Patents

Literature

58results about How to "Save copper resources" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Aluminum-magnesium alloy conductor containing rare earth covering by cuprum as well as manufacturing method and usage thereof

InactiveCN101202130ASimple manufacturing methodEasy to useSingle bars/rods/wires/strips conductorsMetal/alloy conductorsTransmission performanceElectricity

The invention relates to a copper rare earth aluminum-magnesium alloy conductor and the manufacturing method and the application thereof. The manufacturing method of the copper rare earth aluminum-magnesium alloy conductor is simple and reasonable, and mechanical property, service performance, high frequency signal transmission performance and economic performance are all better than those of a pure copper conductor. Meanwhile, all the performances of the copper rare earth aluminum-magnesium alloy conductor of the invention, such as electricity or conductivity property, mechanical property, service performance, high frequency signal transmission performance and economic performance are fairly better than those of a copper aluminum-magnesium alloy conductor.

Owner:徐志峰

Rolling method for producing copper clad aluminum row

InactiveCN101645333ASave resourcesShort processSingle bars/rods/wires/strips conductorsRoll mill control devicesLimited resourcesNitrogen

The invention discloses a rolling method for producing a copper clad aluminum row, which comprises the following steps: 1, selecting a copper pipe with uniform wall thickness and an aluminum bar in transition fit with the inner wall of the copper pipe, and cleaning the copper pipe and the aluminum bar to remove oil stains and oxidation layers; 2, pressing the aluminum bar into the copper pipe to form a composite blank, and plugging two ends of the composite blank tightly; 3, heating the composite blank to between 300 and 540 DEG C, preserving the heat for 30 to 60 minutes, then thermally rolling the composite blank for 1 to 3 times, and coldly rolling the composite blank for 1 to 4 times; 4, straightening and acid-washing a rolled product; 5, carrying out diffusion treatment at the temperature of between 200 and 550 DEG C under the protection of nitrogen of one atmospheric pressure, and preserving the heat for 1 to 3 hours; and 6, drawing the treated product to form a final product. The rolling method for producing the copper clad aluminum row not only has short process flow and high production efficiency, but also can save limited resources and reduce the cost.

