Patents

Literature

393results about How to "Promote technological progress" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

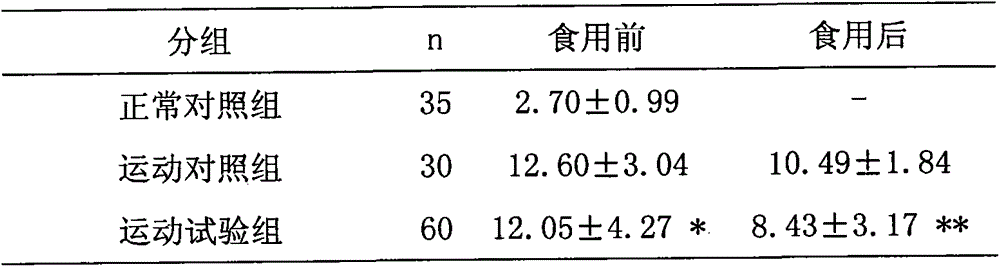

Ugine sport nutrition milk tea powder and preparation method thereof

The invention discloses ugine sport nutrition milk tea powder and a preparation method thereof and belongs to the technical fields of solid drinks, modified milk powder and nutritious foods. The milk tea powder is characterized by comprising whole milk powder, skim milk powder, whey protein powder, collagen powder, soy peptides powder, maize oligopeptide, inulin, maltodextrin, soluble soybean polysaccharide, instant tea powder, phospholipid, L-carnitine, a vitamin premix and a mineral premix. The milk tea powder disclosed by the invention has the advantages of giving a full play to the effects of nutrition complementation and cooperative gain, filling a market vacancy and integrating the functions of supplementing calcium, strengthening bones, losing the weight, relieving fatigues, keeping fit and the like; the milk tea powder is good in taste, convenient to eat, good in safety, strong in acceptability, free of toxic or side effects, simple in production process and easy to product and has a great market development potential.

Owner:BEIJING SANLIYUAN FOOD TRADING

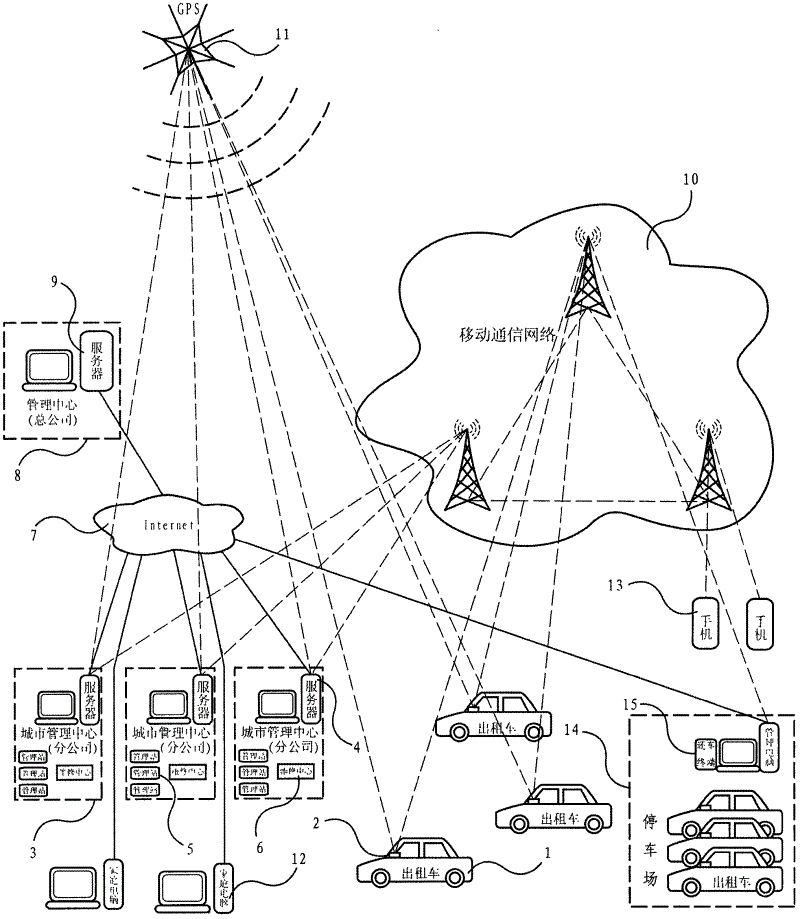

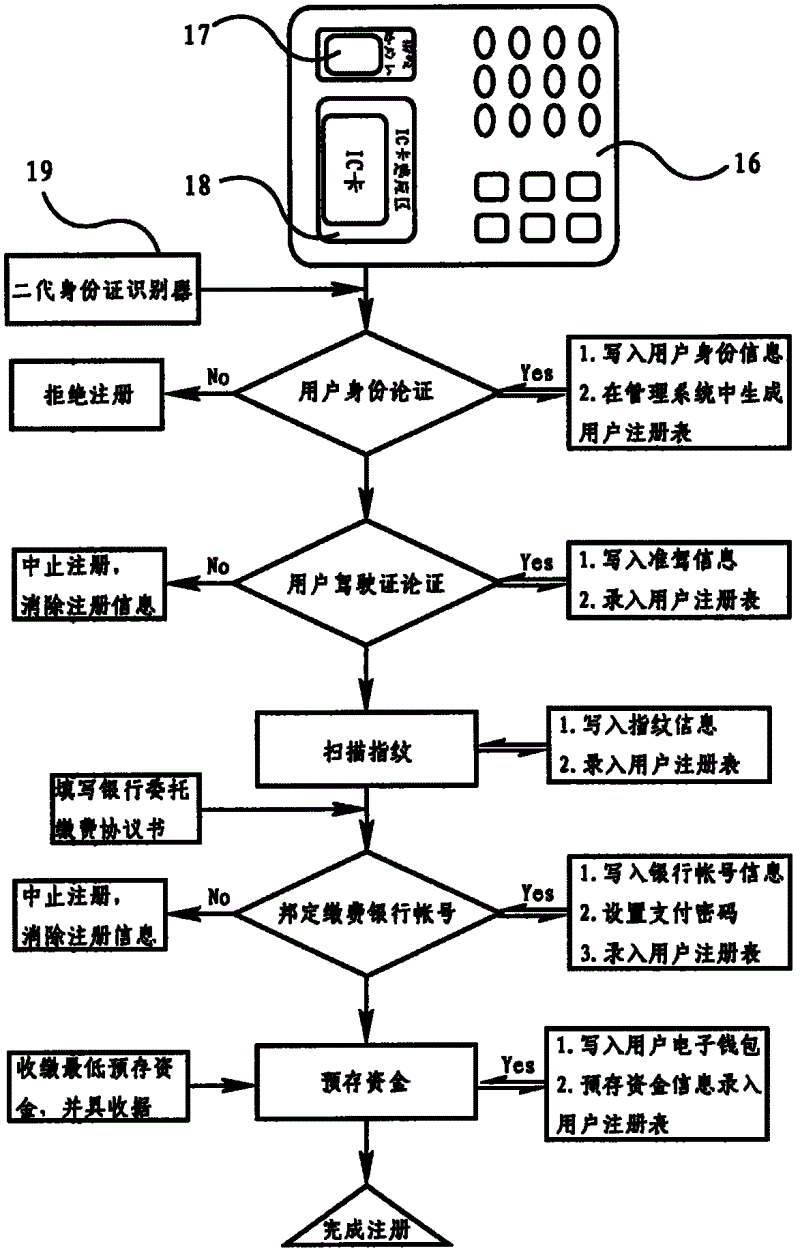

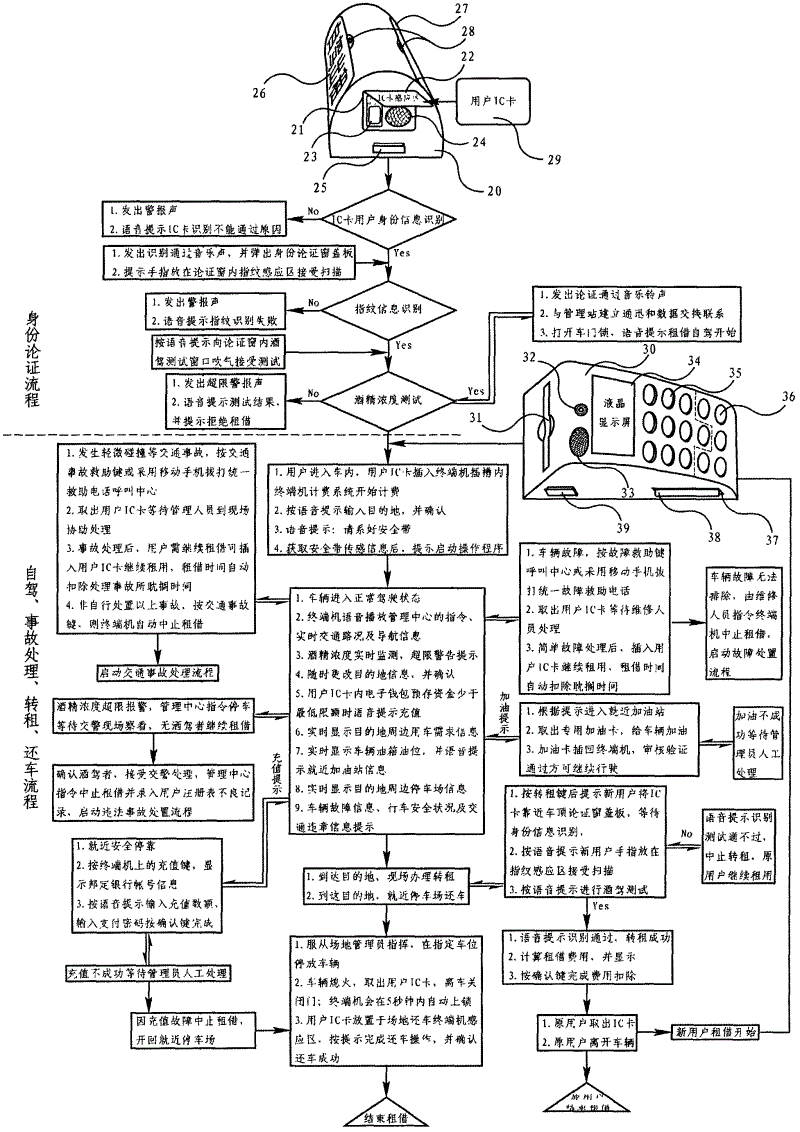

Self-service vehicle renting management system and self-service vehicle renting management method

InactiveCN102622704AGuaranteed uptimeImprove reliabilityPre-payment schemesBuying/selling/leasing transactionsThe InternetEngineering

The invention provides a self-service vehicle renting management system and a self-service vehicle renting management method. The management system is based on technologies in terms of GPS (global positioning system) / GSM (global system for mobile communication) positioning systems, mobile communication systems, the internet, IC (integrated circuit) cards and the like. Self-service vehicle renting is realized by the aid of the management system and the management method, a user can use a user IC card stored with information including an identity card, a driving license, fingerprints and pre-stored fee to rent, transfer and return any vehicle in any one renting and returning (parking) lot within a network coverage range at any time and in any places, electronic money real-time settlement and any-time recharging are realized, and accordingly vehicle renting, returning and settlement are convenient, fast, safe and reliable. The self-service vehicle renting management method can be carried out nationwide, the user can rent a vehicle, return the vehicle, recharge and settle accounts in management centers of various cities only by the aid of the user IC card, and accordingly the vehicles are rented and returned highly freely temporally and spatially.

Owner:ZHEJIANG UNIVERSITY OF SCIENCE AND TECHNOLOGY

Leisure vegetarian meat based on textured soybean protein

ActiveCN103734454ARich categoryFull of nutritionCheese manufactureVegetable proteins working-upVegetarian dietsMeat fibers

The invention discloses leisure vegetarian meat based on textured soybean protein. The vegetarian meaty food is prepared from the textured soybean protein as a raw material by the procedures of soaking and cleaning to remove beany flavor and peculiar smell, dewatering, surface oiling and sizing, imitating meat to supply flavors, sterilizing at high temperature and the like. The product is free of beany flavor, abundant in nutrient, convenient to carry, high in meat imitating degree, and moderate in saltiness and sweetness, mellow and delicious, strong in sensual appeal, and unique in flavor, has the chewing feeling of a real meat fiber and the flavor of meat, is a novel instant leisure flavor vegetarian product. Not only is the variety of the leisure bean products enriched, but also a new convenient and delicious choice is provided for vegetarian crowd.

Owner:ZUMING BEAN PROD

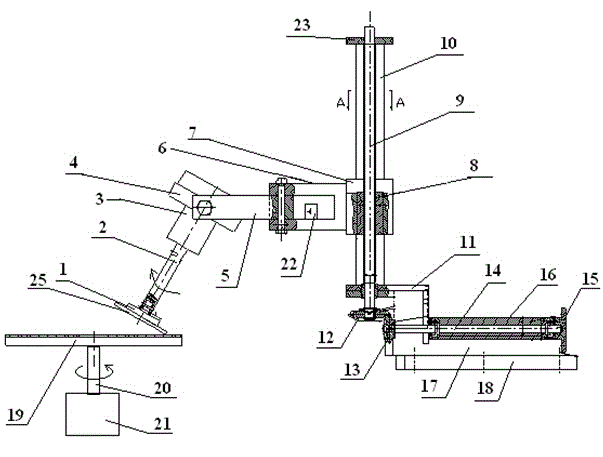

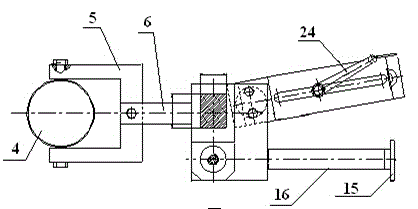

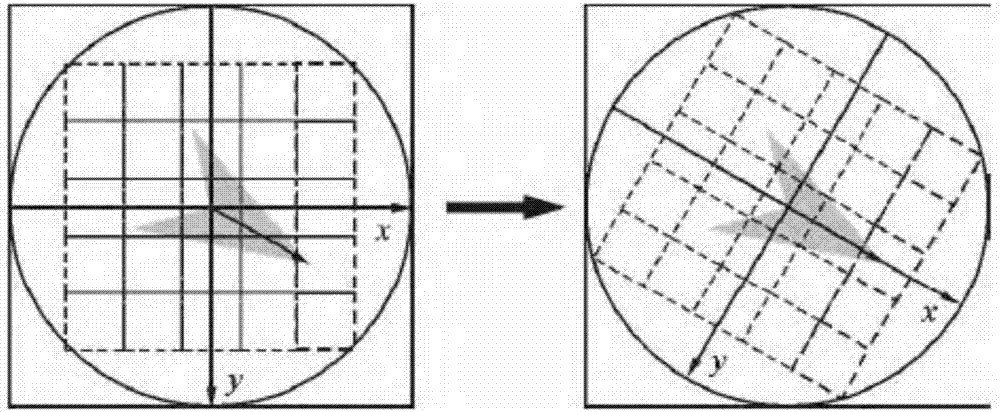

Silicon carbide wafer bevel grinding, milling and polishing machine and operation method thereof

ActiveCN104551900AAvoid chippingImprove processing qualityEdge grinding machinesPolishing machinesEngineeringDrive motor

The invention discloses a silicon carbide wafer bevel grinding, milling and polishing machine and an operation method thereof. The silicon carbide wafer bevel grinding, milling and polishing machine comprises a supporting sheet (1), a rotating shaft (2), a driving motor (3), a motor bracket (4), a vertical rotating arm (5), a horizontal rotating arm (6), a slide frame (7) and a screw rod (9) which are sequentially connected, wherein the lower end of the screw rod (9) is sequentially connected with a first cone gear (12), a second cone gear (13), an adjusting shaft (14) and a rotating wheel (15); a machining tool (19) of a silicon carbide wafer is arranged below the supporting sheet (1). The silicon carbide wafer bevel grinding, milling and polishing machine is reasonable in structural design, convenient to operate and high in working efficiency, bevel grinding, milling and polishing integrated machining can be performed on the silicon carbide wafer, the working efficiency is high, the roughness of a polished bevel can be smaller than 0.1 micron, the machining precision is high, and the applicability is high. The operation method can be applied to the bevel grinding, milling and polishing integrated machining on the silicon carbide wafer which is round or not round.

