Magnetic preloading balance positioning system for photoetching machine workpiece stage

A positioning system and magnetic preloading technology, which is applied in the field of high-speed workpiece positioning system, can solve the problems of poor real-time performance, difficulty in motor selection, and difficulty in suppressing Rz in time, and achieve high motion positioning accuracy, easy control, and small vibration inside the machine Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

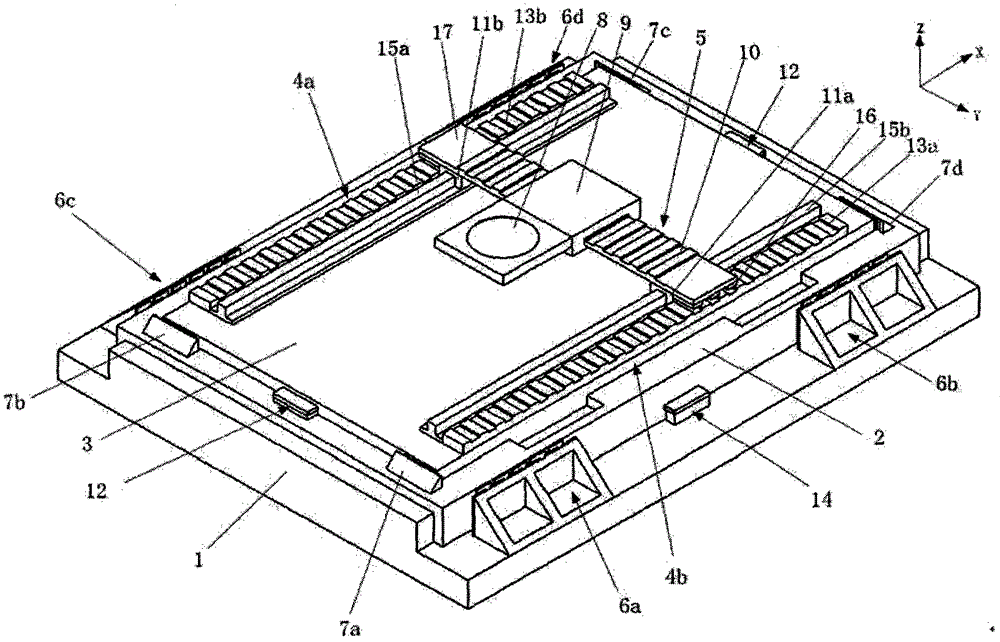

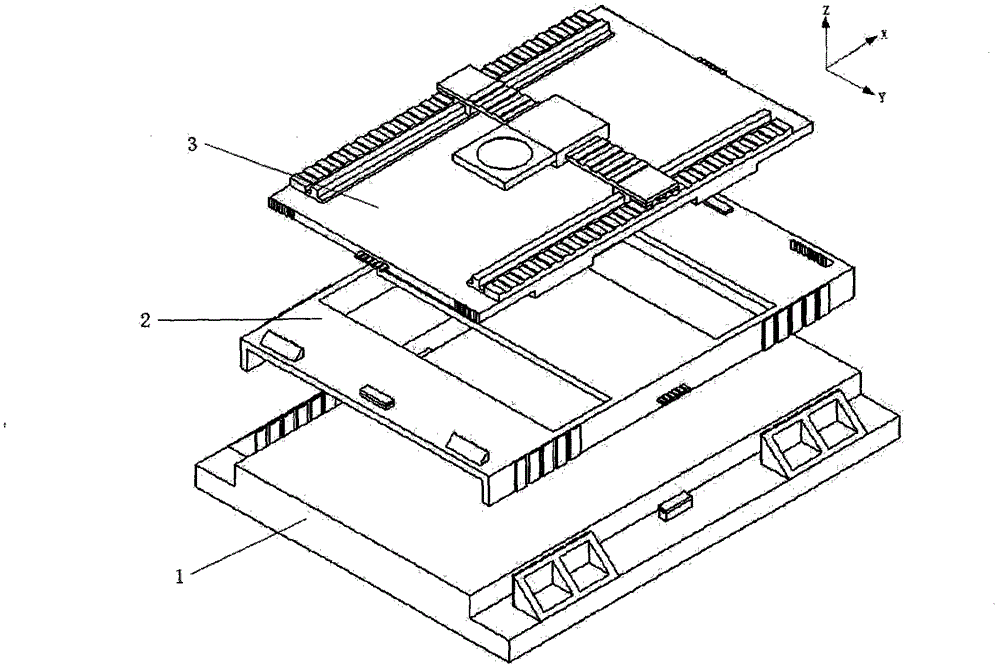

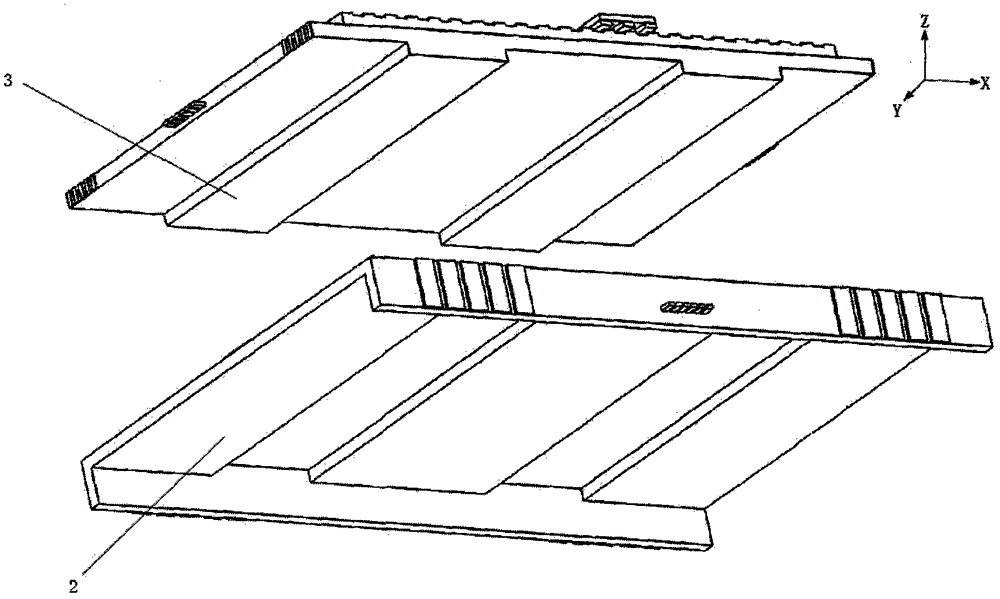

[0031] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0032] A magnetic preload balance positioning system for a photolithography machine workpiece table; the X-direction balance mass system 2 fits with the base 1 through the fixed X-direction air bearing guide rail, and freely slides in the X direction without resistance. The Y-direction balance mass system 3 The fixed Y-direction air bearing guide rail is fitted with the X-direction balance mass system 2, and slides freely in the Y direction without resistance; the X-direction first guide rail 15a and the X-direction second guide rail 15b are rigidly parallel to each other along the X-axis Installed on both sides of the Y-direction balance mass system 3, the X-direction first linear motor stator 13a and the X-direction second linear motor stator 13b are rigidly mounted on the Y-direction along the X-direction first and second guide rails 15a and 15b resp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com