Owner:厦门火炬特种金属材料有限公司

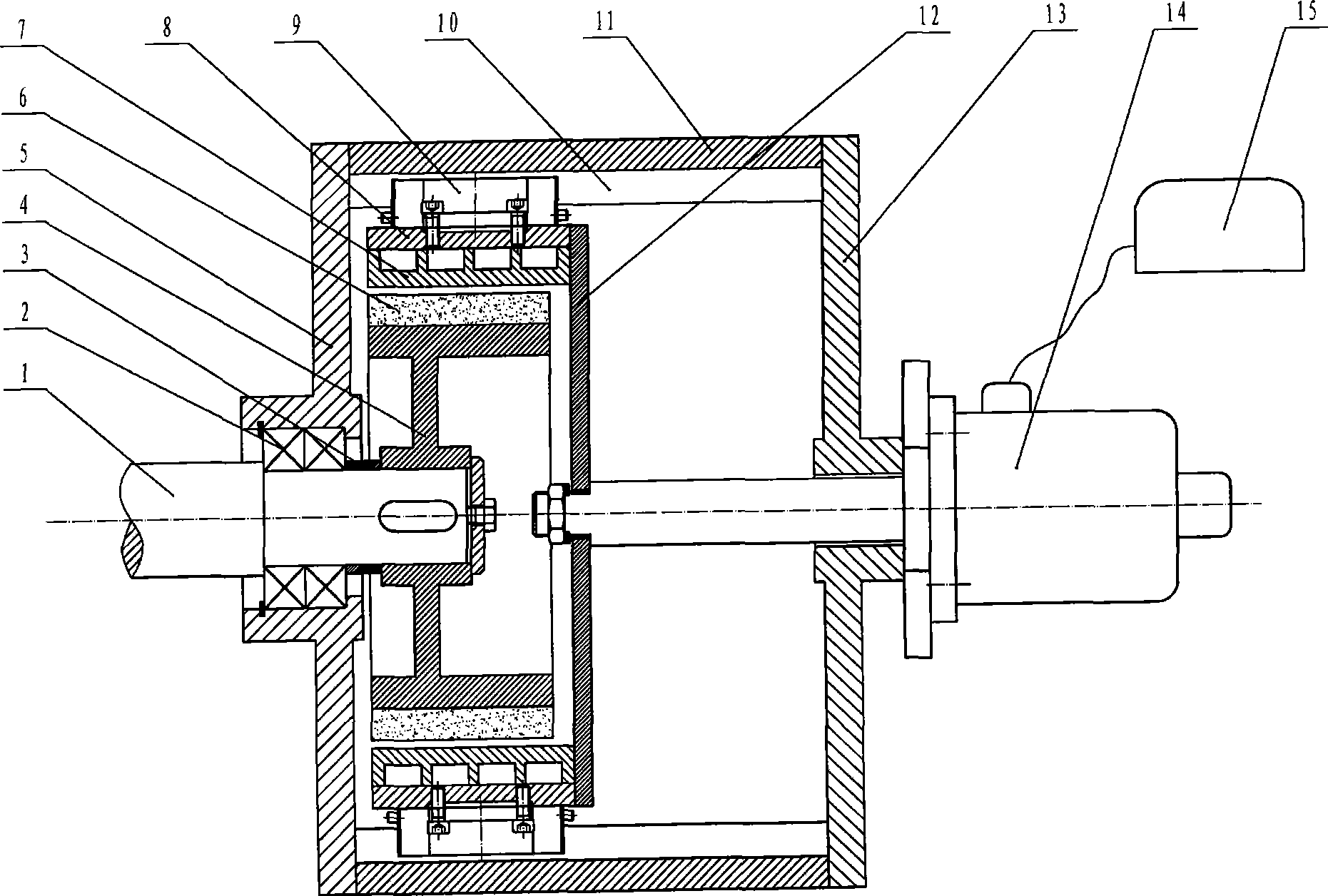

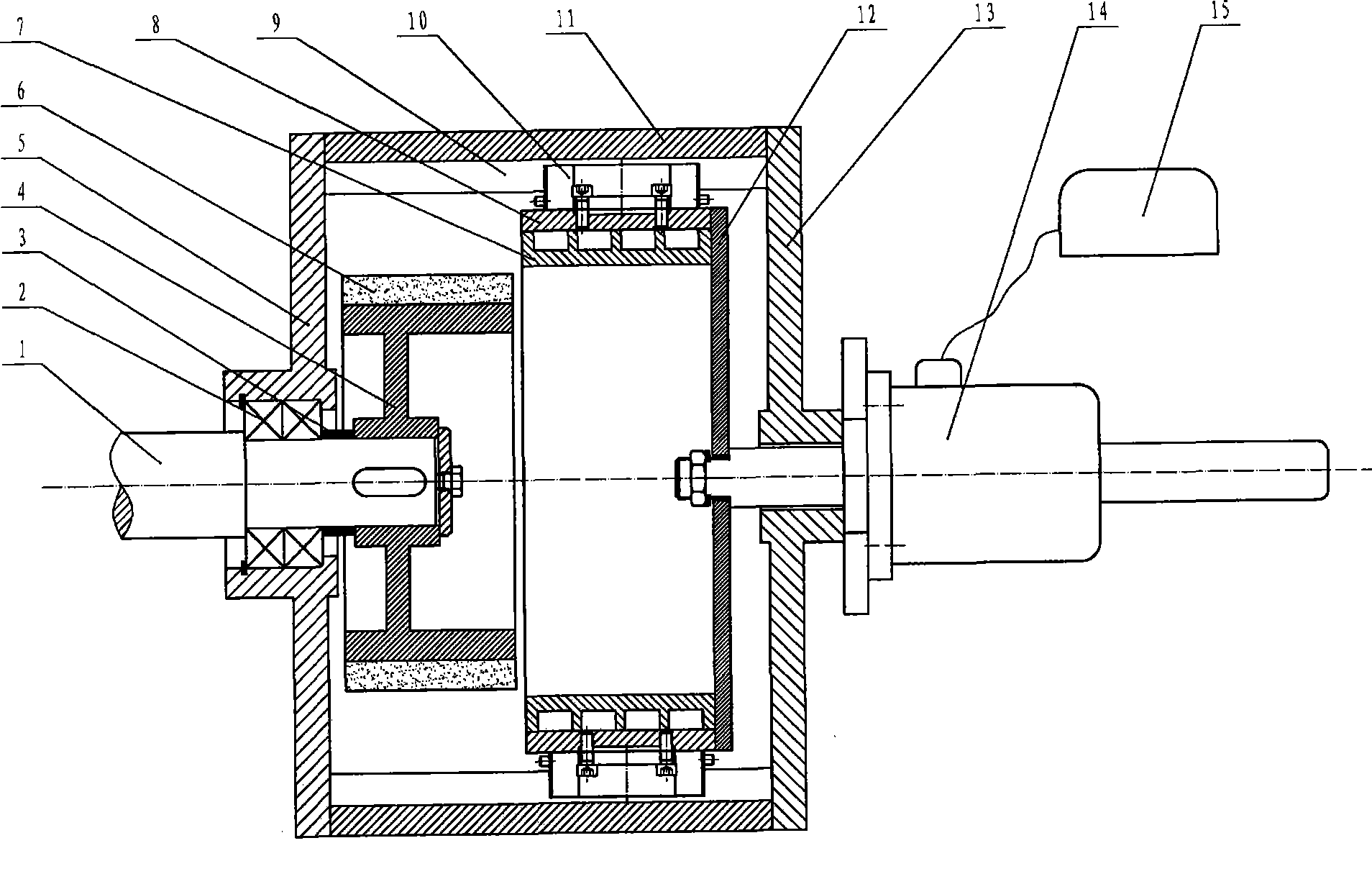

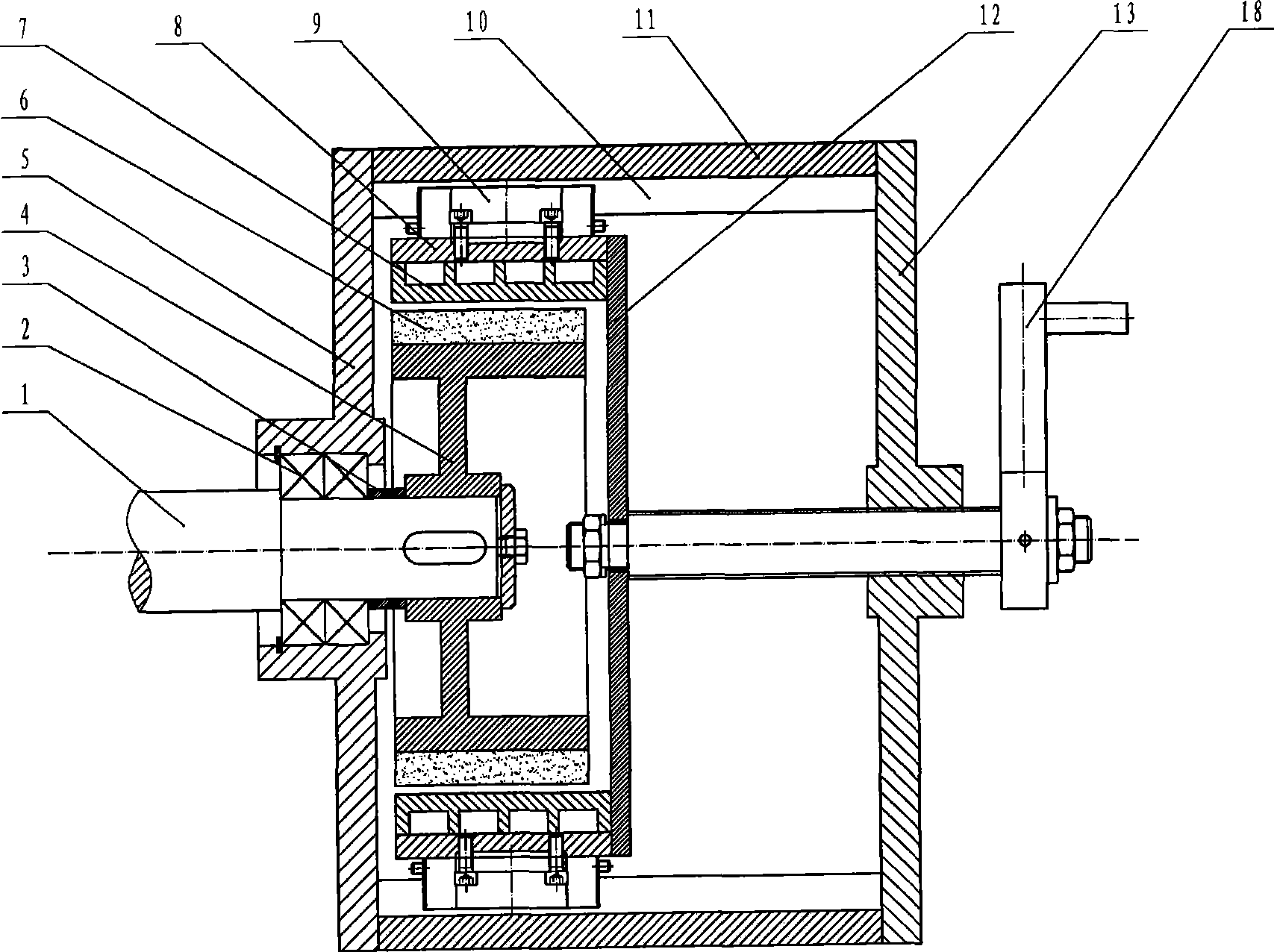

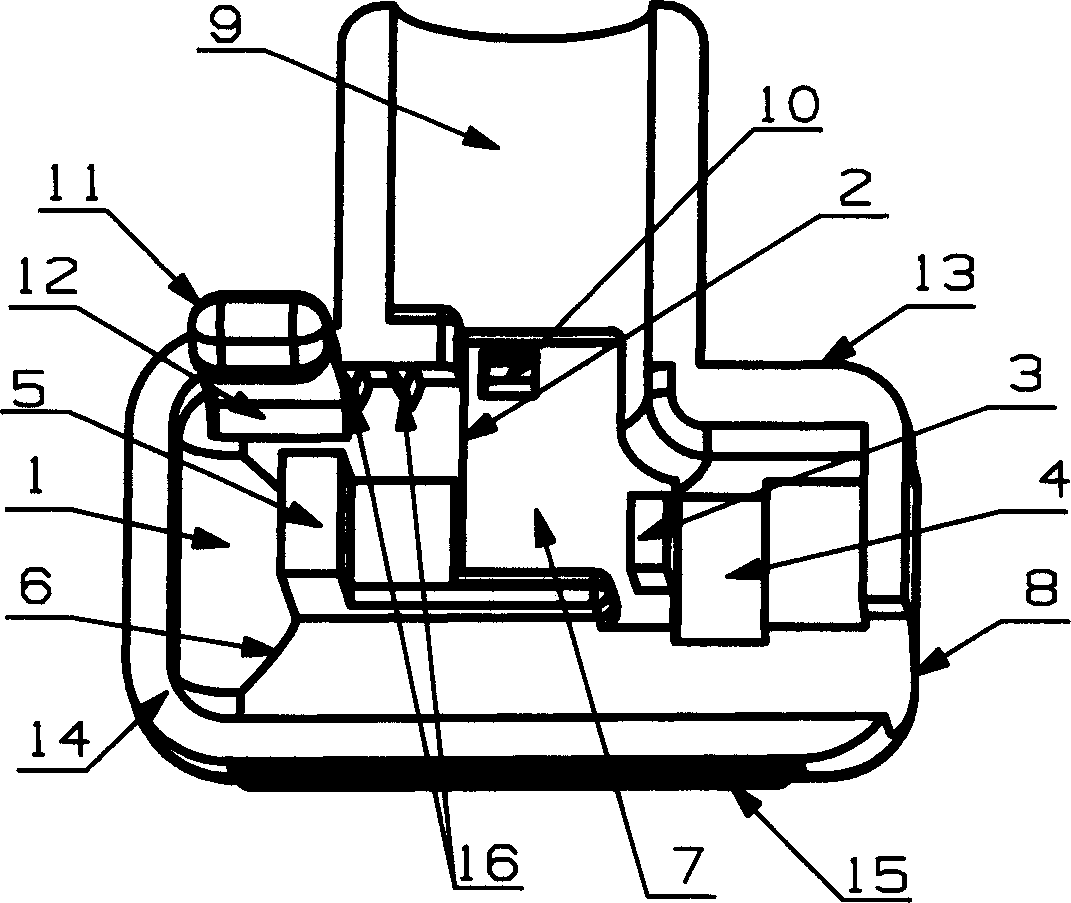

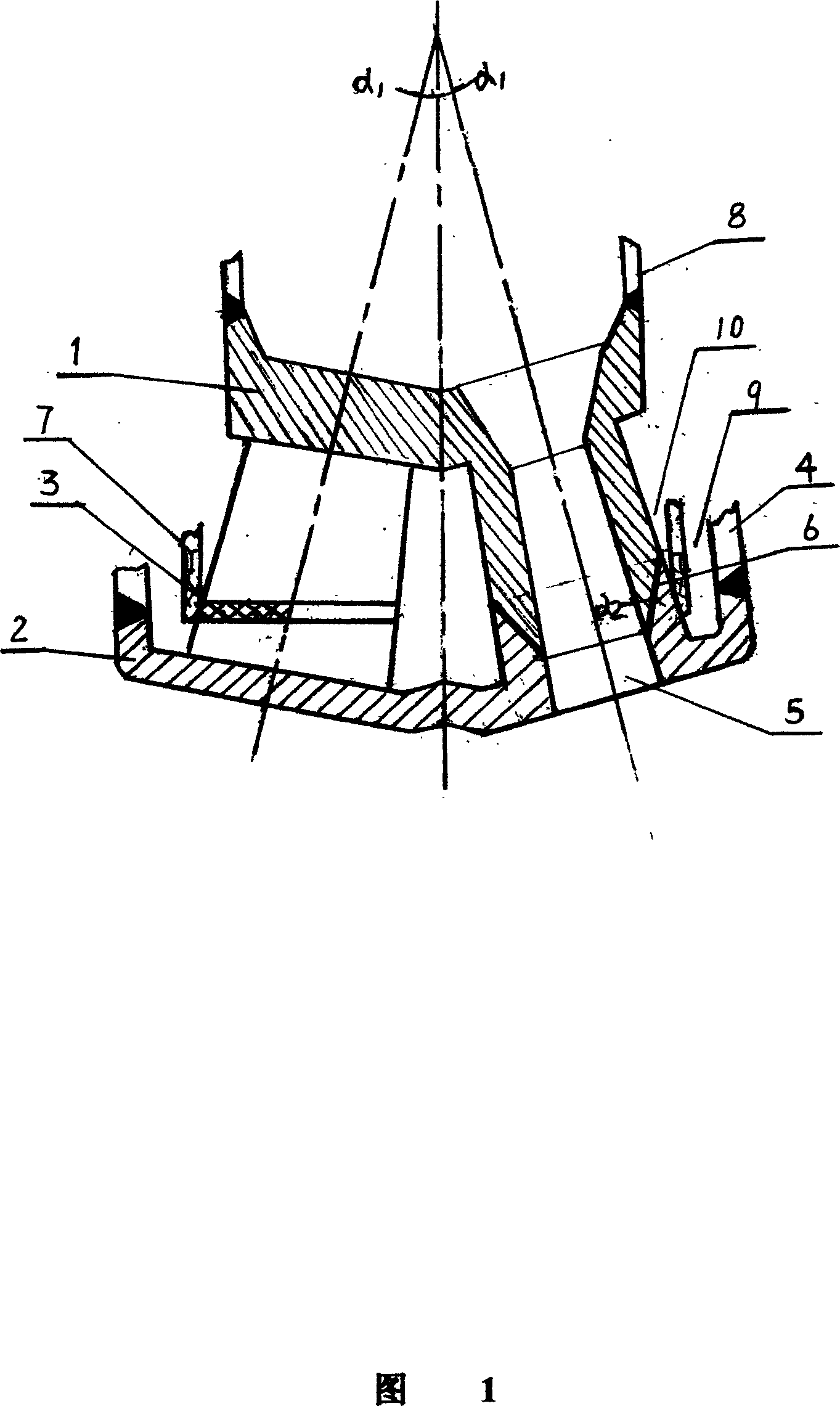

Hub type liquid cooling permanent magnet dynamometer

InactiveCN101382462AImprove cooling effectNo noiseWork measurementTorque measurementLoad torqueElectrical energy consumption

The invention relates to a water circulation cooling hub type liquid cooling permanent magnetic dynamometer, belonging to power machine testing equipment. The dynamometer comprises a shell, a stator and a rotor; the rotor comprises a magnet retainer and a plurality of permanent magnets fixed at the periphery of the magnet retainer. The stator comprises a stator hub and a moving plate fixed at the end face of the stator hub. The outer surface of the stator hub is provided with a spiral water channel which is sealed by a sealing cover on the spiral water channel so as to form a liquid cooling device. The sealing cover and the shell are linked by a guideway mechanism, the moving plate is connected with a control mechanism, and the stator hub, the sealing cover and the moving plate can slide along the axial direction in the shell under the control of the control mechanism. Loading torque generated by the dynamometer in the invention is easy for continuous adjustment; the permanent magnet is used for replacing the magnet exciting coil of an electric eddy current dynamometer, therefore, copper resource is saved, no electrical energy consumption exists during stable operation, and the loading torque is stable for a long time during high speed; the sealed water circulation cooling system has good cooling effect, does not generate noise and is applicable for occasions having high requirement on the noise.

Owner:BEIJING UNIV OF TECH

Aluminum-copper-magnesium alloy wire rod and manufacturing technique thereof

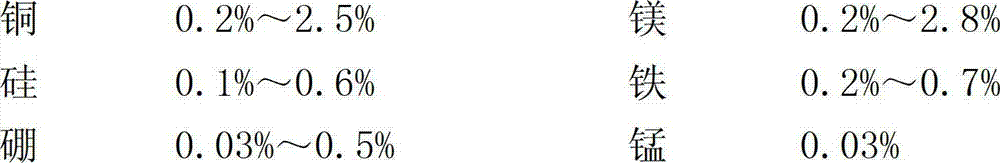

The invention relates to an aluminum-copper-magnesium alloy wire rod and a manufacturing technique of the aluminum-copper-magnesium alloy wire rod. The aluminum-copper-magnesium alloy wire rod is formed by the following raw materials in percentage by weight: 0.2-2.5% of copper, 0.2-2.8% of magnesium, 0.1-0.6% of silicon, 0.2-0.7% of iron, 0.03-0.5% of boron, 0.03% of manganese, 0.03% of zinc, 0.03% of chrome, 0.01% of titanium, and 96%-98% of aluminum. The manufacturing technique comprises the following steps: (1), smelting of aluminum alloy, (2), online treatment of aluminum alloy, (3), casting of aluminum alloy, (4), rolling of aluminum alloy wire rod, and (5), carrying out online aging treatment on the rolled aluminum alloy wire rod to obtain the wire rod, wherein the drawing out temperature is not higher than 60 DEG C. The aluminum-copper-magnesium alloy wire rod meets the performance requirements on the raw material aluminum alloy wire rod in copper clad aluminum alloy in the cable industry field, in particular the requirements on the performances in the aspects of tensile strength, percentage elongation and compressive creep, and the like.

Owner:庆毅 +1

Method for preparing graphene film on low-temperature substrate

InactiveCN104495829AFacilitate large-scale large-scale productionLow costNanocrystalSputter deposition

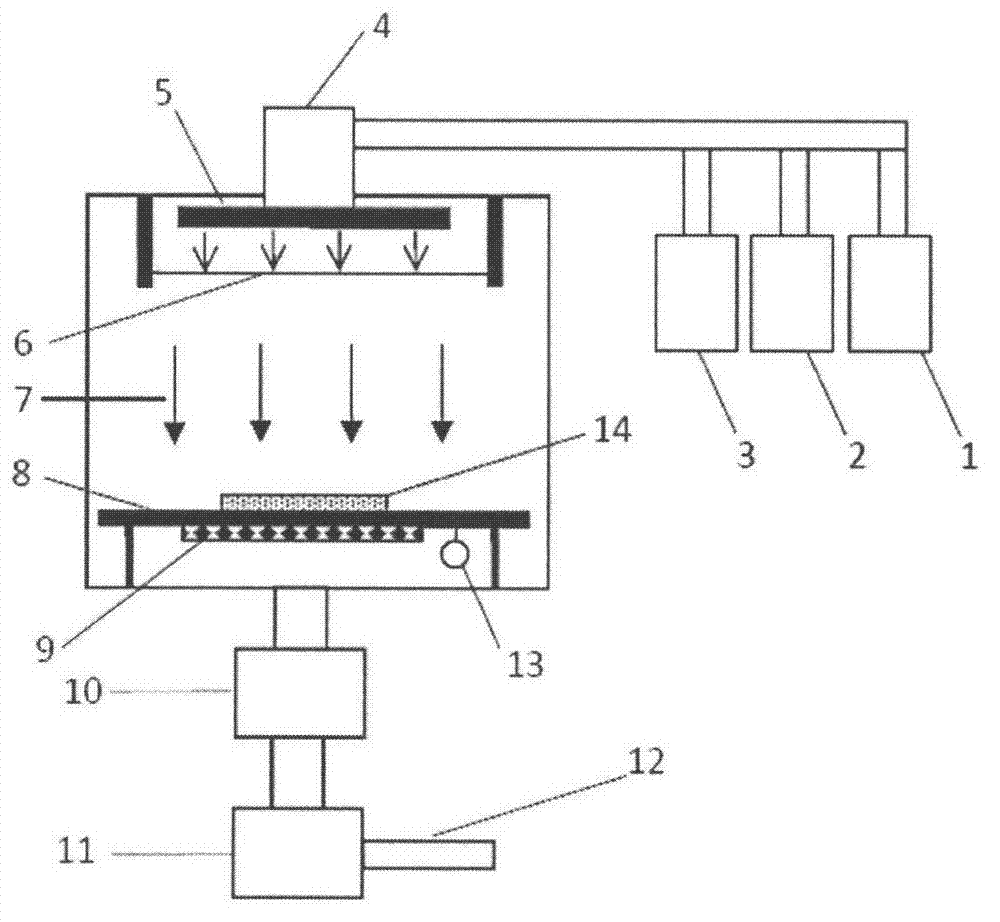

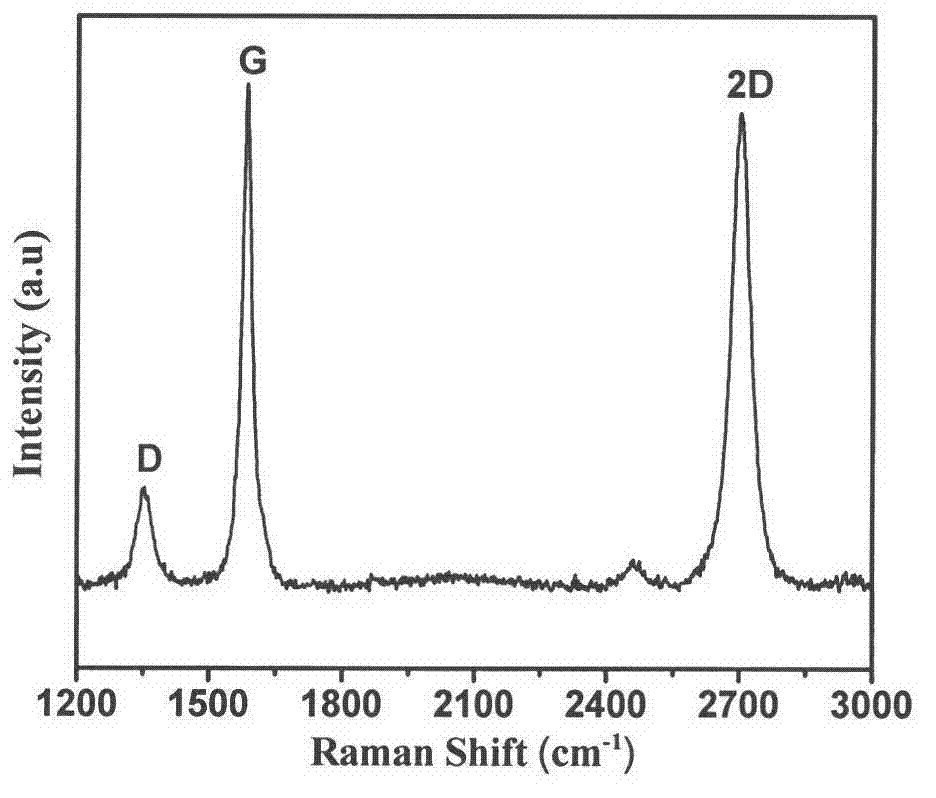

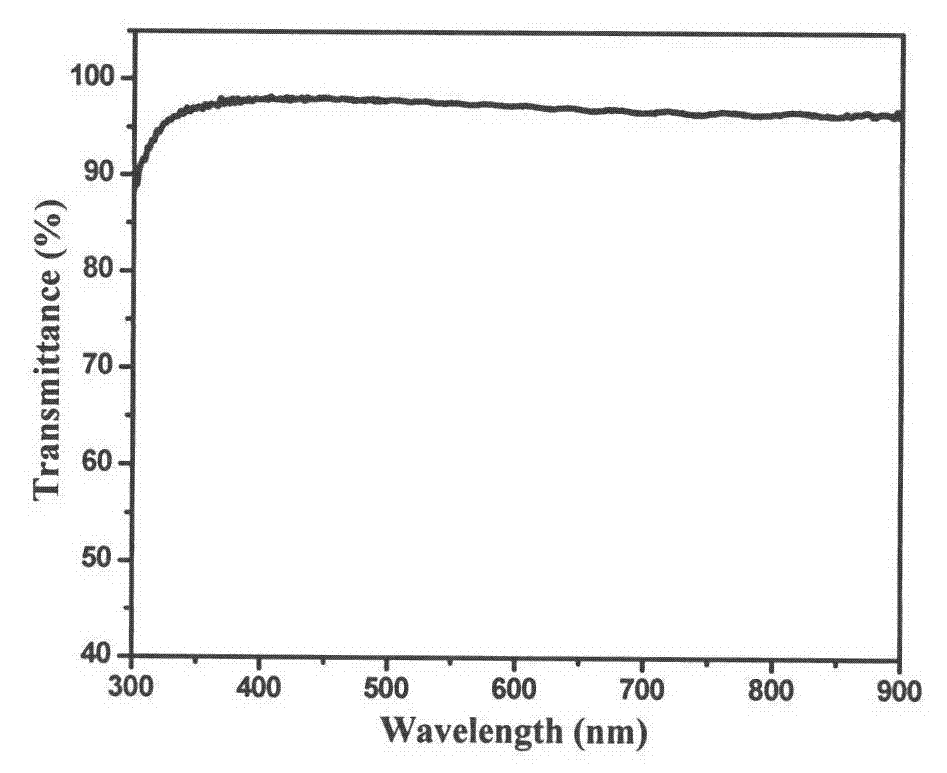

The invention discloses a method for preparing graphene on a low-temperature metal copper film substrate by adopting a hot wire CVD method. A prepared graphene film is a graphene nanocrystal. The method comprises the following processes of: (1) depositing a copper film on a quartz substrate by adopting a magnetron sputtering method; (2) annealing the deposited copper film; (3) growing the graphene film on the annealed copper film at the substrate temperature of 350-450 DEG C by adopting the hot wire CVD method; (4) transferring graphene. The method disclosed by the invention can be used for preparing the graphene film with a controllable layer number on the magnetron sputtering deposited low-cost copper film under the condition of the low-temperature substrate by adopting an ethyne gas-state carbon source or a polyphenylether solid-state carbon source and plays a guiding role on the popularization, application and industrialized production of the graphene.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

