Internal-tooth gear driven type rotary measuring head base

A technology of gear transmission and probe seat, which is applied in the direction of measuring device, mechanical measuring device, angle/taper measurement, etc., can solve the problems of unstable motion, small rotating force, and large motor load, so as to improve motion positioning accuracy and rotation The effect of stable force and large turning force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

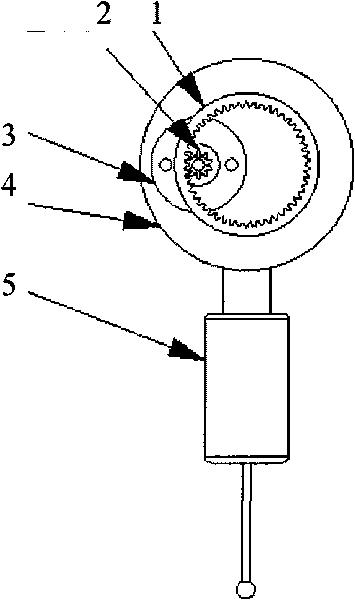

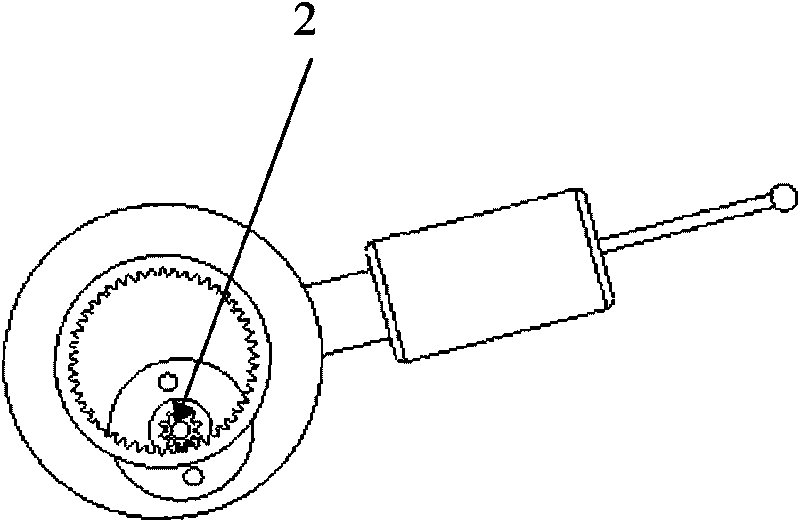

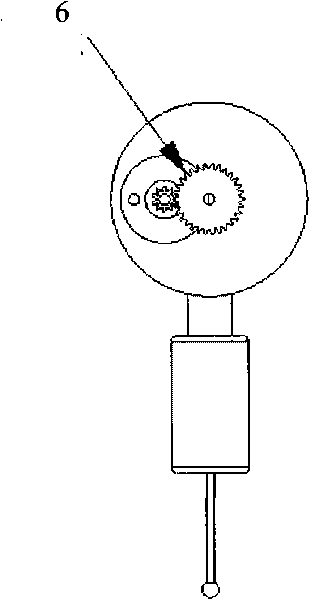

[0011] The present invention's internal tooth gear transmission rotary measuring head seat such as figure 1 , 2 As shown, it consists of a measuring head 5, a motor 3 fixed at the eccentric position of the rotating body 4 of the measuring head base, and a set of transmission gear sets. The transmission gear 2 on the motor meshes with an internal gear 1 fixed inside the probe base, and the center of the internal gear coincides with the rotation center of the probe base. The rotation of the motor 3 makes the motor gear 2 rotate around the internal gear 1, thereby driving the rotating body 4 and the measuring head 5 to perform circular motion.

[0012] The working principle of the present invention is: the internal tooth gear transmission type rotary measuring head base, when the initial position of the rotating measuring head, the measuring head 5 is in the vertically downward position (such as figure 1 Location). When the motor 3 rotates, the motor gear 2 rotates to carry ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com