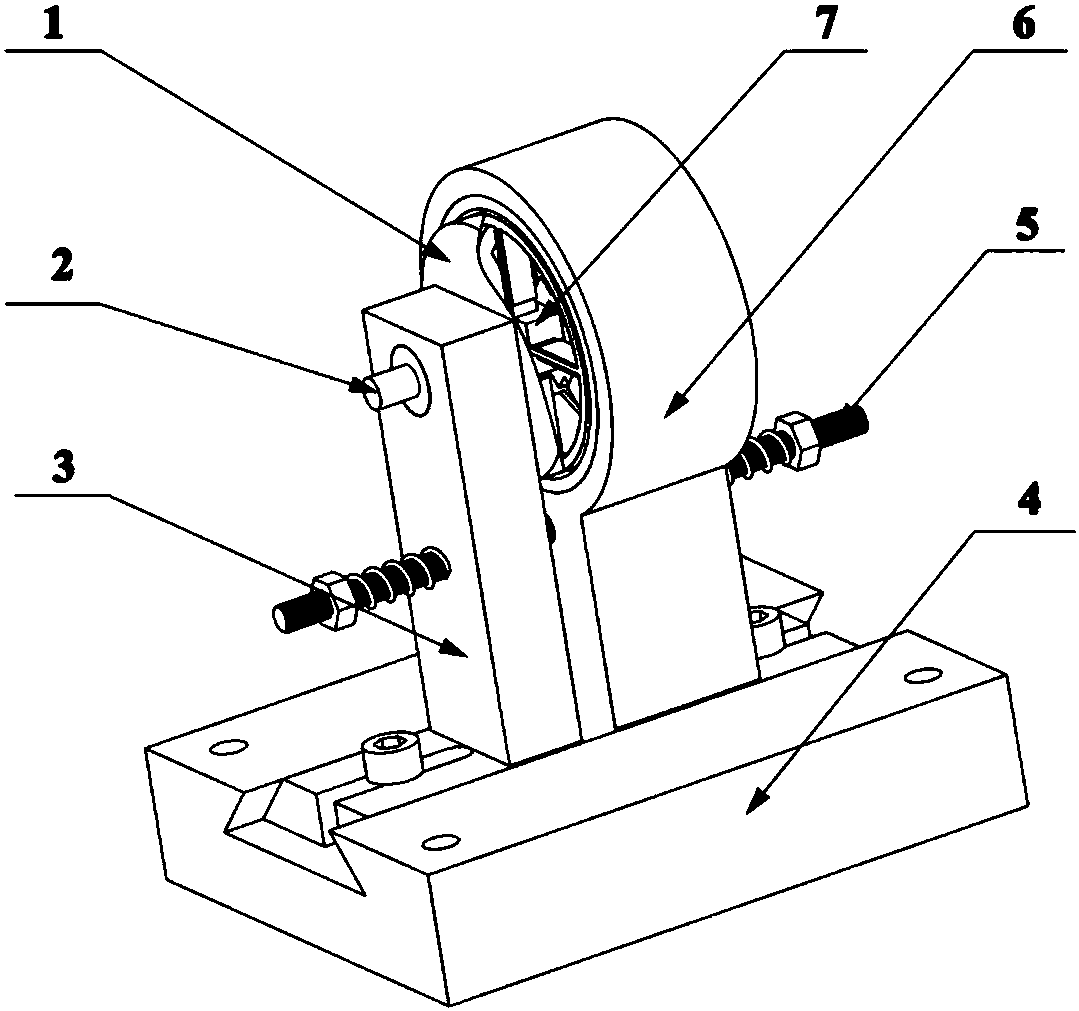

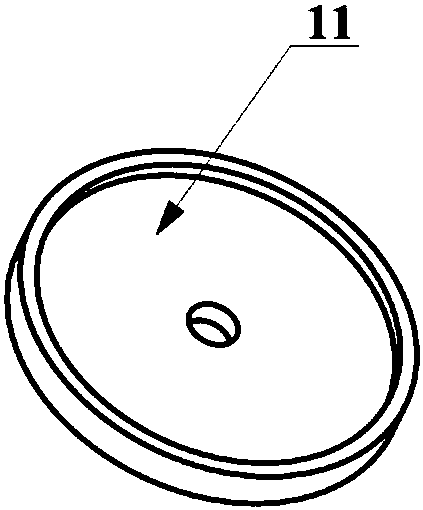

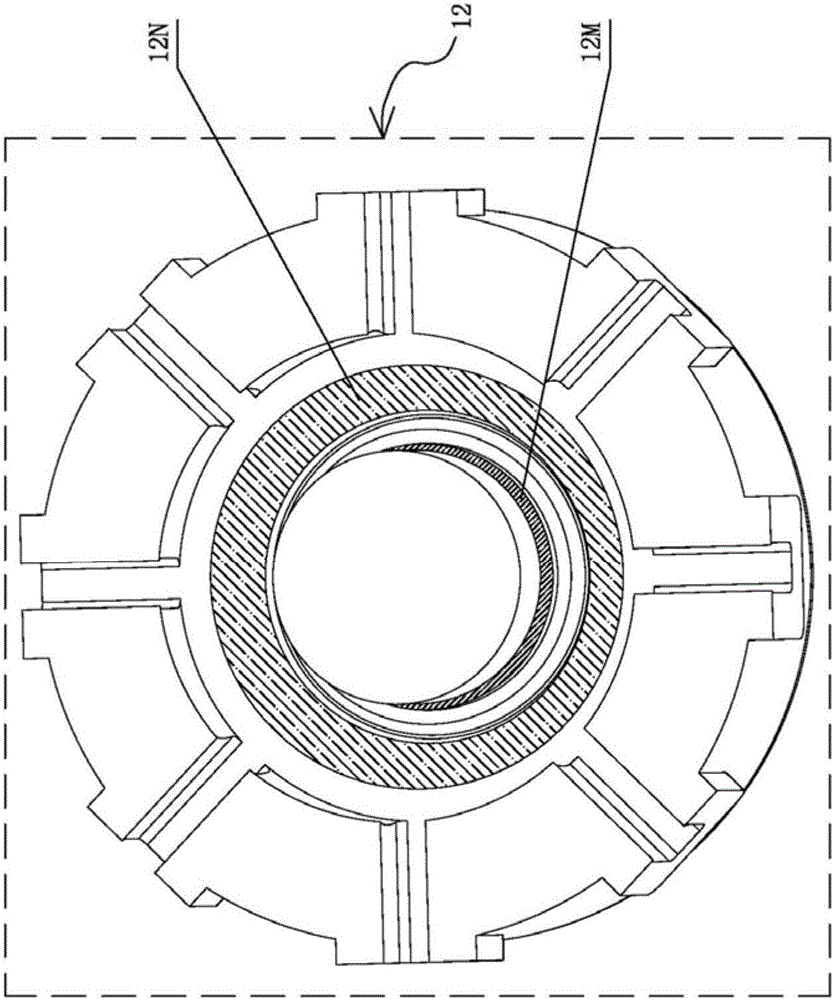

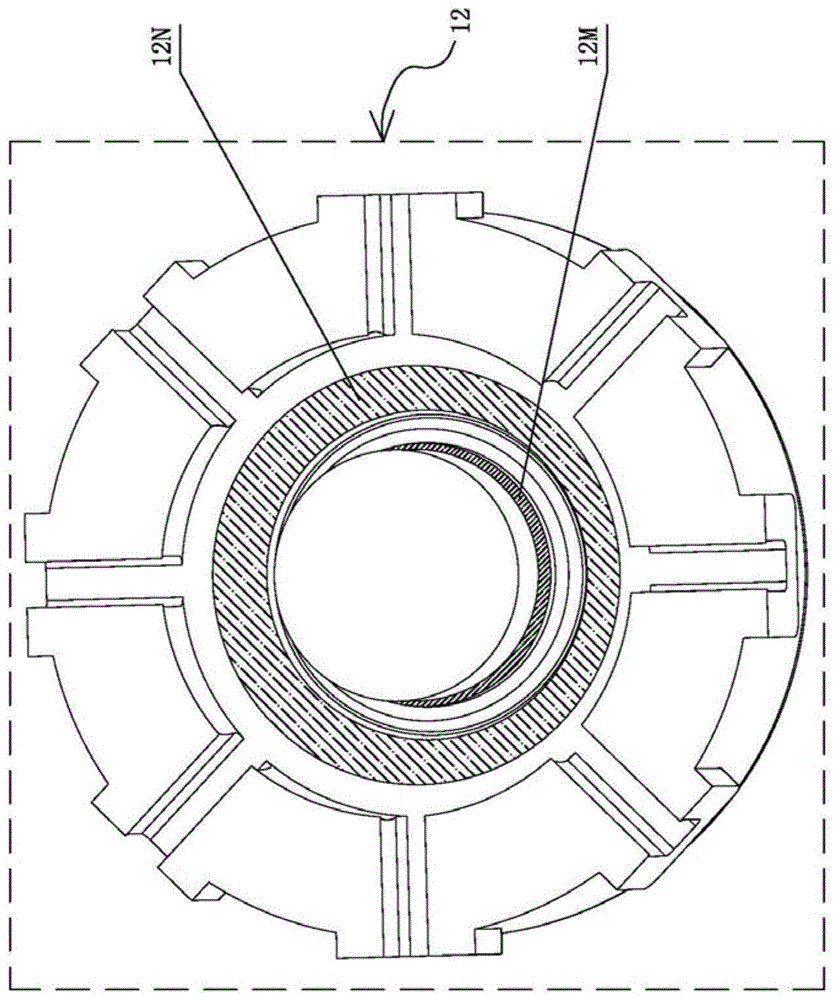

Rotary piezoelectric motor

ActiveCN108365773ALower requirementLow costPiezoelectric/electrostriction/magnetostriction machinesPositional TechniqueRotational vibration

The invention discloses a rotary piezoelectric motor, and belongs to the technical field of precision driving and positioning. The rotary piezoelectric motor comprises double stators, an active cell,a pre-tensioning mechanism, a bearing seat, a stator seat and a base. The main body of the double stators is composed of a metal cross beam and a piezoelectric ceramic, an inner stator generates rotational vibration, an outer stator generates axial vibration, and the double stators are bonded together. The superposition of the vibration of the double stators generates the elliptical motion of a torus mass point of the inner stator, and an active cell shaft is driven to perform one-way rotational motion by friction. The rotary piezoelectric motor has the advantages that the working frequency islower, the working frequency is about 1000 hertz, and the requirement for a matched circuit is lower; the positioning accuracy is high, and the step angle can reach up to 0.01 degree; the structure is simple, the assembly is convenient, and the load capacity is large due to the contact of the whole torus.