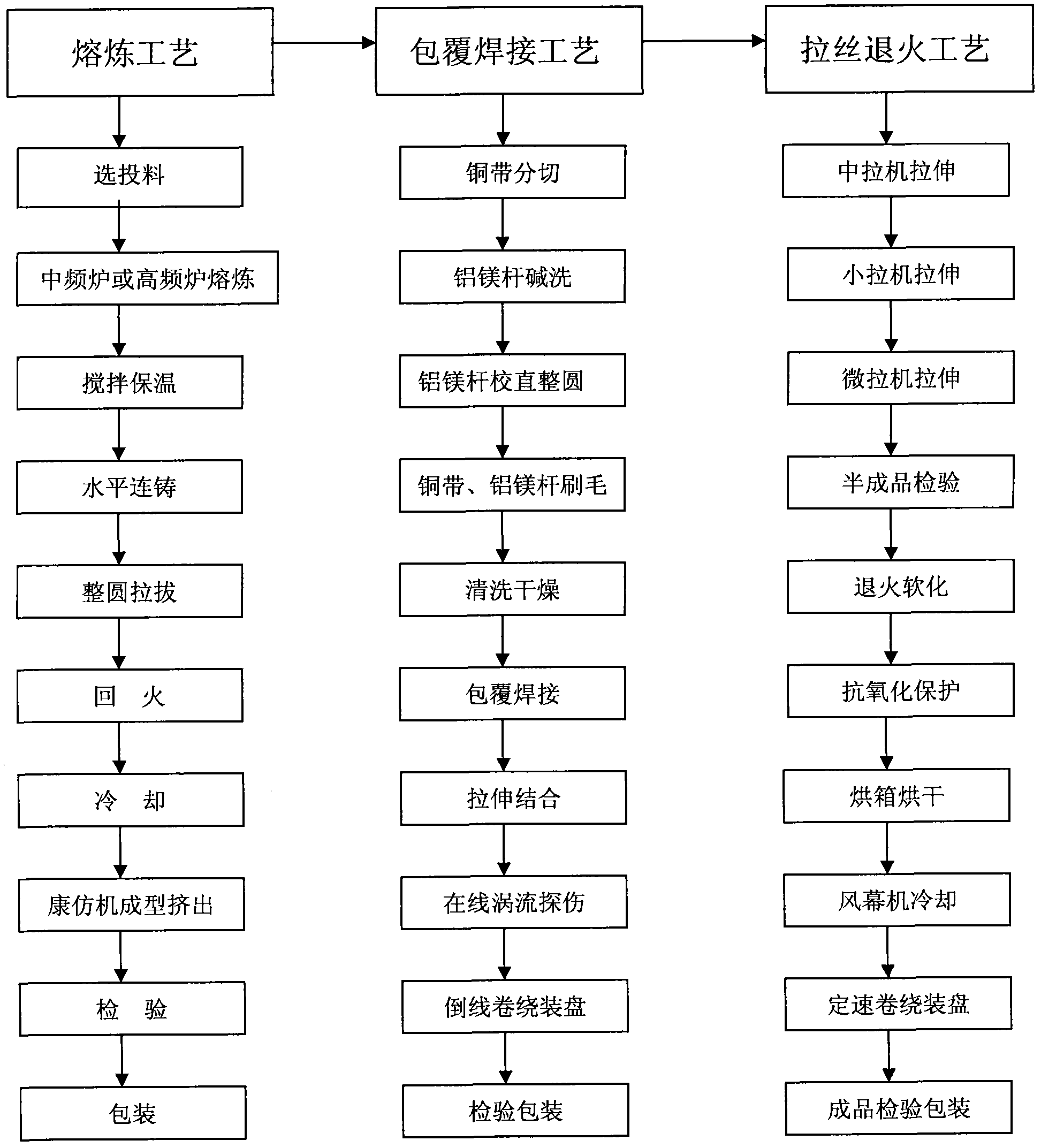

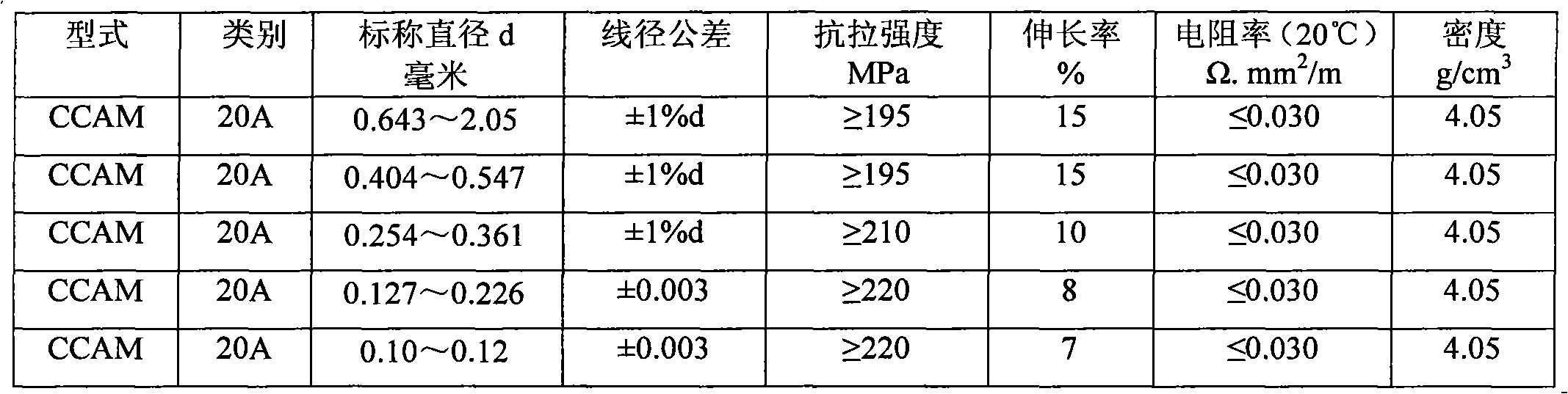

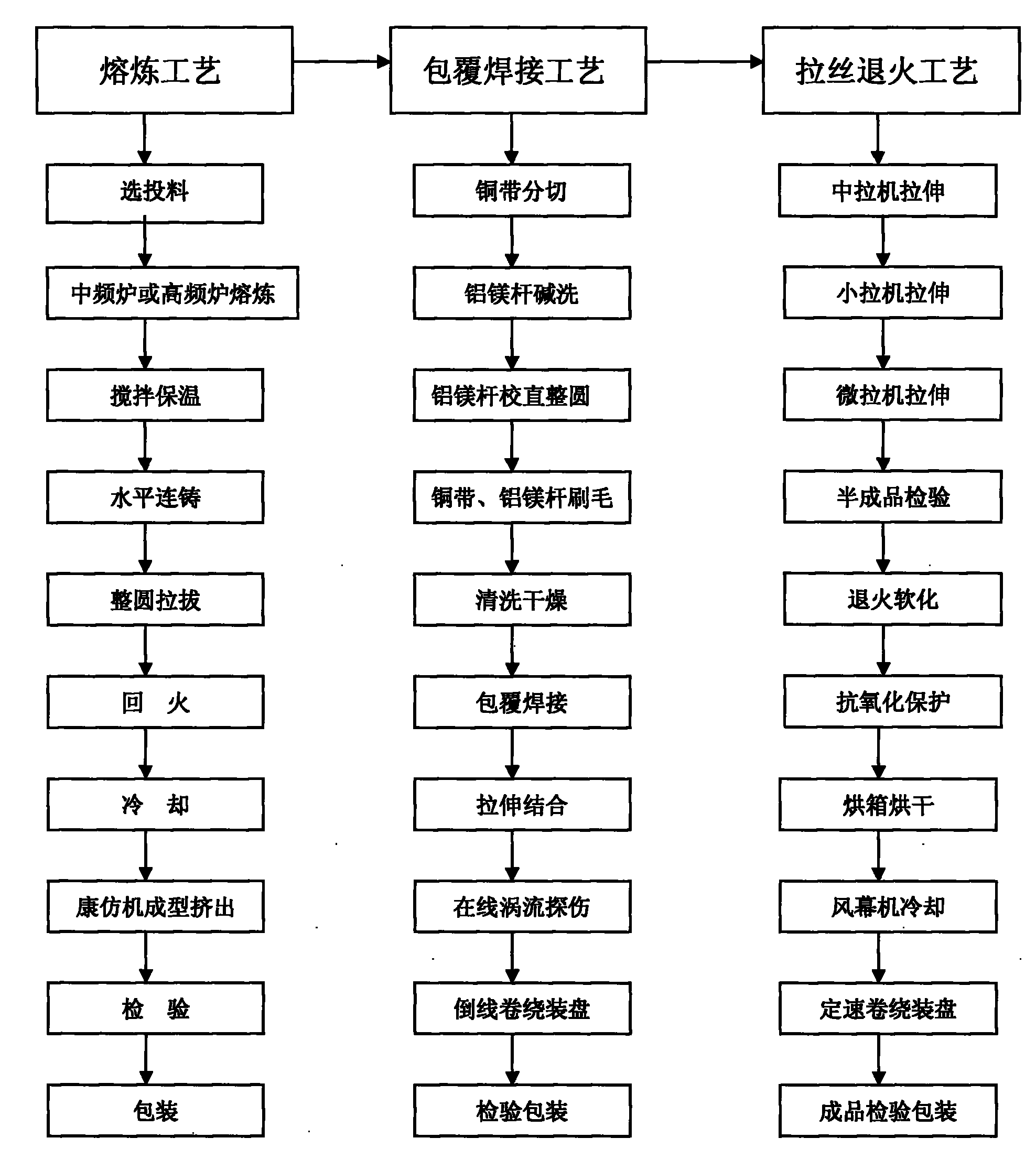

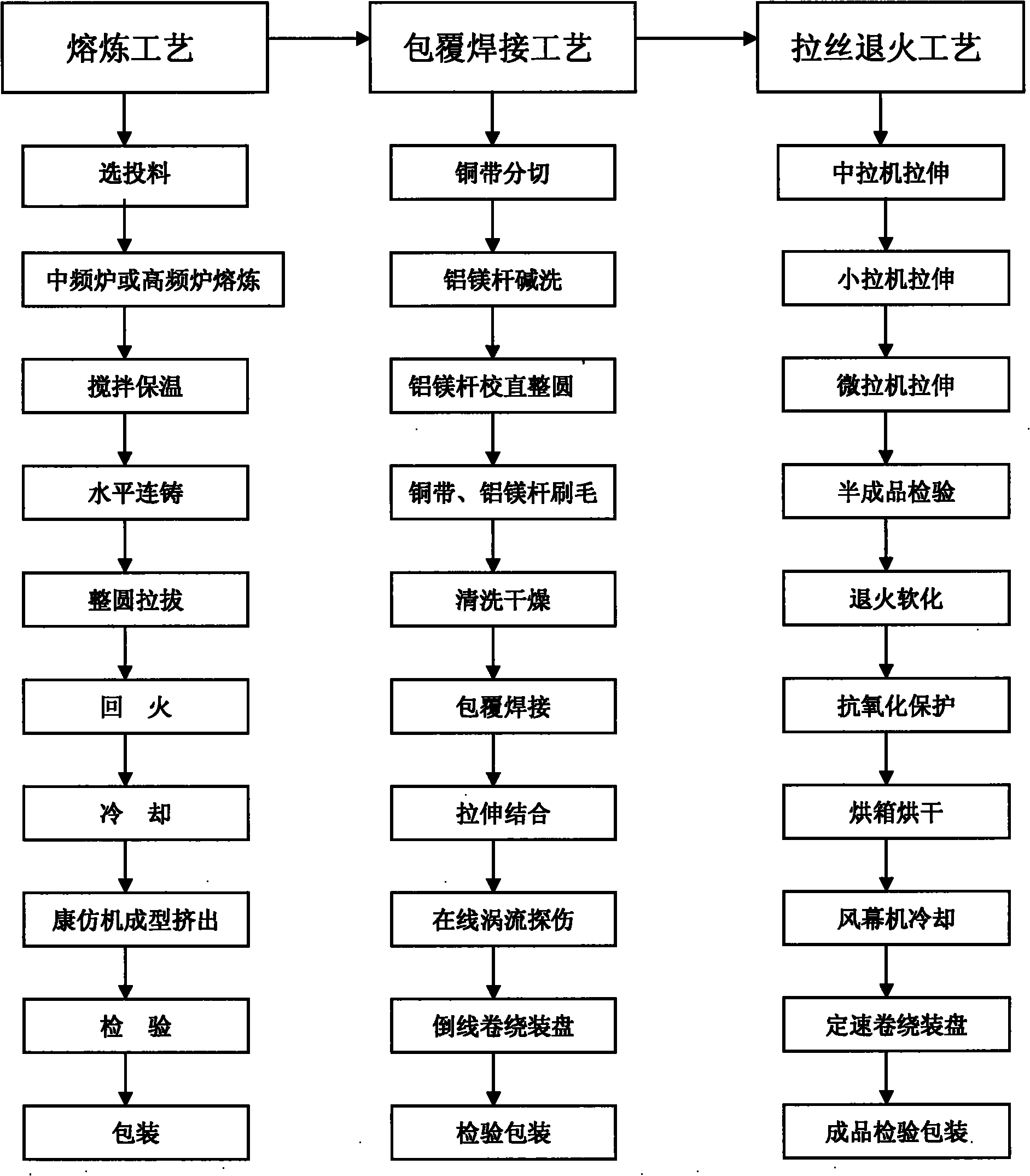

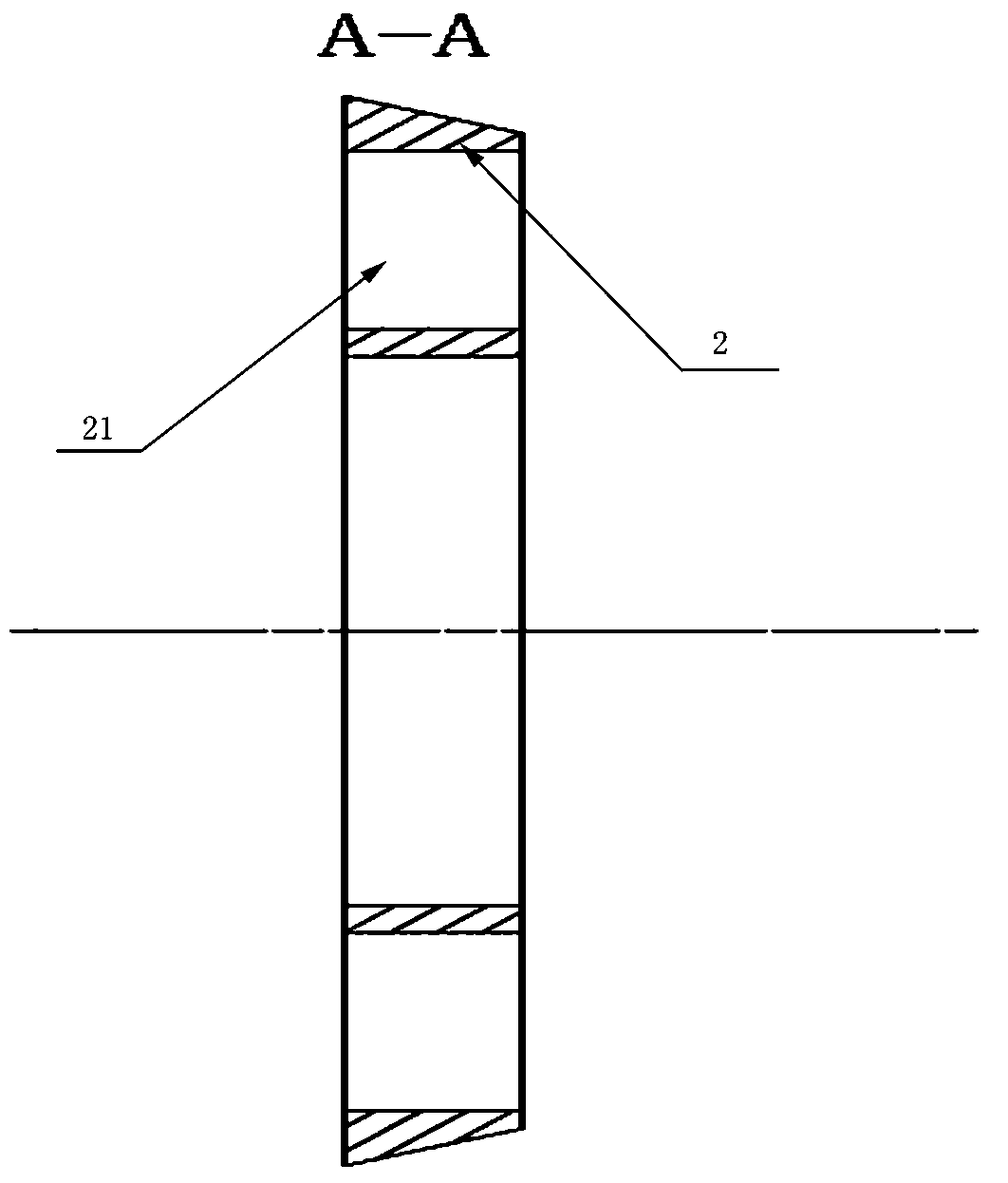

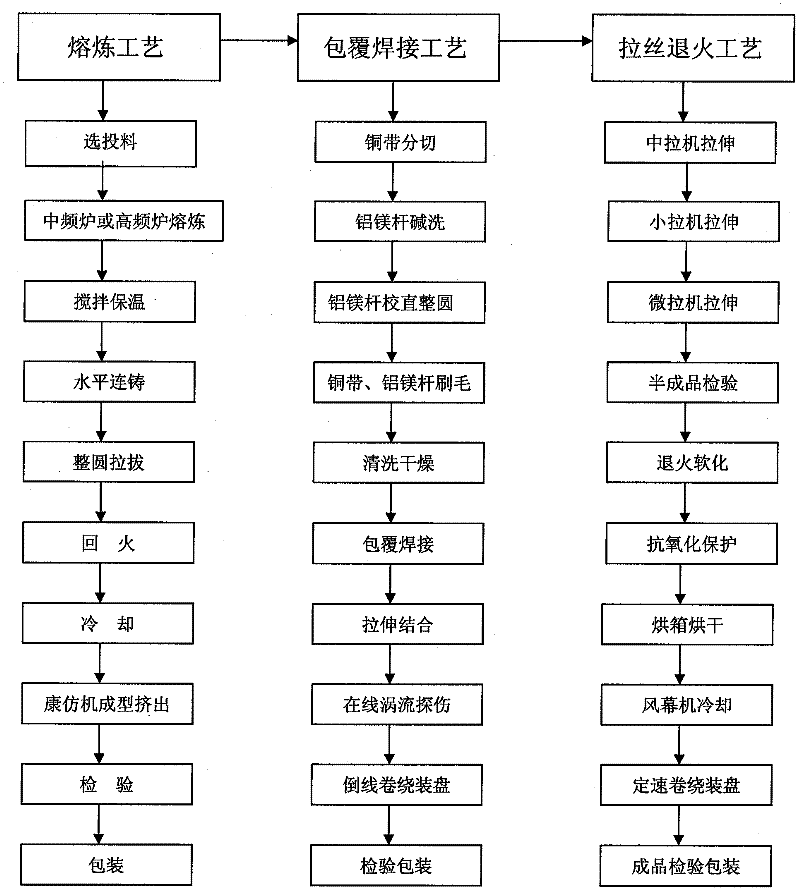

Method for producing copper-coated aluminum magnesium conductor wire for communication cable

InactiveCN102592747AReasonable structureAdvanced technologyMetal/alloy conductorsCable/conductor manufactureElectrical conductorSkin effect

The invention relates to a method for producing a copper-coated aluminum magnesium conductor wire for a communication cable, which comprises an aluminum magnesium core bar and a copper layer. The aluminum magnesium core bar is coated with the copper layer evenly and concentrically, and the volume of the copper layer accounts for 18%-22% of that of the copper-coated aluminum magnesium conductor wire for the communication cable. Method for producing the copper-coated aluminum magnesium conductor wire for the communication cable comprises the steps of melting; coating and welding; and drawing and annealing. The copper-coated aluminum magnesium conductor wire for the communication cable is reasonable in structure, electric properties, mechanical properties and environmental performances can meet the technical specifications of conductors used for communication cables, transmission performances of signals, images and data are completely in conformity with the high-frequency transmission line skin effect, a copper resource is saved by using aluminum instead of copper, energy is saved, emission is reduced, and the cost of raw materials is greatly reduced.

Owner:SHENZHEN SHENZHOU CABLE

Manufacturing process for aluminum alloy capillary tube

The invention discloses a production technology for an aluminum alloy capillary tube, which orderly comprises the following steps that: (1) an aluminum alloy tube blank is prepared, and inner lubricating oil is injected into the tube blank; (2) the tube blank is stretched, the stretching speed is between 70 and 80 meters / minute, and outer lubricating oil is uninterruptedly sprayed on the outer surface of the tube blank during the stretching process; and (3) the step (1) and the step (2) are repeated for 4 to 6 times. The production of the capillary tube by adopting aluminum alloy saves expensive copper resource and greatly reduces production cost. The specific gravity (2.70) of aluminum is only one third or so of the specific gravity (8.93) of copper, so the weight of the capillary tube can be greatly reduced.

Owner:苏州宏太铜材有限公司

Tin-plated copper-coated brass wire and production method thereof and tin plating device

InactiveCN103325439ASolderableAnti-sulphurizationSingle bars/rods/wires/strips conductorsCable/conductor manufactureTinningVulcanization

The invention discloses a tin-plated copper-coated brass wire and a production method thereof and a tin plating device used in a production process. The tin-plated copper-coated brass wire comprises a brass wire body, a copper layer and a tin layer, wherein the outside of the brass wire body is plated with the copper layer, and the outside of the copper layer is plated with the tin layer. The tin-plated copper-coated brass wire not only has weldability, vulcanization resistance, electrical conductivity, oxidation resistance and the like of round tin-plated soft copper wires, but also can save copper resources and is easy and convenient to install. A plating method of hot tinning is adopted in a tinning step, no waste water is generated or discharged in the whole process, and no pollution will be caused to the environment. Meanwhile, the method of hot tinning is adopted, and therefore the tin layer is better in adherence and continuity and more uniform in thickness. When a tin-coated sizing mold used for the tin-plated copper-coated brass wire is compared with asbestos used in the prior art, the steps of tinning are simplified, the plating layers are better in adherence and continuity and more uniform in thickness, and the photometric brightness of the appearance of the tin-plated copper-coated brass wire obtained in the production method is better.