Owner:山东粤海金半导体科技有限公司

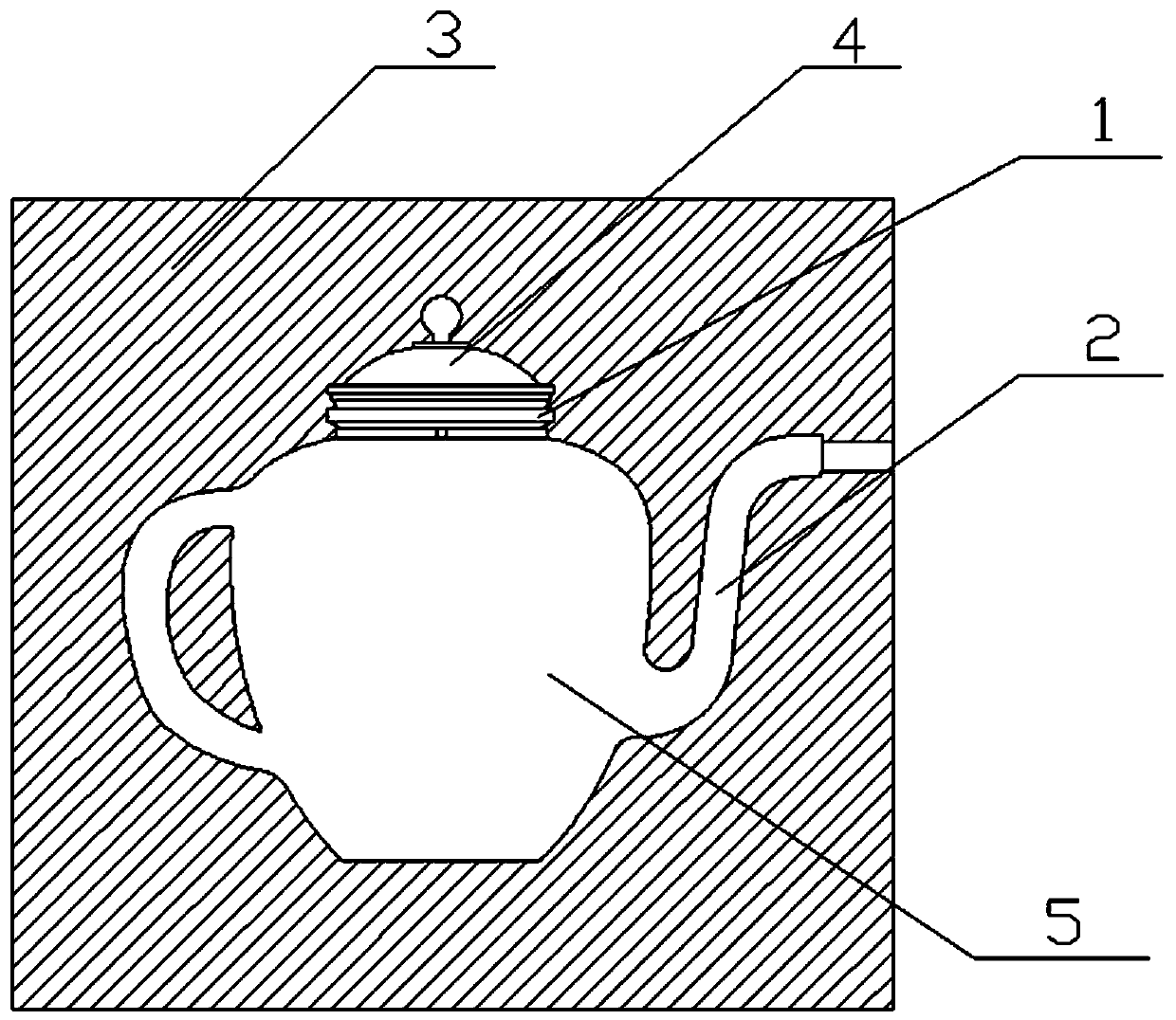

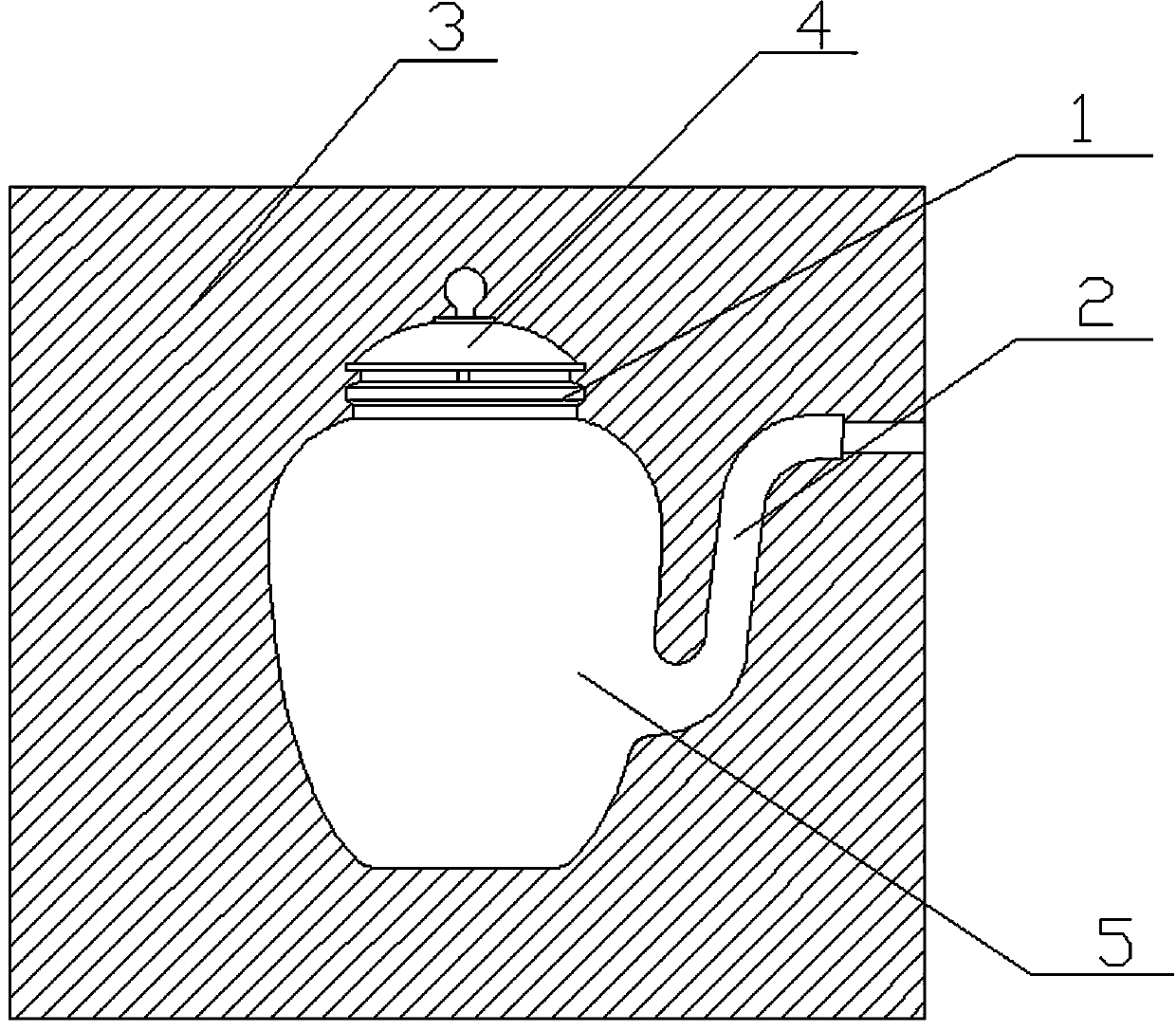

One-step extrusion-blown molding pot forming technology, dedicated mold pressing extrusion molding blow molding die and product

ActiveCN103419355AOvercome the problem of color differencePromote technological progressBlow moldingHollow form

The invention discloses a one-step extrusion-blown molding pot forming technology. According to the one-step extrusion-blown molding pot forming technology, a mold pressing forming technology and an extrusion-blown molding technology are combined into a whole. An air inlet core bar of the extrusion-blown molding technology is also a male mold of the mold pressing forming technology. A pot cover, a spout and a pot body of a formed pot can be formed in an extrusion-blown molding mode with one mold in one step. The technological advance of the hollow forming technology field is promoted, the complex and refine development tendency of current hollow products is met, and more complex products can be developed through the idea.

Owner:临夏市民政福利塑料厂

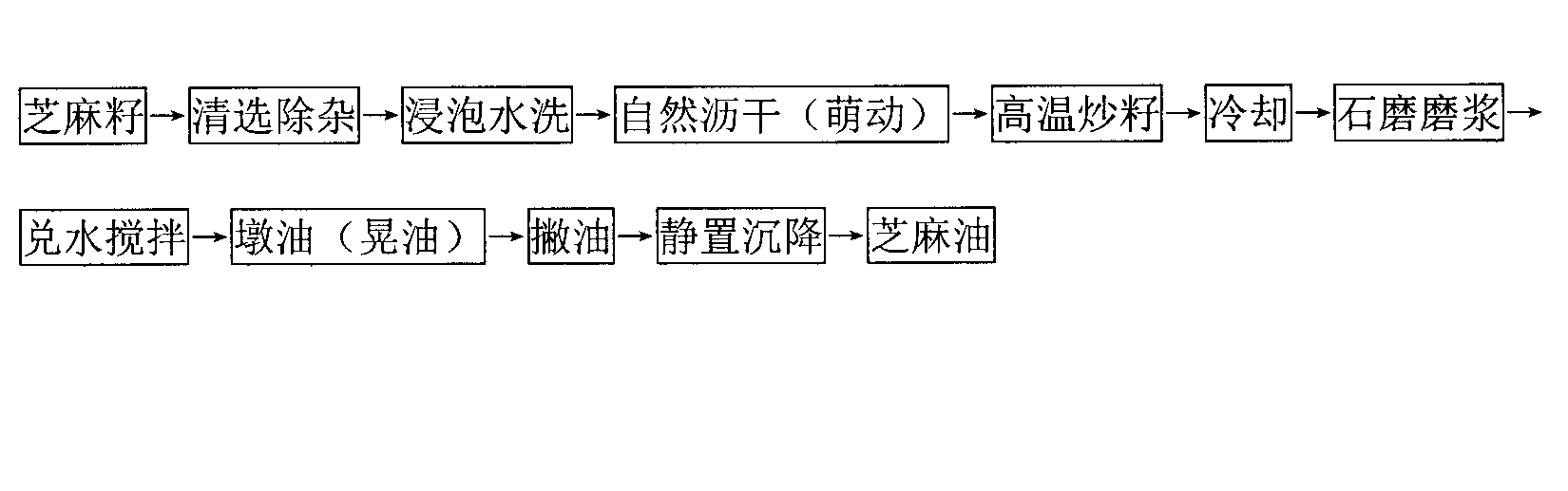

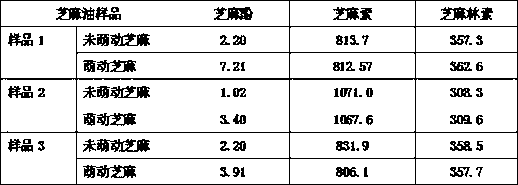

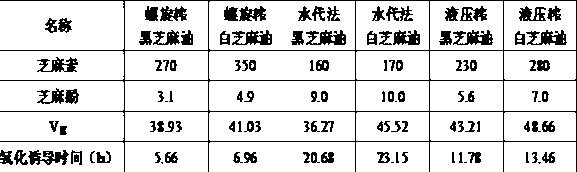

Production process of sesamol-rich fragrant sesame oil

InactiveCN102796609APure fragranceQuality and safetyFatty-oils/fats productionEdible oils/fatsFlavorSesamum

The invention discloses a production process of sesamol-rich fragrant sesame oil. The production process is characterized by comprising the following steps of: cleaning and removing impurities; soaking and washing; naturally draining and germinating; frying seeds at a high temperature; cooling; grinding into pulp with a stone mill; adding water and stirring; turning oil (shaking oil); skimming oil; and standing and settling to obtain a finished product. The production process has the advantages that the defects of high probability of getting burnt during direct roasting of dry sesame and high probability of producing 3,4-benzopyrene after burning are avoided by soaking the sesame with water, draining and then roasting at the high temperature, the sesame seeds are germinated during washing, soaking and drainage of the sesame, the germinated sesame seeds are roasted at the high temperature and then grease is extracted, the sesamol content in the sesame oil is higher than that of the sesame oil extracted from the ungerminated sesame, sesame pulp has high water absorbing speed and high oil yield speed, the obtained sesame oil has better flavor, the content of vitamin E in the sesame oil extracted from the germinated sesame, which is washed and soaked with water and drained, is higher than that of the sesame oil extracted from the ungerminated sesame, and the oil yield is improved by 1-2 percent compared with that in the prior art.

Owner:HENAN UNIVERSITY OF TECHNOLOGY

Soybean tissue albumin dried meat floss

ActiveCN103704463ACrisp textureUnique flavorCheese manufactureVegetable proteins working-upTissue proteinVegetarian diets

The invention discloses soybean tissue albumin dried meat floss. The vegetarian dried meat floss is prepared by performing immersion, cleaning, deodorization, peculiar smell removal, dewatering, chopping into strips, mixing, frying, drying, cooling, packaging and the like on a soybean tissue protein raw material. The soybean tissue protein is used as a full vegetable instead of a filler to be developed and applied; by virtue of rich soybean proteins, the prepared vegetarian dried meat floss is loose, is moderate in sweetness and saltness, tastes mellow and delicious and has a unique flavor; people of all ages can eat the soybean tissue albumin dried meat floss; particularly a new convenient and delicious option is supplied to vegetarians and is a meat-substitute product with rich nutrition.

Owner:ZUMING BEAN PROD

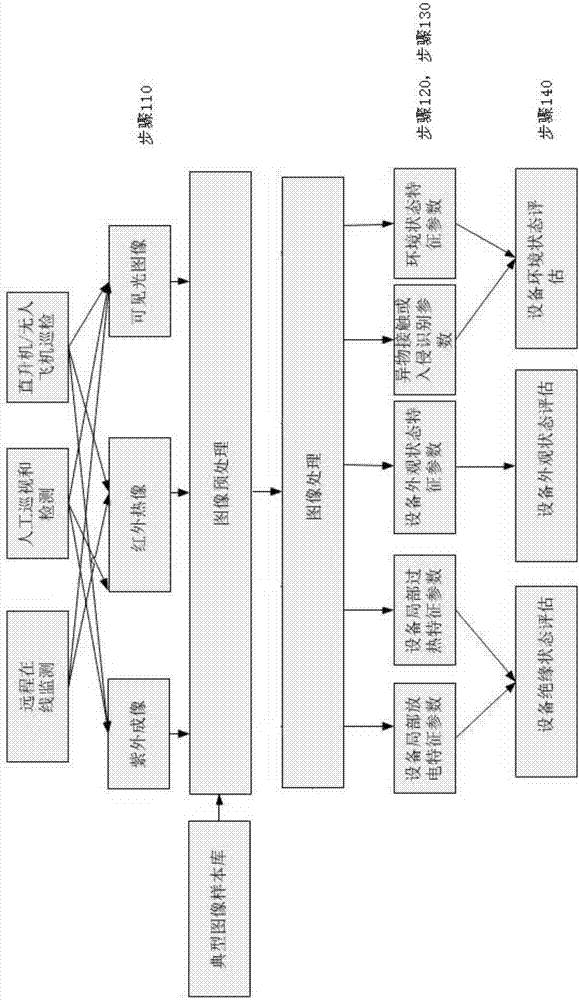

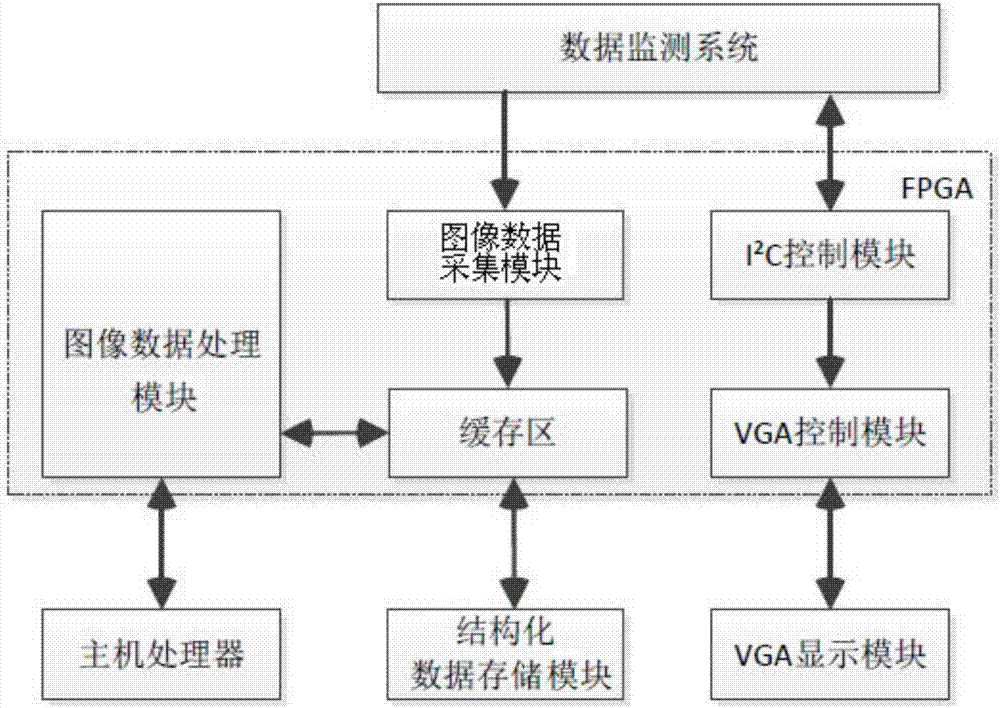

Power equipment image processing method

InactiveCN107392886AReduce labor costsReduce labor requirementsImage analysisImaging processingPower equipment

The invention discloses a power equipment image processing method. The method comprises the steps that a power equipment image and a sample image are acquired and processed, wherein processing comprises image preprocessing and image processing, and image processing comprises feature parameter extraction; and feature parameters of the power equipment image and feature parameters of the sample image are compared, and the state of power equipment corresponding to the power equipment image is described according to the comparison result. By use of the method to process the power equipment image, the power equipment image is converted into state description of the power equipment corresponding to the power equipment image, therefore, information valuable to power equipment monitoring is effectively extracted through computing equipment, labor cost and the storage space demand are greatly lowered, and monitoring efficiency and accuracy are greatly improved.