Owner:HEFEI UNIV OF TECH

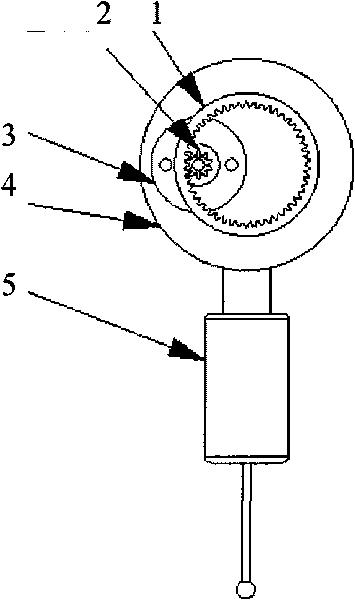

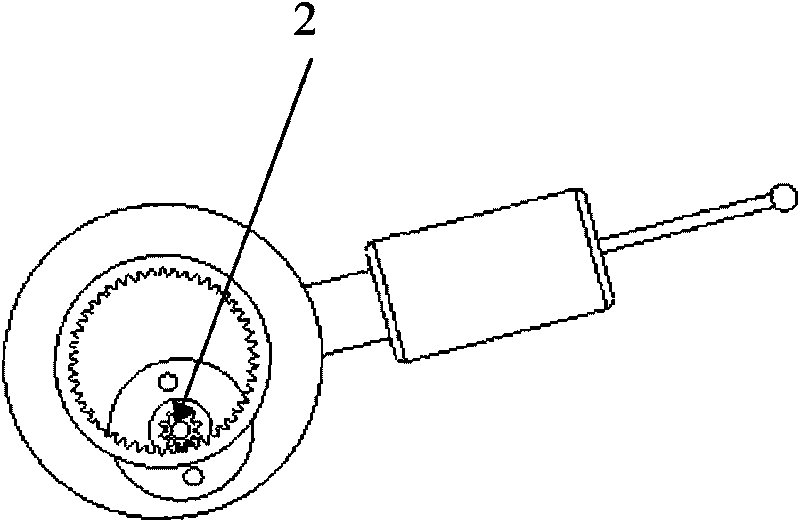

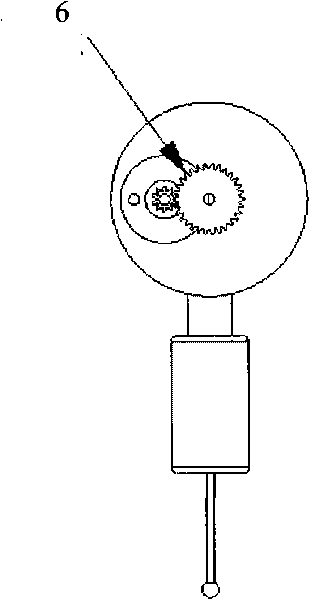

Internal-tooth gear driven type rotary measuring head base

InactiveCN101738149AReduce loadOvercoming the problem of small radiusAngles/taper measurementsGear driveGear wheel

The invention relates to an internal-tooth gear driven type rotary measuring head base, which comprises a measuring head connected to a rotor of the measuring head base, a motor fixed in the eccentric position of the rotor of the measuring head base and a drive gear set. The invention is characterized in that the drive gears on the motor are engaged with an internal-tooth gear fixed in the measuring head base; the circle centre of the internal-tooth gear is coincident with the rotary circle centre of the rotor of the measuring head base. In the internal-tooth gear driven type rotary measuring head base, the internal-tooth gear is used for replacing an external-tooth gear to drive the rotor and the measuring head to do circular motion; the drive ratio of the internal-tooth gear is 5:1, while the drive ratio of the original external gear is 3:1; the rotary radius of the internal-tooth gear is twice as long as that of the external-tooth gear so that the internal-tooth gear has a larger torque, and loads of the motor during rotation are reduced; the rotating force is large and stable so that the motion positioning accuracy is increased. The internal-tooth gear driven type rotary measuring head base also overcomes the defect that the radius of the external-tooth gear is small because of limit internal space of the present rotary measuring head base, and simultaneously saves space of the center so that other parts can be installed.

Owner:孟庆周

Multi-section peristaltic snakelike robot working in nuclear fusion bin

InactiveCN104724199ALarge range of motionMeet the overall technical requirements for depth of involvementVehiclesInterior spaceVisual observation

The invention discloses a multi-section peristaltic snakelike robot working in a nuclear fusion bin. The multi-section peristaltic snakelike robot working in the nuclear fusion bin is characterized in that each walking mechanism is composed of a front body section lateral positioning module and a rear body section lateral positioning module symmetrically arranged at the two ends of a middle body section axial movement module, the walking mechanisms serve as wriggling units, at least two wriggling units are connected in series to form the multi-section peristaltic snakelike robot, and the adjacent wriggling units are connected through telescopic elastic double universal joints. The movement track of the multi-section peristaltic snakelike robot can cover a whole large double annular groove way in the bottom of the nuclear fusion bin, the movement gait is like walking of a multi-section worm, movement stability is good, control is simple, and omnibearing visual information collection of the internal space of the nuclear fusion bin can be realized by mounting a visual observation cloud platform.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

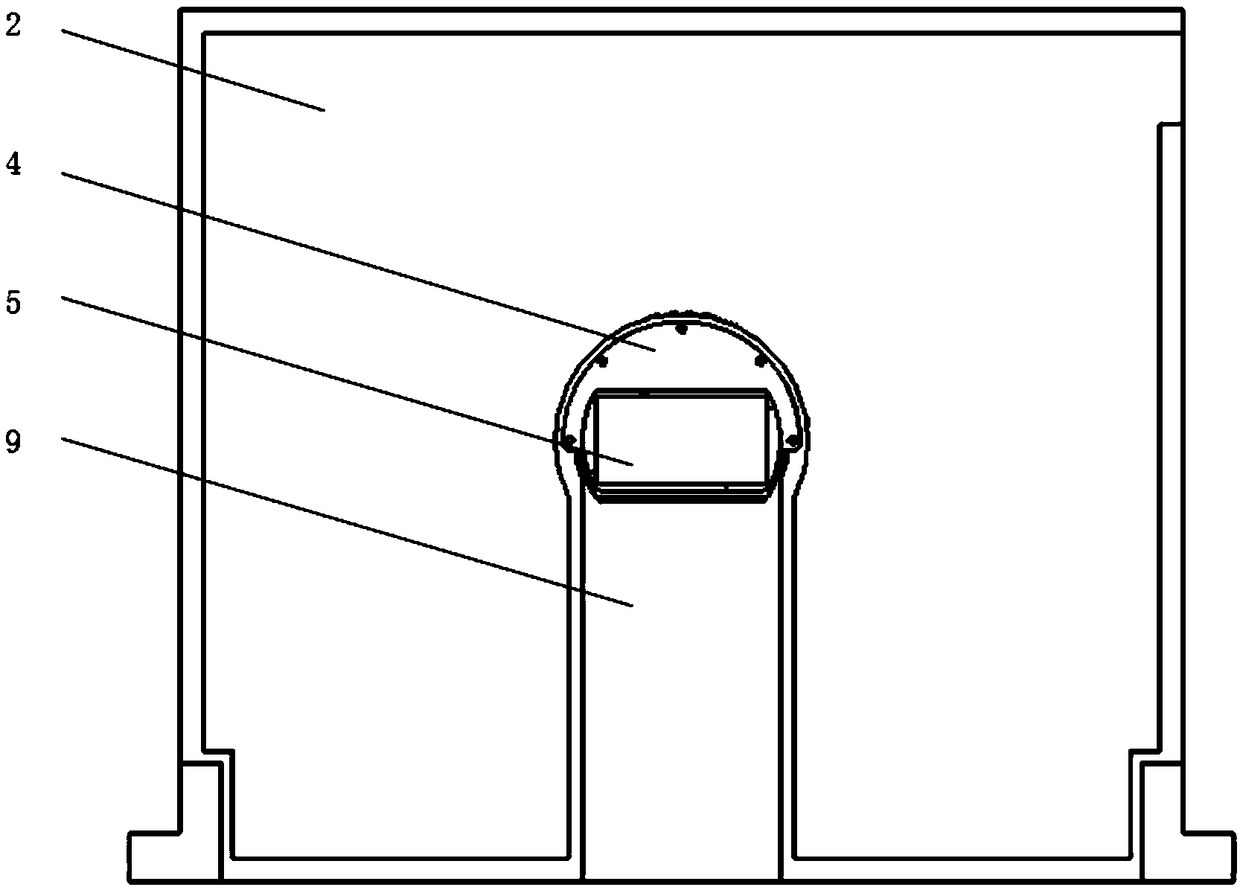

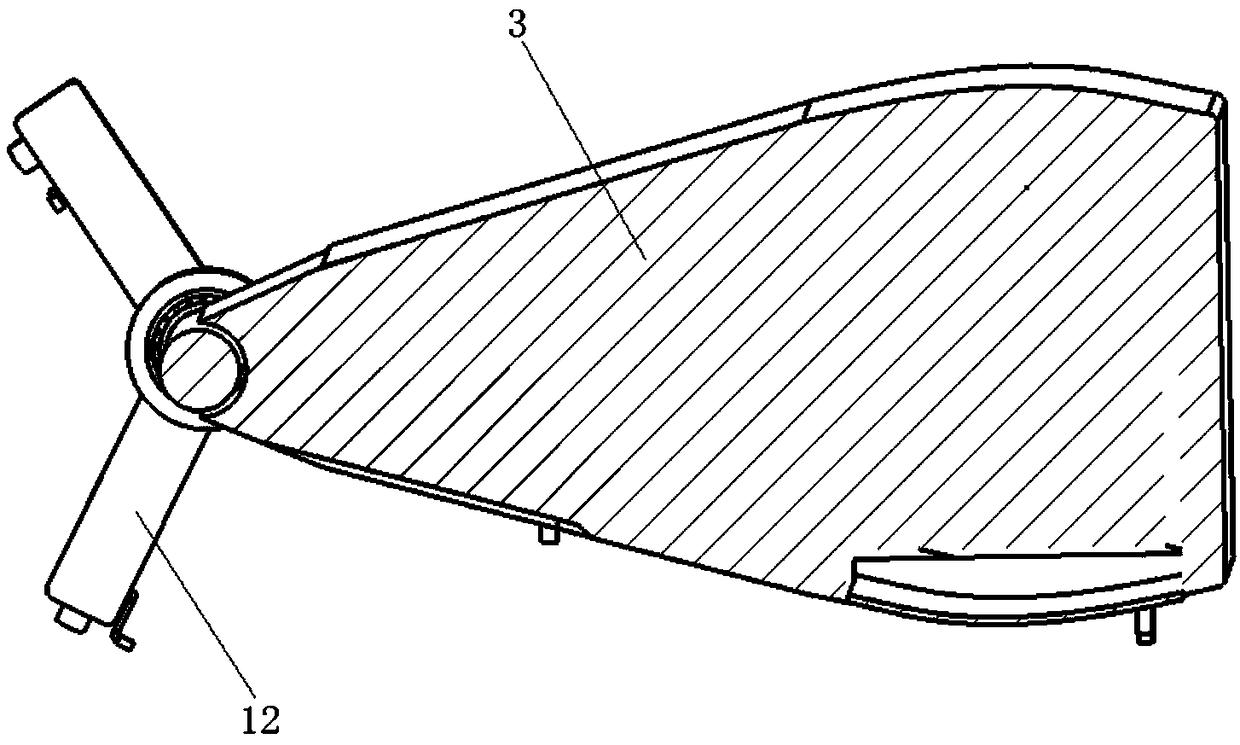

Window scanning type exposure device

ActiveCN108663911AHigh resolutionHigh motion/positioning accuracyPhotomechanical exposure apparatusMicrolithography exposure apparatusTemperature controlExposure control

The invention discloses a window scanning type exposure device. The device is installed coplanarly through four blades, a rectangular window is formed at the position of a gap between a quartz strip and an exposure window, high-resolution projection type exposure control is carried out, and simultaneously, convenient change of easily consumable optical elements and the temperature control of the optical elements and light blocking elements under long-time laser environment can be realized. The invention can be used for establishing the projection type exposure device with high resolution and high movement / positioning precision.