Owner:ANHUI WANGDA COPPER DEV

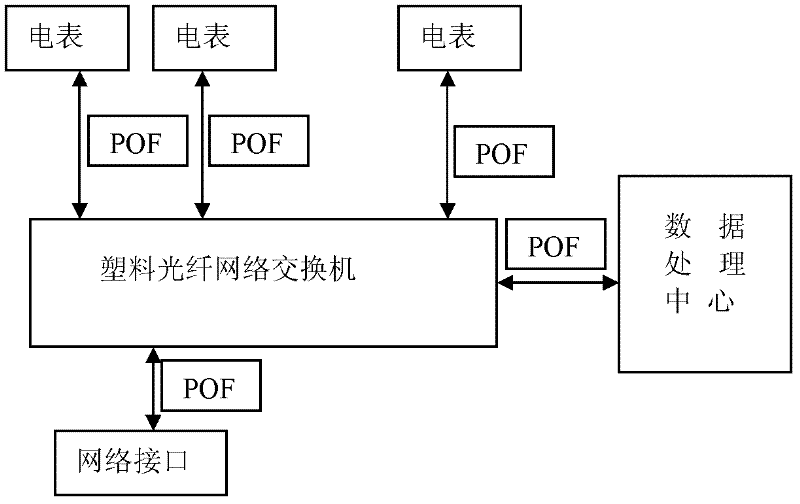

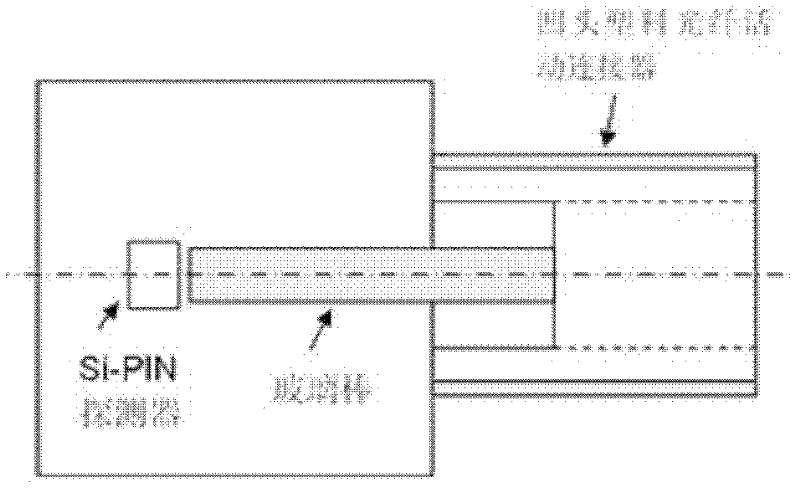

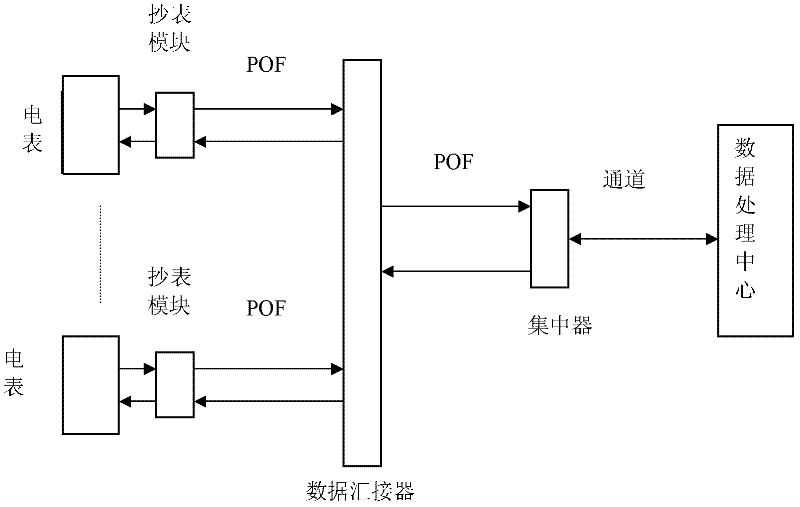

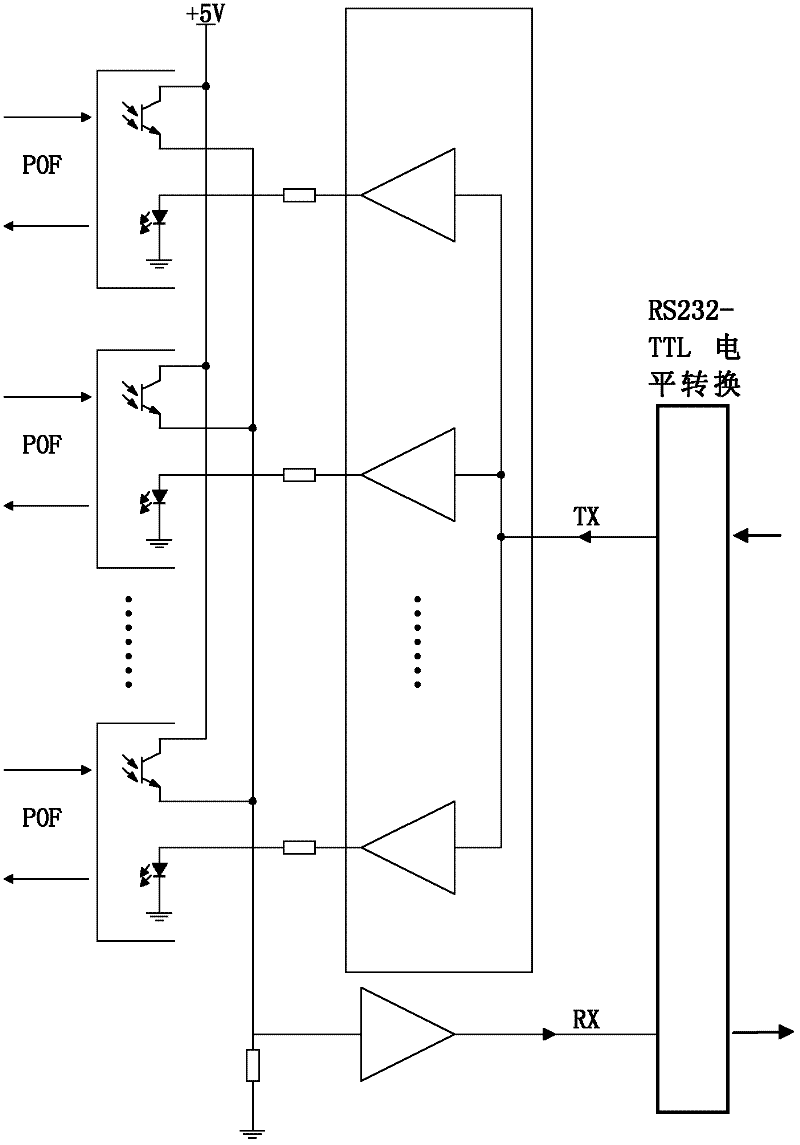

Plastic optical fiber network electricity checks meter system

InactiveCN102314765ALow priceSave copper resourcesNon-electrical signal transmission systemsElectromagnetic transmissionEngineeringElectric power

The invention provides a plastic optical fiber network electricity checks meter system, and belongs to the field of power line information transmission. The checks meter system provided by the invention has strong anti-electromagnetic interference and nuclear radiation resistance as well as reliable performance; collected data has strong real-time performance, and low cost and high speed transmission of data are realized; the plastic optical fiber network electricity checks meter system is composed of electricity meters, a meter reading module, plastic optical fiber, a plastic optical fiber network switch and a data processing center; The signal flow direction of the checks meter system is as follows: an optic transmitter of the meter reading module converts an electricity meter signal to a network optical signal; the optical signal is coupled to the plastic optical fiber; an optical receiver of the meter reading module receives signals and reduces the optical signal to a network electrical signal; the plastic optical fiber network switch is used for data processing; and the data processing center is used to process data so as to complete the whole process of meter reading. The checks meter system provided by the invention has excellent anti-electromagnetic interference performance, strong security, high sensitivity and small volume, is simple to prepare, requires low cost, and has waterproof and moistureproof properties as well as long service life.

Owner:CHINA ELECTRIC POWER RES INST +1

Tin-coated copper plated aluminium magnesium metal recombination line and production process thereof

InactiveCN101178949AImprove shielding effectComparable in conductivitySingle bars/rods/wires/strips conductorsCable/conductor manufactureTinningCopper wire

The invention discloses a tinning copper-clad aluminum and magnesium composite wire, which includes a copper layer coated on an inner core layer which is an aluminum-magnesium core made of aluminum-magnesium alloy; the copper layer is externally coated with a tinned layer. The production method of the invention is as follows: pretreating the stretchability of an aluminum-magnesium alloy rod; scrubbing, cleaning and drying the aluminum-magnesium alloy rod; brushing the aluminum-magnesium alloy rod and tightly wrapping and welding copper belt on the outside of the aluminum-magnesium alloy rod at the same time; and drawing the wrapped and welded composite rod to the required size; annealing in a tubular furnace tube, and cleansing with a promoter groove, hot tinning and fine drawing the tin plating model and winding after a product is finished finally. The invention has the advantages of convenient preparation as well as simple and reasonable process. The conductive and mechanical properties of the composite wire is as well as those of a copper wire; the shielding effect of the composite wire is superior to that of a copper wire and an aluminum-magnesium alloy wire, and the property of signal transmission is better than that of copper wire. The invention has low cost and can save numerous scarce copper resources, and can be an upgraded product of a pure copper line.

