Control system and method for helicopter electrically-driven tail rotor

A technology of control system and helicopter, which is applied in the direction of aircraft power transmission, aircraft power device, aircraft parts, etc., can solve the problems of difficult assembly and maintenance, high driving difficulty, heavy structure weight, etc., achieve convenient driving, reduce operation difficulty, improve performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

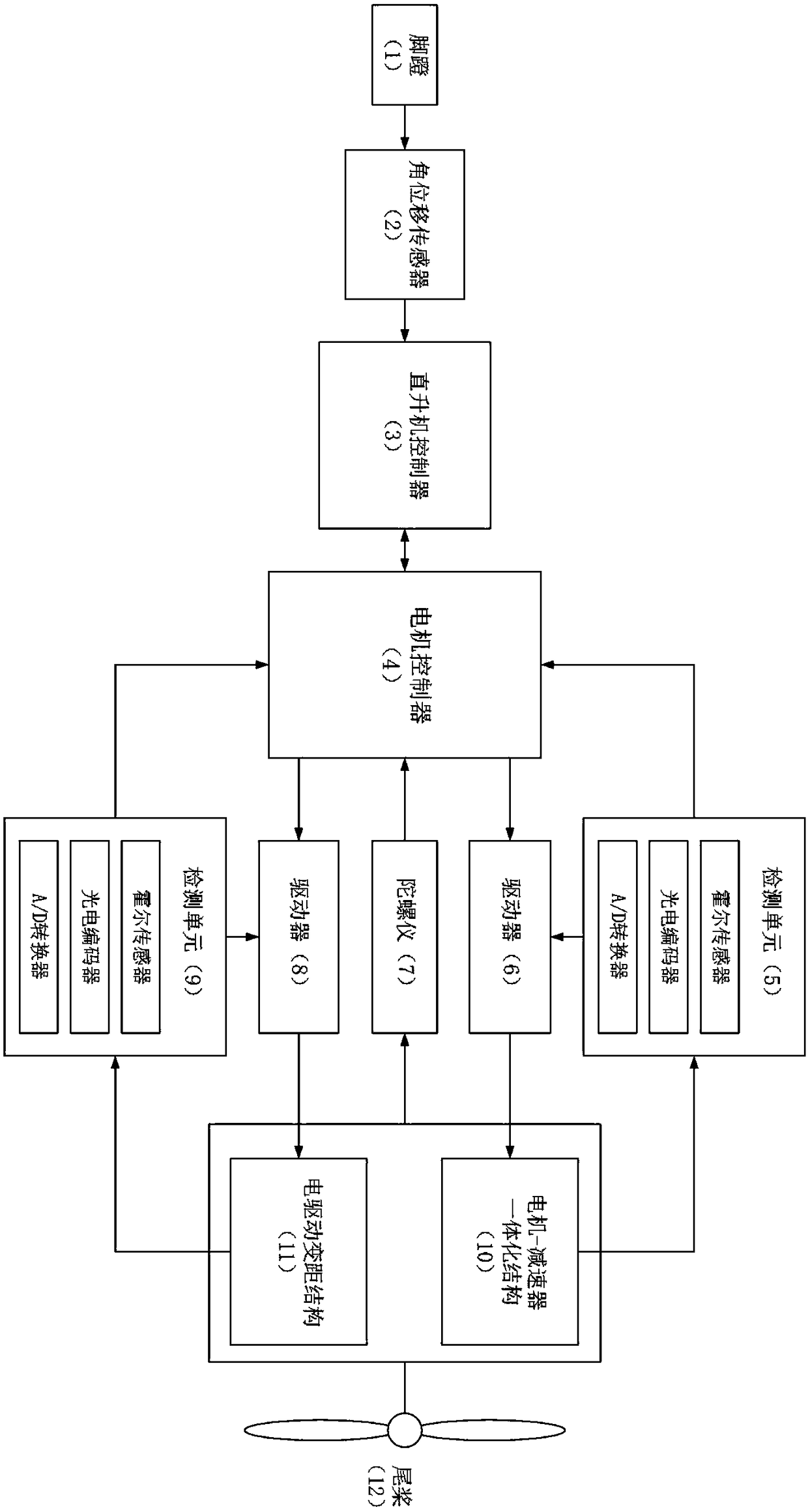

[0037] like figure 1 As shown, a helicopter electric drive tail rotor control system includes: an angular displacement sensor 2, a helicopter controller 3, a motor controller 4, a first detection unit 5, a first driver 6, a gyroscope 7, a second driver 8, A second detection unit 9 , a motor-reducer integrated structure 10 , and an electric drive variable pitch structure 11 . in:

[0038] The angular displacement sensor 2 is connected with the pedal 1 of the helicopter and the helicopter controller 3 respectively, and is used to detect the angle change of the pedal 1 to obtain an angle signal, and transmit the angle signal to the helicopter controller 3 .

