A control method and system for precise positioning of linear motion of translational turnout

A linear motion and precise positioning technology, which is applied in two-dimensional position/channel control and other directions, can solve the problems of low positioning accuracy and large impact, and achieve the effects of high positioning accuracy, simple structure design, and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

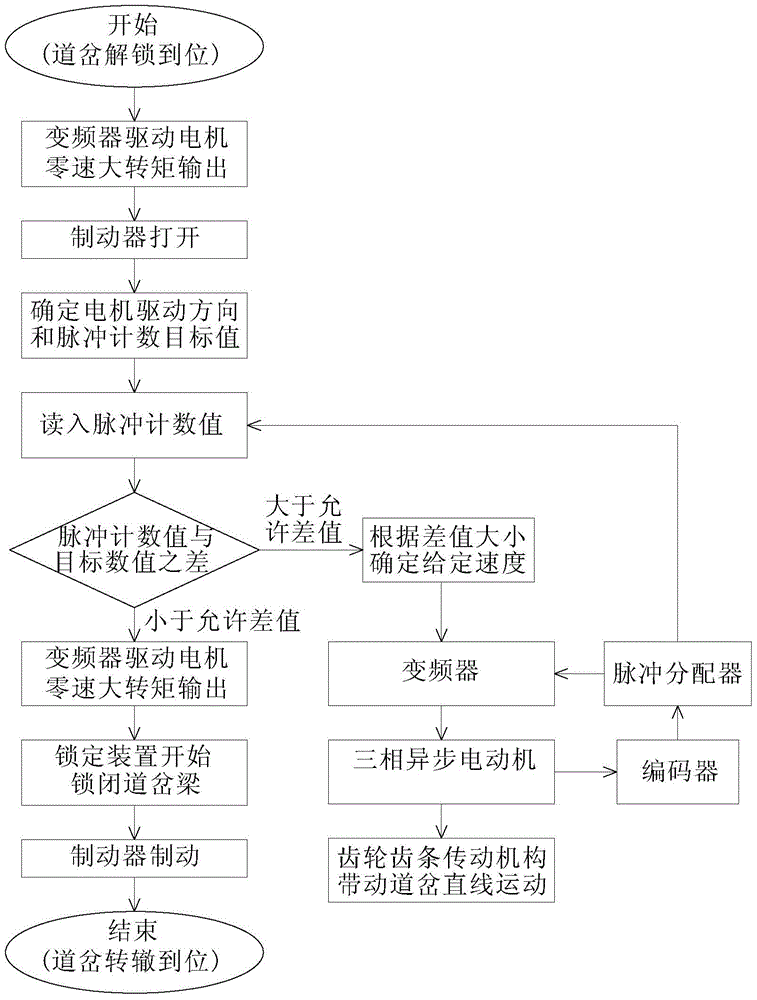

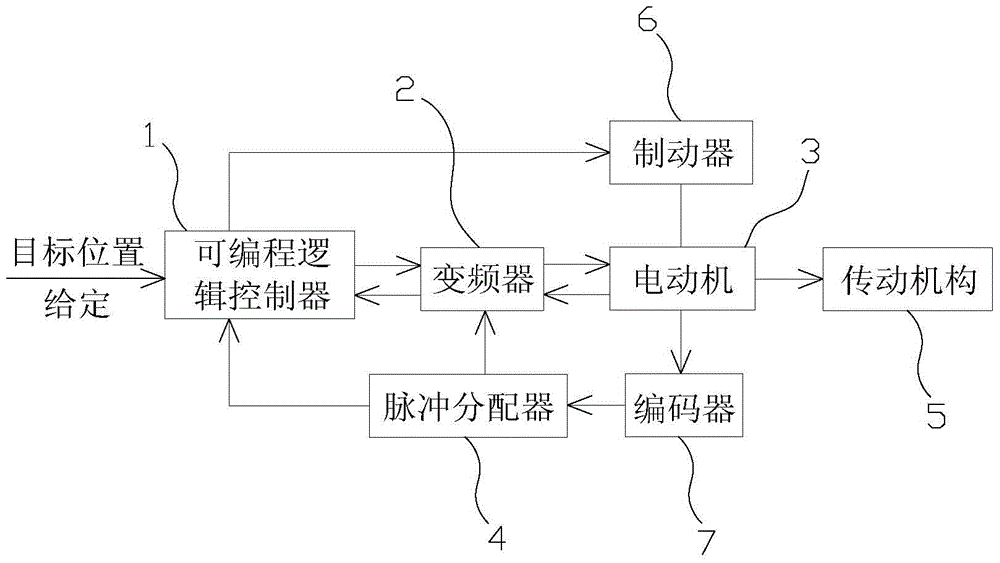

[0021] Such as figure 1 As shown, the control method for the precise positioning of the linear motion of the translation switch of the present invention comprises the following steps:

[0022] S010. First, determine the target value of the pulse count between each switch position of the switch (that is, the pulse count value that satisfies the translational movement distance of the switch), and convert the linear movement distance between each switch position into a switch through the actual measurement of the switch operation The pulse count target value and the allowable difference between the pulse count value and the target value during control to eliminate the influence of the accumulated error of the transmission mechanism;

[0023] S020. Then, when the switch is unlocked in place, make the motor controlled by the frequency converter be in a zero-speed and high-torque output state, so as to prevent the switch from slipping after the brake is opened;

[0024] S030, open ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com