Owner:STATE GRID SHANDONG ELECTRIC POWER +2

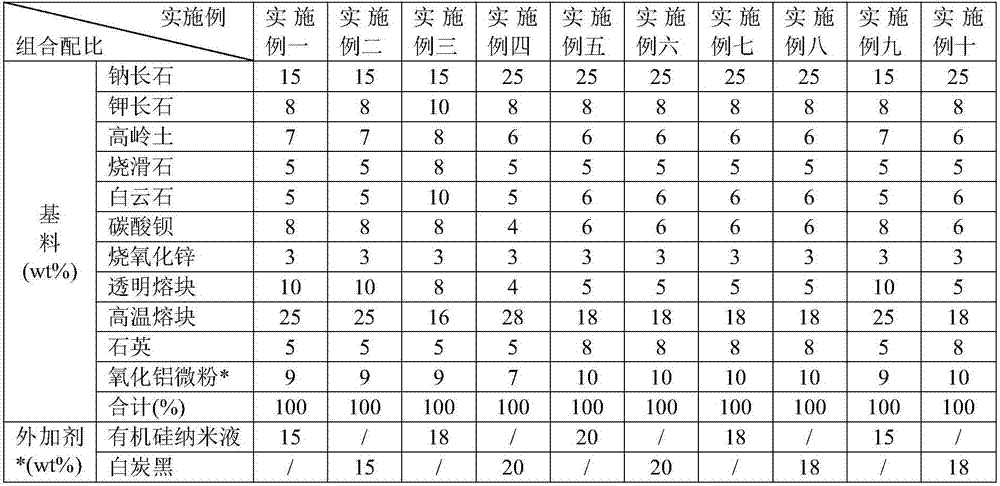

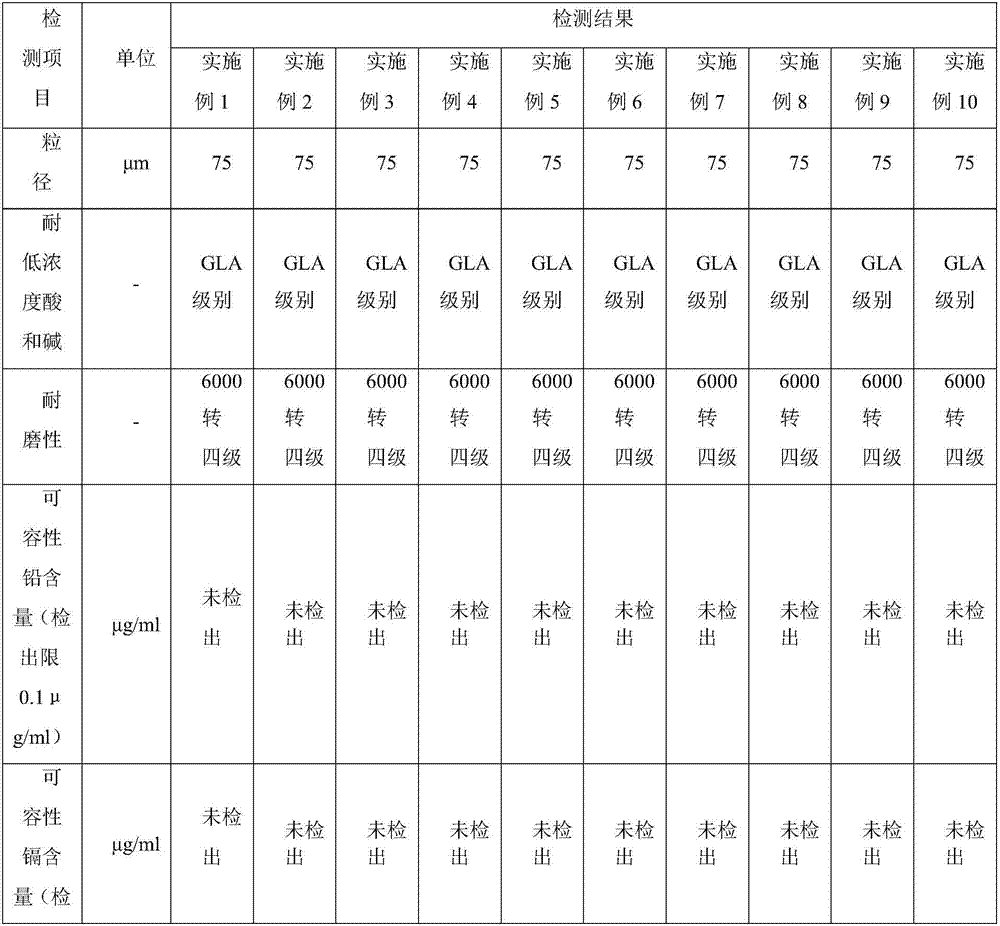

Low-temperature, high-hardness and high-abrasion-resistance fully-polished glaze and preparation method thereof

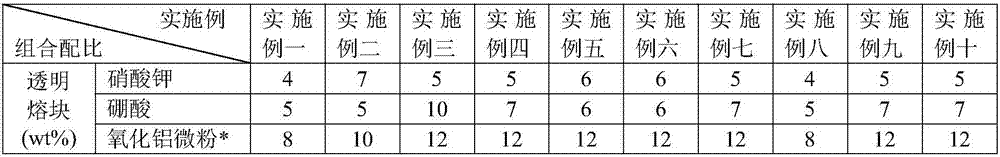

The invention discloses a low-temperature, high-hardness and high-abrasion-resistance fully-polished glaze which contains a base material and an admixture. The base material is prepared from, by weight, 15-25% of albite, 8-16% of potassium feldspar, 6-10% of kaolin, 5-8% of calcined talc, 5-10% of dolomite, 4-12% of barium carbonate, 3-5% of calcined zinc oxide, 4-20% of transparent frit, 16-28% of high-temperature frit, 5%-18% of quartz and 7-15% of alumina micro-powder, wherein the admixture is an organic silicon nano-solution or white carbon black, and the usage amount of the admixture is 15-2% by weight. In addition, the invention further discloses a preparation method of the low-temperature, high-hardness and high-abrasion-resistance fully-polished glaze and a product prepared by the same. The melting temperature is reduced through a reasonable formula system, the melting temperature range of the glaze is enlarged while energy saving and emission reduction are promoted, the hardness and abrasion resistance of the glaze surface are remarkably improved, the higher usage requirements can be very well met, and technical progress and application development of the industry of architectural ceramics are promoted.

Owner:JINGDEZHEN CERAMIC INSTITUTE

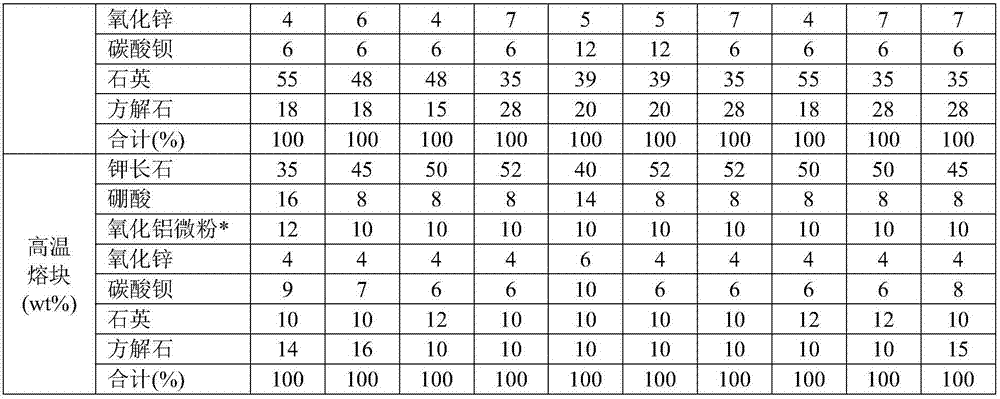

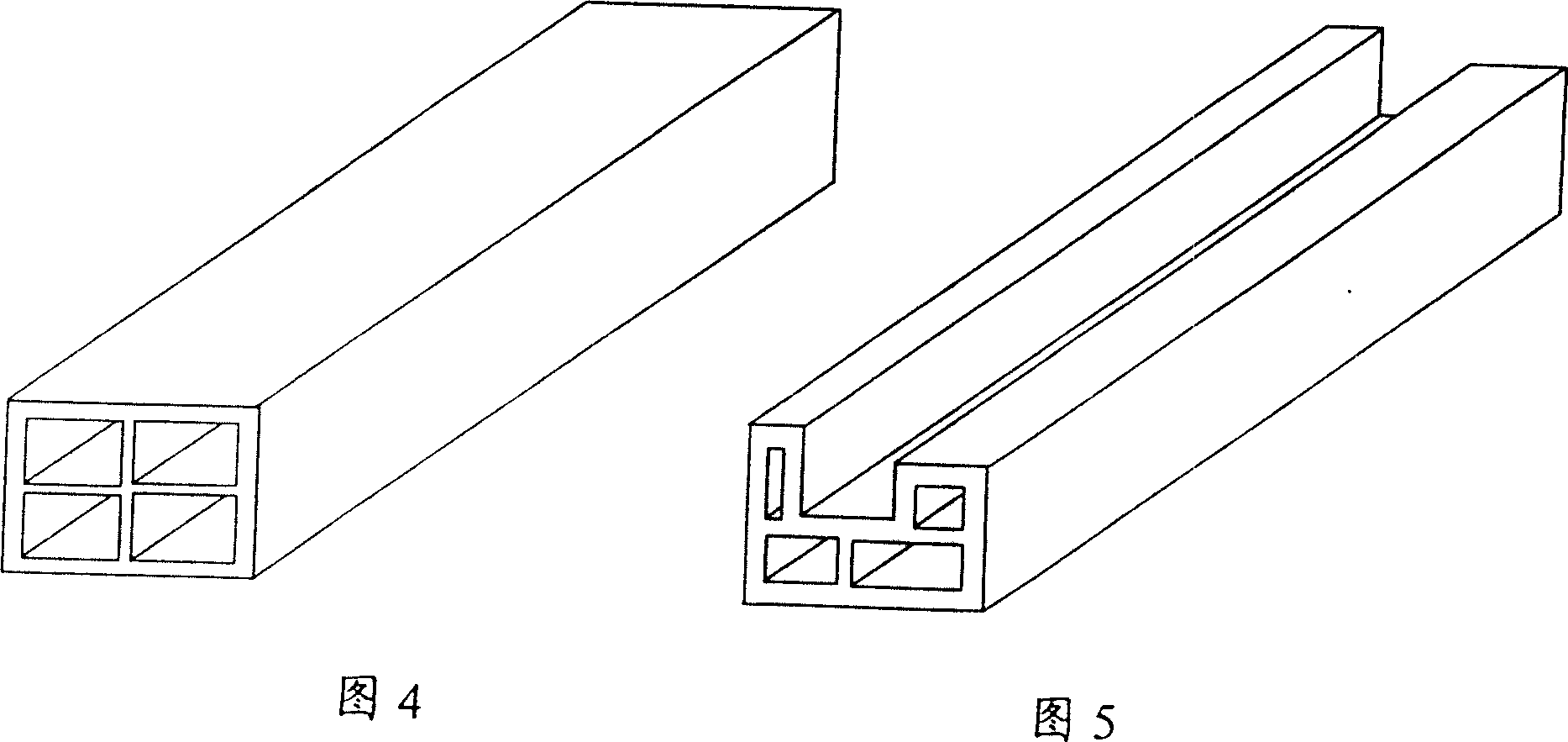

Nano composite woody material, and preparation method

A nano-class composite wooden material for plate, tube, or section is proportionally prepared from laminar silicate, high-molecular resin, natural plant fibers, inorganic filler, and chemical assistant through proportional mixing, and extruding out or injection moudling. It is possible to granulate before it is shaped.

Owner:赵永生

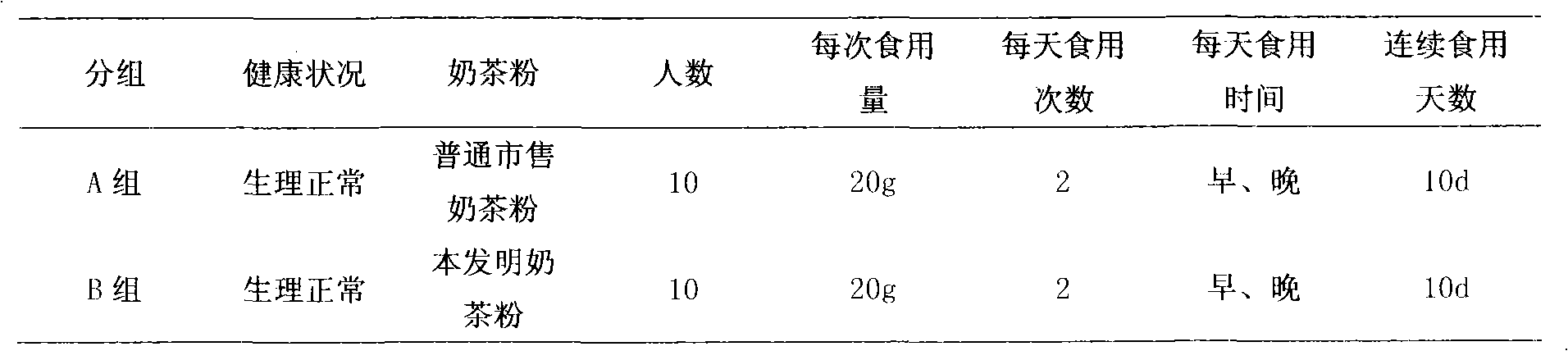

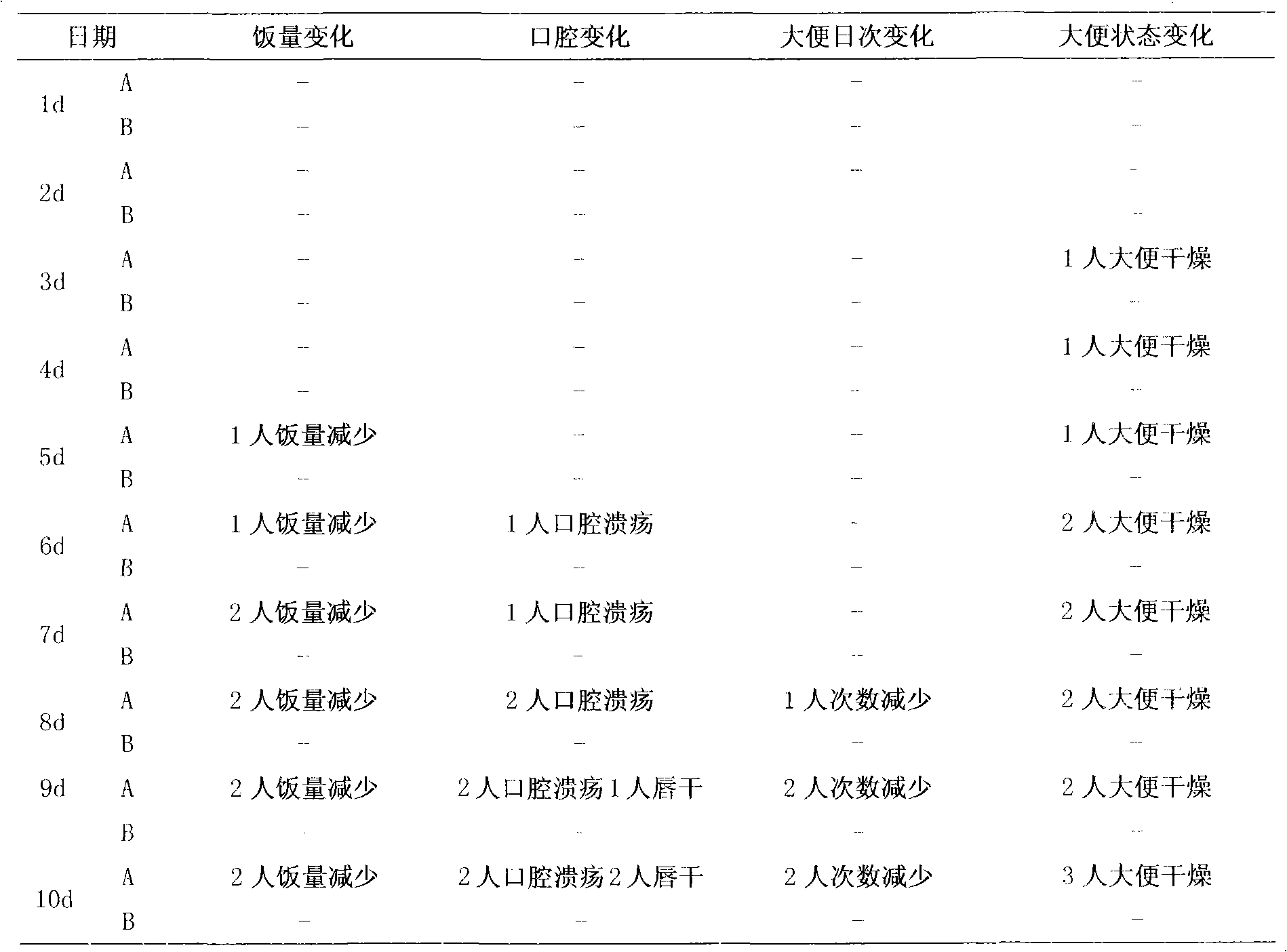

Functional milky tea powder and preparation method thereof

ActiveCN101810223AStrong targetingImprove immunityMilk preparationPre-extraction tea treatmentToxic materialDigestion

The invention discloses functional milky tea powder and a preparation method thereof. The functional milky tea powder is characterized by containing or being strengthened with various nutrients such as taurine, magnesium, zinc, vitamins and the like and integrating various functions of clearing away heat and toxic materials, preventing dental ulcers, invigorating stomachs and promoting digestion, loosening bowels and relieving constipation, lowering blood fat, blood pressure and blood sugar, losing weight, resisting fatigue and the like. The invention has the advantages that the preparation method creatively enables the milky tea powder to be subdivided, has reasonable proportioning, strong pertinence and obvious synergy function and fills the market blank; and the milky tea powder has the characteristics of the mellow and smooth taste of milk, the delicate fragrance of tea and the like and has the advantages of convenient edibility and carrying, simple production process, easy production and very great market development potential.