Owner:HARBIN INST OF TECH

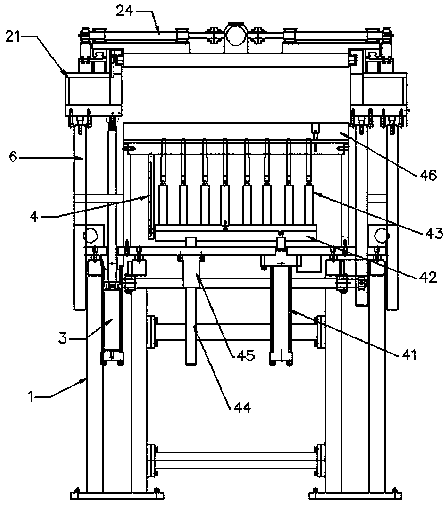

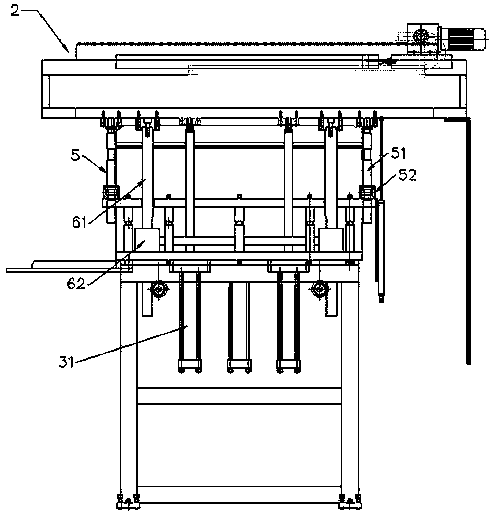

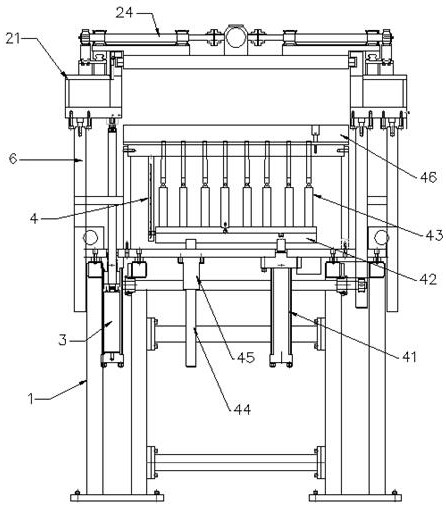

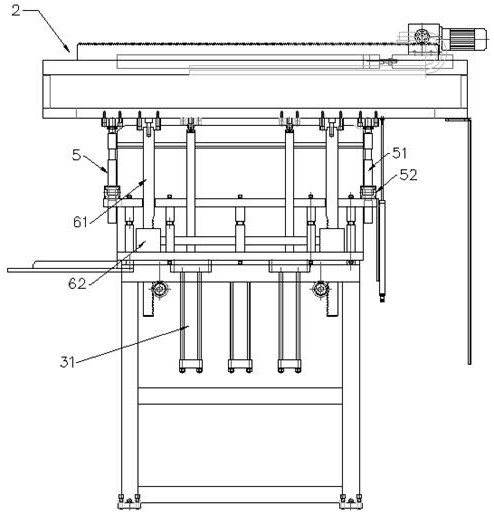

Mold moving and jacking-out system of large injection mold and intermittent production method of large injection molding machine

A mold moving and jacking-out system of a large injection mold comprises a support, a horizontal mold moving mechanism, a lifting mechanism and a jacking-out mechanism, wherein the horizontal mold moving mechanism is located over the jacking-out mechanism and supported through the lifting mechanism; the horizontal mold moving mechanism comprises two horizontal moving guide platforms, a mold pulling plate, a mold fixing sliding plate and a driving assembly; the mold pulling plate is connected with the mold fixing sliding plate in a matched mode in the horizontal direction through a pulling hookto drive the mold fixing sliding plate to move in the horizontal direction; the mold is fixed to the mold fixing sliding plate and moves into or out of an injection molding main machine along with movement of the mold fixing sliding plate; the upper end of the lifting mechanism is fixed to the bottom surface of one of the horizontal moving guide platforms to drive the horizontal mold moving mechanism to ascend and descend, and the mold fixing sliding plate and the jacking-out mechanism are made to get close to or away from each other. The mold moving and jacking-out system of the large injection mold can meet the moving and jacking-out requirements of the large injection mold, realize intermittent work of the large injection molding machine, and improve the production efficiency and automation level of the large injection molding machine. The invention further provides an intermittent production method of the large injection molding machine.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

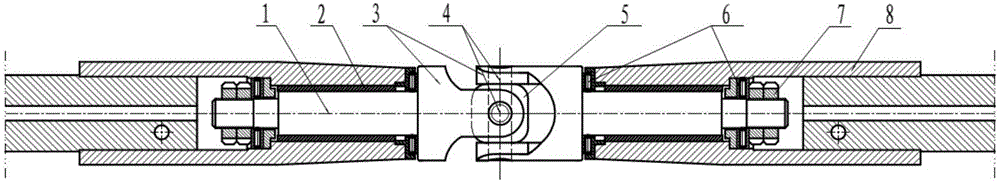

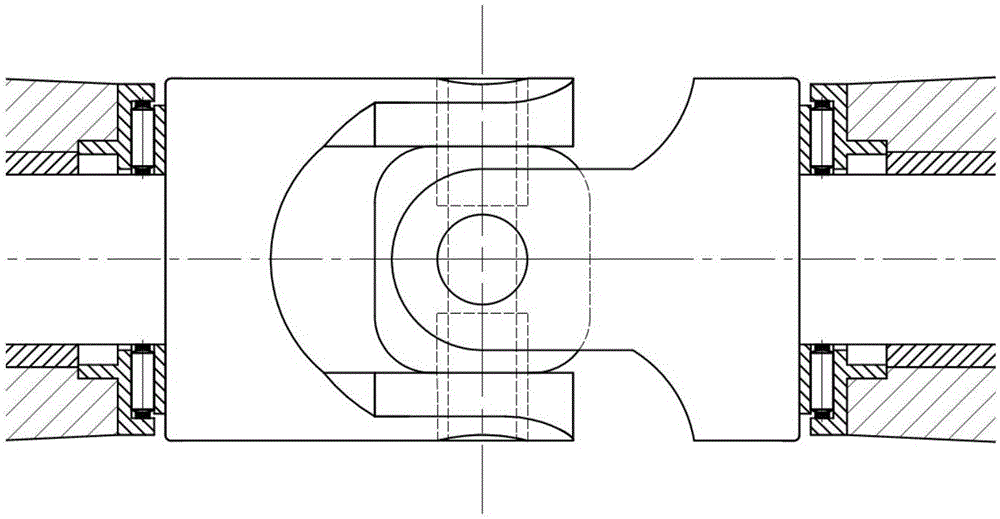

Hooke hinge mechanism provided with rolling motion pair

ActiveCN106122296AMeet the requirements of three rotational degrees of freedomMeet the requirements of rotational freedomYielding couplingRange of motionEngineering

The invention discloses a hooke hinge mechanism provided with a rolling motion pair. The hooke hinge mechanism comprises a first rotating rod, a second rotating rod, a first sleeve, a second sleeve, a first fastening component and a second fastening component, wherein the first rotating rod and the second rotating rod are hinged together rotatably and thus define a hinged part, and the first rotating rod and the second rotating rod are located on the two sides of the hinged part correspondingly; the first rotating rod and the second rotating rod are sleeved with and in rotary connection with the first sleeve and the second sleeve correspondingly, the first end of the first sleeve and the first end of the second sleeve are pressed on outer walls of the hinged part correspondingly and are in rotary connection with the outer walls of the hinged part; and the first fastening component and the second fastening component are arranged on the outer sides of the positions where the first and second sleeves and the first and second rotating rods are in rotary connection correspondingly, so that pressing force for pressing the first sleeve and the second sleeve to the hinged part is provided. The hooke hinge mechanism provided with the rolling motion pair has three rotational degrees of freedom, the rotational space is small, the connecting precision is high, the range of motion is wide, and the hooke hinge mechanism provided with the rolling motion pair is especially suitable for a parallel type multi-degree of freedom motion platform with a high requirement for positioning precision.

