Multistage vibration isolation system and method for precise instrument

A technology of precision instruments and vibration isolation systems, applied in protection devices, buildings, infrastructure engineering, etc., can solve the problems of excessive vibration, the accuracy of silicon wafer motion positioning cannot meet the index requirements, and can not be isolated from vibration, etc., to reduce vibration. , The effect of reducing vibration level and improving motion positioning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

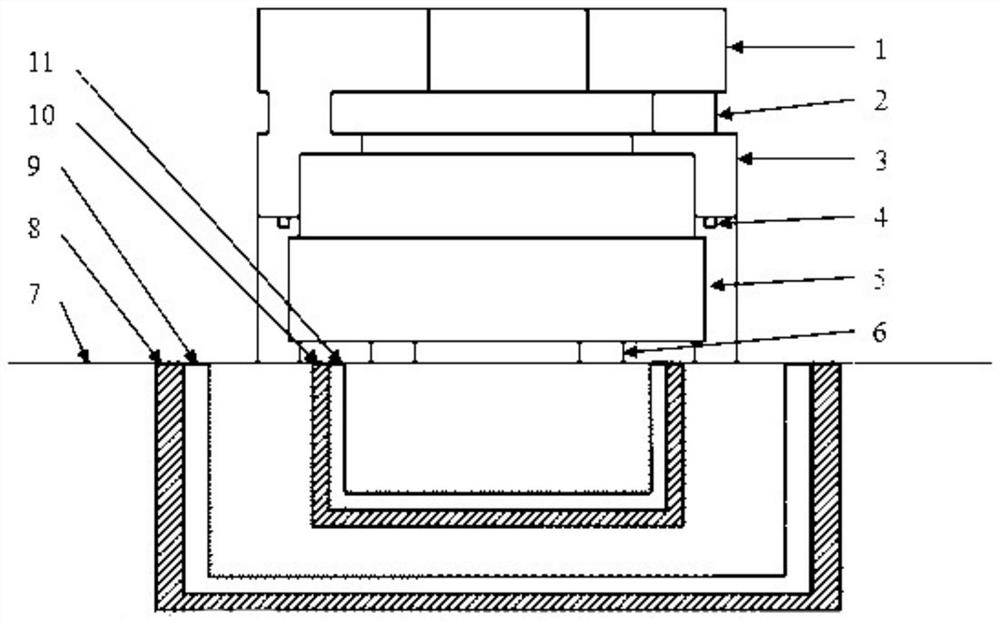

[0039] In the existing lithography machine, the moving parts are supported by air springs and placed directly on the ground, and the moving parts and the frame are connected through a pin-fitted mechanical interface. In order to isolate the low-frequency vibration of the ground, the technical solution usually adopted In order to use three to four active vibration isolators to connect between the rack and the main base plate, although active vibration isolators are used to separate the moving parts from the main base plate, due to the limitation of the vibration isolation rate, the active However, the vibration cannot be completely isolated. The excitation generated by the moving parts during the working process is coupled with the low-frequency random vibration of the ground, and is transmitted to the installation position of the active vibration isolator through the two paths of the ground and the mechanical interface, so that the vibration on the main substrate after being at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com