Owner:呼伦贝尔海乳乳业有限责任公司

Super-pure electro-slag remelting method for super-invar alloy

ActiveCN102127652AHigh purityImprove tissue uniformityIncreasing energy efficiencyMolten stateInvar alloy

The invention discloses a super-pure electro-slag remelting method for a super-invar alloy, which comprises the following steps of: a) preparing a self-melting electrode rod, namely performing vacuum induction melting on the components of the self-melting electrode rod of the super-invar alloy: 32 to 34 weight parts of Ni, 3.5 to 5.5 weight parts of Co and 60.5 to 64.5 weight parts of Fe, and casting to obtain a round rod, namely the self-melting electrode rod for electro-slag remelting; and b) performing electro-slag remelting, namely heating slag for electro-slag remelting, which is prepared from 40 to 85 weight parts of CaF2, 10 to 30 weight parts of GaO2 and 30 to 5 weight parts of Al2O3 into a melted state, pouring into a crystallizer, descending the self-melting electrode rod into the melted slag for electro-slag remelting, ensuring that liquid drops of the melted self-melting electrode rod pass through the melted slag layer and react with the slag, recrystallizing purified steel liquid at the bottom of the crystallizer to obtain an electro-slag ingot, forging to obtain a black rod, and performing solid solution and stabilization treatment to obtain the super-invar alloy. The purity of the super-invar alloy is improved, the structure is optimized, the thermal expansion coefficient is smaller, the processability of the alloy is improved, and the yield of a product is greatly improved.

Owner:CHONGQING MATERIALS RES INST

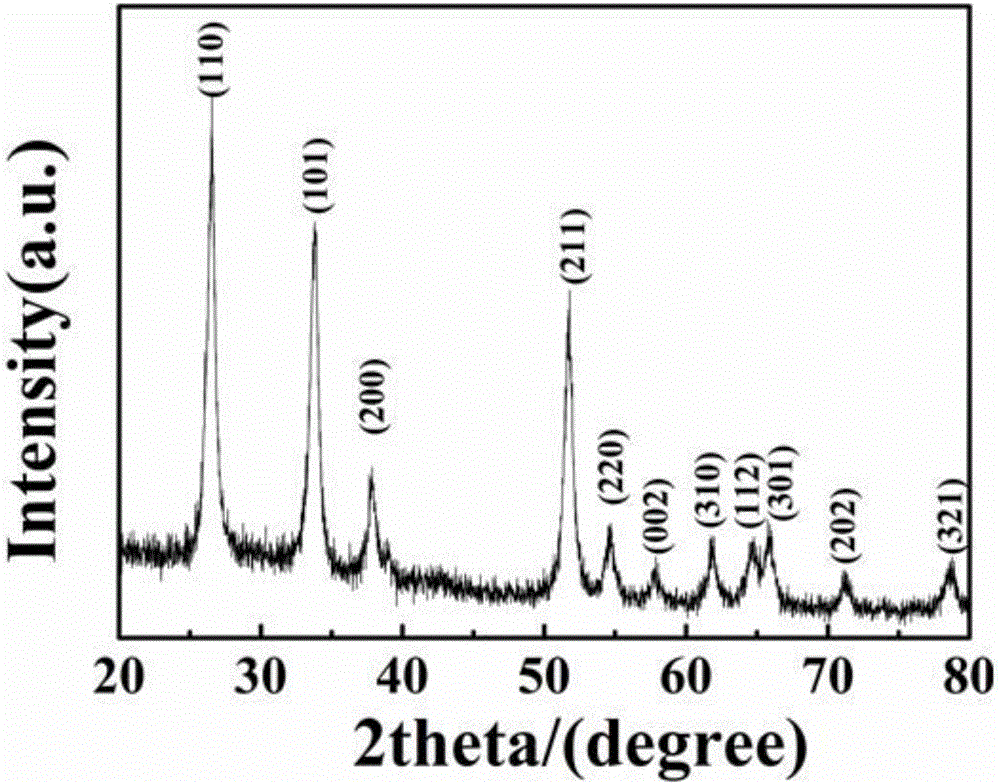

Preparation method of perovskite crystal nanowire

The invention discloses a preparation method of a perovskite crystal nanowire. Firstly perovskite nano-particles are synthesized and dissolved in an organic solvent and evenly stirred, the solution isdropped on a substrate of 80-150 DEG C so that the solvent is enabled to be rapidly evaporated and the perovskite nano-particles are enabled to be evenly adhered on the substrate, then the substrateis arranged in an enclosed culture dish so that the perovskite nano-particles are enabled to be exposed in the saturated vapor pressure environment of good solvent for culturing 1-15 days under the temperature of 10-50 DEG C, and the perovskite crystals grow along the one-dimensional direction so as to obtain the nanowire material. The method comprises the process of rapid precipitation of the nanocrystals in solvent evaporation under high temperature and the process of self-assembling of the nanocrystals occurred in the culture dish under the saturated vapor pressure. The size of the perovskite nanowires changes along with the change of the culture time, the hydrophilic-hydrophobic property of the substrate material and the culture temperature.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

Rolling method for producing copper clad aluminum row

InactiveCN101645333ASave resourcesShort processSingle bars/rods/wires/strips conductorsRoll mill control devicesLimited resourcesNitrogen

The invention discloses a rolling method for producing a copper clad aluminum row, which comprises the following steps: 1, selecting a copper pipe with uniform wall thickness and an aluminum bar in transition fit with the inner wall of the copper pipe, and cleaning the copper pipe and the aluminum bar to remove oil stains and oxidation layers; 2, pressing the aluminum bar into the copper pipe to form a composite blank, and plugging two ends of the composite blank tightly; 3, heating the composite blank to between 300 and 540 DEG C, preserving the heat for 30 to 60 minutes, then thermally rolling the composite blank for 1 to 3 times, and coldly rolling the composite blank for 1 to 4 times; 4, straightening and acid-washing a rolled product; 5, carrying out diffusion treatment at the temperature of between 200 and 550 DEG C under the protection of nitrogen of one atmospheric pressure, and preserving the heat for 1 to 3 hours; and 6, drawing the treated product to form a final product. The rolling method for producing the copper clad aluminum row not only has short process flow and high production efficiency, but also can save limited resources and reduce the cost.

Owner:厦门火炬特种金属材料有限公司

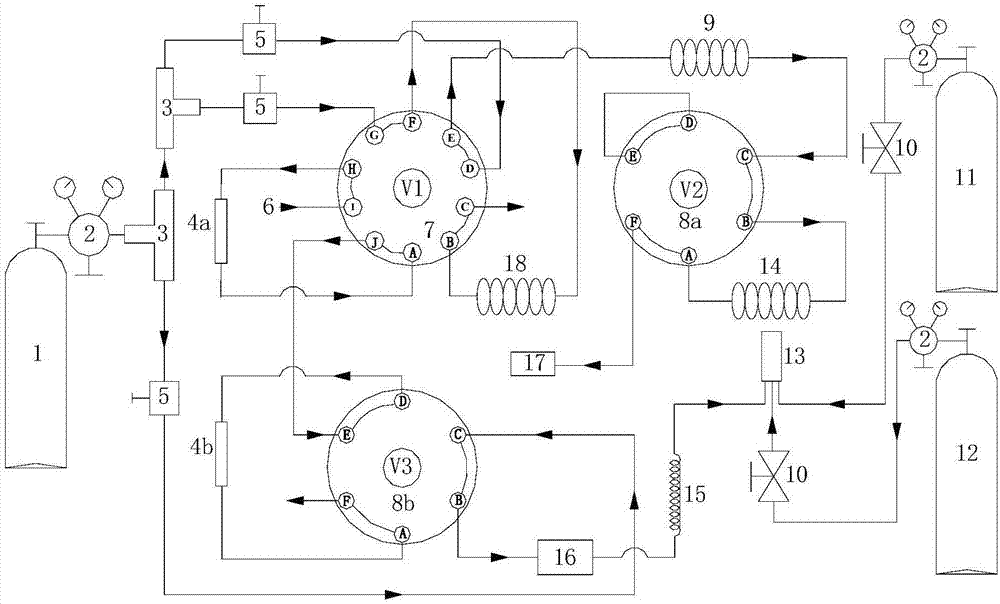

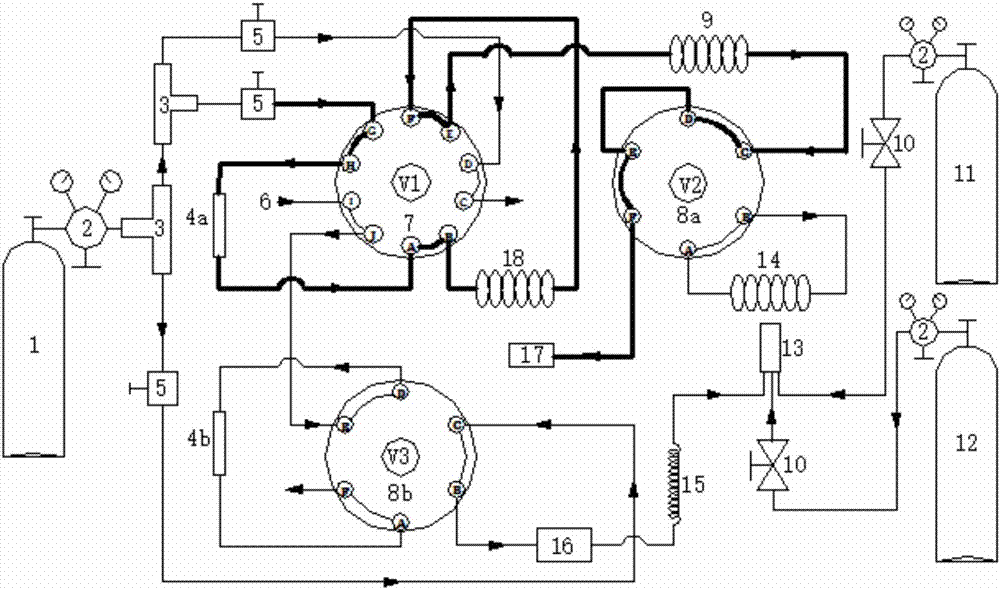

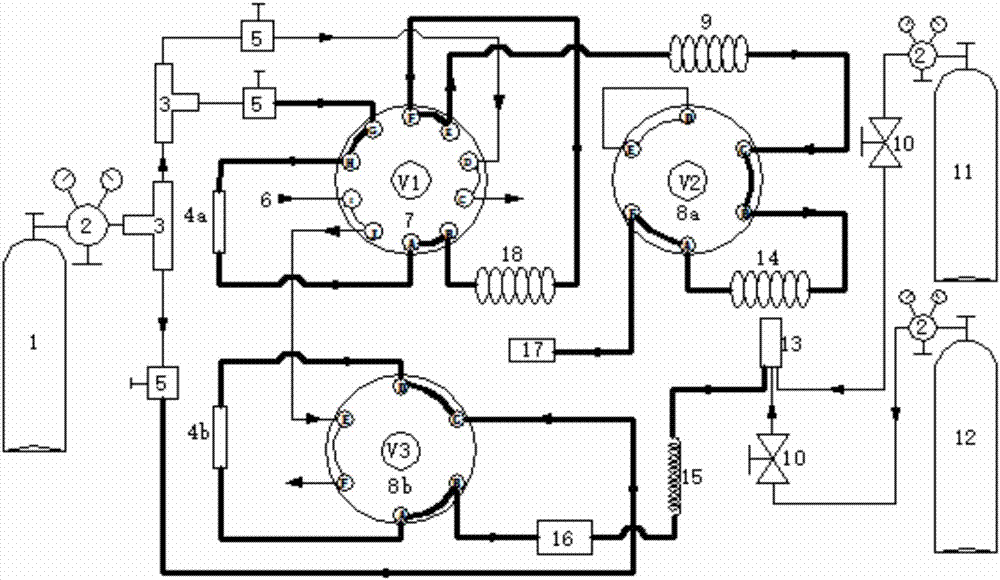

Quick analysis method of fuel gas component and gas chromatography system thereof

ActiveCN107271597AImprove work efficiencyThe result is high sensitivityComponent separationGas phaseGas liquid chromatographic

The invention discloses a gas chromatography system containing four pillars, three valves and double detectors, and a method for quick analysis of multiple fuel gases by the system. Only by one sampling, analysis of light hydrocarbon, heavy hydrocarbon and inorganic gas in every fuel gas can be rapidly completed. After sampling, a ten-way valve is switched to an analysis state, and a sample in a first sample pipe enters a SE-30 column; after inorganic gas and light hydrocarbon flow out, the ten-way valve is switched again to reversely blow the heavy hydrocarbon in the column out of the SE-30 column; inorganic gas and light hydrocarbon enter the PQ column again, carbon dioxide flows out firstly, and the other inorganic gas and light hydrocarbon flowed out latter enter a 5A chromatographic column and then orderly enter TCD (thermal conductivity detector) to detect. A sample in the second sample tube enters the Al2O3 column and then enters FID to realize the separation and testing of the heavy hydrocarbon component. The inorganic gas, the light hydrocarbon, heavy hydrocarbon of multiple fuel gases are effectively separated, and three sets of data are assembled on one spectrogram, thus the fuel gas component analysis and calorific value are quickly completed through one sampling.