Owner:CHINA ACAD OF AEROSPACE AERODYNAMICS

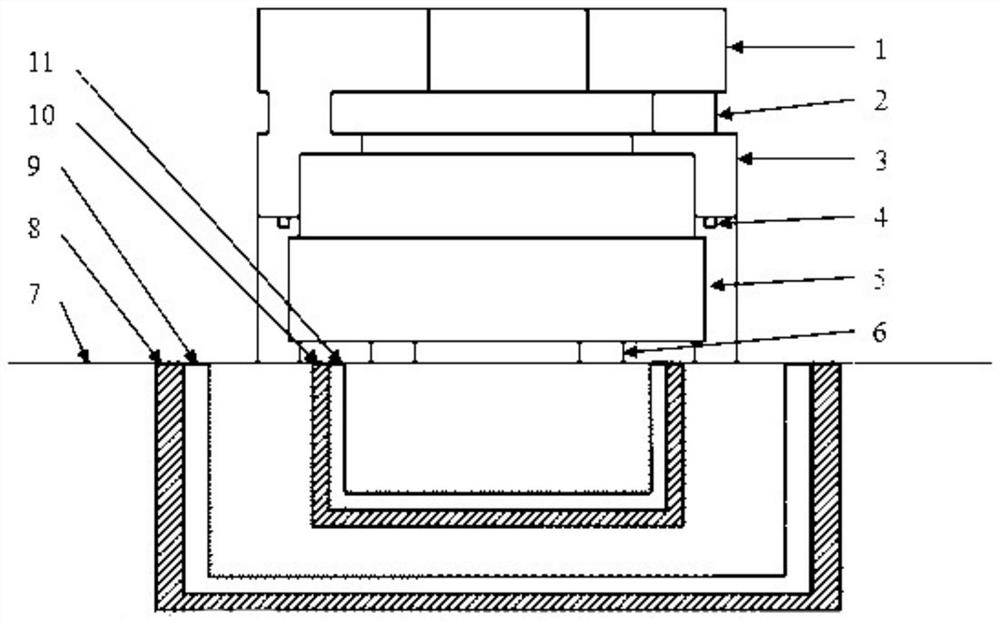

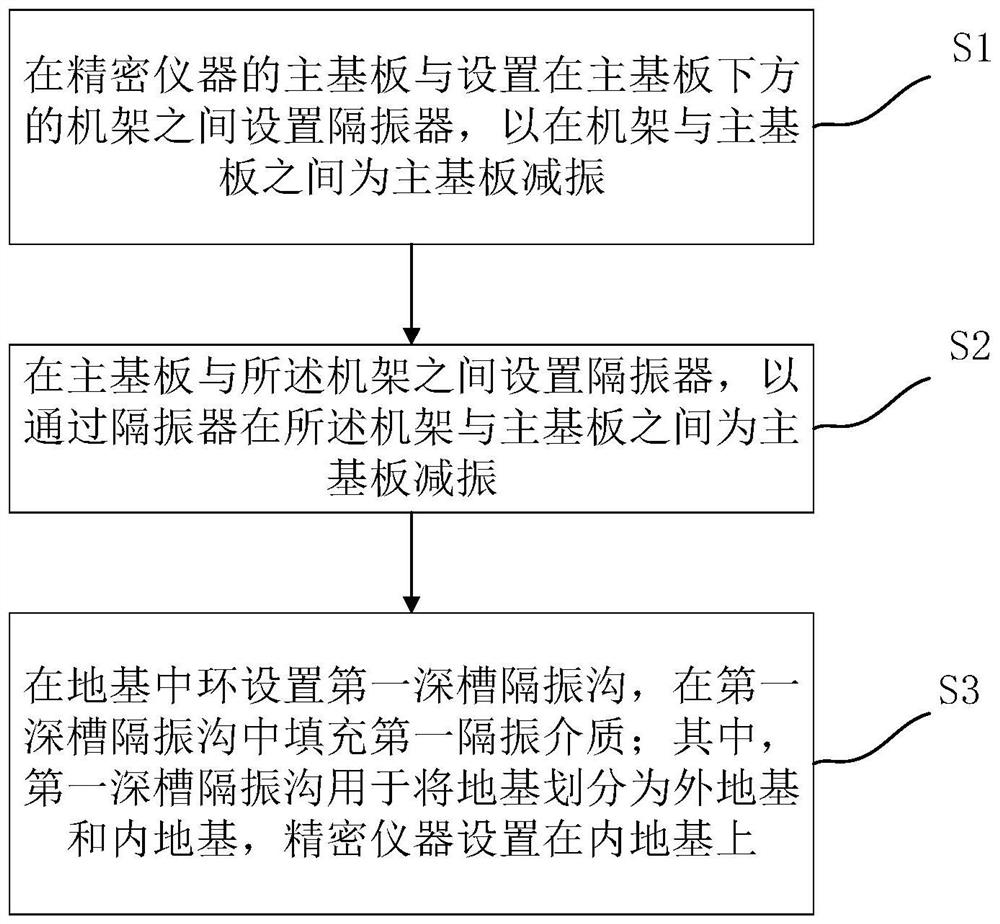

Multistage vibration isolation system and method for precise instrument

ActiveCN114032969AReduce vibration levelsHigh precision requirementsProtective foundationIsolatorEngineering

The invention provides a multi-stage vibration isolation system for a precise instrument, first deep groove vibration isolation trenches are annularly arranged in a foundation, and the first deep groove vibration isolation trenches are used for dividing the foundation into an outer foundation and an inner foundation; a precise instrument is arranged on the inner foundation, and the first deep groove vibration isolation trenches are filled with the first vibration isolation medium, so that vibration reduction is performed in multiple aspects, vibration excited by a moving part and ground low-frequency random vibration can be decoupled, and vibration on the main substrate is reduced from a vibration source by blocking a transmission path of disturbance force of the moving part. Different high-damping vibration isolation materials are selected as first vibration isolation media according to broadband vibration and narrow-band vibration, the first deep groove vibration isolation grooves are filled in a series connection mode so as to meet the high-precision requirement for silicon wafer positioning, in this way, moving parts and the main substrate are separated through the vibration isolators, vibration sources can be reduced, vibration is greatly reduced, and the motion positioning precision of a silicon wafer in a photoetching machine is improved.

Owner:BEIJING U PRECISION TECH +1

Control method of visual detecting device in nuclear fusion cabin

InactiveCN106356103ALarge range of motionMeet the technical requirements for depth of involvementNuclear energy generationThermonuclear fusion reactorVisual observationUniversal joint

The invention discloses a control method of a visual detecting device in a nuclear fusion cabin. The control method of the visual detecting device in the nuclear fusion cabin is characterized in that a front body segment lateral positioning module and a rear body segment lateral positioning module are symmetrically arranged on two ends of a middle body segment axial movement module so as to form a walking mechanism; a visual observation cradle head is arranged on the front body segment lateral positioning module and located in the front of the front body segment lateral positioning module; the front body segment lateral positioning module is connected with the middle body segment axial movement module through a front dual-universal-joint; the rear body segment lateral positioning module is connected with the middle body segment axial movement module through a rear dual-universal-joint. According to the control method of the visual detecting device in the nuclear fusion cabin provided by the invention, the movement range of the walking mechanism is wide, a walking track can spread across the circumference of a large dual-annular channel in the bottom part of the nuclear fusion cabin, and the visual observation cradle head is arranged in a matching way, so that the omni-directional visual information acquisition of a D-shaped section annular space in the nuclear fusion cabin can be completed.

Owner:HEFEI INST OF PHYSICAL SCI OF CHINESE ACAD OF SCI

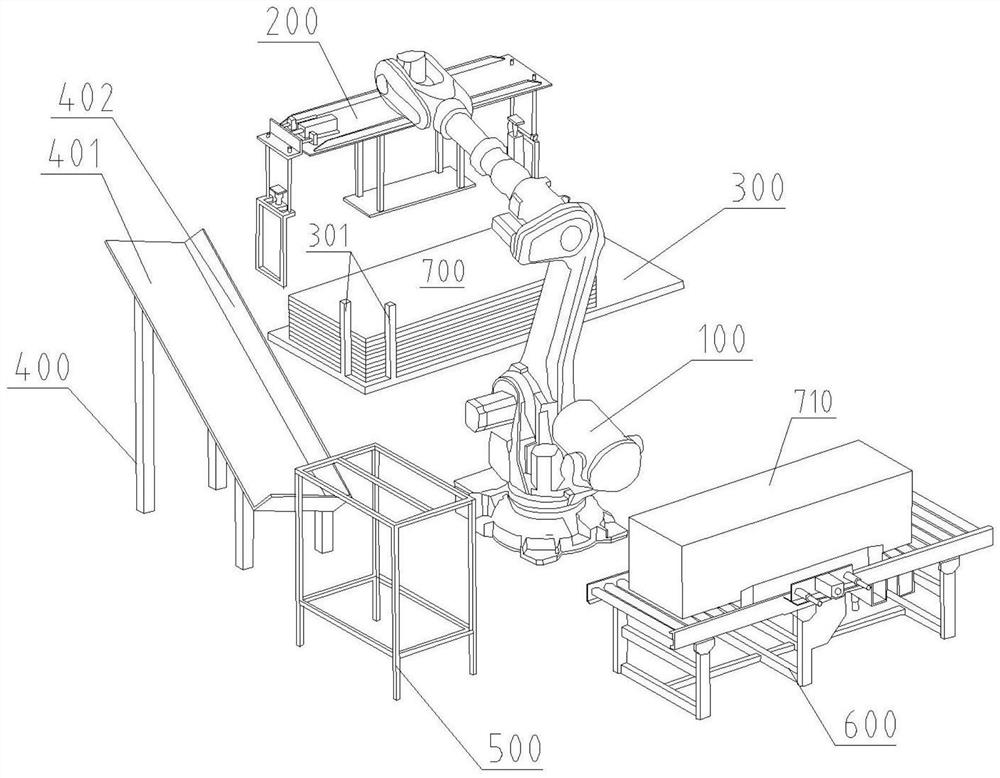

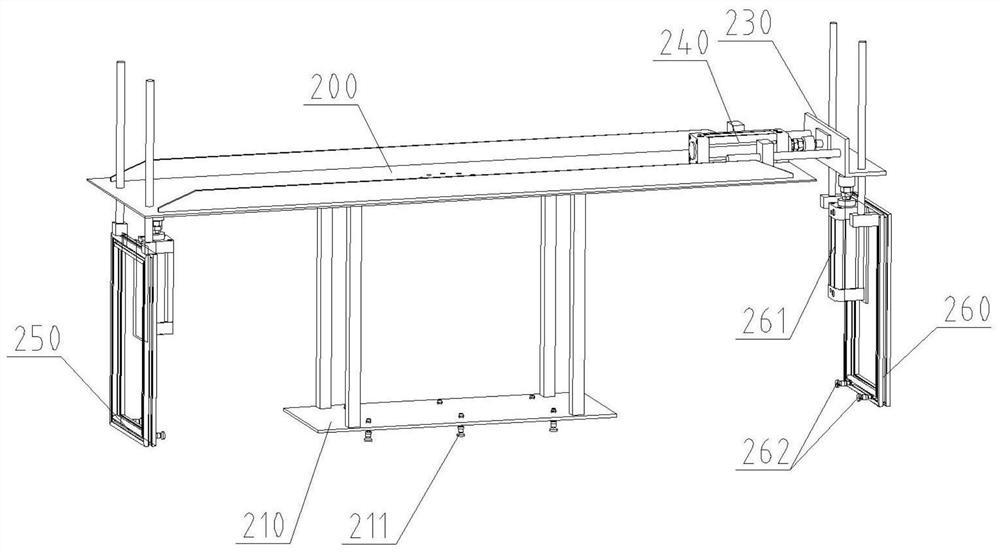

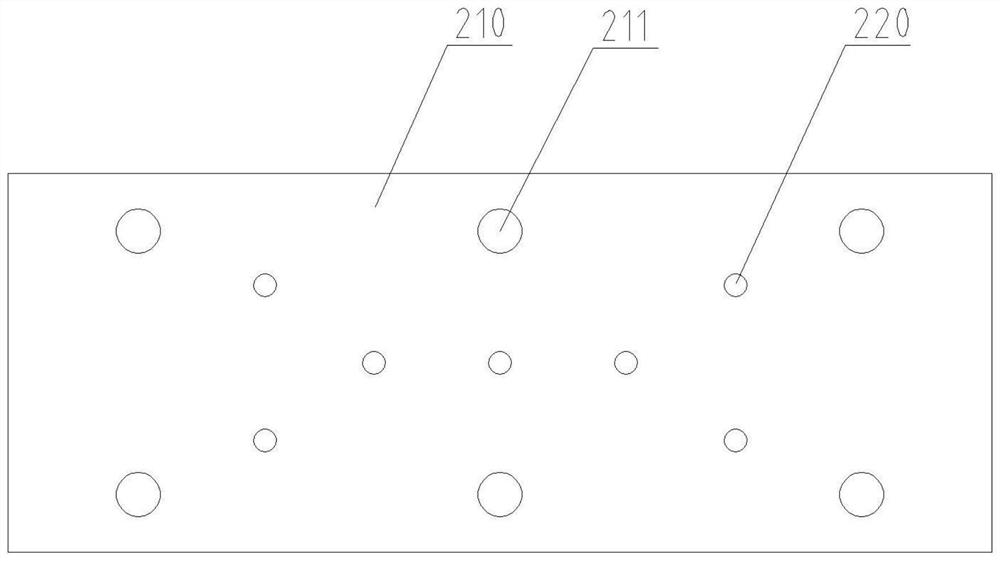

Fan outer packing boxing system and control method thereof

PendingCN112193534AHigh motion positioning accuracyAvoid damagePackaging automatic controlIndividual articlesCartonStructural engineering

The invention relates to the field of fan production equipment, in particular to a fan outer packing boxing system and a control method thereof. The fan outer packing boxing system comprises a robot module, a material frame, an inclined positioning table, a secondary positioning table and a conveying line, wherein the material frame, the inclined positioning table, the secondary positioning tableand the conveying line are arranged around the robot module, the material frame is provided with a positioning structure, and the conveying line is provided with a left centering module and a right centering module. According to the fan outer packing boxing system and the control method thereof, boxing is carried out by a robot, so that the working efficiency is improved, and the labor cost is saved; and the positioning precision of the action of the robot is high, so that the phenomenon that a carton is damaged during manual operation is avoided, and the utilization rate of the carton and thebeauty of the appearance of a fan are guaranteed.

