A multi-layer piezoelectric actuator independent time-sharing drive device and method

A piezoelectric actuator, laminated piezoelectric technology, applied in piezoelectric effect/electrostrictive or magnetostrictive motors, generators/motors, electrical components, etc., can solve the problems of complex control and high cost, Achieve the effect of improving motion positioning accuracy, low cost and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Embodiment 1 Independent time-sharing drive and parallel drive hysteresis measurement

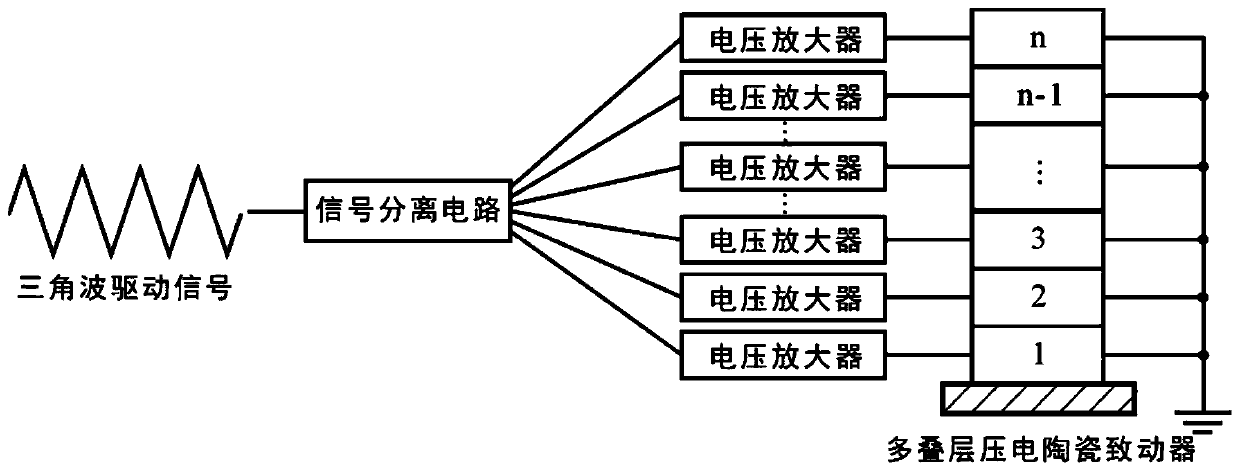

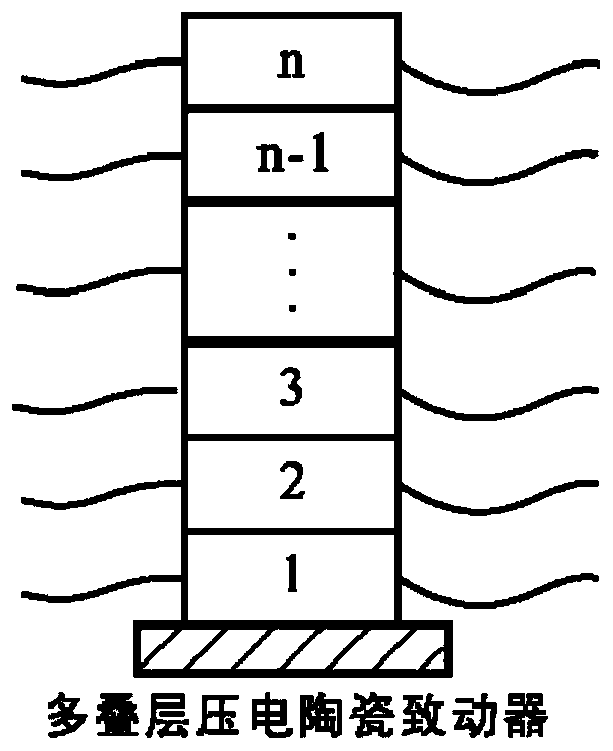

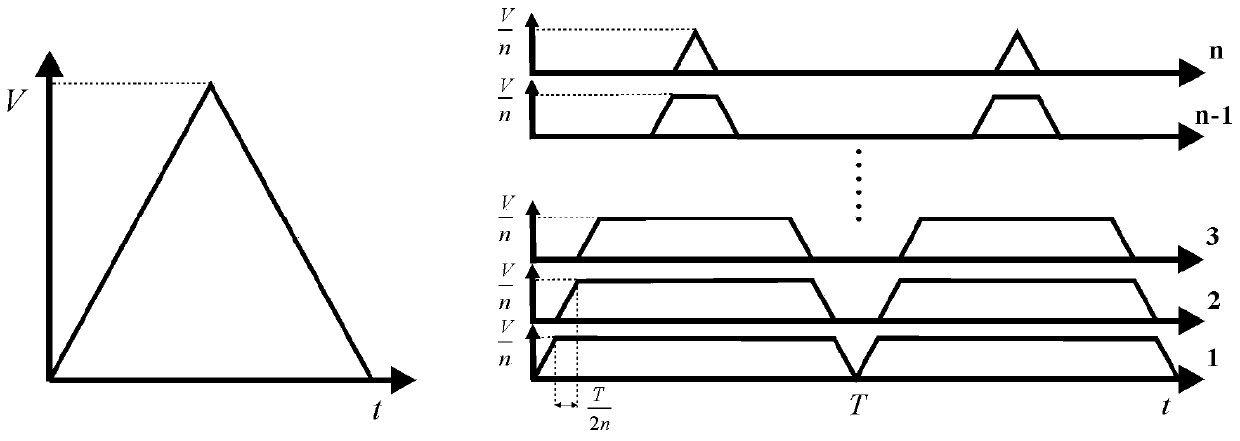

[0036] The piezoelectric actuator used in the experiment is AL 1.65*1.65*5D-4F from NEC Corporation of Japan, with three piezoelectric stacks and a triangular wave signal with a driving signal amplitude of 0-6V to conduct experiments at different signal frequencies. For independent time-sharing drives, follow the figure 1 The structure shown connects the experimental setup. The 0-6V triangular wave driving signal is input to the independent time-sharing driving device (signal separation circuit), through which the signal will be automatically separated into three sub-signals with an amplitude of 0-2V. The three-way sub-signals are amplified 45 times by the corresponding three-way voltage amplifiers and then output to the corresponding piezoelectric stacks. For parallel drive, the 0-6V triangular wave drive signal is directly amplified by 15 times and then connected to the input term...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com