Rolling method for producing copper clad aluminum row

A technology of copper-clad aluminum row and copper pipe, which is applied in metal rolling, metal rolling, rolling mill control devices, etc., can solve the problems of low total processing rate, cladding layer and core material fracture, yield rate and electrical conductivity reduction, etc. problem, to achieve the effect of reducing production cost, short process flow and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

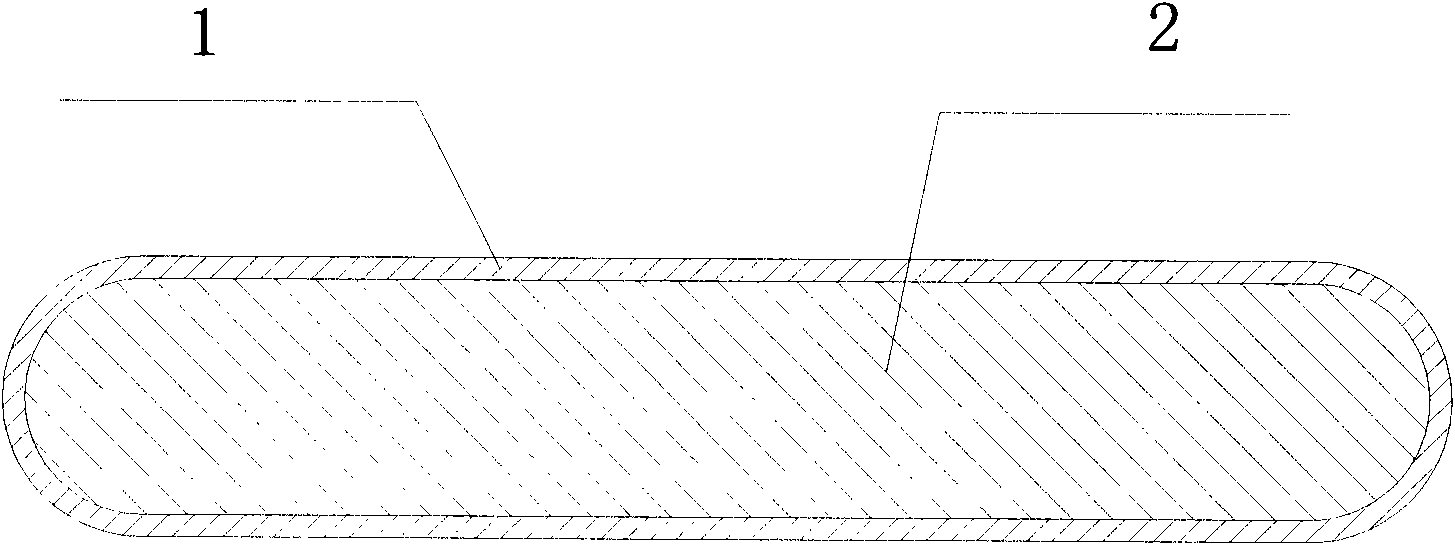

Image

Examples

Embodiment 1

[0016] Example 1: ①Choose a copper tube with a uniform wall thickness and an aluminum rod that is in transition with the inner wall size of the copper tube, then soak the copper tube and aluminum rod with 15wt% to 30wt% sulfuric acid solution, after soaking for a period of time, use water Rinse and dry the inner wall of the copper tube and the outer wall of the aluminum rod with a steel brush to remove impurities and oxide layers on the surface. ②Press the above aluminum rod into the copper tube, and seal the two ends tightly with the ends of the copper tube to form a composite billet; then heat the composite billet to 300°C, keep the temperature for 60 minutes, and preheat the roll to 200°C and keep the temperature for 30 minutes. minutes, and then rolling. First, two passes of hot rolling are carried out, and two passes of cold rolling are carried out after the composite billet is naturally cooled, and the pass processing rate is controlled between 20% and 60%. ③ Straighten...

Embodiment 2

[0017] Example 2: ①Choose a copper tube with uniform wall thickness and an aluminum rod that is transitionally matched with the inner wall size of the copper tube, then soak the copper tube and aluminum rod with 15wt% to 30wt% sulfuric acid solution, after soaking for a period of time, use water Rinse and dry the inner wall of the copper tube and the outer wall of the aluminum rod with a steel brush to remove impurities and oxide layers on the surface. ②Press the above-mentioned aluminum rod into the copper tube, and seal the two ends tightly with the ends of the copper tube to form a composite billet; then heat the composite billet to 480°C, keep the temperature for 50 minutes, and preheat the roll to 300°C and keep the temperature for 30 minutes. minutes, and then rolling. First, two passes of hot rolling are carried out, and two passes of cold rolling are carried out after the composite billet is naturally cooled, and the pass processing rate is controlled between 20% and 6...

Embodiment 3

[0018] Example 3: ①Choose a copper tube with a uniform wall thickness and an aluminum rod that is in transition with the inner wall size of the copper tube, then soak the copper tube and aluminum rod with a 15wt% to 30wt% sulfuric acid solution, after soaking for a period of time, use water Rinse and dry the inner wall of the copper tube and the outer wall of the aluminum rod with a steel brush to remove impurities and oxide layers on the surface. ②Press the above aluminum rod into the copper tube, and seal the two ends tightly with the ends of the copper tube to form a composite billet; then heat the composite billet to 540°C, keep the temperature for 30 minutes, and preheat the roll to 300°C and keep the temperature for 30 minutes. minutes, and then rolling. First, two passes of hot rolling are carried out, and two passes of cold rolling are carried out after the composite billet is naturally cooled, and the pass processing rate is controlled between 20% and 60%. ③ Straight...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com