Owner:青岛星华智能装备有限公司

Worm-simulation rotor walking mechanism running in nuclear fusion compartment and control method thereof

InactiveCN104690734AMeet the overall technical requirements for depth of involvementLarge range of motionManipulatorInterior spaceVisual observation

The invention discloses a worm-simulation robot walking mechanism running in a nuclear fusion compartment and a control method thereof. The worm-simulation robot walking mechanism is characterized by comprising an anterior somite lateral positioning module and a posterior somite lateral positioning module which are symmetrically arranged at two ends of a middle somite axial moving module, wherein the anterior somite lateral positioning module is connected to the middle somite axial moving module through two front universal joints; the posterior somite lateral positioning module is connected to the middle somite axial moving module through two rear universal joints. The moving track of the worm-simulation robot walking mechanism covers a large double-ring channel at the bottom of the whole nuclear fusion compartment; the moving pace is similar to the walking of worms; the mechanism is excellent in running stability and simple to control; three-freedom-degree all-direction visual information acquisition of the inner space of the nuclear fusion compartment can be implemented by carrying a visual observation platform.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

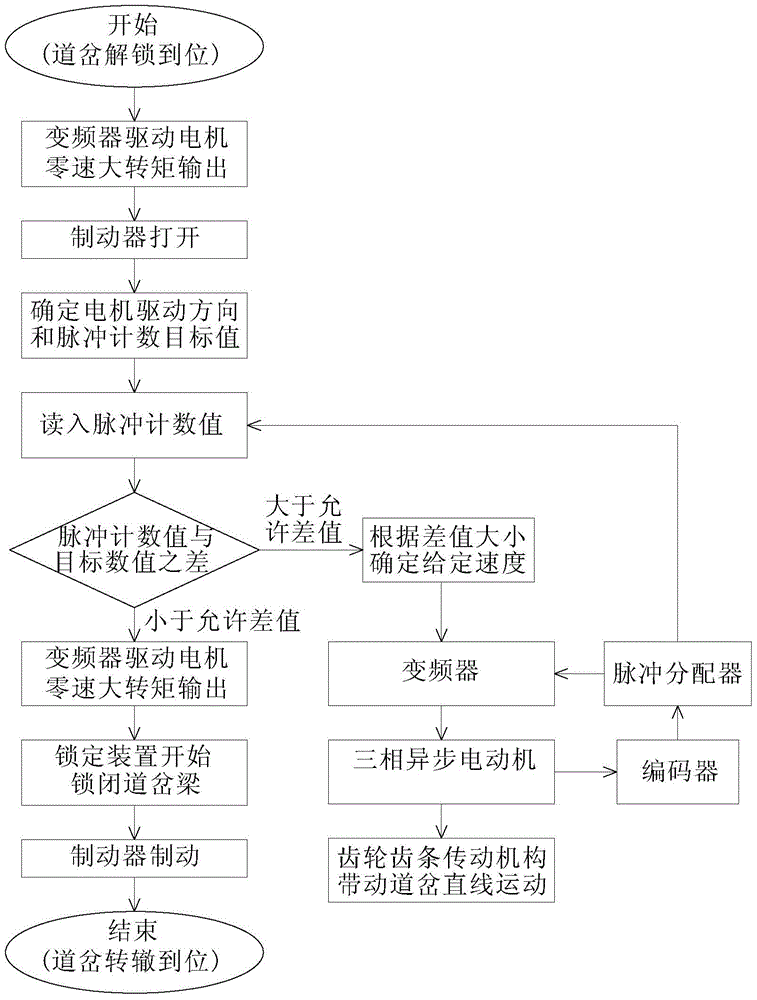

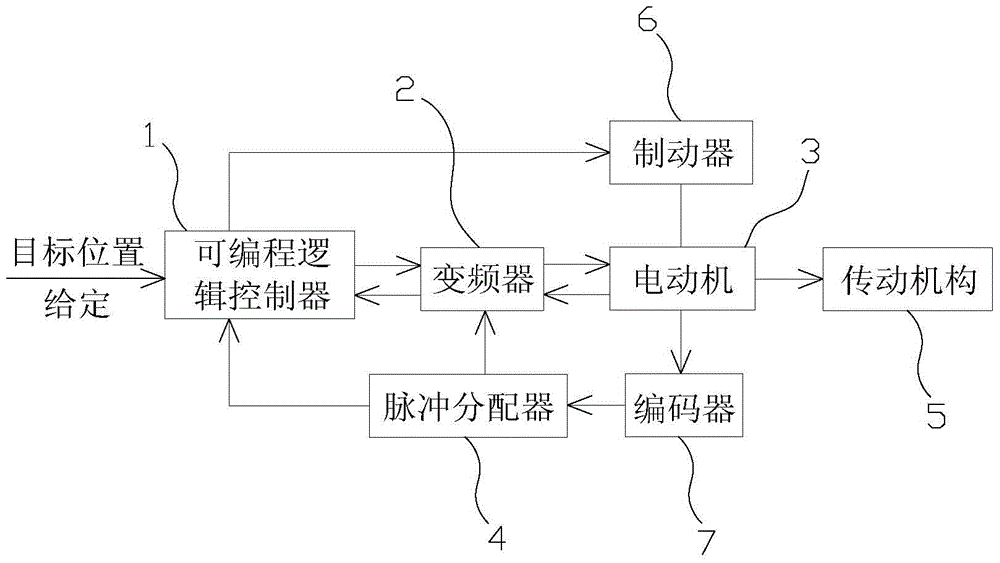

A control method and system for precise positioning of linear motion of translational turnout

ActiveCN104460677BHigh movement precisionMeet the positioning detection requirementsPosition/course control in two dimensionsFrequency changerLinear motion

Owner:CHINA RAILWAY BAOJI BRIDGE GRP +1

A multi-layer piezoelectric actuator independent time-sharing drive device and method

InactiveCN108448928BHigh motion positioning accuracyEasy to operatePiezoelectric/electrostriction/magnetostriction machinesElectricityHysteresis

The invention provides a multi-stack piezoelectric actuator independent time-sharing driving device and method and relates to the application in the field of a precision displacement platform. Each layer of piezoelectric actuators is independently driven. A driving signal is separated into sub signals in time series connection according to a voltage evenly-spaced rule. A signal applied to an independent piezoelectric actuator of each layer is an amplified sub signal. The voltage evenly-spaced rule is achieved by a signal separating circuit. The driving signal may be any desired signal. Compared with the piezoelectric stack with the parallel connection of multiple layers of piezoelectric actuators, according to the driving device of the invention, the hysteresis accumulation due to paralleldriving can be effectively eliminated, only the hysteresis of a piezoelectric actuator of one layer exists at the same moment, the hysteresis in the displacement process of the multiple layers of piezoelectric actuators is effectively reduced, the motion positioning accuracy is improved, the operation is simple, and the cost is low.

Owner:HEFEI UNIV OF TECH

Actively driven cable stage for silicon wafer stage of lithography machine

ActiveCN103246168BSimple structureHigh motion positioning accuracyPhotomechanical exposure apparatusMicrolithography exposure apparatusAir bearingLithographic artist

The invention provides an active driving wire cable table of a silicon wafer stage of a lithography machine. The active driving wire cable table comprises a Y-direction sliding table, a Y-direction guide rail and a cross-telescopic linkage mechanism, wherein the Y-direction sliding table is disposed on the Y-direction guide rail through an air bearing; the Y-direction sliding table is driven by a sliding table motor and moves synchronously in the Y direction and on the silicon wafer stage; wire cable instrument is conveyed to the silicon wafer stage along the cross-telescopic linkage mechanism through the Y-direction sliding table; the cross-telescopic linkage mechanism comprises a cross telescopic connecting rod and a driver; one end of the cross telescopic connecting rod is connected with the Y-direction sliding table; the other end of the cross telescopic connecting rod is connected with the silicon wafer stage through the wire cable instrument; and the driver is used for driving the cross telescopic connecting rod to move along with an X direction, so that the wire cable is driven to move along the X direction. The active driving wire cable table of the silicon wafer stage of the lithography machine can realize active control of the wire cable table and follow motion of the wire cable table to the silicon wafer stage in an X-Y plane.

Owner:SHANGHAI MICRO ELECTRONICS EQUIP (GRP) CO LTD

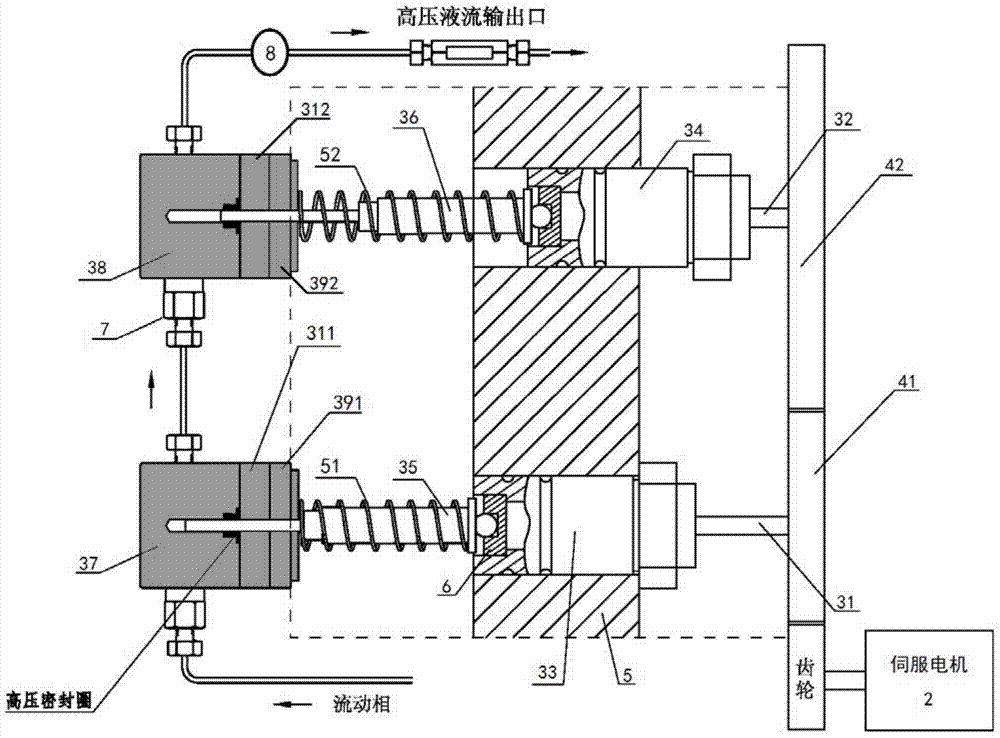

A high-pressure infusion pump and a miniature high-pressure infusion pump system

Owner:SHANGHAI WUFENG SCI INSTR

Control method of multi-segment peristaltic snake-like robot running in nuclear fusion cabin

InactiveCN104627266BLarge range of motionMeet the overall technical requirements for depth of involvementVehiclesNuclear fusionUniversal joint

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

A work table cable device

ActiveCN103901734BIncrease stiffnessHigh elastic modulusSemiconductor/solid-state device manufacturingPhotomechanical exposure apparatusPower stationEngineering

A work station cable apparatus comprises a work station (110), a silicon wafer station (120), a cable device (130), a cable connection station (140), an X-direction moving device and a Y-direction moving device. The silicon wafer station (120) and the cable connection station (140) are respectively mounted on the upper side and the lower side of the work station (110). The two ends of the cable device (130) are connected to the silicon wafer station (120) and the cable connection station (140) respectively. The X-direction and Y-direction moving devices are both connected to the cable connection station (140) and respectively drive the cable connection station (140) to move following the silicon wafer station (120) along the X-direction and the Y-direction. The cable connection station (140) drives the cable device (130) to synchronously move following the silicon wafer station (120) along the X-direction and the Y-direction, thus being able to reduce disturbance of the cable device (130) to the motion of the silicon wafer station (120), reduce the bending times of the cable device (130) and prolong the service life of the cable device.