Owner:SOUTHWEST RES & DESIGN INST OF CHEM IND

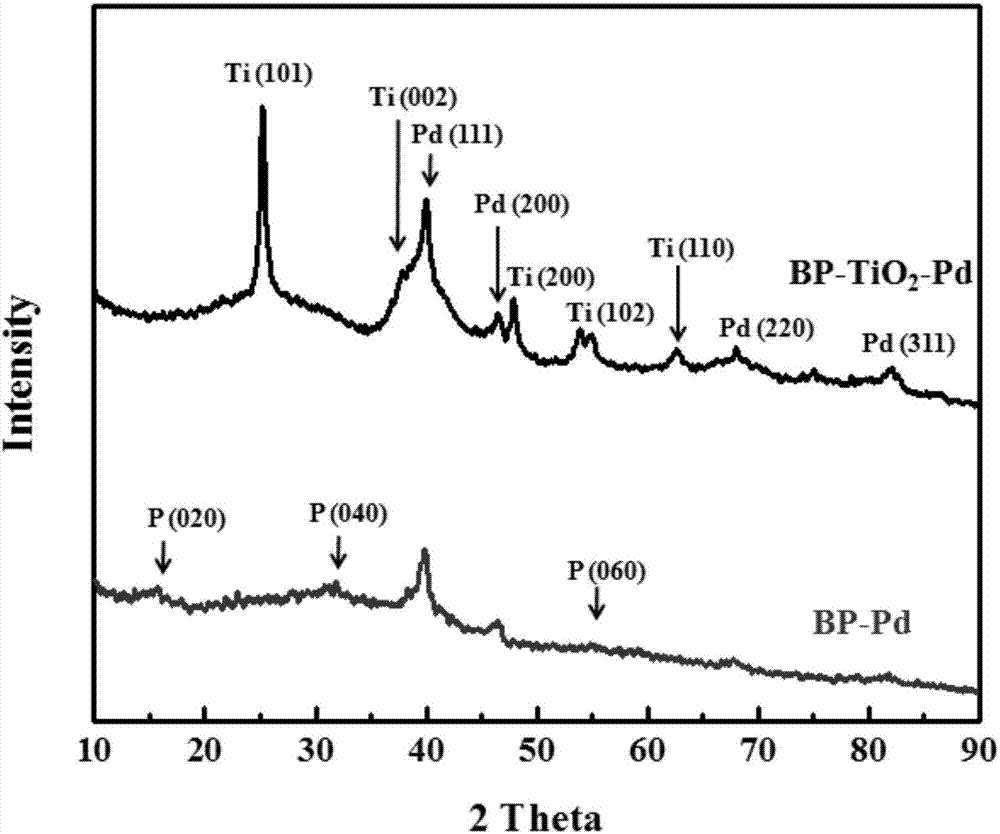

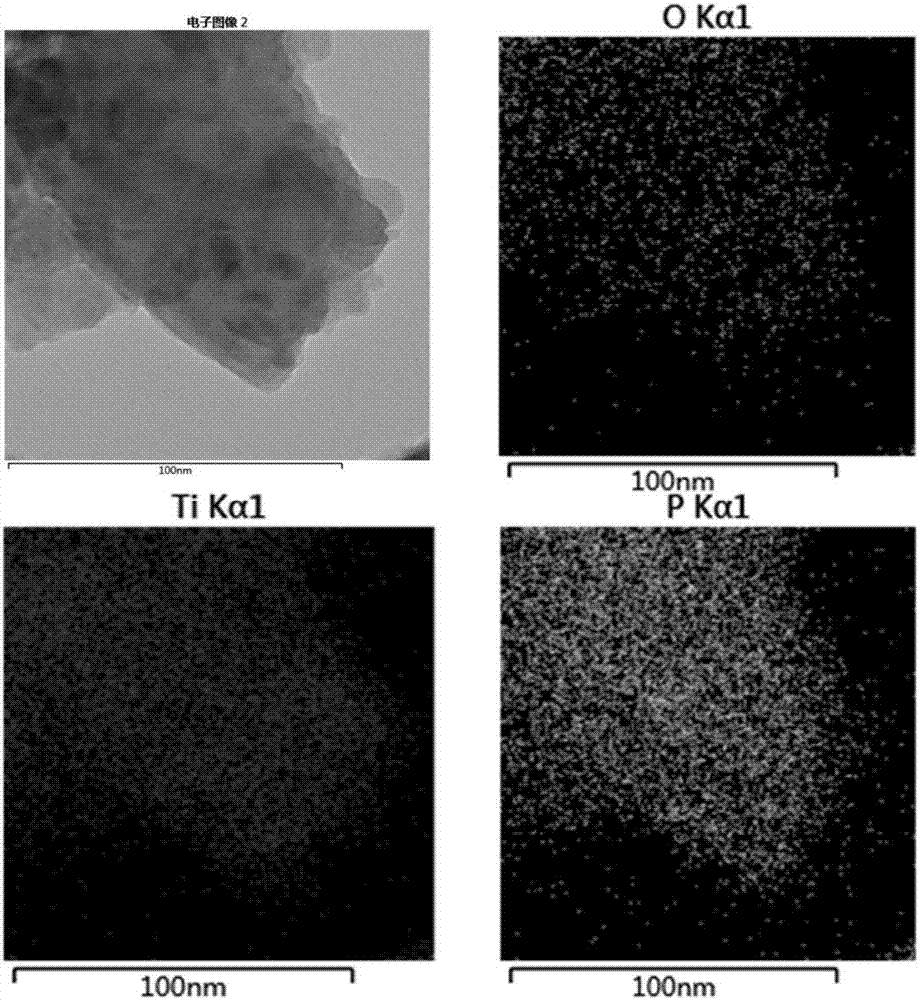

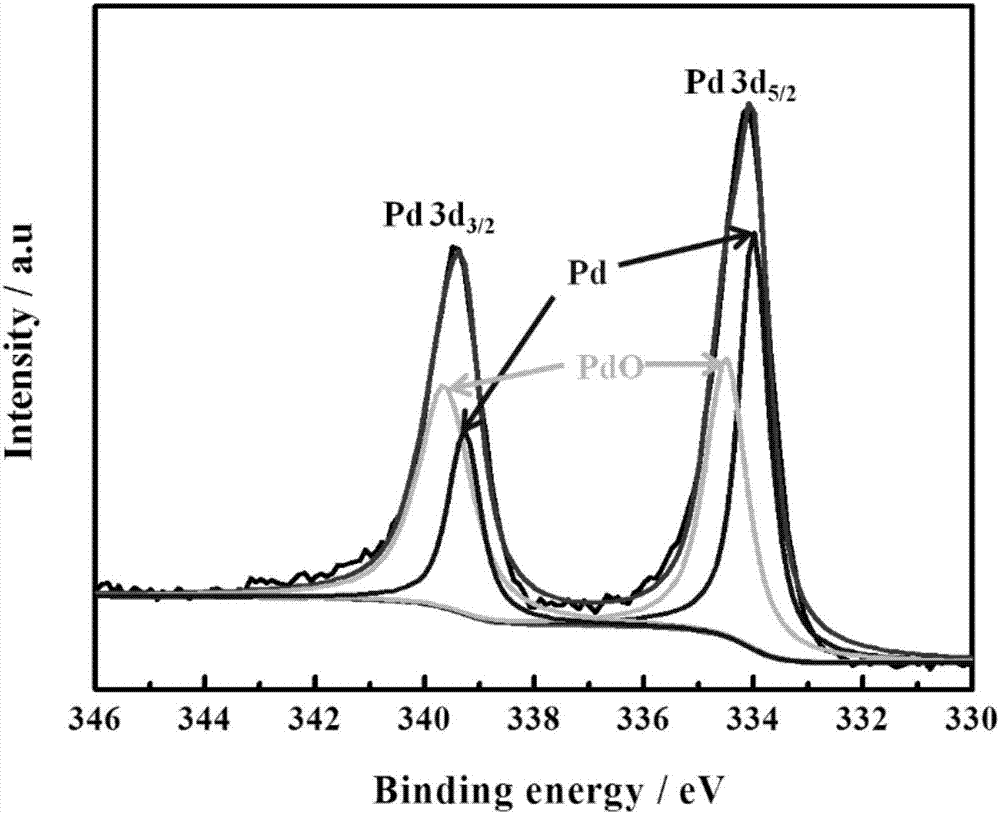

Preparation method of black phosphorus TiO2 heterojunction structure material loaded precious metal nanoparticle

The invention provides a preparation method of a black phosphorus TiO2 heterojunction structure material loaded precious metal nanoparticle. The preparation method comprises the steps of preparing a black phosphorus TiO2 heterojunction structure material, in which a black phosphorus nanosheet layer material and a TiO2 nanosheet layer material are ball-milled under argon protection, the black phosphorus nanosheet layer material and the TiO2 nanosheet layer material are respectively washed with ethanol and water, and the black phosphorus TiO2 heterojunction structure material is obtained by suction filtration, is dried in vacuum and is collected; and dispersing the black phosphorus TiO2 heterojunction structure material in the ethanol, adding a stabilizer and a metal precursor after ultrasonic processing, continuing to perform ultrasonic stirring, adjusting pH to 9-11, adding a reducing agent, continuing to stir, and obtaining the black phosphorus TiO2 heterojunction structure material loaded precious metal nanoparticle after vacuum drying. The black phosphorus TiO2 heterojunction structure material carrier is combined with precious metal better, and the electrochemical activity and the stability of a fuel cell catalyst are effectively improved; and moreover, the preparation process is easy to operate and is suitable for production on a large scale.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

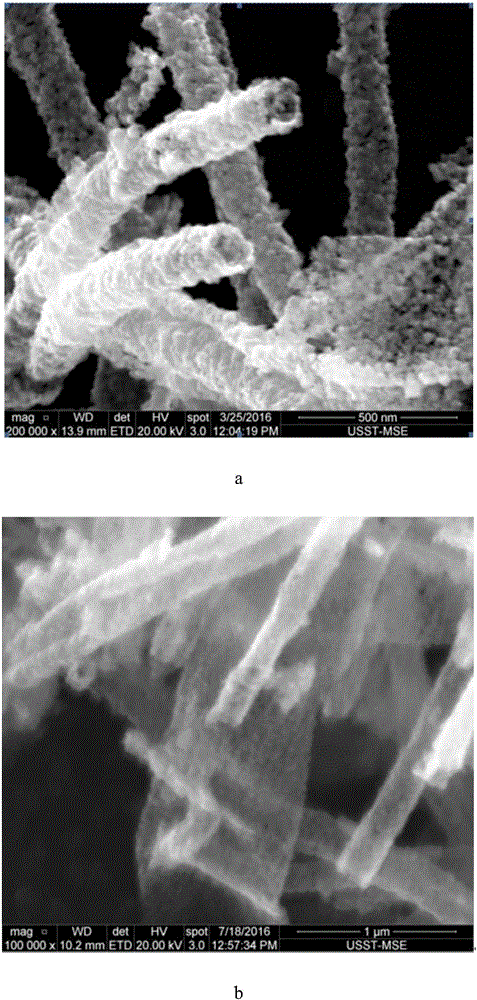

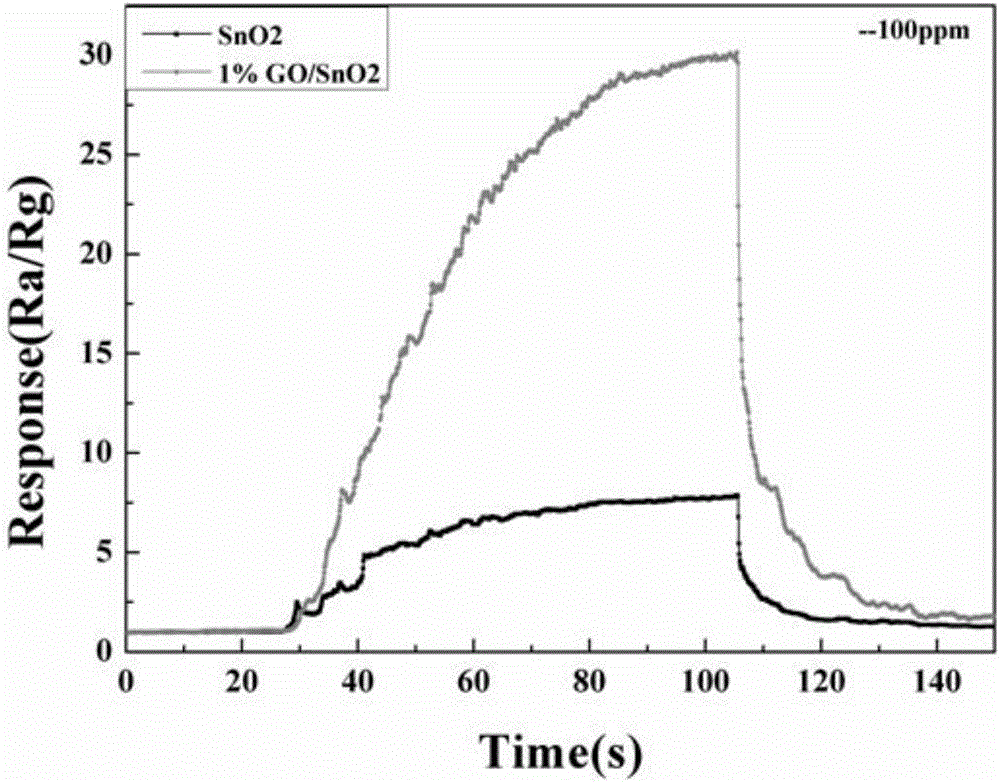

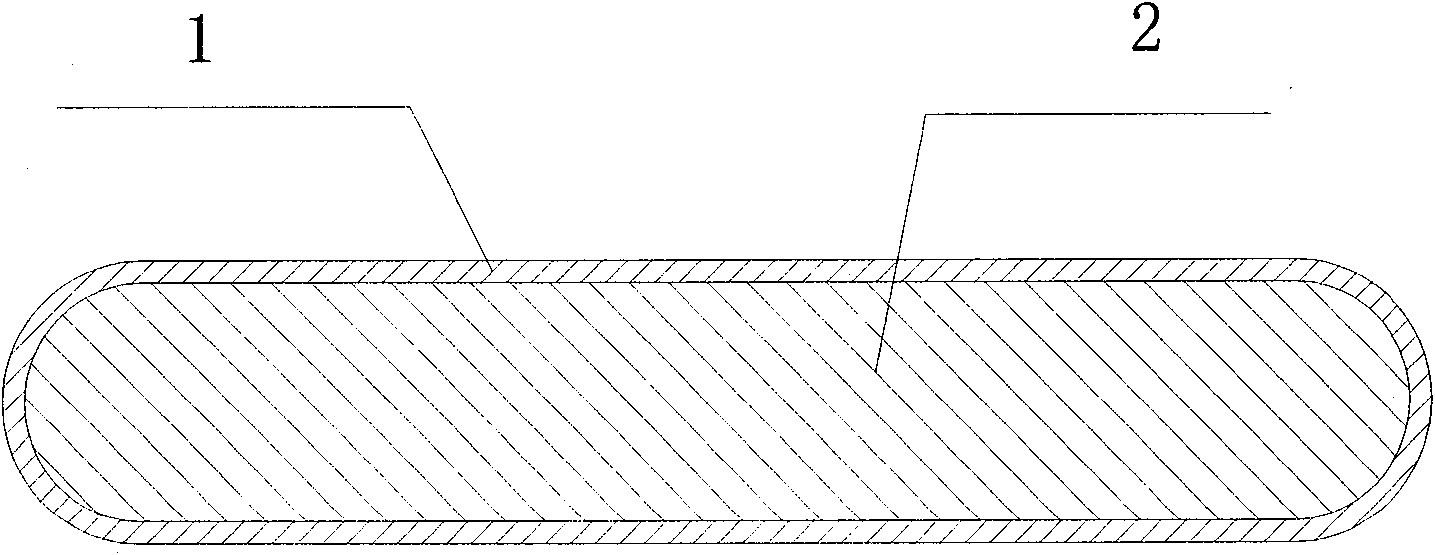

Gas-sensitive material for detecting formaldehyde gas and preparation method

The invention provides a gas-sensitive material for detecting formaldehyde gas. The gas-sensitive material is prepared by compounding hollow tin oxide nano-fibers and graphene oxide. The graphene oxide accounts for 0.5-5% of the gas-sensitive material by mass, and the balance is the hollow tin oxide nano-fibers. The invention further provides a gas-sensitive element. The gas-sensitive element comprises a semiconductor element, and the surface of the semiconductor element is evenly coated with the gas-sensitive material. The invention further provides a preparation method of the gas-sensitive material. The hollow tin oxide nano-fibers are firstly prepared through an electrostatic spinning method, a graphene oxide solution is prepared, an equivalent-volume impregnation method is adopted, the prepared graphene oxide solution and the prepared hollow tin oxide nano-fibers are mixed, absolute ethyl alcohol is added, and the materials are ground to obtain pulp, namely, the gas-sensitive material. The semiconductor element is coated with the pulp, and the gas-sensitive element is prepared. The prepared gas-sensitive element has the advantages of high sensitivity to the formaldehyde gas, good selectivity to interfering gas, good stability and low working temperature, and can be used for indoor and outdoor formaldehyde concentration detection.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

Extrusion rolling composite method for producing copper clad aluminum row

InactiveCN101645334ASave resourcesShort processSingle bars/rods/wires/strips conductorsRoll mill control devicesLimited resourcesNitrogen

The invention discloses an extrusion rolling composite method for producing a copper clad aluminum row, which comprises the following steps: 1, selecting a copper pipe with uniform wall thickness andan aluminum bar in transition fit with the inner wall of the copper pipe, and cleaning the copper pipe and the aluminum bar to remove oil stains and oxidation layers; 2, pressing the aluminum bar intothe copper pipe to form a composite blank, heating the composite blank to between 400 and 540 DEGC, preserving the heat for 30 minutes, and then extruding the composite blank to form a copper clad aluminum row semi-finished product through a horizontal extruder; 3, heating the semi-finished product to between 300 and 540 DEG C, preserving the heat for 30 to 60 minutes, and then thermally rollingand coldly rolling the semi-finished product; 4, straightening and acid-washing the semi-finished product; 5, carrying out diffusion treatment for the copper clad aluminum row at the temperature of between 200 and 550 DEG C under the protection of nitrogen of one atmospheric pressure, and preserving the heat for 1 to 3 hours; and 6, drawing the copper clad aluminum row to form a final product. Theextrusion rolling composite method for producing the copper clad aluminum row not only has short process flow and high production efficiency, but also can save limited resources and reduce the cost.

Owner:厦门火炬特种金属材料有限公司

Chicken manure organic fertilizer and production method thereof

InactiveCN101723714APromote absorptionLow costBio-organic fraction processingClimate change adaptationMicroorganismOxygen

The invention discloses a chicken manure organic fertilizer and a production method thereof. The chicken manure organic fertilizer is produced by the following raw materials of fresh chicken manure with 75-80% of water content, power straw mixture with 2-5% of water content and high-efficiency decomposed bacteria according to the weight ratio of 80-88:10.5-19.5:0.5-1.5. The preparation method of the high-efficiency decomposed bacteria comprises the following steps: weighing chicken manure which contains 25-35% of water content and is piled and stored for 30-60 days; adding 0.3-0.7wt% of agar, 0.3-0.7wt% of beef extract, 1-3wt% of brown sugar and 1-3wt% of fried bean flour, wherein, the agar and the beef extract are used after being dissolved by boiling with hot water; evenly mixing the above materials; adjusting the water content to be 50-60%; adjusting the pH value to be 5-8; improving the temperature to be 50-65 DEG C; introducing oxygen to lead the oxygen concentration to reach 18-19%; manually turning over once at every two hours; and taking out 5 days later. The chicken manure organic fertilizer of the invention is easily absorbed and utilized by plants, contains various multi-functional microorganisms and rich organic matters, and has low cost and quick effect.