Owner:张家港市盛天金属线有限公司

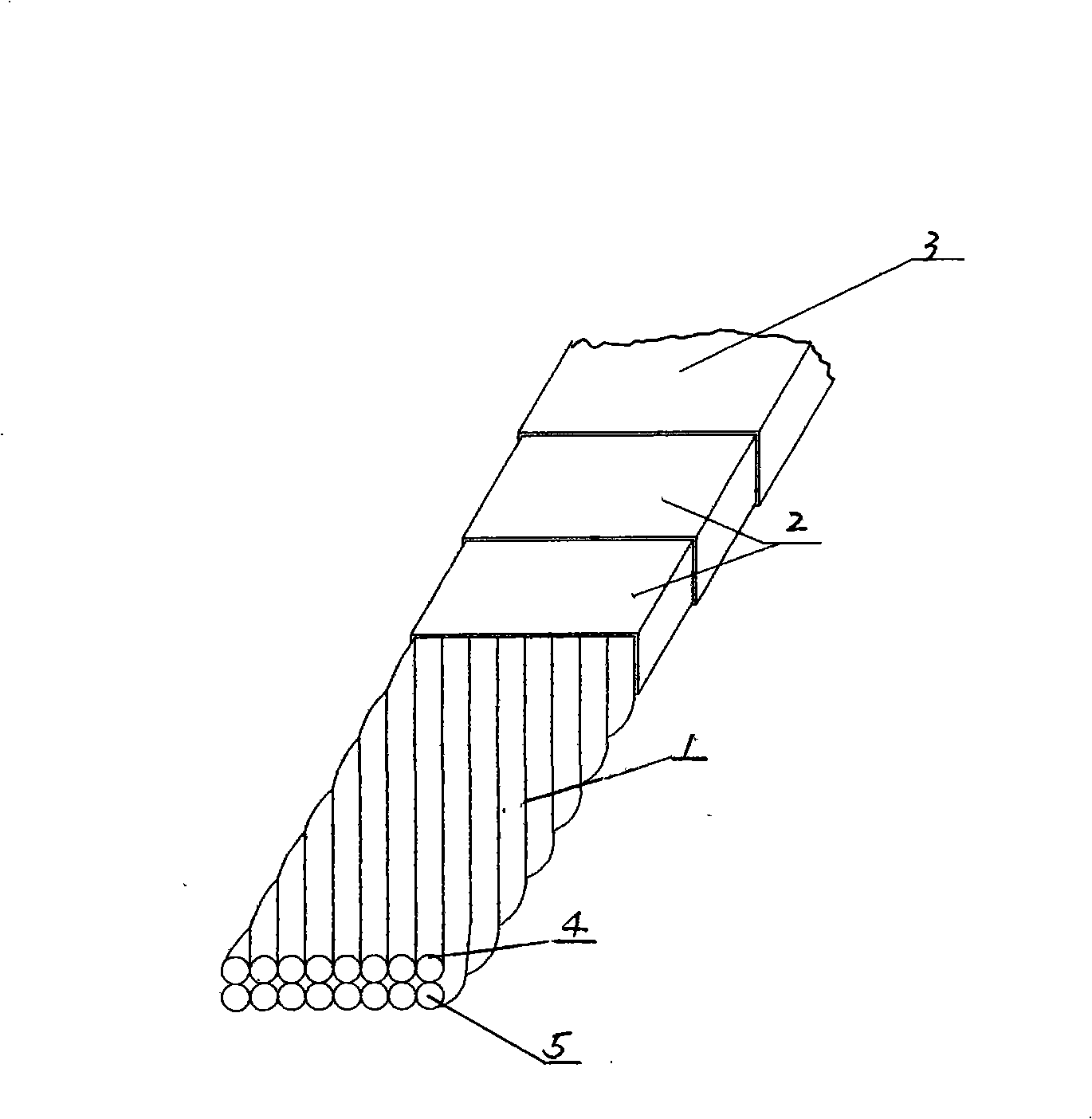

Method for producing copper wrapped aluminum bus

InactiveCN100501879CReduce weightSave copper resourcesConductorsWelding/soldering/cutting articlesCopper conductorHeating furnace

A processing method of a copper-clad aluminum bus-bar includes the following steps: selecting a copper pipe and an aluminum bar, and removing the oxide skins of the copper pipe internal hole and the aluminum bar excircle by mechanically scrubbing; then putting them into the protective gas to prepare for assembly, inserting the aluminum bar into the copper pipe in the protective gas and closing the two ends to prevent from the air; heating the body with closed-ends in the heating-furnace and preventing them from being oxidized; drawing them to form metallurgical combination; rolling the finished bus-bar rough into copper-clad aluminum bus-bar conductors with different sizes in the rolling mill. The copper-clad aluminum bus-bar combines the two defined conductive metals, copper and aluminum, into one conductor, thereby provides a: lower cost and lighter weight conductor than fine copper conductor under the situation of guaranteeing its reliability. It is very considerable in saving of the material and labor cost. Its cost is lowest, saving 30% to 50%, and it is considered as an environmental conservation product because of saving a mass of copper resource. The density of the fine copper bus-bar is 8.9g / cm3, which is 3.47 times higher than that of the copper-clad aluminum bus-bar, which is 3.63g / cm3, and the copper-clad aluminum bus-bar is 3.47 times longer than the fine copper bus-bar with same weight and width.

Owner:FUSHI INT DALIAN BIMETALLIC CABLE

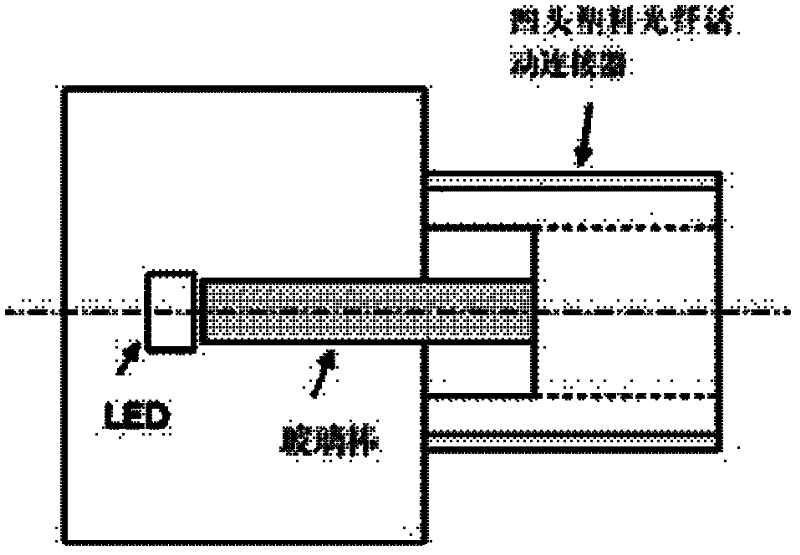

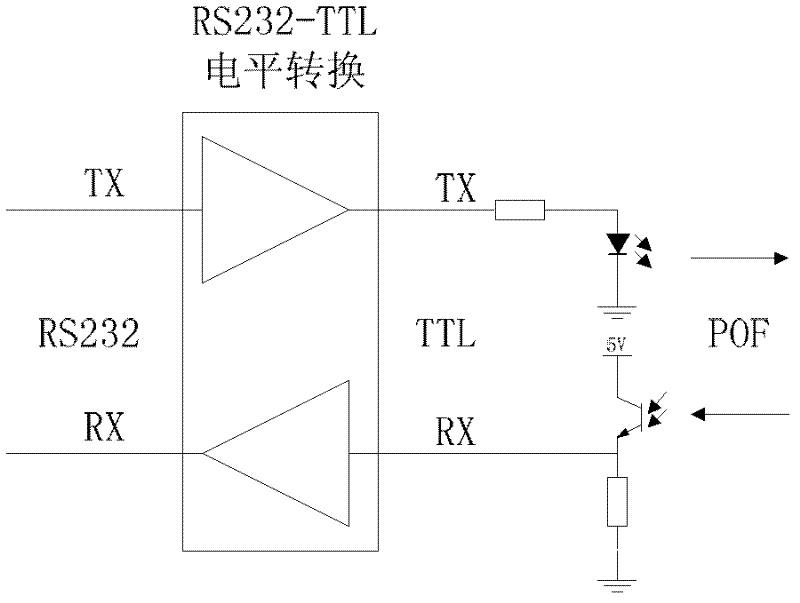

Plastic optical fiber electric power meter reading system

InactiveCN102394003ALow priceSave copper resourcesNon-electrical signal transmission systemsElectric power systemConfidentiality

The invention provides a plastic optical fiber electric power meter reading system, and belongs to the field of transmission of digital information on electric power lines. The plastic optical fiber electric power meter reading system has strong electromagnetic interference resisting and nuclear radiation resisting capabilities as well as reliable performance, and achieves low cost and high-speed transmission of data. The plastic optical fiber intelligent electric power meter reading system is composed of an optical transmitter, an optical receiver, plastic optical fiber, a data joint device, a data concentrator and a plurality of passive devices, wherein an electric meter signal (such as a Transistor-Transistor Logic (TTL) level signal) of the optical transmitter drives an optical signal, the optical signal is coupled to the plastic optical fiber and transmitted to the optical receiver through the plastic optical fiber, the light receiver restores the optical signal to the electric signal (such as a TTL level signal), and data processing is carried out by the data concentrator to finish the whole process of POF (plastic optical fiber) intelligent electric power meter reading. The meter reading system has the advantages of excellent electromagnetic interference resistance, high reliability, strong confidentiality, high sensitivity, smaller volume, simpleness in preparation, low cost, waterproof and moisture-proof properties and long service life.

Owner:CHINA ELECTRIC POWER RES INST +1

Novel transposition aluminum conductor

ActiveCN101409117AEnsure safetyAvoid and reduce eddy current lossInsulated cablesInsulated conductorsUltra high voltageEddy current

A novel transposition electrical aluminium wire relates to a winding wire. The aluminium product, a substitute for copper product, is used for supervoltage and ultra-high voltage fields and can reduce eddy current loss in coils and save energy. The wire is characterized by comprising a flat transposition wire, a film insulating layer and a compound insulating layer; the flat transposition wire is a rectangle transposition stranded wire, which consists of a plurality of non-defective single-stranded circular aluminum wires with insulated film lapping layers and arrayed in double layers; the film insulating layer is the insulated film lapping layer; the compound insulating layer is a compound non-woven fabric lapping layer with an insulated film, the film insulating layer is covered at the outside of the flat transposition wire, and the compound insulating layer is covered at the outside of the film insulating layer. The aluminium wire is used for making the windings supervoltage or ultra-high voltage reactors and high voltage electric appliances.

Owner:天津经纬电力科技有限公司

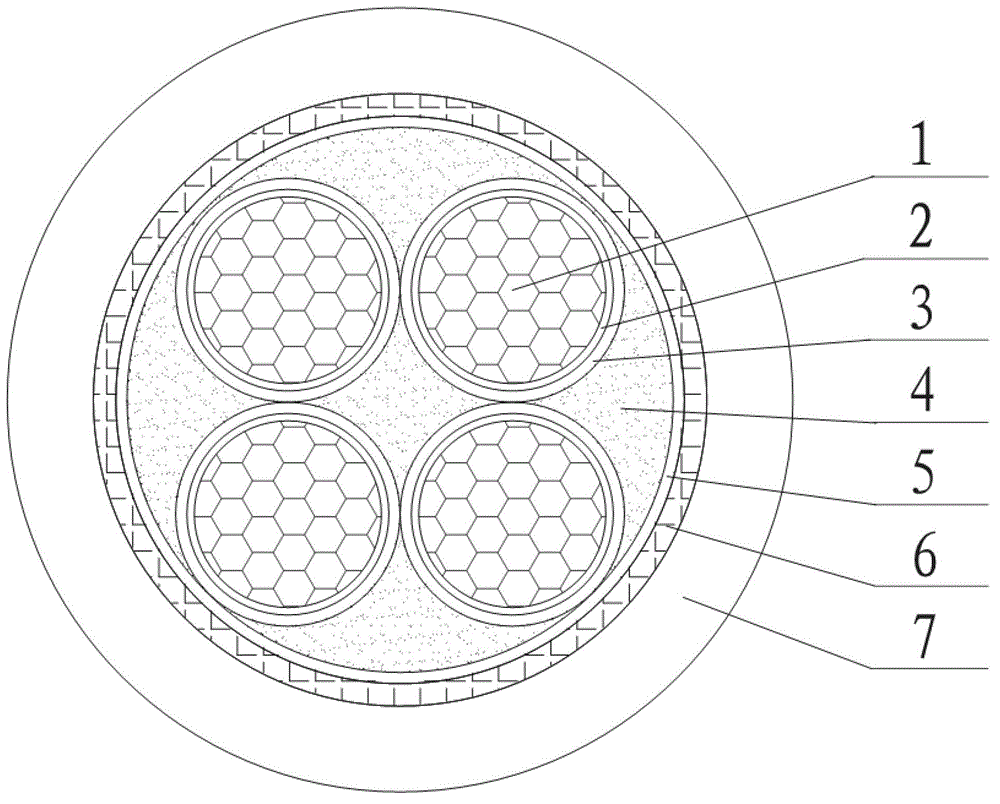

High-performance aluminium alloy cable for building

InactiveCN103337290AExtended durationHas flame retardant propertiesInsulated cablesPower cablesElectricityInsulation layer

The invention discloses a high-performance aluminium alloy cable for buildings, which solves the problems that the conventional power cables for buildings consume more copper resources, are worse in bending performance, and have short service life and the like, and has the advantages of light weight, the capability of corrosion-resistance and halogen-free flame retardant, small bending radius, excellent electrical property, long service life and the like. The high-performance aluminium alloy cable structurally comprises a cable core, wherein the cable core is formed by a plurality of wire core conductors arranged inside a filler and made of aluminium alloy; a conductor double-layer insulation layer is arranged on the outer wall of each wire core conductor; the plurality of wire core conductors are intertwisted in a symmetric arrangement manner; the outer wall of the filler is wrapped with a cable belting layer, a cable armored layer and a cable shield layer sequentially from the inside out.

Owner:SHANGDONG HUALING CABLE

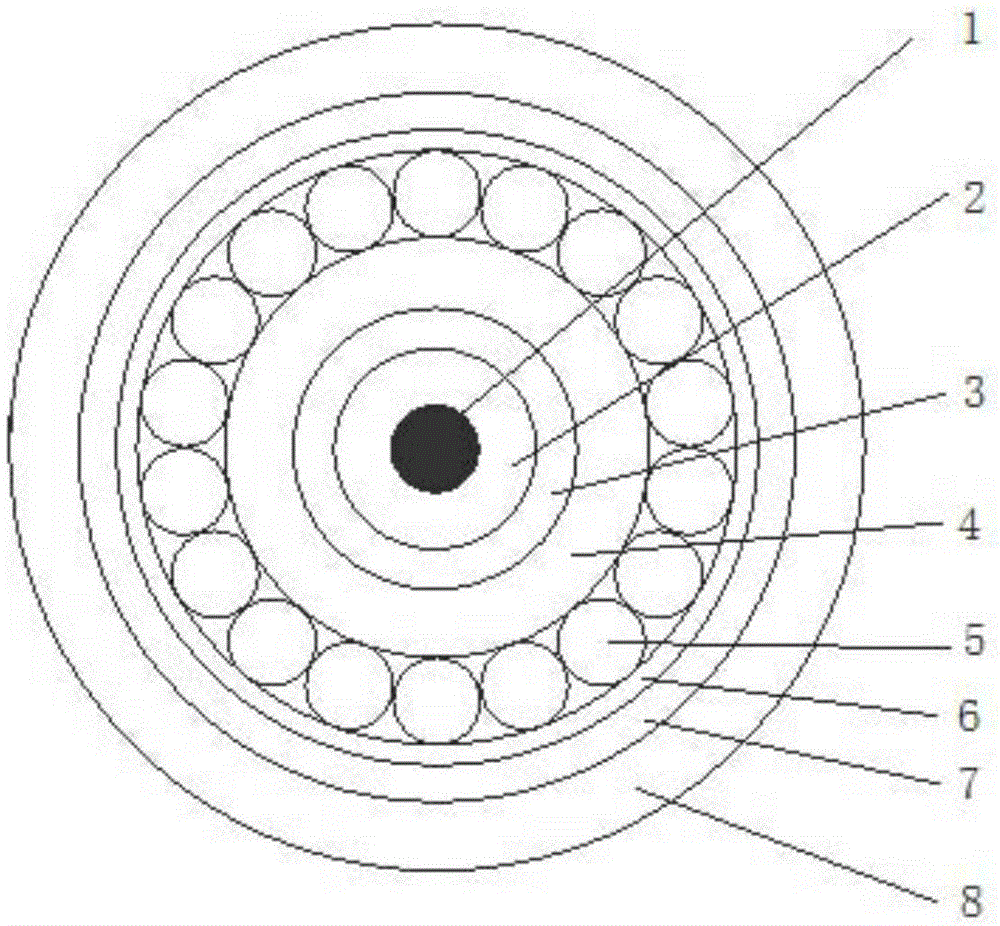

Composite magnetic coupling resonance type wireless power transmission coil

PendingCN110011427APerformance is not affectedReduce performanceTransformersCircuit arrangementsCopper conductorInternal resistance

The invention relates to a composite magnetic coupling resonance type wireless power transmission coil. The cross section of a transmission line adopted for winding a transmission coil is a layered structure which is formed by compounding a solid copper conductor, a first insulating layer, a copper conducting layer, a high-conductivity material conducting layer and a second insulating layer; the solid copper conductor forms an excitation coil or a load coil of the composite magnetic coupling resonance type wireless power transmission coil, and the copper conducting layer and the high-conductivity material conducting layer commonly form a transmitting coil or a receiving coil of the composite magnetic coupling resonance type wireless power transmission coil, so that the excitation coil andthe transmitting coil or the load coil and the receiving coil are compounded into a whole. The internal resistance, caused due to the skin effect, of the transmitting coil and the receiving coil in ahigh-frequency condition can be reduced in a four-coil magnetic coupling resonance type wireless power transmission system, the quality factor of the coils can be improved and high-efficiency transmission of power is achieved so as to provided convenience for miniature and miniaturized devices using the four-coil magnetic coupling resonant wireless power transmission technology.