Owner:SHANGHAI MICRO ELECTRONICS EQUIP (GRP) CO LTD

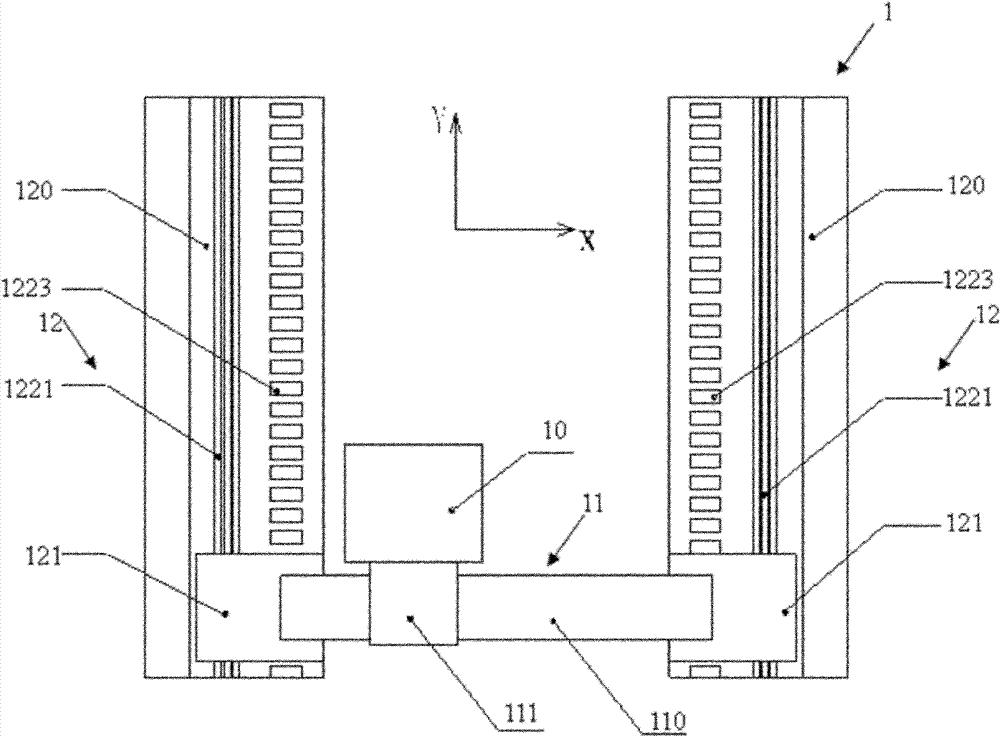

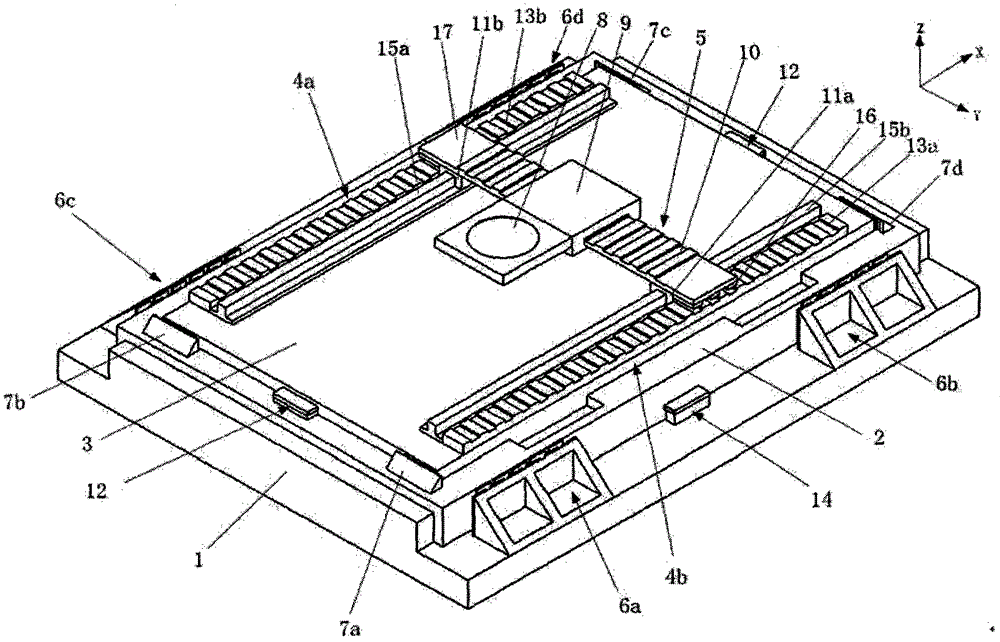

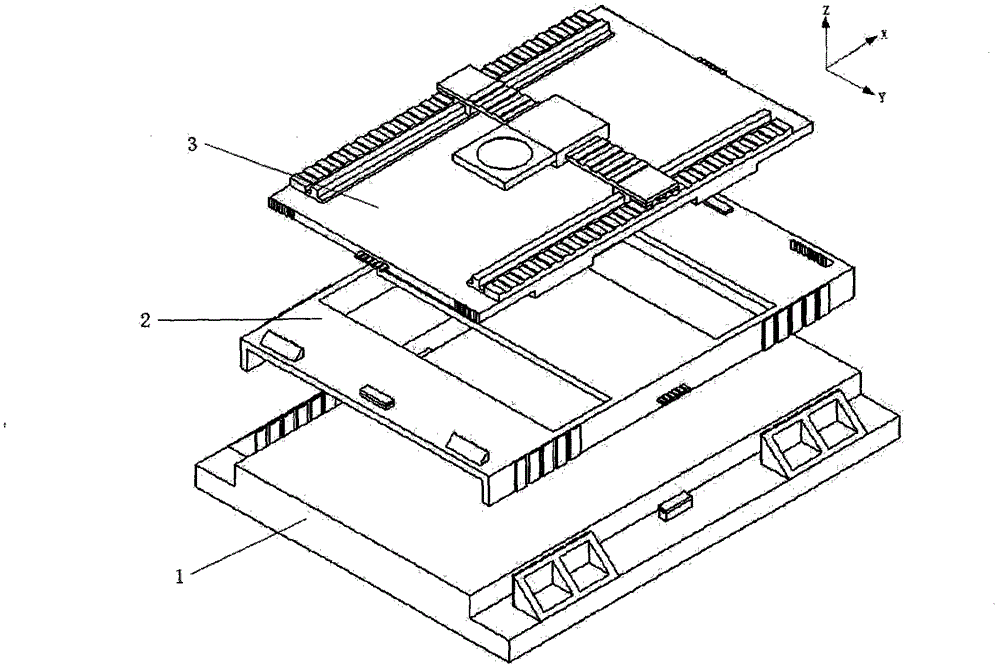

Two-dimensional long-stroke table movement system

ActiveCN102566293BHigh motion positioning accuracySide air flotationPhotomechanical exposure apparatusMicrolithography exposure apparatusEngineeringMovement system

The invention discloses a two-dimensional long-stroke table movement system, which comprises a bearing platform, a first direction movement device and two second direction movement devices. The first direction movement device comprises a first direction guide rail, a first direction sliding table and a first direction motor. The two direction movement devices are respectively connected to the two sides of the first direction movement device. Each second direction movement device comprises a second direction guide rail, a second direction sliding table and a two-dimensional motor. The second direction sliding tables can be suspended above the second direction guide rails slidingly along the first direction and the second direction, and are connected to the first direction guide rail. The two-dimensional motors are connected to the second direction sliding tables, and drive the second direction sliding tables and the first direction movement device to do 1-2 mm small-stroking motion in the first direction while doing long-stroking motion along the second direction. According to the two-dimensional long-stroke table movement system disclosed by the invention, the mechanical structure is simplified, and the cost is reduced.

Owner:SHANGHAI MICRO ELECTRONICS EQUIP (GRP) CO LTD

Blood treatment working station based on micronano magnetic particle and its control method

