Nano composite woody material, and preparation method

A wood material and nano-composite technology, which is applied in the fields of nano-composite wood materials and preparation, materials of nano-composite wood building materials, and materials of building materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 2

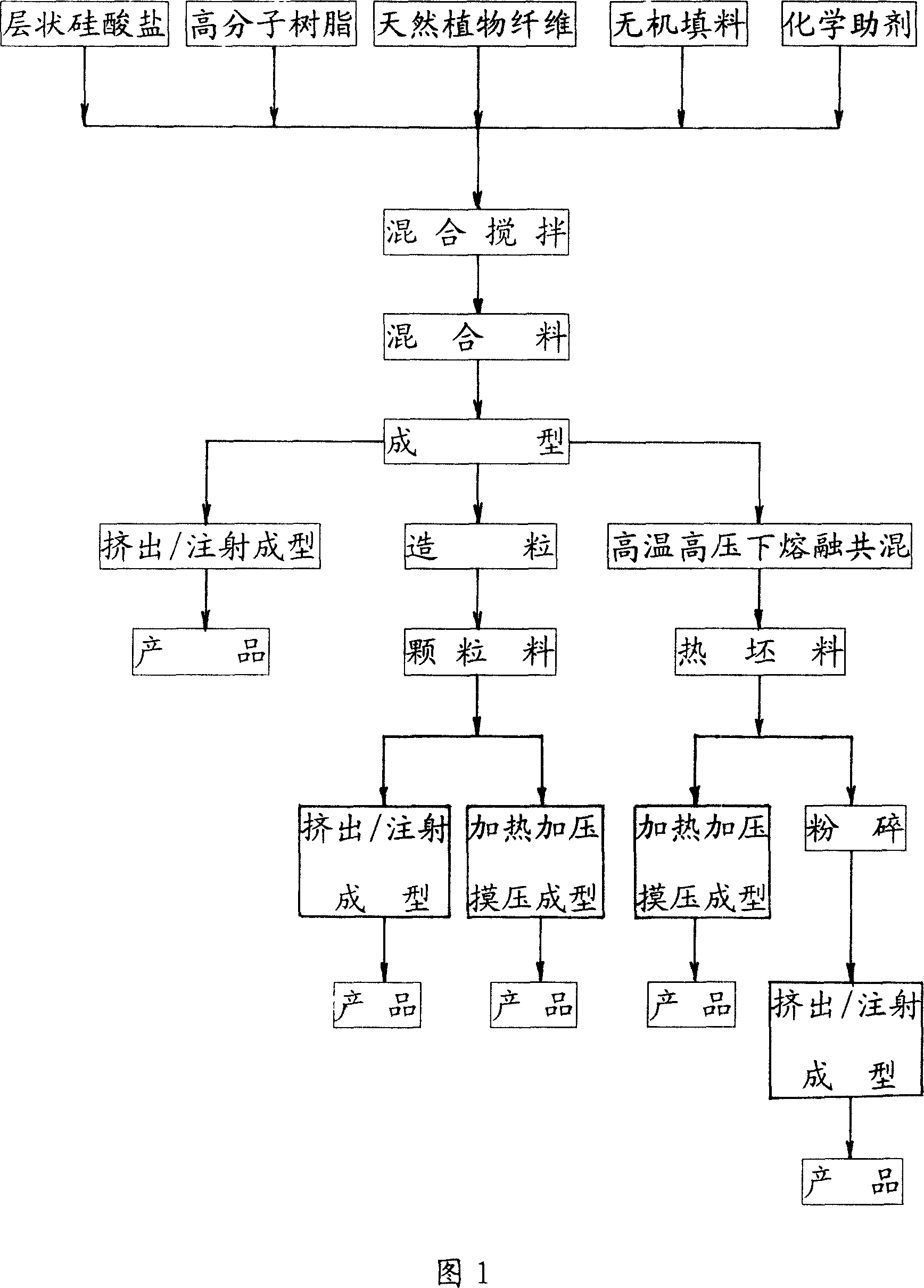

[0080] The nanocomposite wood material and the preparation method of the present invention will be described in detail below in conjunction with the accompanying drawings. As shown in Figure 1 of the manual:

[0081] A nano-composite wood material and its preparation method, using the raw material of the nano-composite wood material according to the weight ratio described in Embodiment 1, according to the following steps:

[0082] (1) Prepare the following raw materials according to the following ratio and operation by weight:

[0083] (1). ①, phyllosilicate: 2 kg of 2% is ready for use;

[0084] (1). ②. Polymer resin: 10 kg at 10% is ready for use;

[0085] (1). ③, natural plant fiber: 85 kilograms with 85%, the powder body that diameter is below 5 millimeters is ready for use through crushing and grinding;

[0086] (1). ④. Inorganic filler: 2 kg of 2% is ready for use;

[0087] (1). ⑤, chemical additives: 1 kg is ready for use at 1%;

[0088] (2) Mixing and stirring: pu...

specific Embodiment approach 3

[0104] Carry out by specific implementation mode one, two, just:

[0105] (1) in operation step (1). 1. layered silicate: take 1% as 1 kilogram;

[0106] (1) in the operation step (1). 2., macromolecule resin: be 70 kilograms with 70%;

[0107] (1) in the operation step (1). 3., natural plant fiber: 20 kilograms with 20%;

[0108] (1) in the operation step (1). 4., inorganic filler: 3.5 kilograms with 3.5%;

[0109] (1) in operation step (1). ⑤, chemical auxiliary agent: be 5.5 kilograms with 5.5%;

[0110] (3) in the operation step (3). ③. Molding after high temperature and high pressure melt blending: the temperature is 400°C.

specific Embodiment approach 4

[0111] Carry out by specific implementation mode one, two, just:

[0112] (1) in the operation step (1). 1. layered silicate: 0.1 kg with 0.1%;

[0113] (1) in operation step (1). 2., polymer resin: be 40 kilograms with 40%;

[0114] (1) in operation step (1). 3., natural plant fiber: be 52.5 kilograms with 52.5%;

[0115] (1) in operation step (1). 4., inorganic filler: be 5 kilograms with 5%;

[0116] (1) in the operation step (1). ⑤, chemical auxiliary agent: be 2.4 kilograms with 2.4%;

[0117] (3) in operation step (3). ③. Molding after high temperature and high pressure melt blending: the temperature is 265°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com