Owner:LANZHOU UNIVERSITY

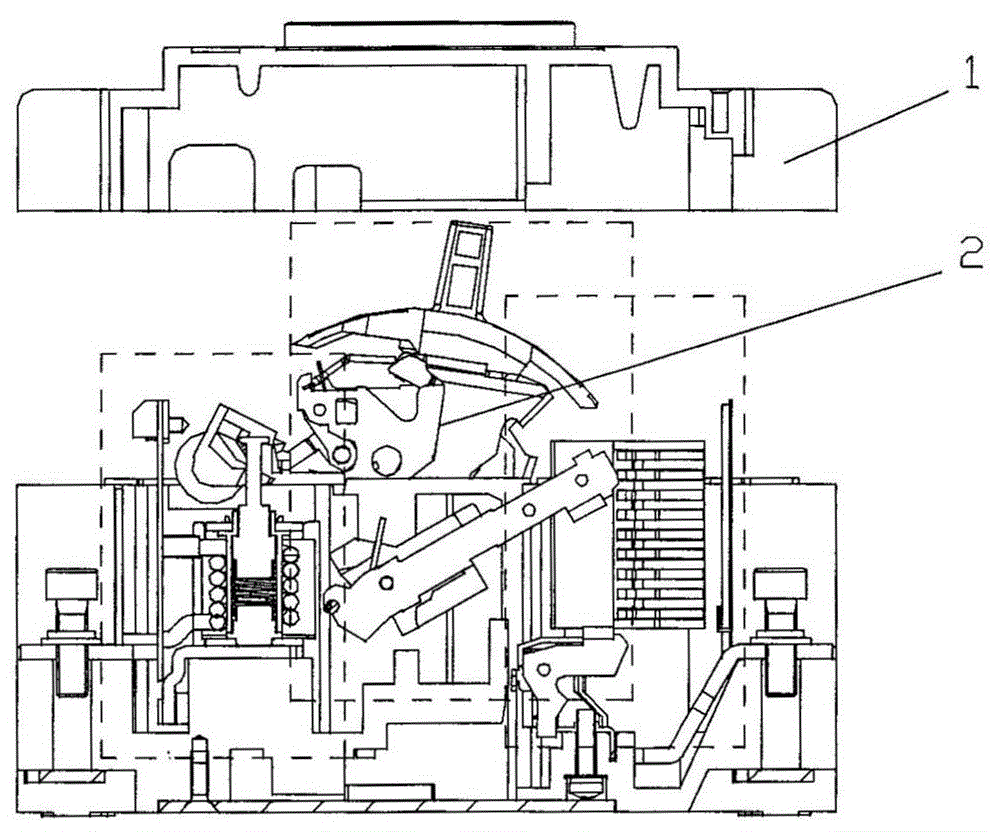

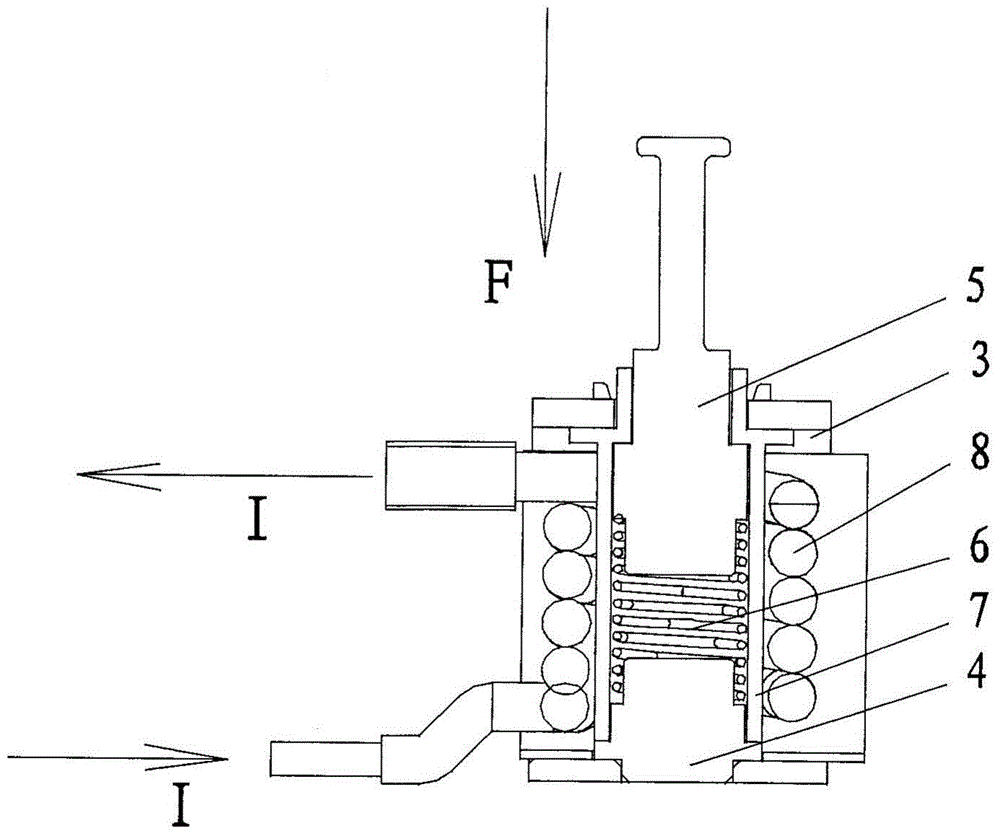

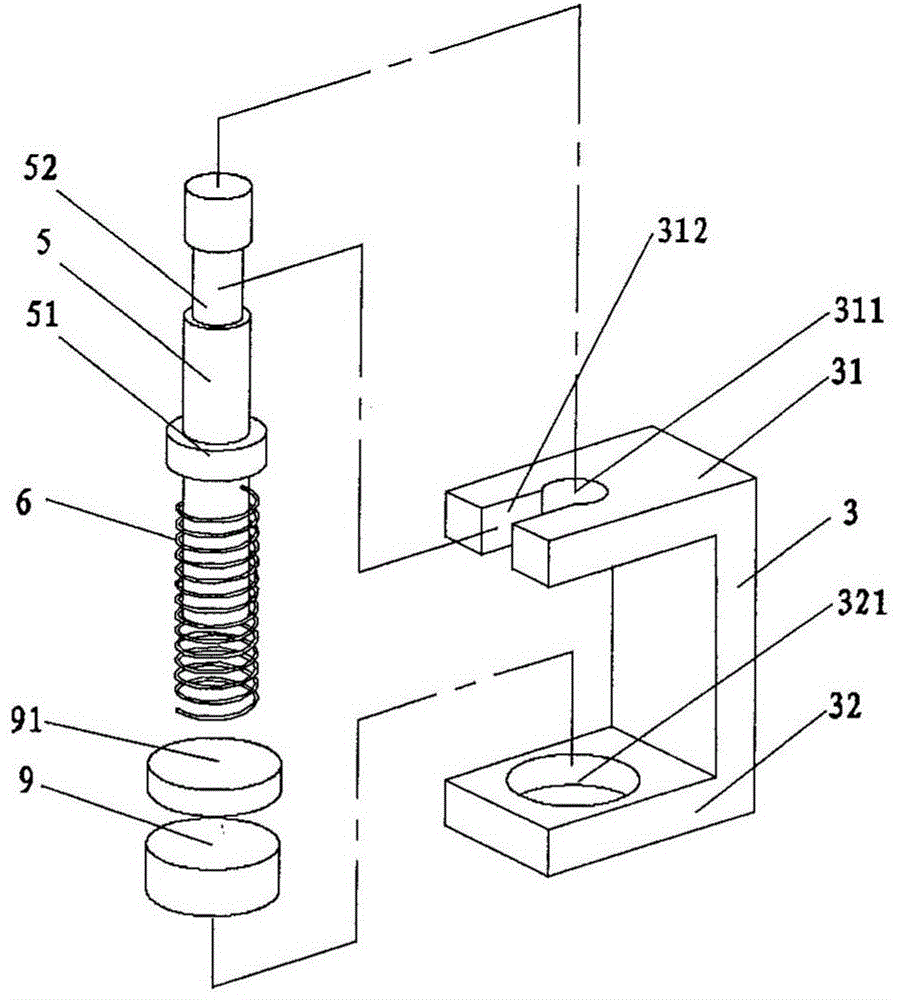

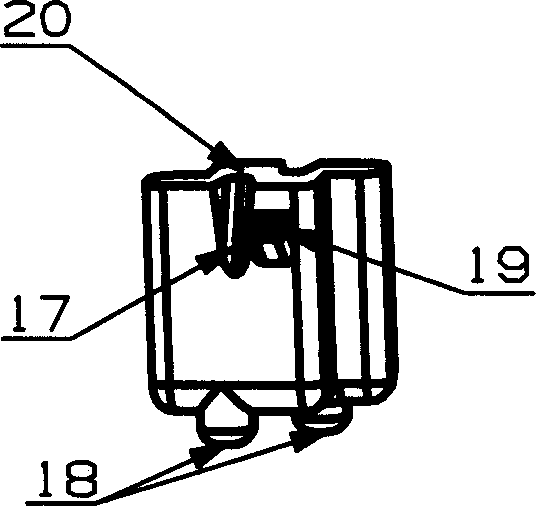

Electromagnetic tripping device and circuit breaker equipped with the electromagnetic tripping device

ActiveCN104465251BSave copper resourcesReduce power consumptionProtective switch operating/release mechanismsPower flowLow voltage

The invention belongs to the technical field of low-voltage apparatuses, and relates to an electromagnetic trip device and a breaker with the electromagnetic trip device. The electromagnetic trip device comprises a magnetic yoke, a movable iron core and a counter-force spring. The movable iron core is arranged on the magnetic yoke, the upper end of the movable iron core extends out of the magnetic yoke, and the counter-force spring is arranged on the movable iron core in a sleeving mode. The electromagnetic trip device is characterized by further comprising a permanent magnet used for providing magnetic flux flowing through a magnetic path and generating electromagnetic attraction force to the movable iron core, the permanent magnet is arranged on the magnet yoke, the lower end of the movable iron core corresponds to the permanent magnet, the upper end of the counter-force spring is borne by the movable iron core, the lower end of the counter-force spring is borne by the permanent magnet, and when the large current flows through an external current loop, the movable iron core is trigged to act. The current carrying row of a main loop or the constraint factor of the current-carrying coil section is eliminated; the size is reduced, the installing space is saved, the electromagnetic trip device can be completely isolated from the main loop, the safety coefficient is increased, installing is flexible and convenient, and the electromagnetic trip device can be installed at reasonable positions of the breaker; copper product resources can be saved, and the resistance value and the power consumption of the breaker can also be obviously reduced.

Owner:CHANGSHU SWITCHGEAR MFG CO LTD (FORMER CHANGSHU SWITCHGEAR PLANT)