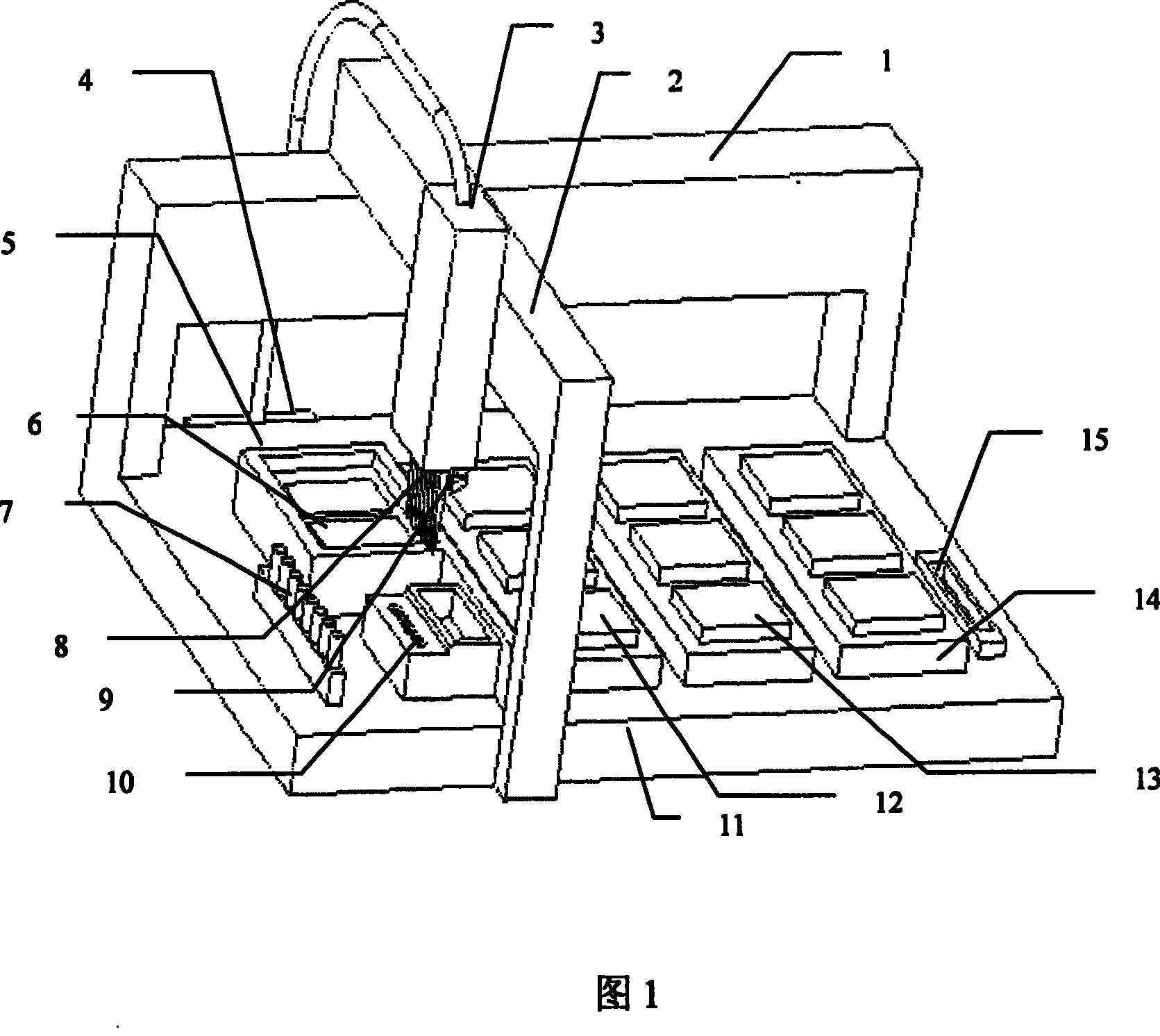

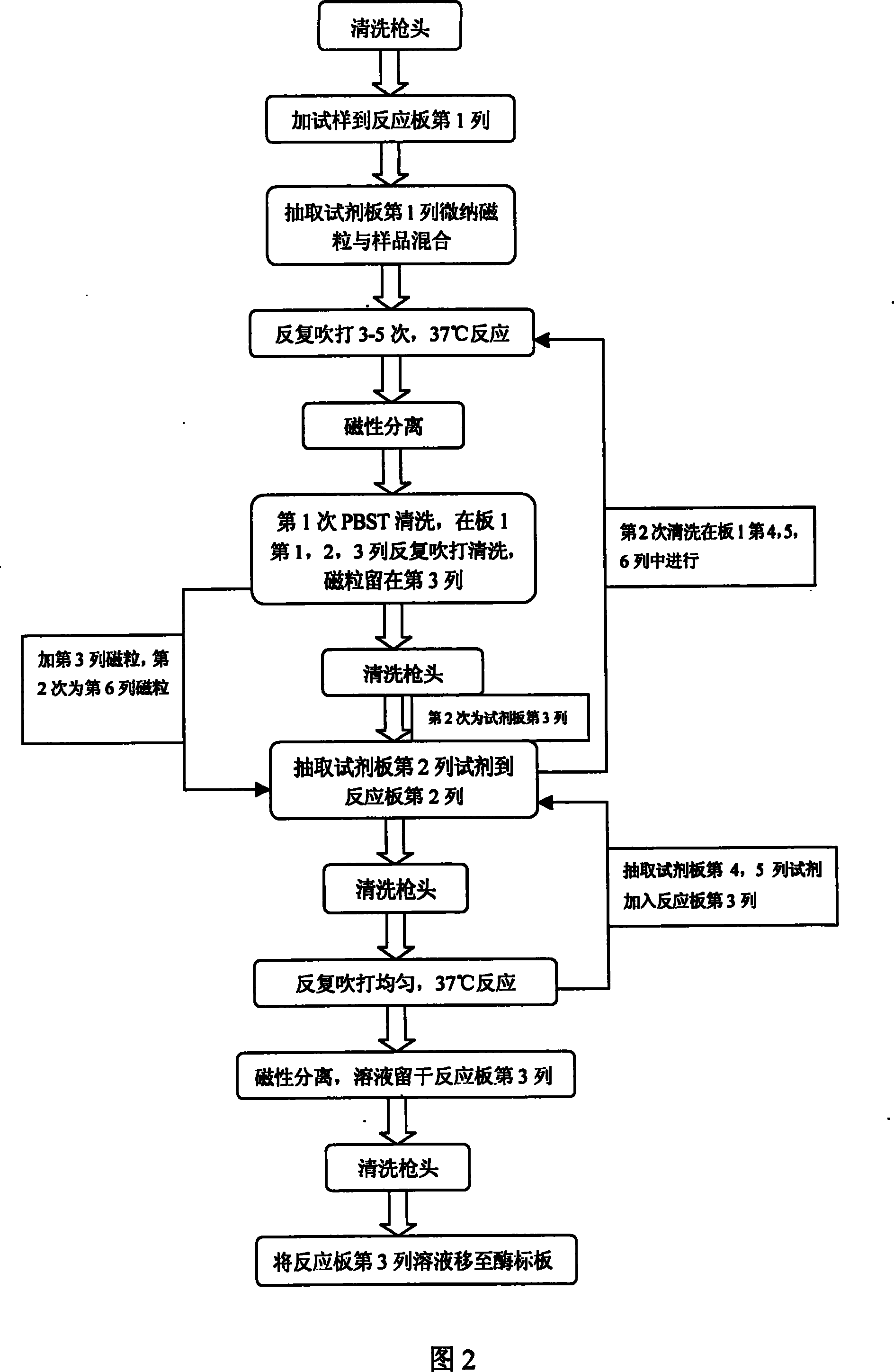

ActiveCN1912627BReduce demandFully automatedPreparing sample for investigationBlood treatmentsEngineering

A blood treatment station based on magnetic micronanoparticles applies arch-type structure with X,Y and Z shafts to drive gun head set on Z shaft to suck up blood and corresponding detection liquid for realizing automatic treatment. It is featured as applying new magnetic micronanoparticles technique for decreasing demand of blood sample and adding oscillating unit at constant temperature for realizing automatization of blood and related fluid detection.

Owner:XIAN GOLDMAG NANOBIOTECH +1

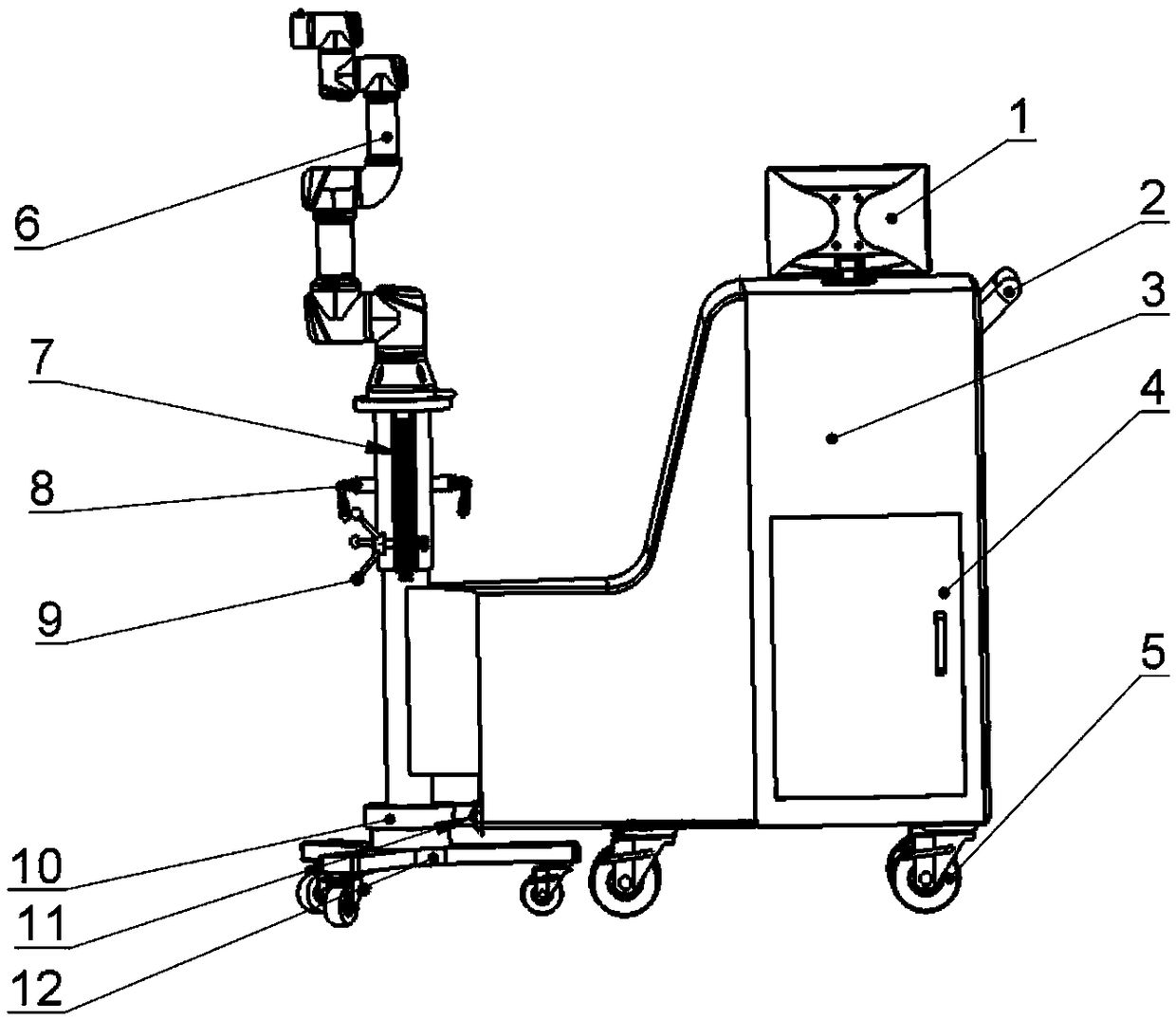

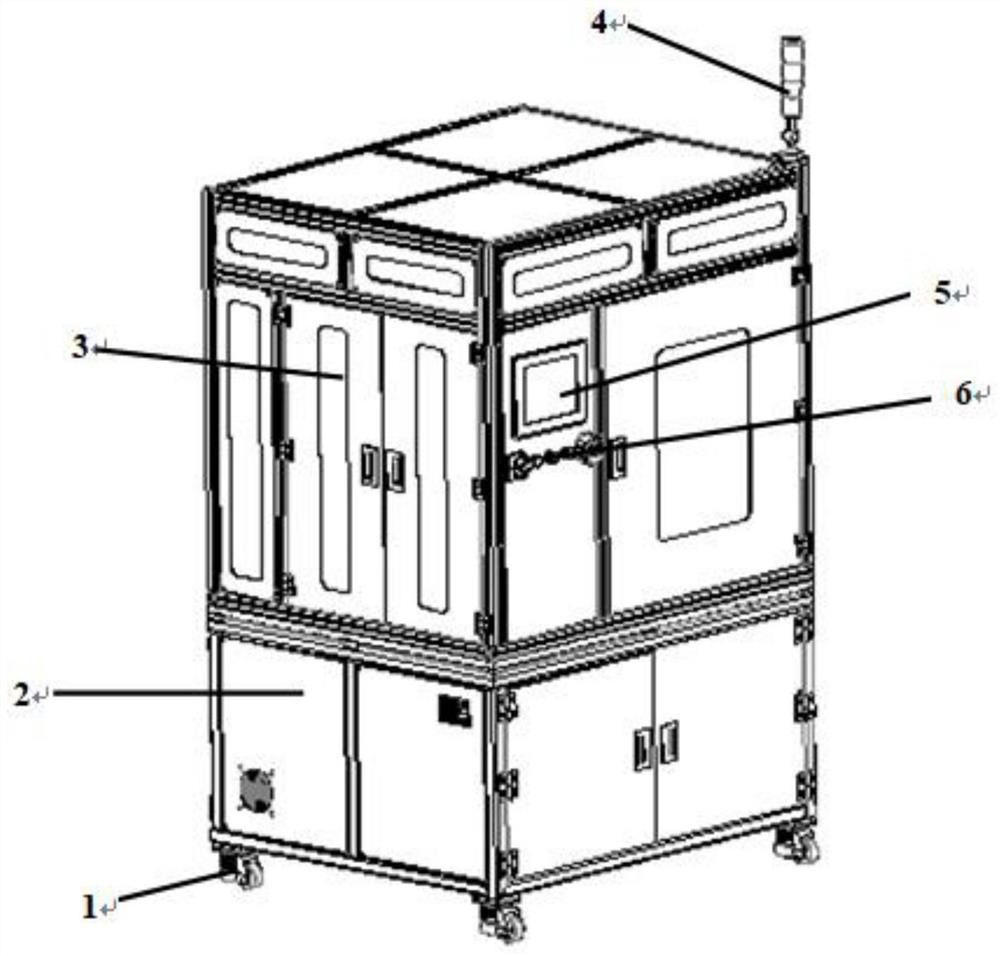

Operation table for puncture robot

PendingCN108784800AHigh motion positioning accuracyResponsiveSurgical needlesSurgical robotsEngineeringMedical equipment

The invention belongs to the technical field of medical equipment, an relates to an operation table for a puncture robot. The operation table comprises a stand column and a control cabinet. A liftinglocking mechanism is arranged at the top of the stand column, the puncture robot is arranged at the top of the lifting locking mechanism, a connecting piece is arranged at the bottom of the stand column, the control cabinet is detachably connected with the stand column through a connecting piece, under the connecting state, the control cabinet can rotate around the stand column, and a movable mechanism is arranged between the bottom of the stand column and the bottom of the control cabinet. By arranging the lifting locking mechanism, the puncture robot can be rapidly lifted; by adopting rotational connection between the control cabinet and the stand column, puncture in the multi-angle and multi-direction puncture mode can be achieved; by adopting the detachable connection mode of the control cabinet and the stand column, separation of the control cabinet and the stand column of the puncture robot can be achieved, more space can be emptied so that great convenience can be brought to work of medical workers and the puncture robot, and the operation table has the high market value and is worthy of being popularized.

