Two-dimensional long-stroke table movement system

A motion system and long-stroke technology, applied in the field of two-dimensional long-stroke workbench motion systems, can solve the problems of reducing the structural rigidity, complex structure, and high cost of the system, and achieve the effects of reducing costs, simplifying the mechanical structure, and improving motion positioning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

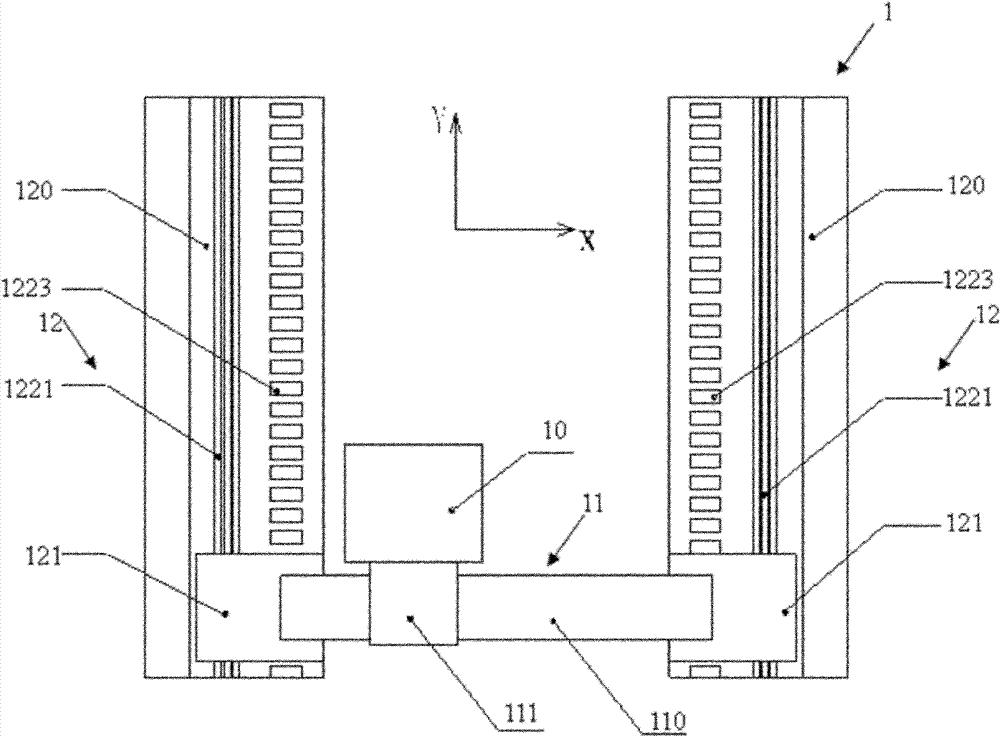

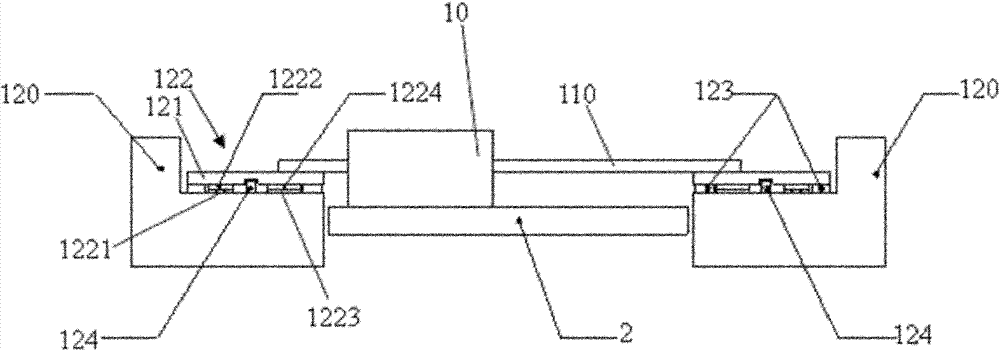

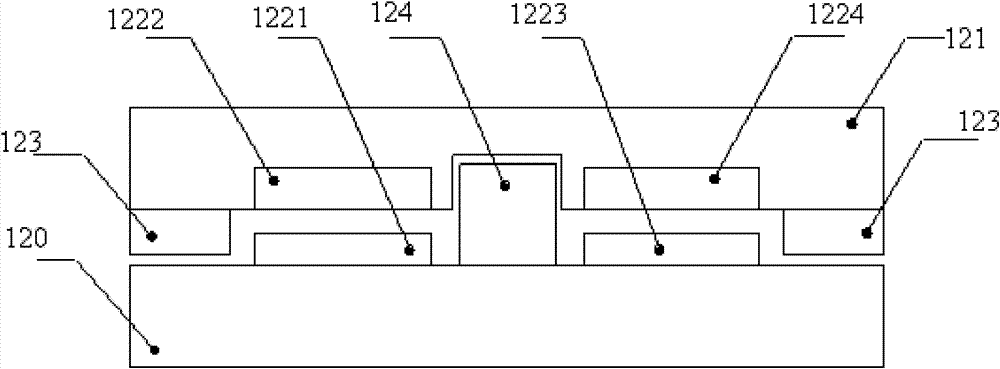

[0026] figure 1 It is a schematic diagram of a two-dimensional long-stroke table motion system in a preferred embodiment of the present invention. figure 2 It is a front view of a two-dimensional long-stroke table motion system in a preferred embodiment of the present invention. Please refer to figure 1 and figure 2 . In this embodiment, the two-dimensional long-stroke table motion system 1 includes a carrying platform 10 , a first-direction motion device 11 and two second-direction motion devices 12 . The carrying platform 10 is used for carrying workpieces (not shown in the figure), and is connected to the first direction moving device 11 . The two second-direction moving devices 12 are respectively symmetrically connected to both sides of the first-direction moving device 11 to realize synchronous and constant-speed motion. Thus, the workpiece can realize the two-dimensional long-stroke motion on the marble platform 2 by using the two-dimensional long-stroke table mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com