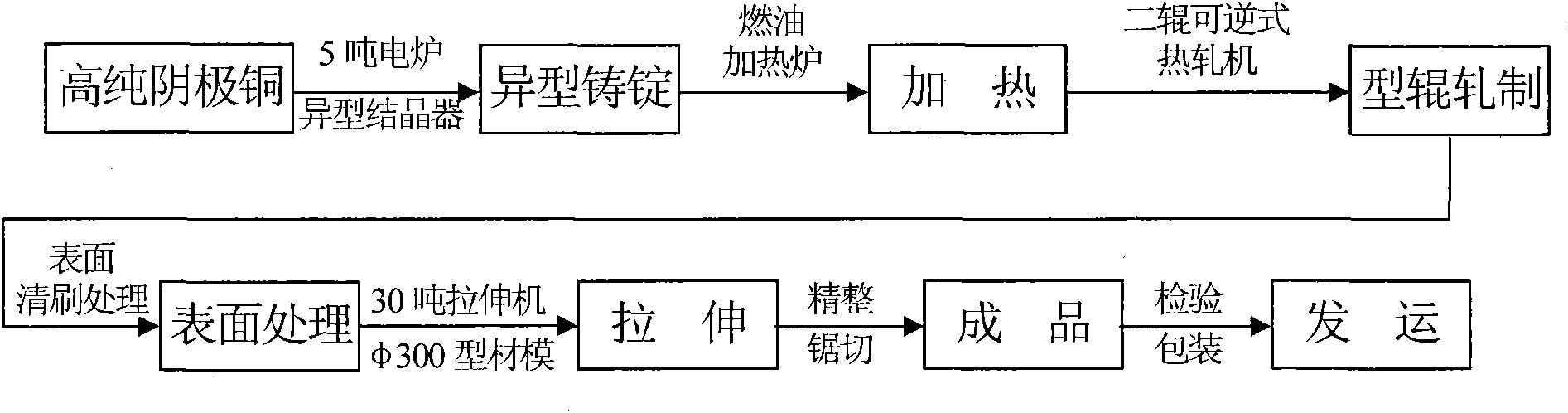

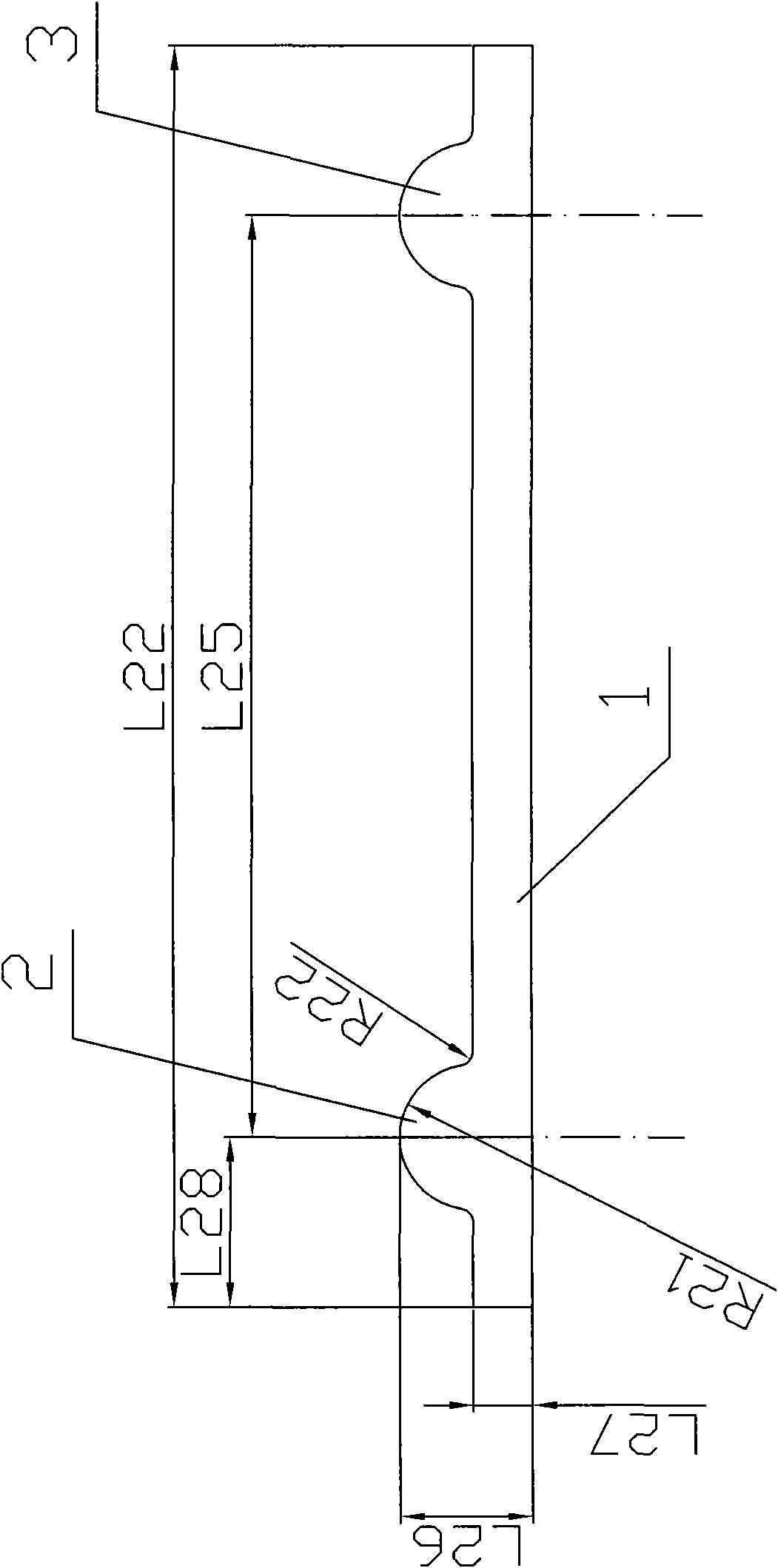

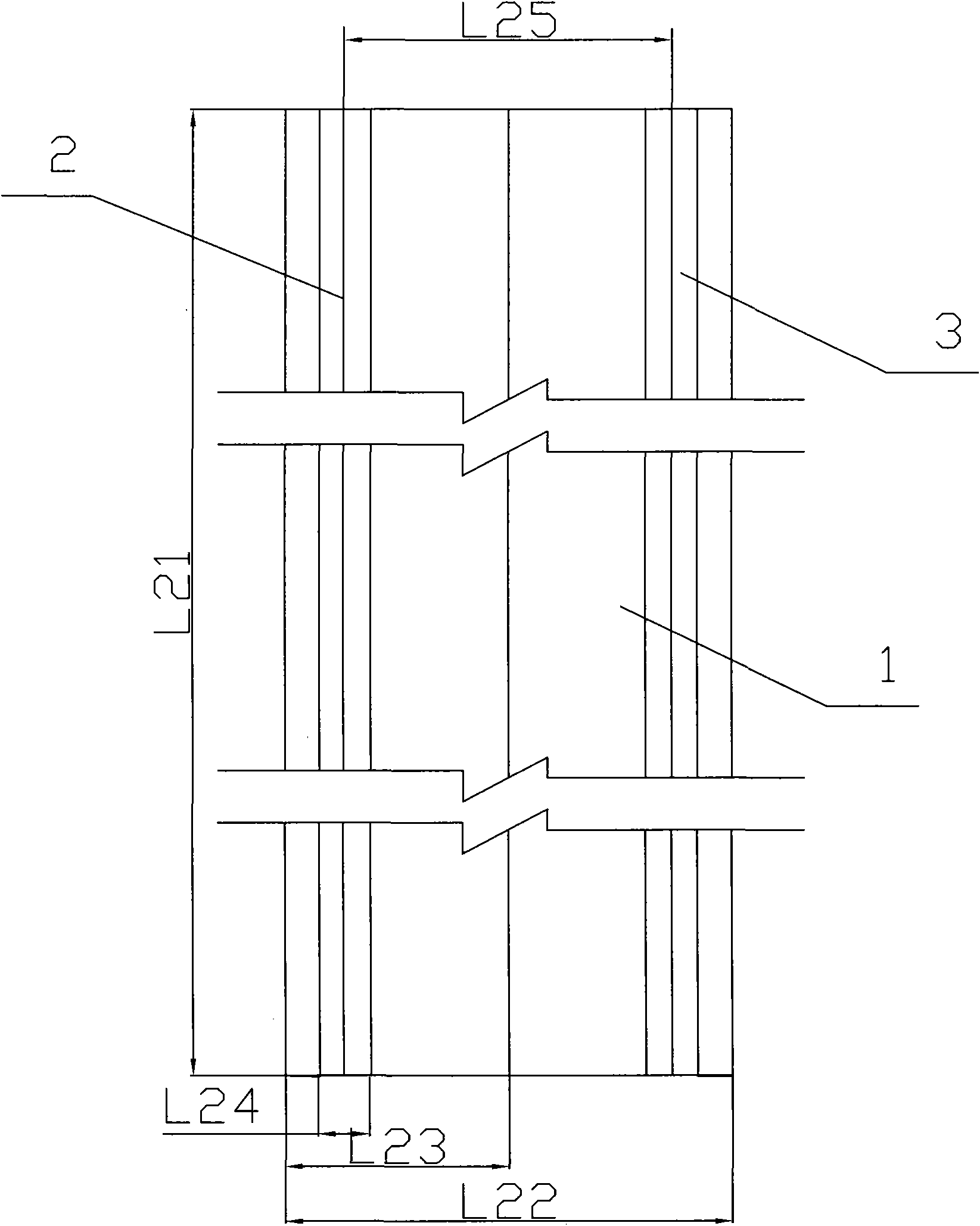

Preparation process of special solid conductive plate and bus board for electrolysis

InactiveCN101850492ASolve the problem of high-precision conductive materialsLow costRollsMetal rolling arrangementsIndustry Standard ArchitectureIngot

The invention relates to a preparation process of a conductive plate and a bus board, in particular to the preparation process of the solid special conductive plate and the bus board which are applied to an ISA (Industry Standard Architecture) method novel electrolytic process. The preparation process of the solid conductive plate and the bus board comprises the following steps of: (1) preparing special cast ingots which respectively have the same shape of the solid conductive plate and the bus board; (2) preparing blanks of the solid conductive plate and the bus board by using a two-roller reversible hot rolling mill; (3) stretching the blanks; and (4) refining and cutting into a finished product. By adopting a production process of matching the rolling of the special cast ingot with stretching to replace the traditional production process of machining a flat plate, the invention can solve the problem of the production process of the large-size solid special conductive plate and the bus board which are required by the ISA method novel electrolytic process introduced by foreign countries and are provided with two rows of continuous conductive ribs. By adopting the invention, the solid special conductive plate and the bus board which are applicable for the ISA method novel electrolytic process can be prepared.