[0039] The gyroscope 7 is installed at the tail of the helicopter, and is connected with the motor controller 4 and the helicopter controller 3 respectively, and is used to detect the attitude change of the helicopter to obtain an attitude signal, and transmit the attitude signal to the motor control device 4 and the heli...

Embodiment 2

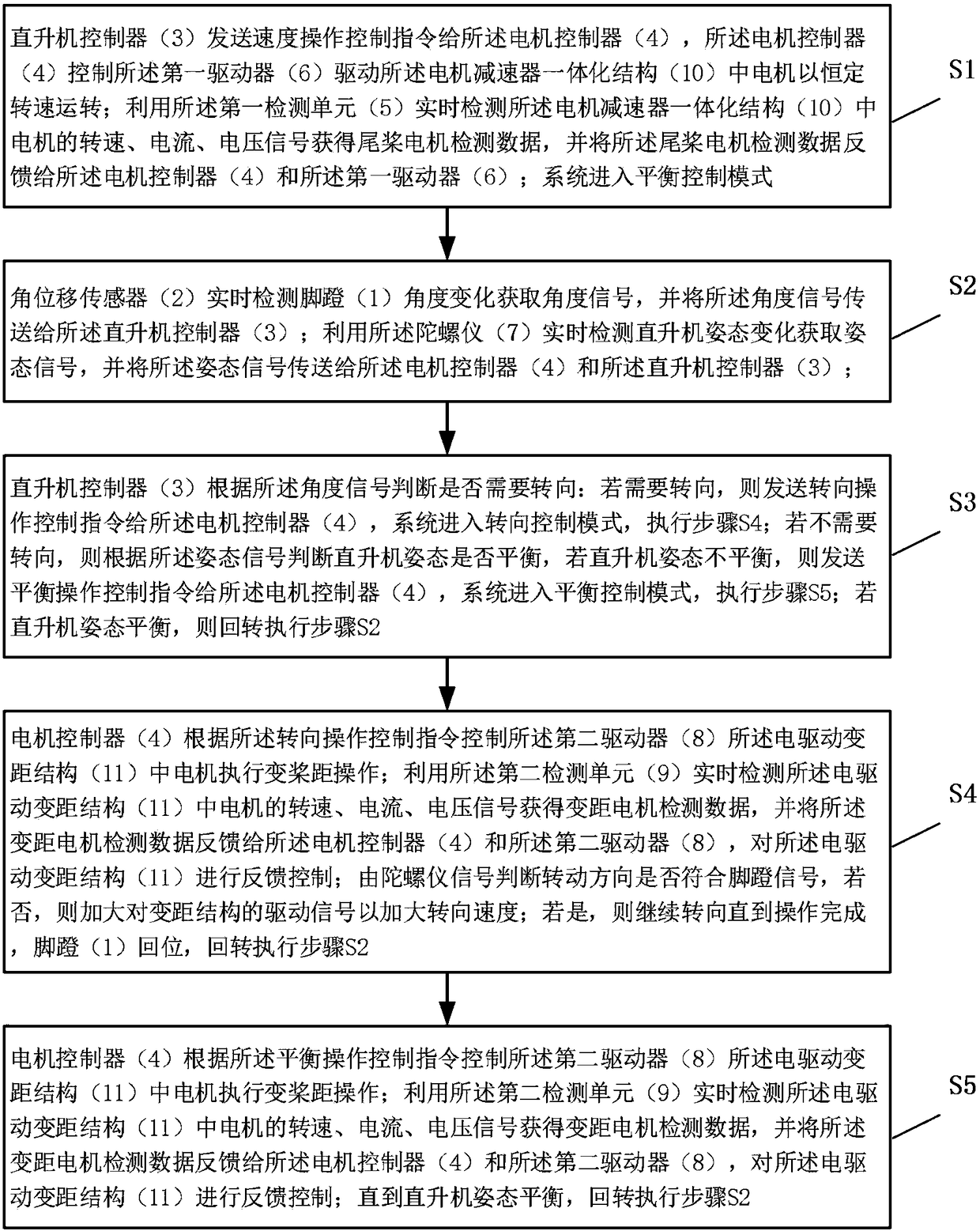

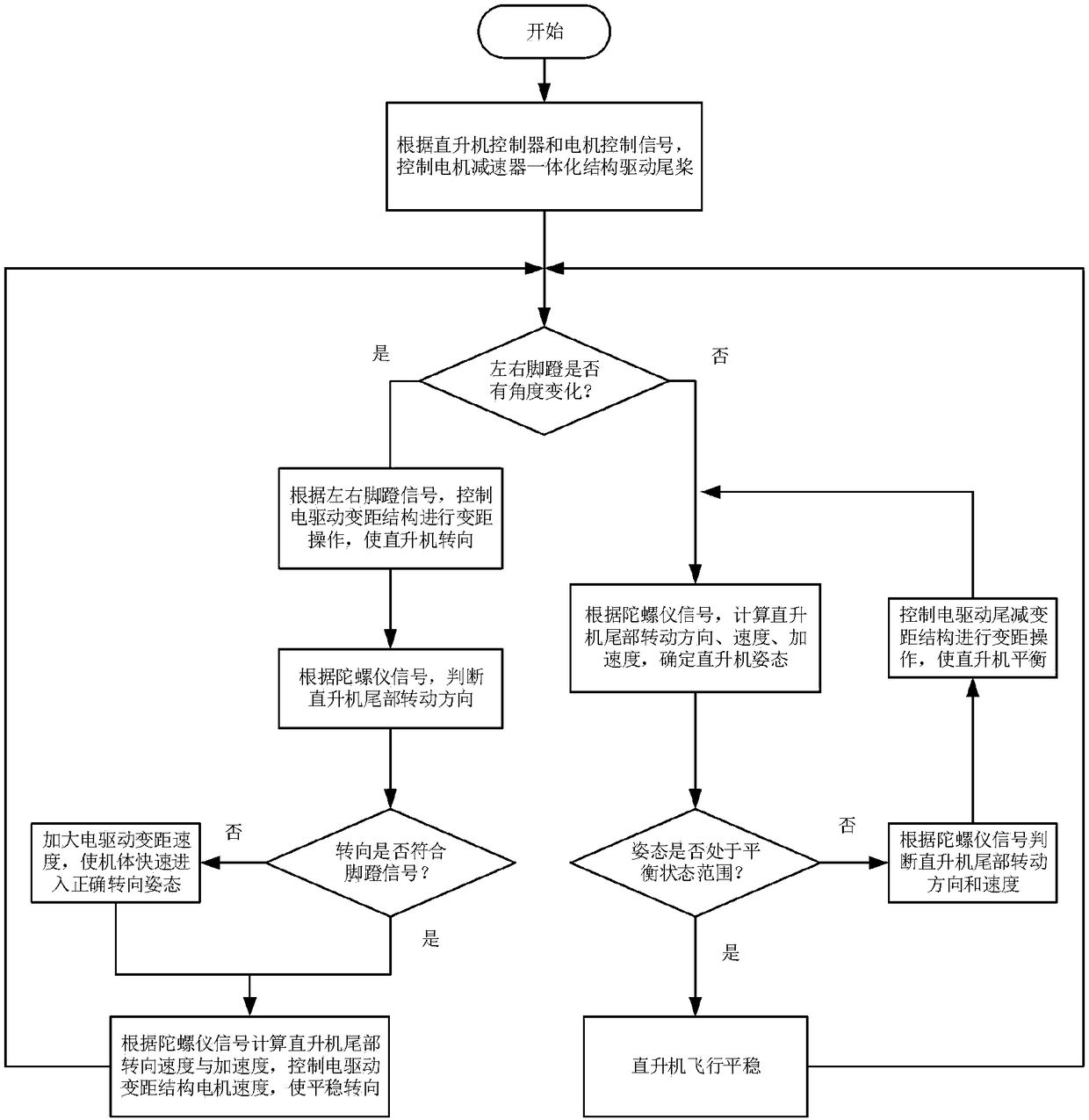

[0053] like figure 2 and image 3 As shown, based on the control system provided in Embodiment 1, this embodiment provides a method for controlling the electrically driven tail rotor of a helicopter, including the following steps:

[0054] Step S1, using the helicopter controller 3 to send a speed operation control command to the motor controller 4, and the motor controller 4 controls the first driver 6 to drive the motor in the motor-reducer integrated structure 10 to Constant speed operation. Use the first detection unit 5 to detect in real time the rotational speed, current and voltage signals of the motor in the motor-reducer integrated structure 10 to obtain the detection data of the tail rotor motor, and feed back the detection data of the tail rotor motor to the motor The controller 4 and the first driver 6 form a feedback control.

[0055] The beneficial technical effect of the above-mentioned feedback control is: when the external load changes, such as when the he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com