Owner:GUIZHOU LIUJIANG ANIMAL & POULTRY

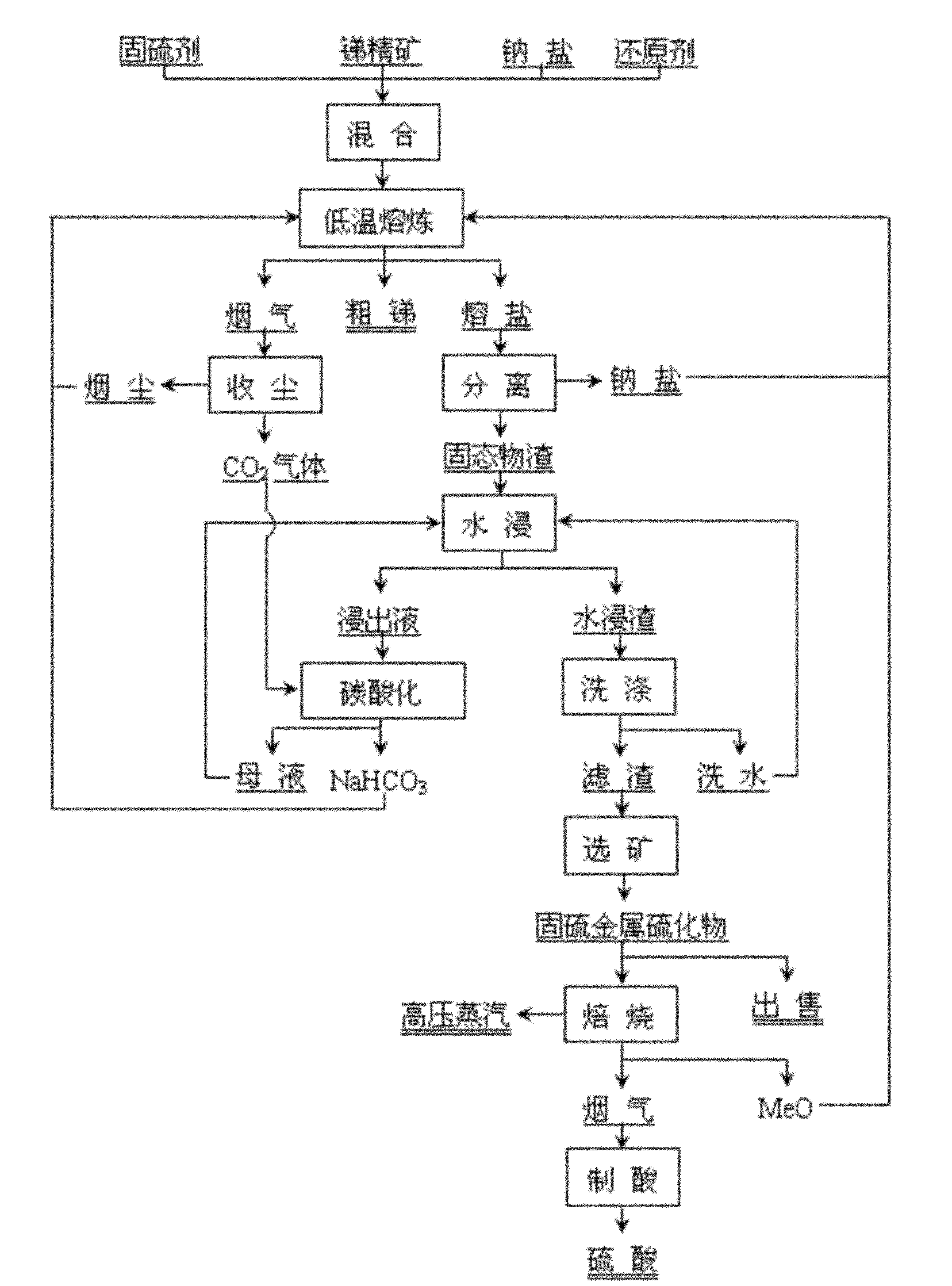

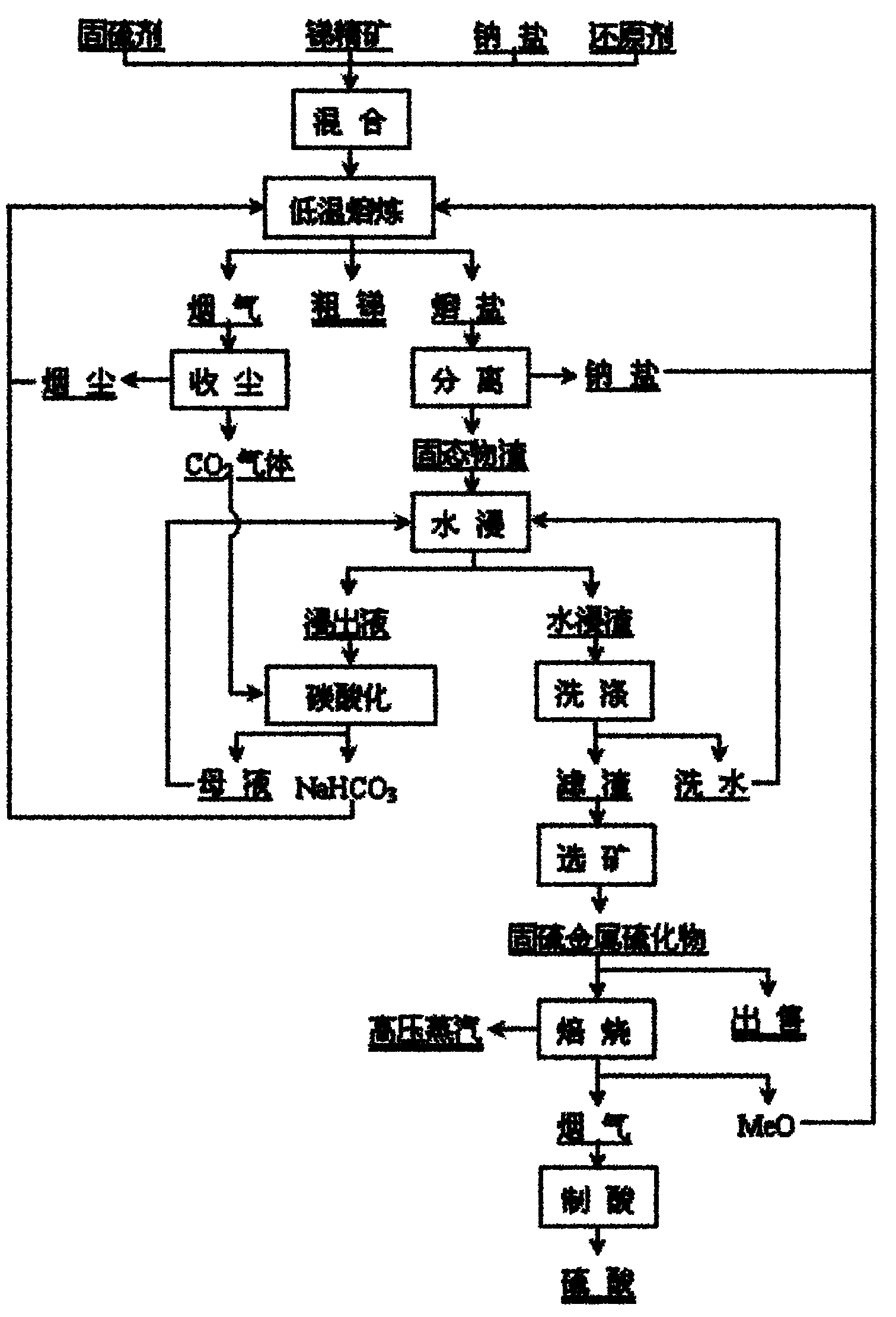

Clean metallurgical method for low-temperature molten salt of antimony

InactiveCN101914693ALower the smelting temperatureImprove direct yieldProcess efficiency improvementSlagSulfide

The invention discloses a clean metallurgical method for low-temperature molten salt of antimony, and belongs to the metallurgical field of non-ferrous metals. The method is characterized by comprising the following steps of: performing reductive sulfur-fixing melting on antimony concentrate and oxide of metal with higher sulfur affinity compared with the antimony in low-temperature inert molten salt to generate liquid metal antimony and sulfur-fixed metal sulfide, and forming molten salt slag by using the sulfur-fixed metal sulfide and non-reacted substances as solid substances; and separating most inert molten salt from the solid substances and then thermally returning the most inert molten salt to the melting process, regenerating NaHCO3 for recycling by using the molten salt slag through a 'water leaching-carbonated precipitation' process, reclaiming the sulfur-fixed metal sulfide concentrate for selling from the leached residue by ore dressing, or performing roasting desulfuration on the leached residue for heat energy utilization and smoke acid making, and returning oxide roasting sand serving as a sulfur-fixing agent to the melting process. The method greatly reduces the antimony melting temperature, produces the crude antimony at one step, realizes reclamation of sulfur and energy utilization of sulfide, thoroughly eliminates environmental pollution of low-concentration SO2 smoke at the same time of simplifying the flow, reducing the cost and greatly improving the direct yield of the antimony, and has the advantages of low carbon, cleanness and high efficiency.

Owner:CENT SOUTH UNIV

High-performance transparent ceramic whiteware glaze and production method thereof

ActiveCN107162424AImprove thermal shock resistanceHigh melting temperatureMaterials preparationKaolin clay

The invention discloses a high-performance transparent ceramic whiteware glaze and production method thereof, and belongs to the technical field of daily ceramic glazes. The high-performance transparent ceramic whiteware glaze mainly comprises water-milled potassium feldspar, kaolin, calcined talcum, dolomite, barium carbonate, calcined zinc oxide, water-milled quartz, a glaze stabilizer and an expansion coefficient regulator. The production method of the high-performance transparent ceramic whiteware glaze includes the following steps: material preparation, ageing and glaze firing. The high-performance transparent ceramic whiteware glaze produced from the above raw materials has the advantages of high melting temperature, wide melting temperature range of 1290-1330 DEG C, small affection by the fluctuation of the kiln temperature, few pinholes of the glaze surface, bright and smooth glaze surface, adjustable expansion coefficient of the glaze surface, and increase of one stress to the surface of a ceramic body to realize no cracking in the 200-20 DEG C one-shot quick cooling and heating process.

Owner:FUJIAN DEHUA FIVE CONTINENTS CERAMIC MFG CO LTD

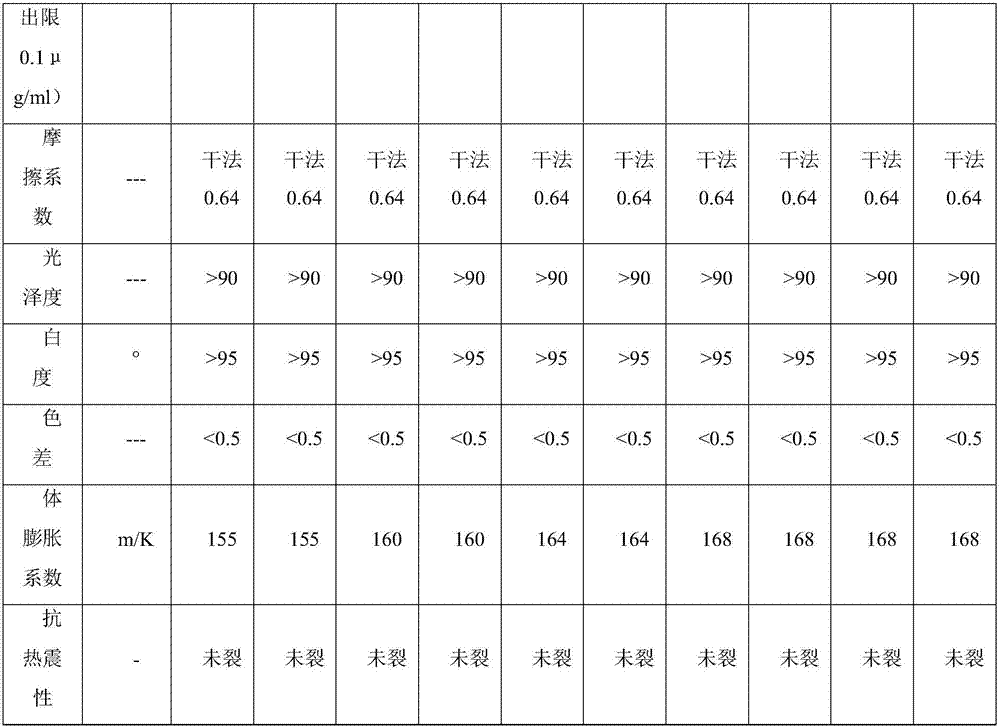

Composition capable of adjusting structure of intestinal floras and preparation method and applications thereof

ActiveCN106942724ASave time and costSafe and effective intestinal bacteria structureDigestive systemNatural extract food ingredientsDiseaseGut flora