Owner:INST OF INTELLIGENT MFG TECH JITRI

Large-scale injection mold shifting and ejection system, large-scale injection machine uninterrupted production method

ActiveCN108237664BRealize Alternate MoldingReduce standby timeControl engineeringProcess engineering

A mold moving and jacking-out system of a large injection mold comprises a support, a horizontal mold moving mechanism, a lifting mechanism and a jacking-out mechanism, wherein the horizontal mold moving mechanism is located over the jacking-out mechanism and supported through the lifting mechanism; the horizontal mold moving mechanism comprises two horizontal moving guide platforms, a mold pulling plate, a mold fixing sliding plate and a driving assembly; the mold pulling plate is connected with the mold fixing sliding plate in a matched mode in the horizontal direction through a pulling hookto drive the mold fixing sliding plate to move in the horizontal direction; the mold is fixed to the mold fixing sliding plate and moves into or out of an injection molding main machine along with movement of the mold fixing sliding plate; the upper end of the lifting mechanism is fixed to the bottom surface of one of the horizontal moving guide platforms to drive the horizontal mold moving mechanism to ascend and descend, and the mold fixing sliding plate and the jacking-out mechanism are made to get close to or away from each other. The mold moving and jacking-out system of the large injection mold can meet the moving and jacking-out requirements of the large injection mold, realize intermittent work of the large injection molding machine, and improve the production efficiency and automation level of the large injection molding machine. The invention further provides an intermittent production method of the large injection molding machine.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

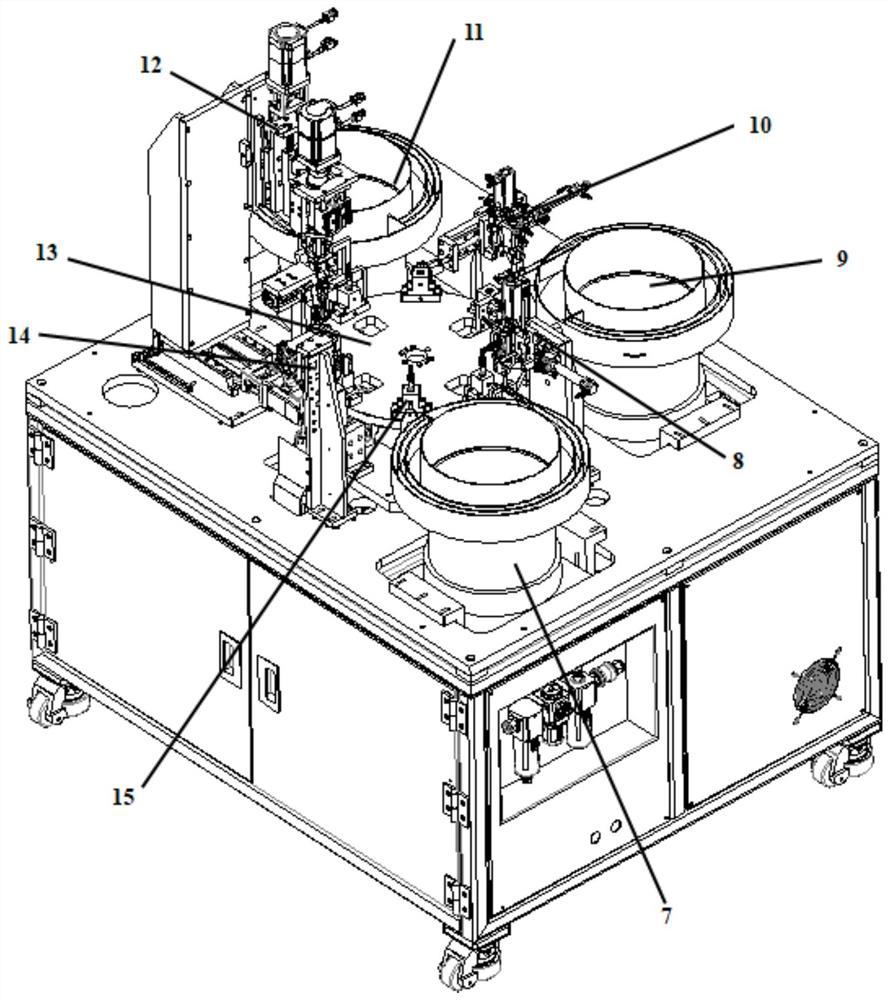

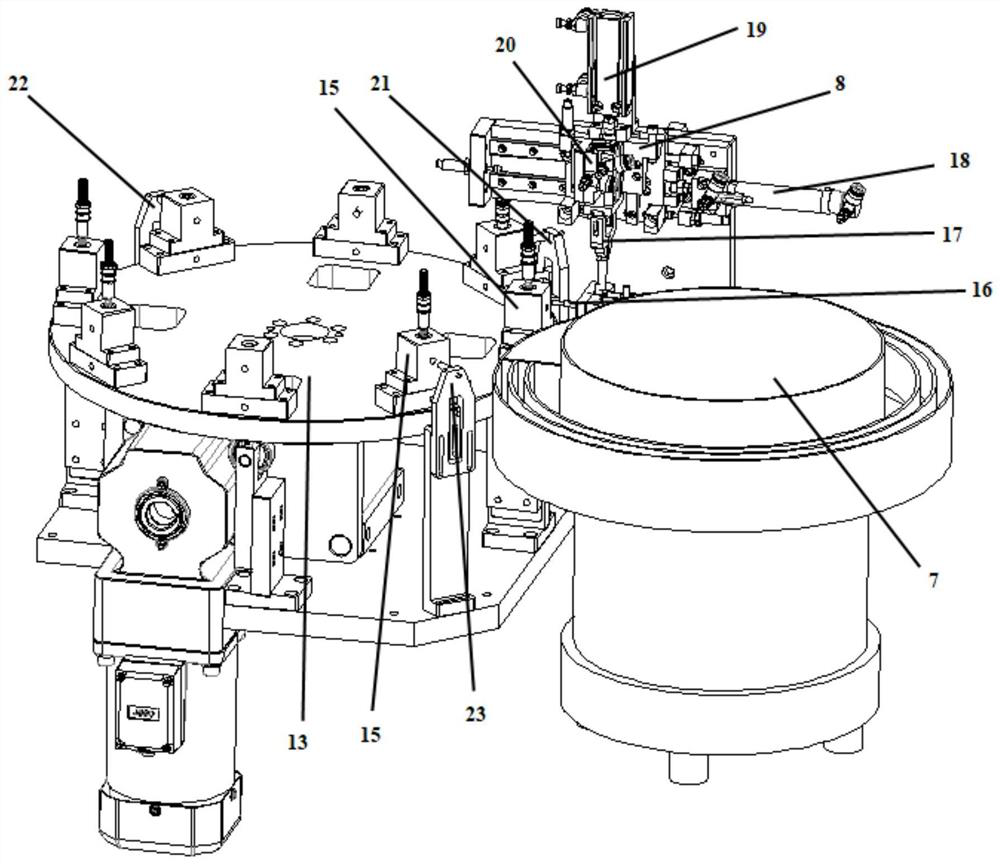

Full-automatic locking and assembling device for automobile antenna base and control method of full-automatic locking and assembling device

PendingCN113036399AIngenious structureImprove stabilityAntenna supports/mountingsAntenna adaptation in movable bodiesAutomatic controlControl engineering

The invention relates to a full-automatic locking and assembling device for an automobile antenna base. The full-automatic locking and assembling device comprises a rack; a base feeding module, a base taking module, a copper sleeve feeding module, a copper sleeve taking module, a spring feeding module, a spring taking module, an index plate module, a locking module, a finished product discharging module, a detection module and a control module are arranged on the rack; By means of the modules, a copper sleeve, a spring and a base are sequentially installed on a bearing seat, the base, the spring and the copper sleeve are locked through the locking module, and the copper sleeve, the spring and the base are fixed into a whole and meet a preset torsion value requirement. According to the full-automatic locking and assembling device for the automobile antenna base and the control method of the full-automatic locking and assembling device of the invention, the self-designed automatic locking module is adopted, so that the locking force can be automatically controlled, the stability is high, the working efficiency of automobile antenna locking is improved, the locking quality is ensured, and full-automatic operation and control are realized. In the full-automatic production process realized by the full-automatic locking and assembling device provided by the invention, the problem of manual assembly in the prior art is effectively solved, the working efficiency is greatly improved, and meanwhile, the working thought is provided for automatic production.

Owner:深圳市艺盛科五金电子有限公司

Magnetic preloading balance positioning system for photoetching machine workpiece stage

InactiveCN102393611BHigh motion positioning accuracyGood real-time compensationPhotomechanical exposure apparatusMicrolithography exposure apparatusEngineeringMechanical engineering

A photoetching machine workpiece stage magnetic preloading balance positioning system belongs to the field of semiconductor photoetching technology; the system mainly comprises a base stage, a balance mass system, a magnetic preloading system, a motion unit, a silicon wafer stage, and a balance mass drift-resistant system; the balance mass system comprises two frames which nest each other, and has freedom degrees in the X and Y directions; the motion unit is disposed at the upper part; the impact force caused by the motion part to the base stage is weakened by momentum conservation principle; the balance mass drift-resistant system is used to compensate the position displacement of the balance mass system caused by external resistance during working; the magnetic preloading system is used for real-time compensation of the torsion of the workpiece stage along a Z axis; the invention can effectively reduce internal vibration, compensate the torsion of the workpiece stage along the Z axis, and thus greatly improve the motion positioning precision of the silicon wafer stage.

Owner:HARBIN INST OF TECH

Visual observation mechanism and control method working in nuclear fusion cabin

InactiveCN104637550BLarge range of motionMeet the technical requirements for depth of involvementNuclear energy generationThermonuclear fusion reactorVisual observationRange of motion

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com