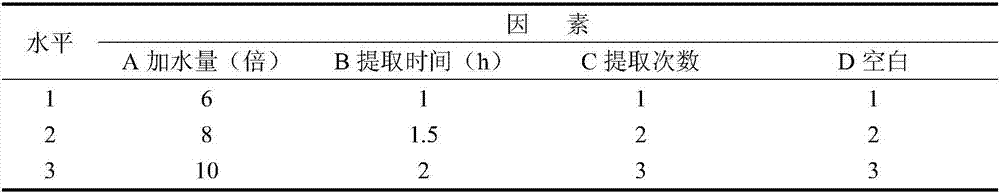

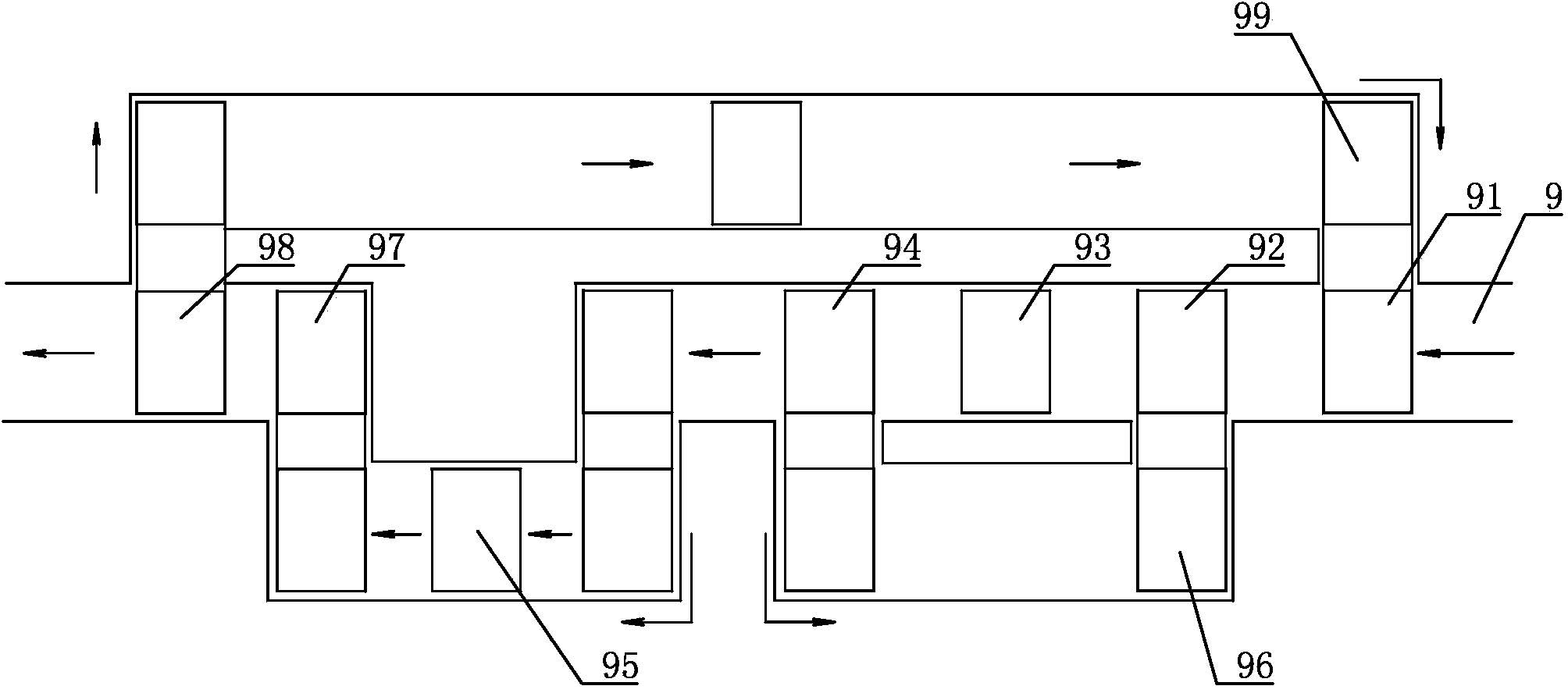

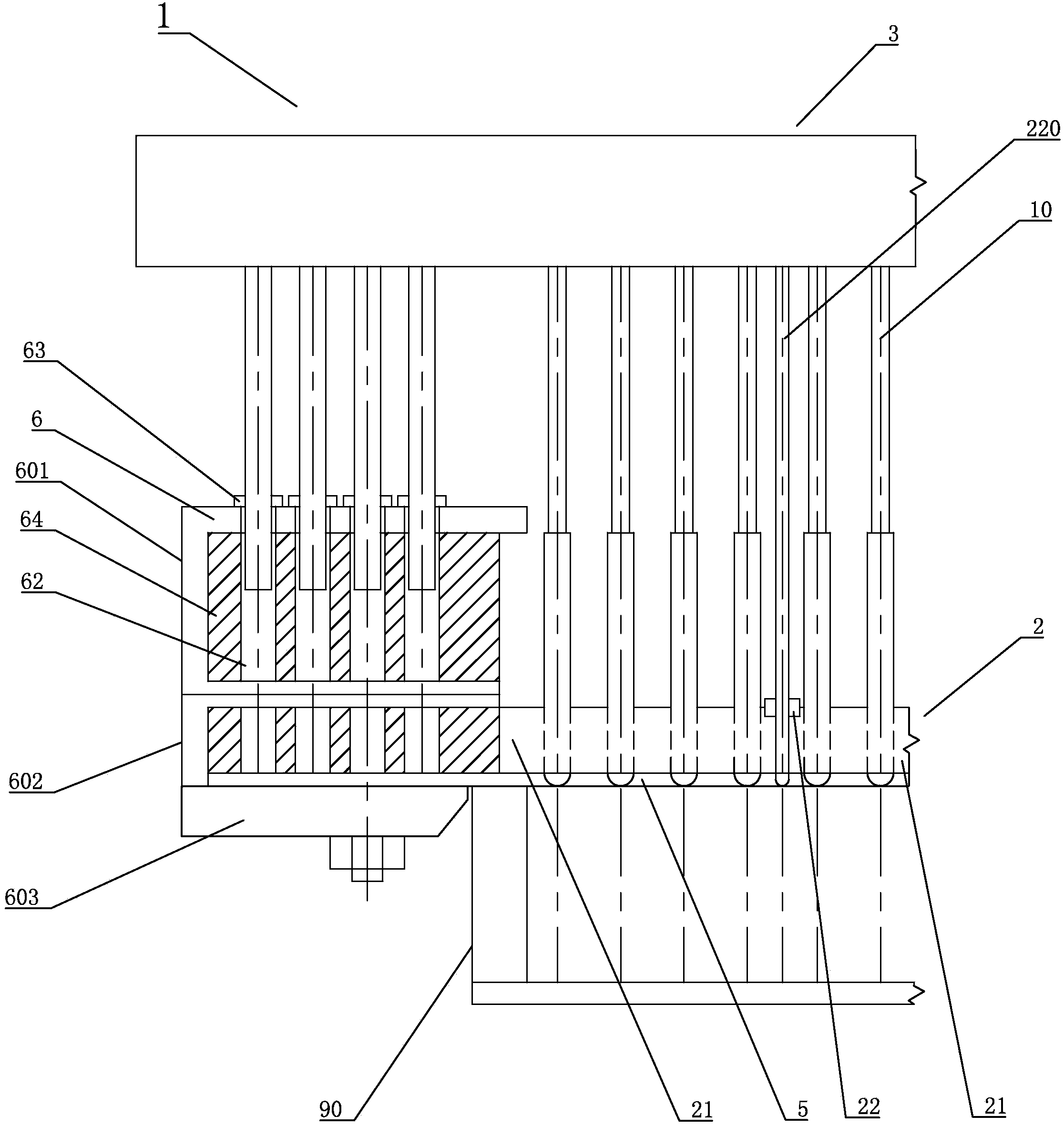

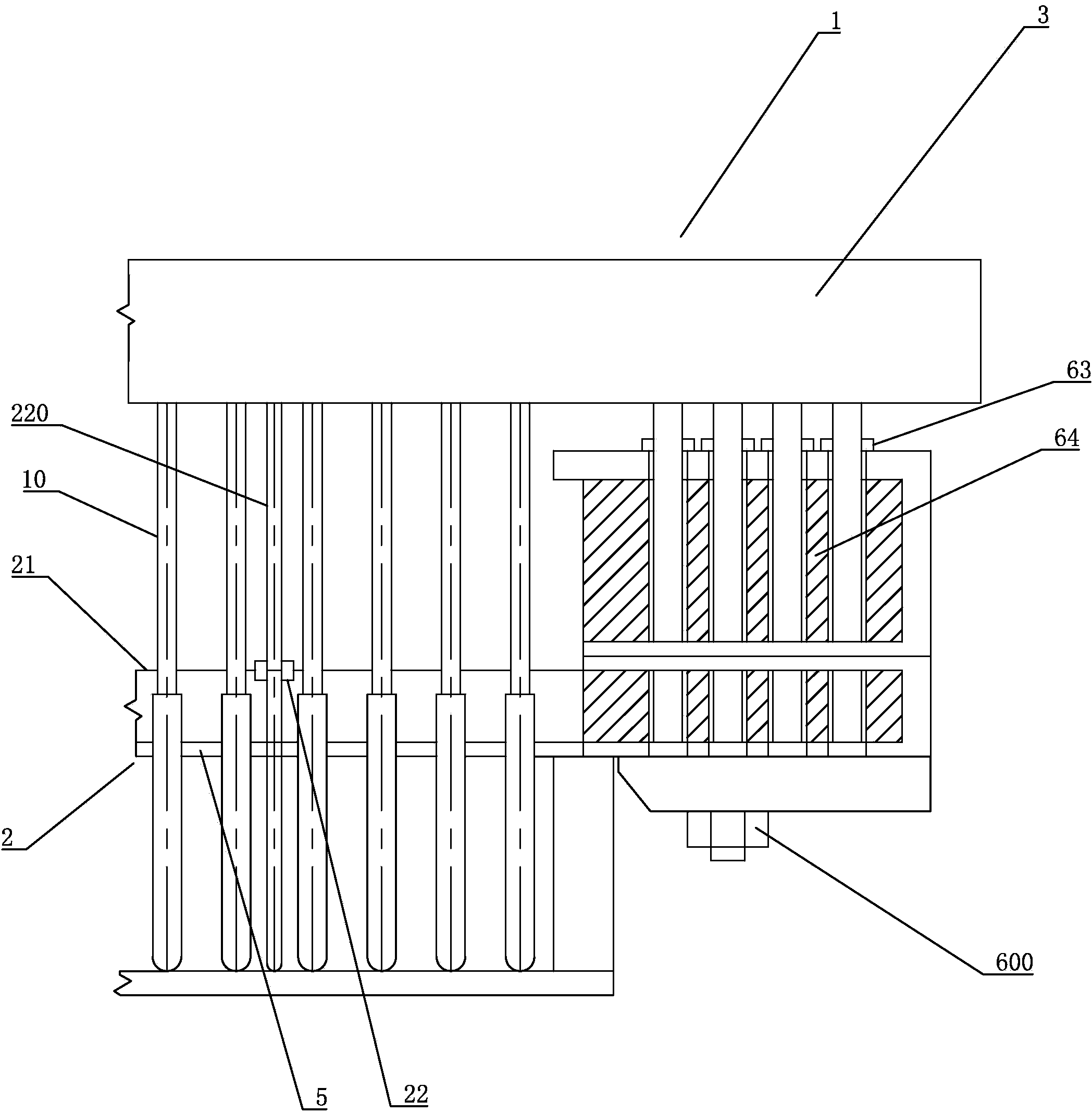

The invention discloses a composition capable of adjusting the structure of intestinal floras and a preparation method thereof. The composition is prepared from the following raw materials in parts by weight: 4 to 20 parts of radix rehmanniae, 1 to 5 parts of poria cocos, and 0.1 to 3 parts of ginseng. The provided composition is made of pure natural plants. The optimal formula is obtained through a large amount of tests and a selected modern preparation technology. The test results show that the provided composition can obviously increase the number of beneficial bacteria such as lactobacillus, bifidobacteria, and the like, at the same time, can inhibit the growth of escherichia coli, enterococcus, and clostridium perfringens in the intestinal tracts, is capable of well regulating the intestinal tracts and treating intestinal diseases (constipation, abdominal distension, diarrhea, etc.), has a health care function, is very safe, and does not have any side or toxic effect.

Owner:JIANGSU PROVINCE INST OF TRADITIONAL CHINESE MEDICINE

Method for producing optical variable device (OVD) two-dimensional code hot stamping foil through aluminum washing process

ActiveCN102700285AWith compound anti-counterfeiting functionIncrease production speedDuplicating/marking methodsPattern printingLaser etchingHot stamping

The invention provides an anti-fake mark production method which enables two-dimensional codes and optical variable device (OVD) positioning hot stamping foil to be combined to be applied, carries out further treatment on parts of the OVD positioning hot stamping foil undergoing aluminum washing and reinforces composite multiple anti-fake function of anti-fake marks. The production method aims at overcoming the shortcomings that in the prior art, anti-fake marks prepared through a laser etching or aluminum washing process are single in anti-fake function, process equipment is complex, production efficiency is low, and equipment investment is large, and the like. The production method improves efficiency on the basis of traditional laser etching production. Besides, due to the fact that the requirements of the method for equipment, plants and staff configuration are simple, the investment is small, the difficulty in expanding production scale is low, and the method is favorable for popularizing and improving an anti-fake technology of products and promotes technical progress of the anti-fake printing industry. The adopted technical scheme is that the method comprises coating of a release layer and an information layer, die pressing, printing of protecting gloss oil, positioning printing of aluminum washing ink in a code-varying code-spraying mode, vacuum aluminizing, partial aluminum washing, application of gum and striping.

Owner:YUNNAN HOLOBEAM SECURITY TECH

Split inserting type hole forming die and device and automatic manufacturing method of perforated brick of split inserting type hole forming die

The invention discloses a split inserting type hole forming die which comprises an upper die and a lower die. The upper die is formed by arranging a plurality of insertion rod beams which are provided with hole forming insertion rods. The lower die comprises an insertion hole board, the two ends of the lower die are provided with side boxes for supporting, and guide rods are arranged on the insertion rod beams. Annular grooves are formed in the guide rods, and guide tubes are arranged in the side boxes. The top ends of the guide tubes are fixedly connected with clamping springs, and the upper die is supported through the clamping springs and the side boxes. The insertion rod beams are divided into more than two groups according to a downwards-moving order, and each group of the insertion rod beams comprises the plurality of insertion rod beams, the insertion rod beams of the same group are driven by the same pressure vibration table, and the rods are inserted into materials in batches to form holes. The split inserting type hole forming die is combined with a pole pulling device, and therefore the hole forming process of inserting the rods and pulling the rods out of a perforated brick can be finished. According to the split inserting type hole forming die, perforated brick products are more diverse, perforated bricks with smaller holes and higher hollow rates can be obtained, and in addition, the production efficiency is high, and the shapes of the holes are complete.

Owner:桂林市城昌建材科技有限公司

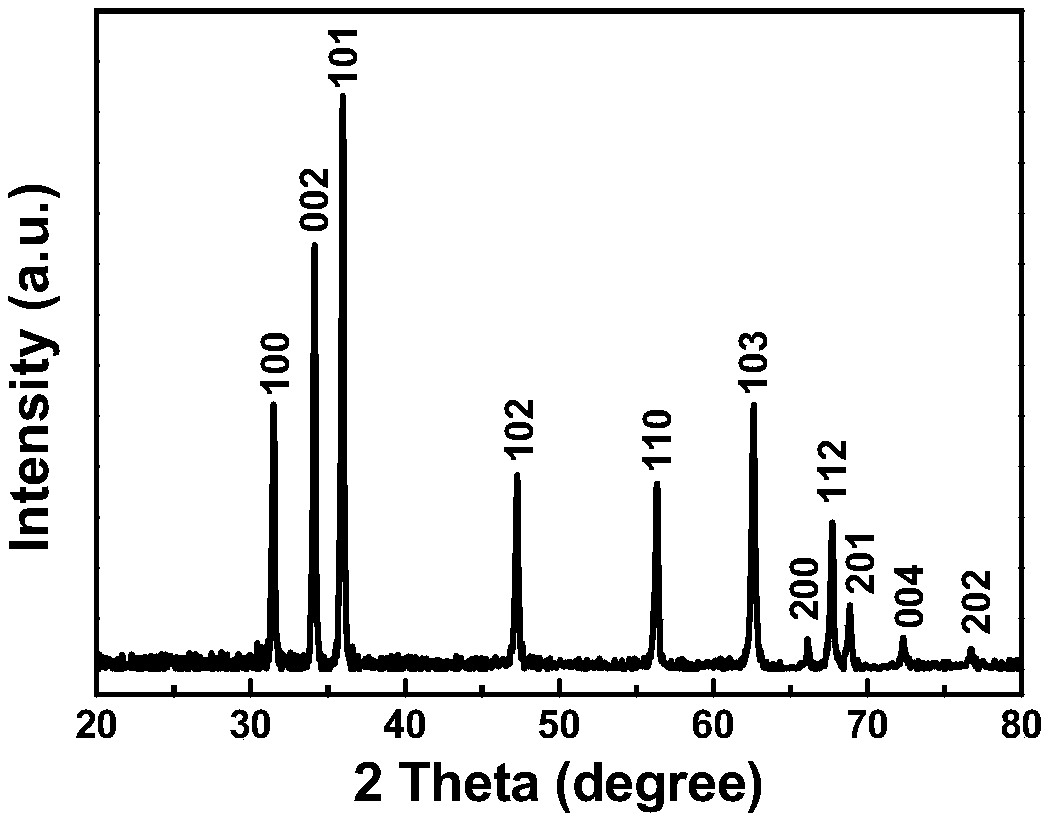

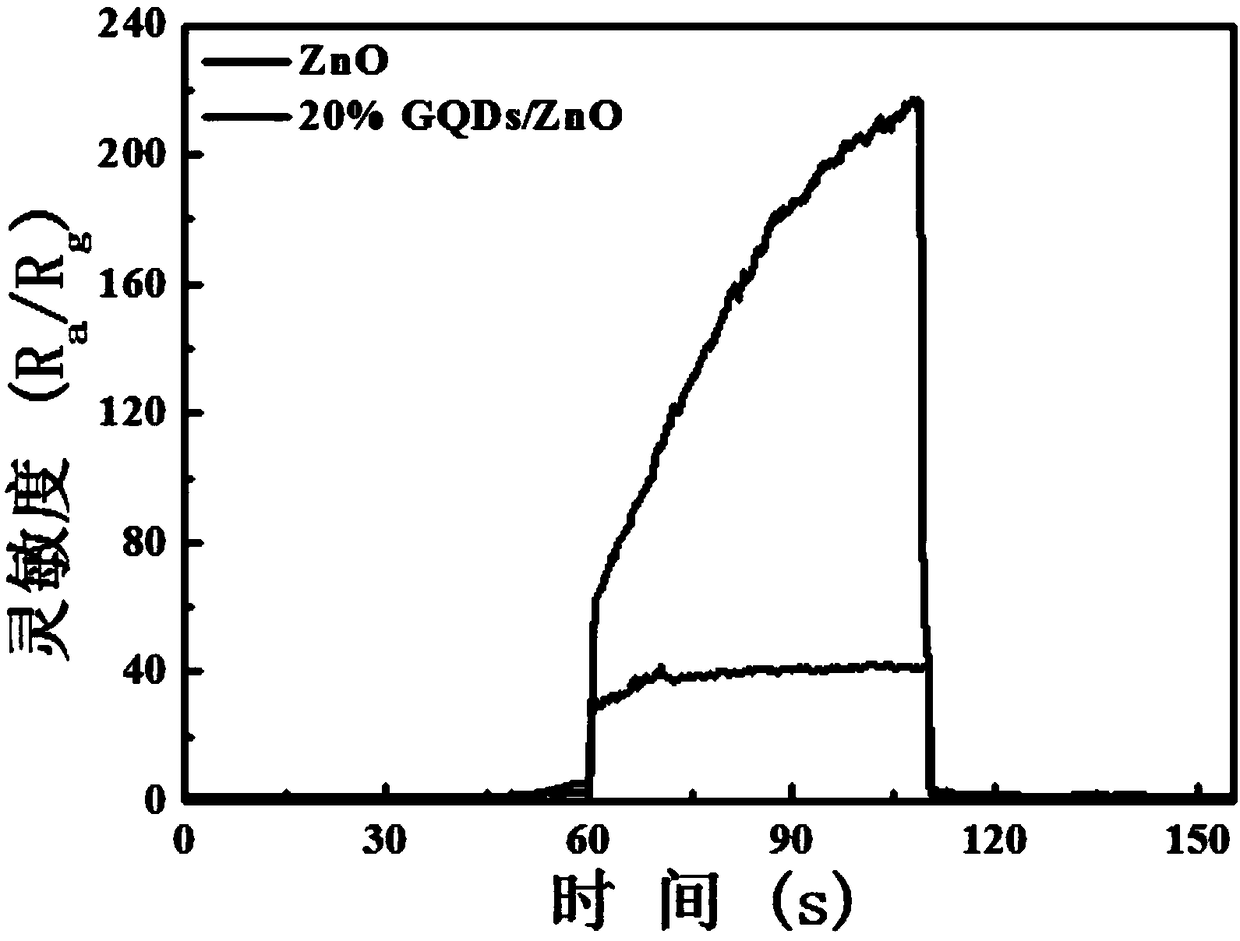

Composite gas-sensitive material used for detecting formaldehyde gas and preparation method thereof

InactiveCN108398408AReduce sensitivityHigh sensitivityFluorescence/phosphorescenceProduct gasCvd graphene

The invention provides a composite gas-sensitive material used for detecting formaldehyde gas. The composite gas-sensitive material is composited by a two-dimensional sheet metal oxide and a graphenequantum dot material, the two-dimensional sheet metal oxide accounts for 70-99.99% of mass percentage of the composite material, and the graphene quantum dot material accounts for 0.01-30% of mass percentage of the composite material. The invention also provides a preparation method of the composite gas-sensitive material used for detecting the formaldehyde gas. The invention provides a gas-sensitive element, which comprising a semiconductor element, and the surface of the semiconductor element is uniformly coated with the composite gas-sensitive material used for detecting formaldehyde gas. The invention also provides a preparation method of the above gas-sensitive element. The gas-sensitive element has the advantages of high sensitivity of formaldehyde gas, low operating temperature, good selectivity for interference gas, good stability, and low work temperature, and can be used for detecting formaldehyde gas under different occasions.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

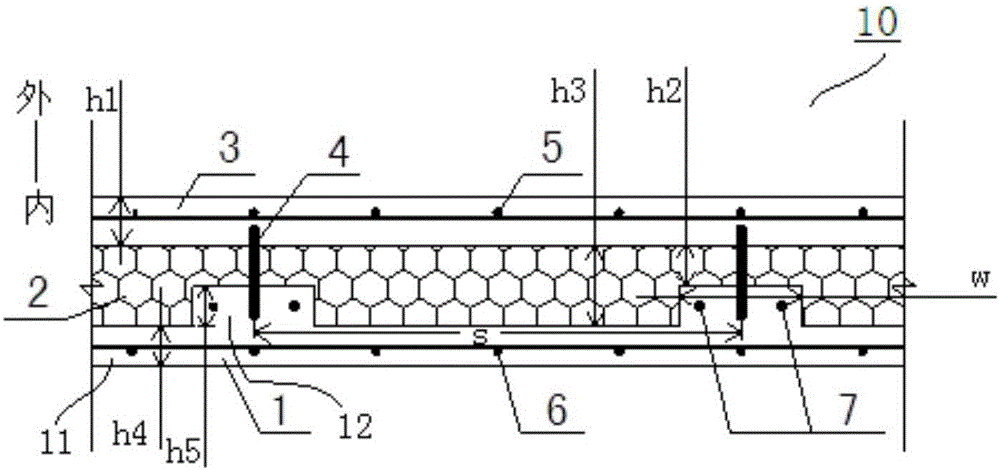

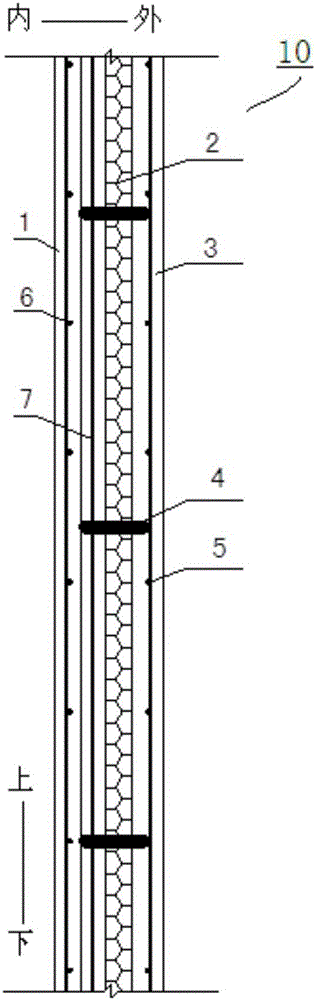

Precast concrete sandwich cladding wall panel provided with ribs

InactiveCN105971189AStable insulation systemImprove insulation effectBuilding componentsThermal insulationUltimate tensile strength

The invention discloses a precast concrete sandwich cladding wall panel provided with ribs. The precast concrete sandwich cladding wall panel sequentially comprises an inner vane board, a thermal insulation layer and an outer vane board from inside to outside, wherein the thermal insulation layer is arranged between the inner vane board and the outer vane board, and the inner vane board, the thermal insulation layer and the outer vane board are integrally connected through pulling parts; the inner vane board comprises a flange plate and the ribs arranged on the flange plate, and the ribs are arranged on one side, facing the outer vane board, of the inner vane board. In the embodiment, the inner vane board is designed to be in a ribbed form, by comparison with common precast concrete sandwich cladding wall panels with inner vane boards being rectangular sections, the rigidity, the strength, the thermal insulation efficiency, the durability performance and the fireproof performance of the wallboard are guaranteed, the thickness of the wall panel is reduced, the effective use space of a building is increased, the use amount of concrete is reduced, the self-weight of the wall panel is reduced, the safety and the seismic performance of connected nodes are improved, and the precast concrete sandwich cladding wall panel is applicable to thermal insulation engineering of external walls of the building.

Owner:ANHUI BAOYE CONSTR ENG GRP CO LTD

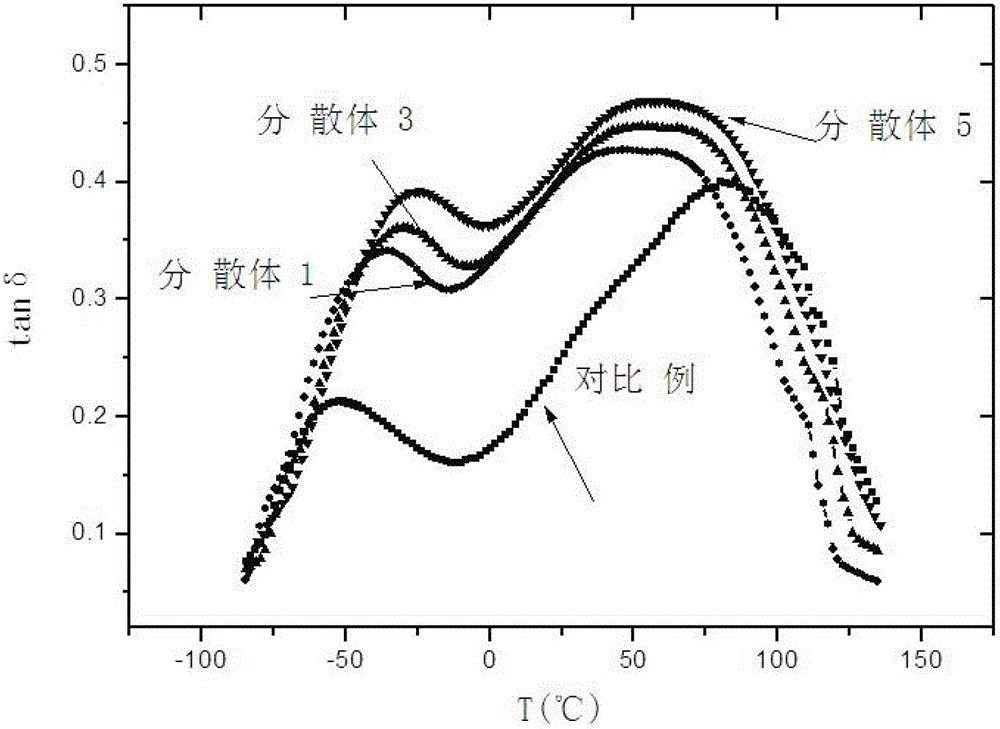

Preparation method of high-solid content wide-temperature range damping polyurethane aqueous dispersion containing nanofiller

The invention discloses a preparation method of a high-solid content wide-temperature range damping polyurethane aqueous dispersion containing nanofiller. The preparation method mainly comprises the following steps of: combining polyhydric alcohols and isocyanate to prepare a polyurethane prepolymer (a); preparing an emulsifiable polyurethane prepolymer by using a hydrophilic chain extender (b); and neutralizing and emulsifying, then carrying out secondary chain extension and nanometer hybridization to obtain the aqueous dispersion. The olyurethane dispersion disclosed by the invention is in line with environmental requirements of modern industries by taking water as a dispersion medium, has good storage stability and is simple and practicable in a preparative technology. Compared with a conventional waterborne polyurethane aqueous dispersion, the high-solid content wide-temperature range damping polyurethane aqueous dispersion containing nanofiller has super-high solid content of 50%-60% and high damping behavior (tan delta greater than 0.3) in a wide-temperature range of -50 DEG C to 90 DEG C. The high-solid content wide-temperature range damping polyurethane aqueous dispersion containing nanofiller is an environment-friendly functional polyurethane damping material and can be widely applied to various fields of national economy such as aerospace, automobiles, ship building, precise instruments, architectural ornaments and the like.

Owner:SICHUAN UNIV

Method for removing oil tea seed coats

InactiveCN102618380APromote technological progressImprove product added valueFatty-oils/fats productionHuskingThermal treatmentHeat processing

The invention provides a method for removing oil tea seed coats with high coat removing rate and good integrity. The method comprises the following steps of: (1) raw material pretreatment: taking dry oil tea fruits, and removing oil tea fruit shells by using a shelling machine to obtain shelled oil tea seeds; (2) cold treatment: putting the shelled oil tea seeds into a fluidized monomer instant freezer, and performing fluidized instant freezing for 5 to 10 minutes at the temperature of between 30 DEG C below zero and 40 DEG C below zero to obtain cold oil tea seeds; (3) thermal treatment: quickly heating the cold oil tea seeds to the temperature of between 150 and 200 DEG C through infrared, and performing thermal treatment for 2 to 4 minutes to obtain hot oil tea seeds; and (4) coat removal: putting the hot oil tea seeds into a crusher, crushing and removing coats by using roll pair differential, and separating the coats from kernels through wind. The method has the advantages of simple process, high coat removal rate and good integrity. The coat removed oil tea seeds obtained by the method are particularly suitable for processing low-temperature squeezed tea oil, and the processed tea oil has good color and high quality and has market competitiveness.

Owner:HEFEI UNIV OF TECH

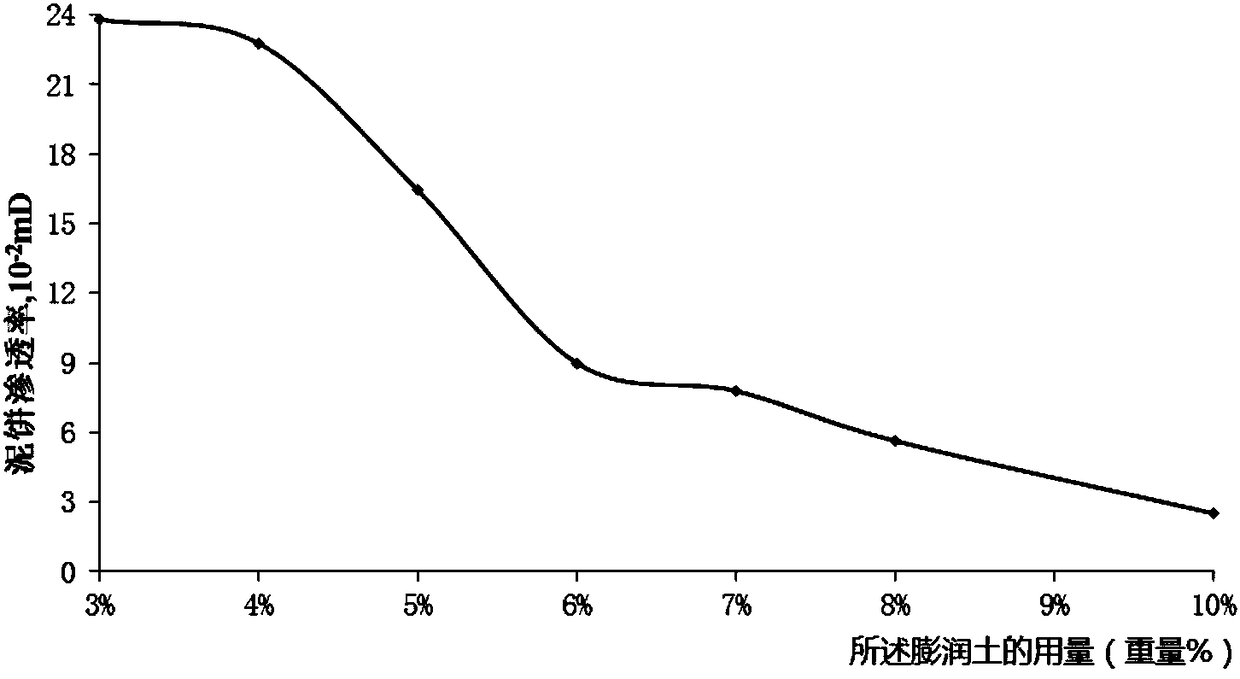

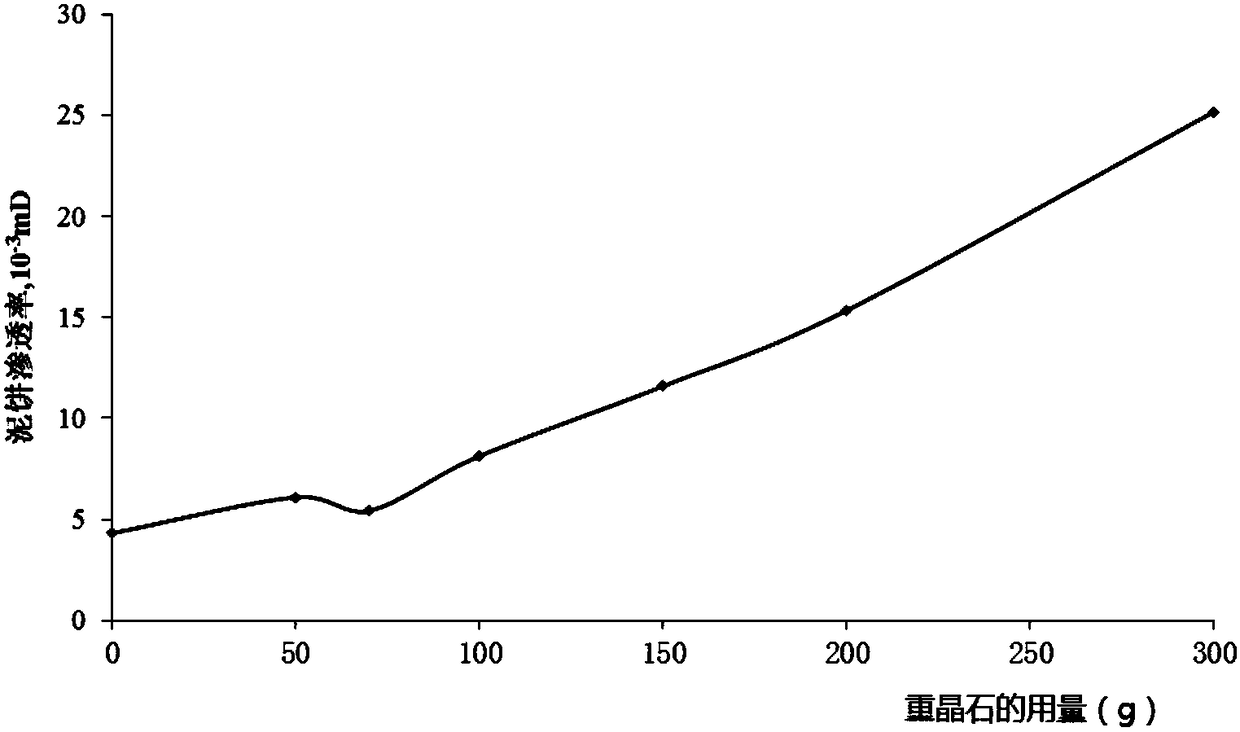

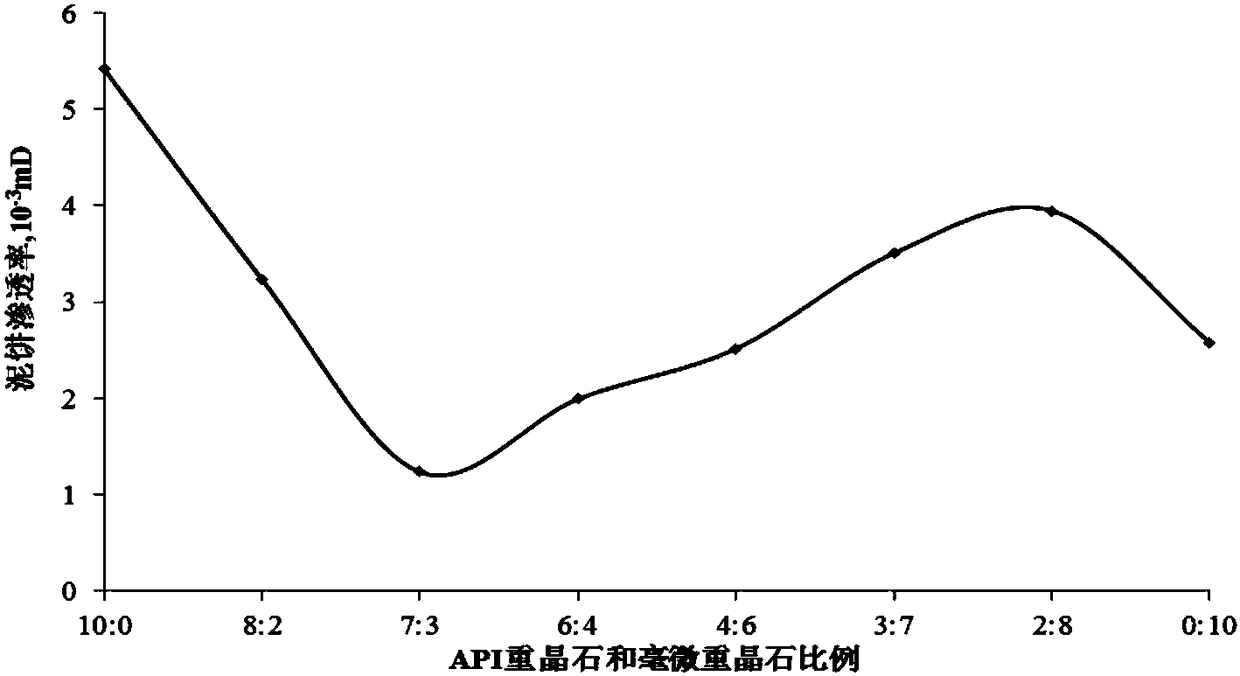

Plugging effect evaluation method for low-aperture low-permeability formation

ActiveCN108518216APromote technological progressEasy to operateBorehole/well accessoriesWater basedReduction rate

The invention belongs to the field of evaluation of plugging effects, relates to a test evaluation method, and particularly discloses a plugging effect evaluation method for a low-aperture low-permeability formation. The method comprises the following steps that (1) 'simulation corestone' of the low-aperture low-permeability formation is prepared; (2) the prepared 'simulation corestone' serves asa filtering medium of a high-temperature and high-pressure filtration instrument, and the average permeability of a drilling fluid the drilling fluid not containing a blocking agent and drilling fluidcontaining the blocking agent is measured; and (3) the reduction rate of the average permeability of the drilling fluid containing the blocking agent is calculated. The method has the advantages of simple operation, good repeatability, low cost, short time consumption, accurate evaluation results and the like, in addition, the established plugging effect evaluation method for the low-aperture low-permeability formation is conductive to quickening the technological progress of the water-based drilling fluid such as shale gas.

Owner:SOUTHWEST PETROLEUM UNIV

Production process of peeled sesame oil

InactiveCN105132125APromote technological progressImprove product added valueFatty-oils/fats refiningFatty-oils/fats productionOil productionFlavor

The invention provides a production process of peeled sesame oil. The process is characterized in that it comprises the following steps in order: A. airing sesame; B. adding A treated sesame kernels into boiling water, using a water gun to introduce cool and clean water to flush the sesame kernels in a jacketed pan so as to remove attached peel, and repeating the operation over and over again; C. steaming the B treated sesame kernels with a food steamer; D. pressurizing the C treated sesame kernels with a hydraulic machine to obtain crude oil; E. performing hyperfiltration treatment on the filtered sesame oil; F. conducting ultraviolet radiation; and G. carrying out low-temperature vacuum bumping to remove fishy smell. The product provided by the invention has strong aroma and unique flavor, can be widely applied in cooking various food and dishes, has high nutritional value and health care effect, and ensures high antioxidant active components. The production process provided by the invention is especially suitable for popularization in the technical field of small batch special oil production.

Owner:查光圣

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com