Owner:江西九星铜业有限公司

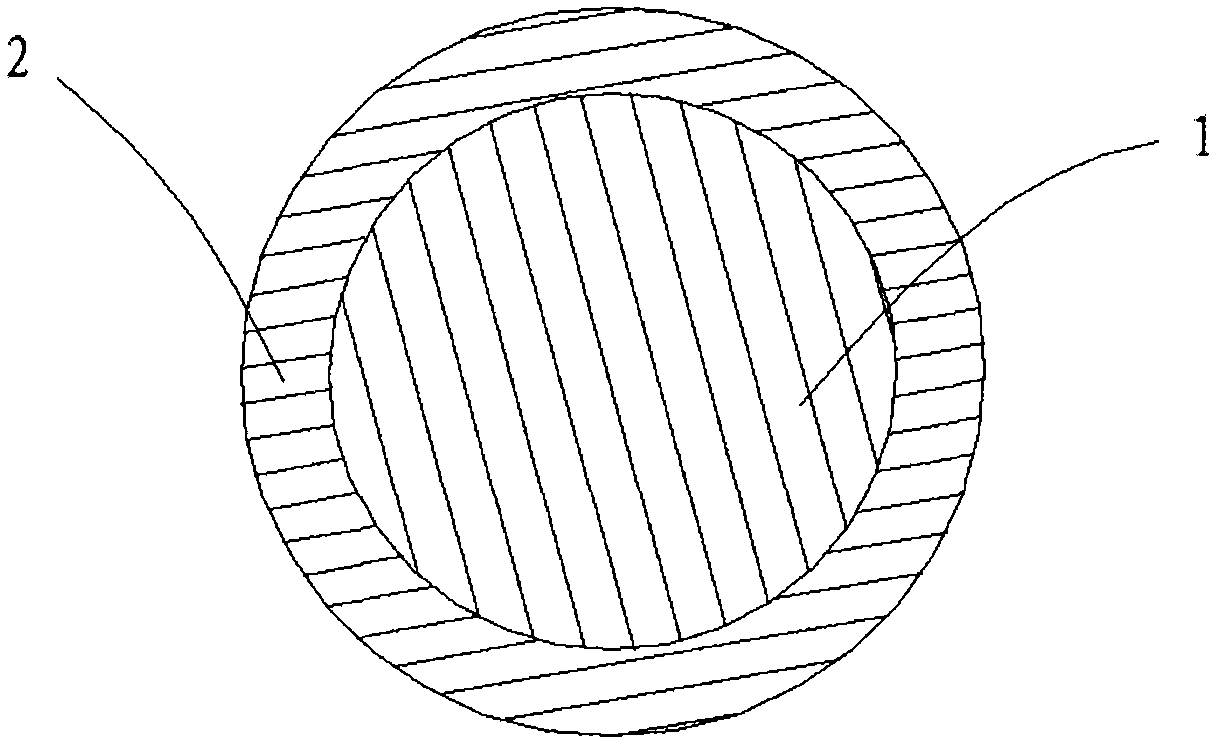

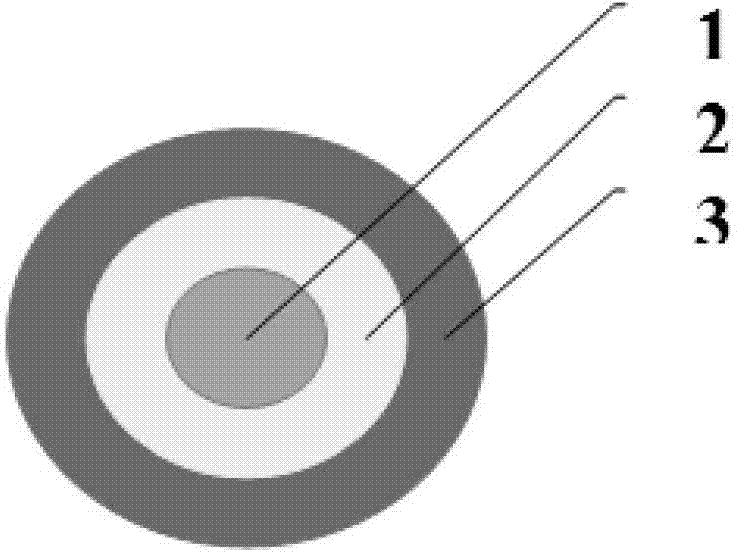

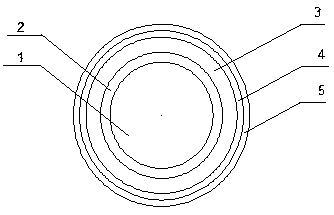

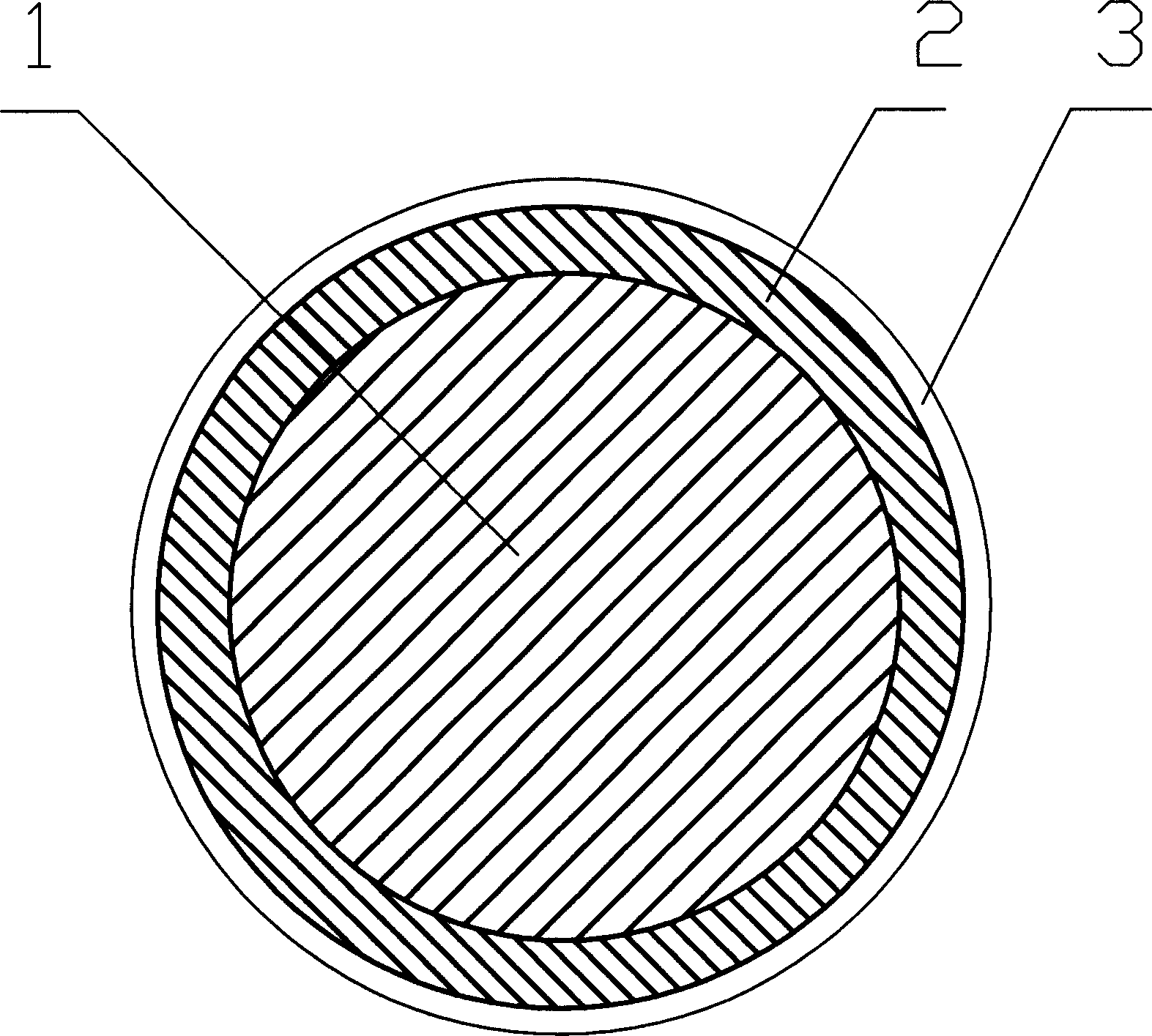

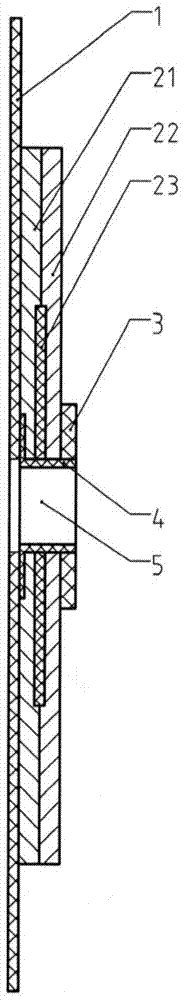

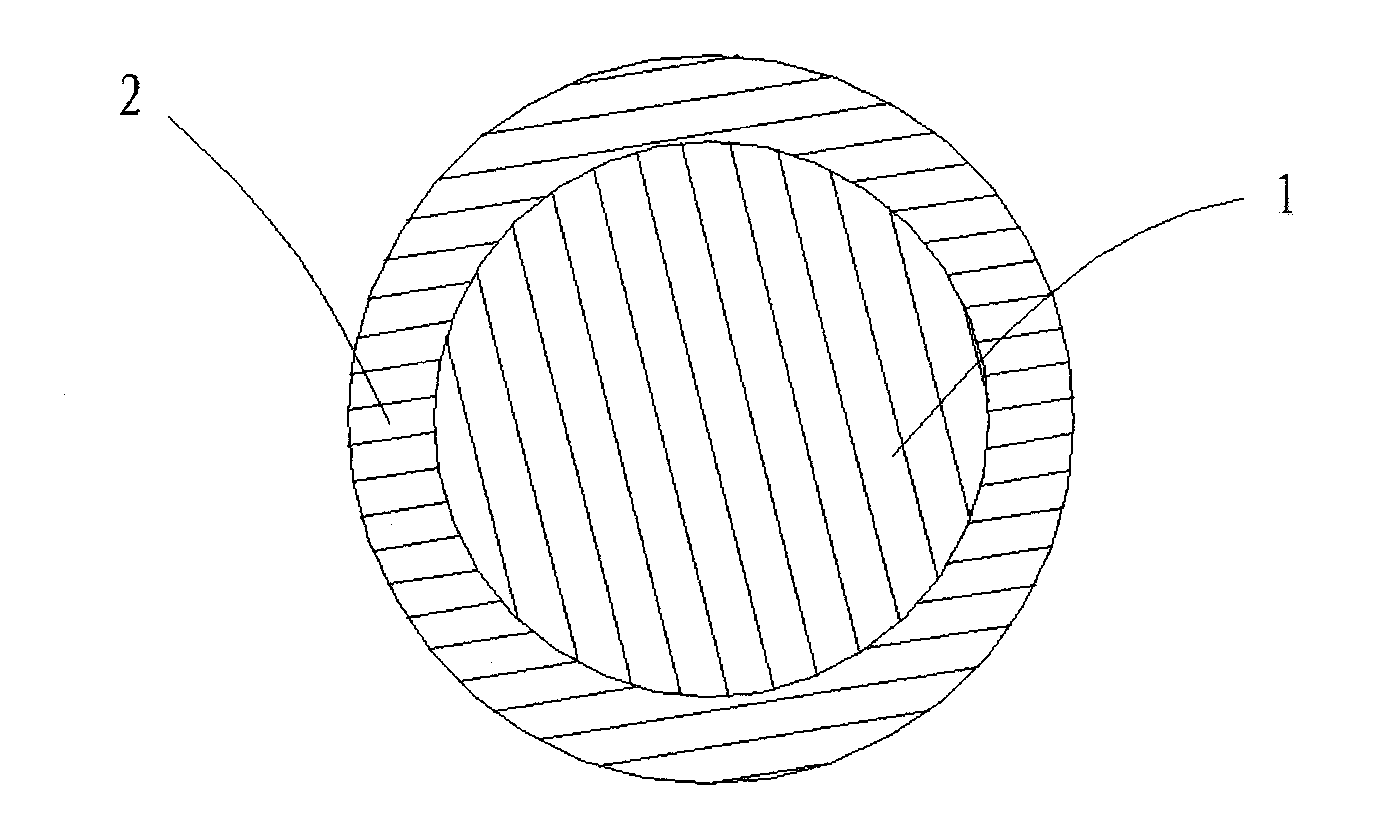

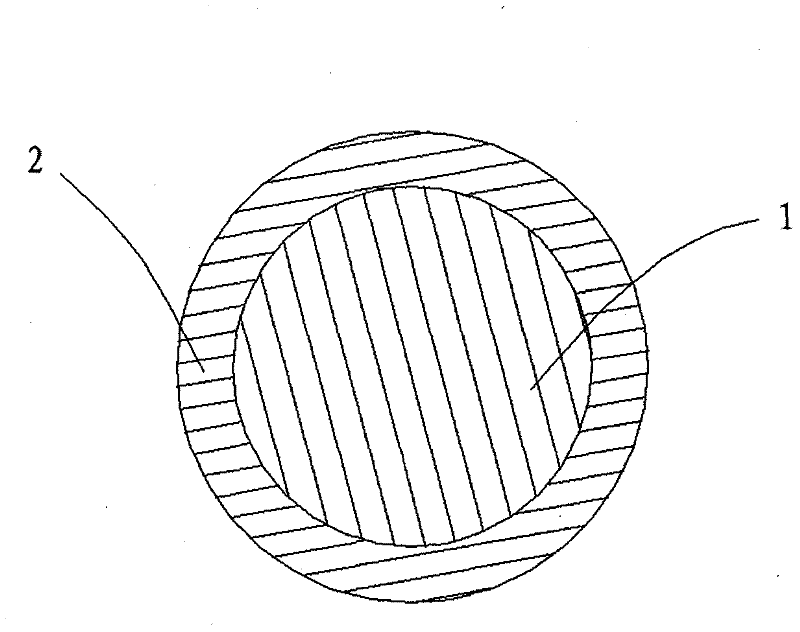

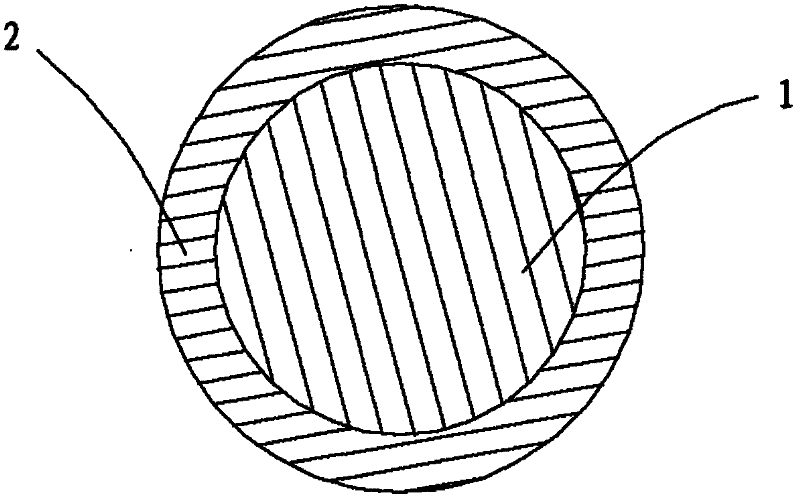

Aluminium-in-copper nano mica enamel-covered wire

InactiveCN1979696AAdvanced technologyWith ultra-thinWindings insulation materialTransformers/inductances coils/windings/connectionsInsulation layerLacquer

This invention discloses a kind of copper wrapped aluminium nano mica emamelled wire, including aluminium core (1) and the copper layer (2) covered over the aluminium core (1), a layer of nana mica insulation paint is coated over the outer surface of the said copper layer (2). The invention is a kind of aluminium- in- copper nano mica enamelled wire with thin insulation layer, strong performance of insulation, and with high performance of temperature-proof, pressure-proof, waterproof, oil-proof, corona proof,and simple structure, convenient fabrication as well as reliability.

Owner:胡明钦

Colour lamp base of non-binding post on colour lamp string

InactiveCN1773785AAvoid weak contactGuaranteed not to pull outCoupling device connectionsElectric discharge tubesBinding postElectric wire

A colored lamp seat without wiring terminal on colored lamp string consists of groove for placing bared wire, insertion hole for connecting conductive wires and projection for connecting to wire in groove. It features that said seat is prepared in two parts longitudinally and two separated parts can be buckled up by plastic hook, said projection can be dropped in groove to press wire firmly for enduring reliability of electric connection when colored lamp is inserted on seat.

Owner:徐建国

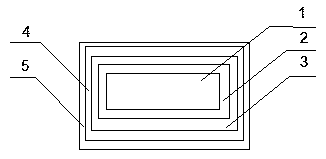

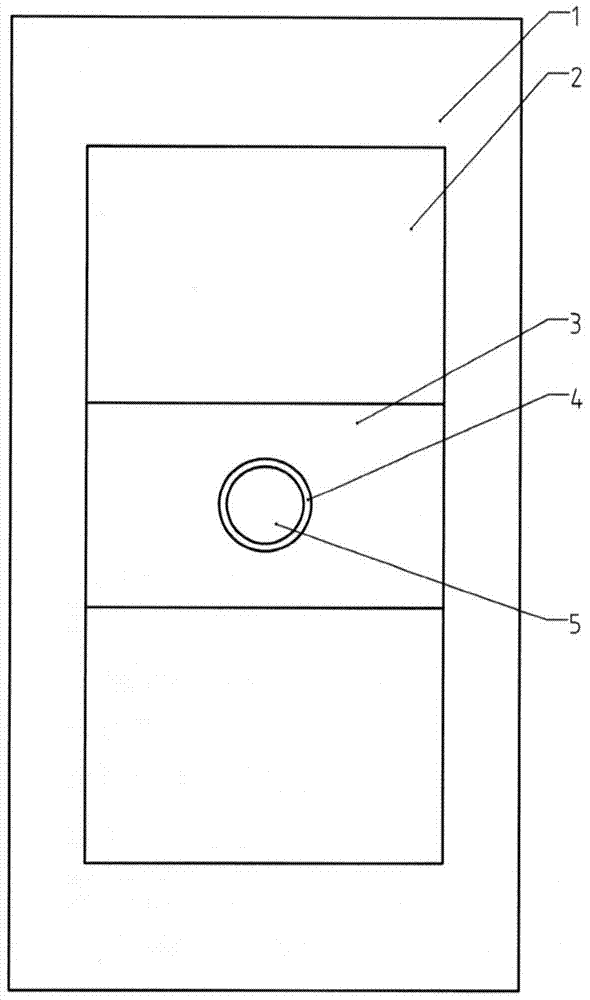

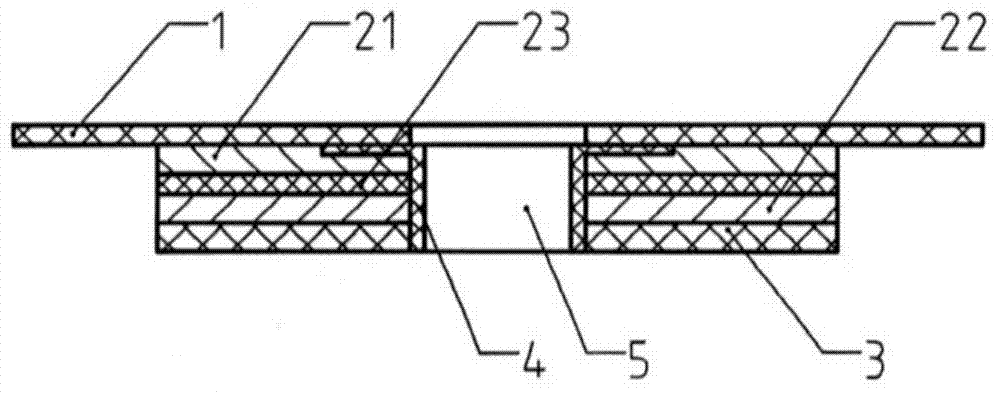

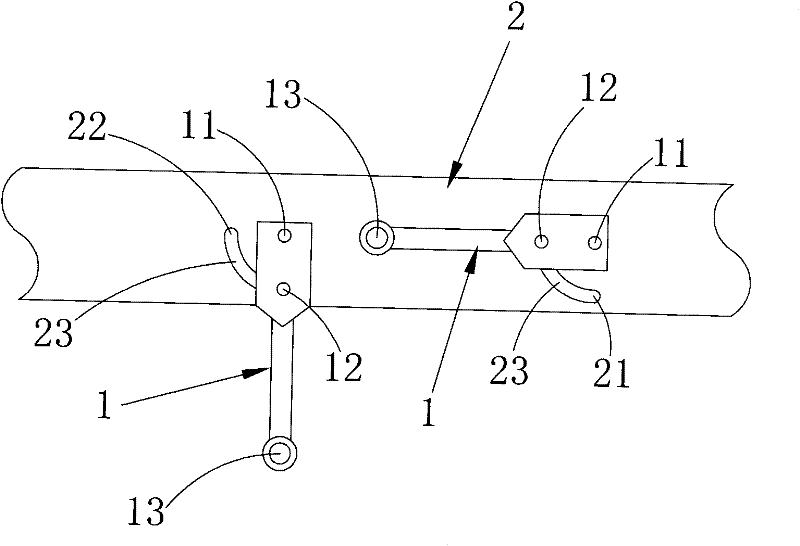

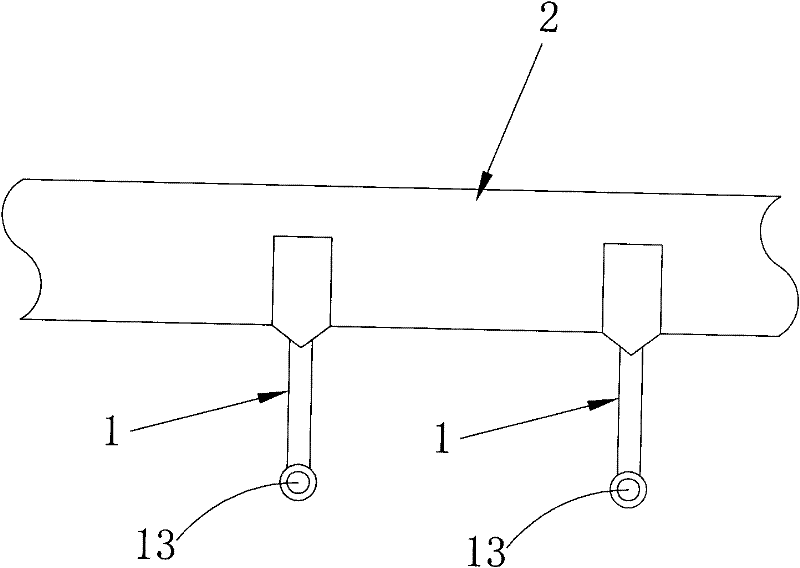

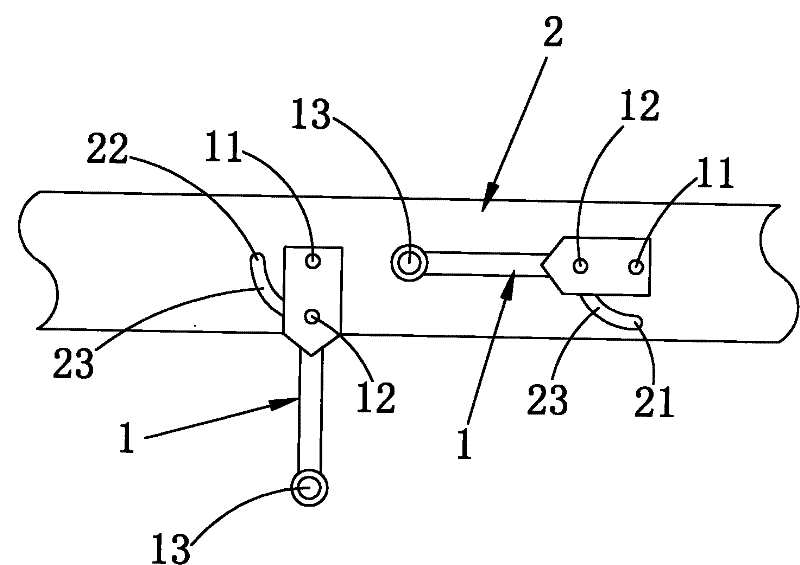

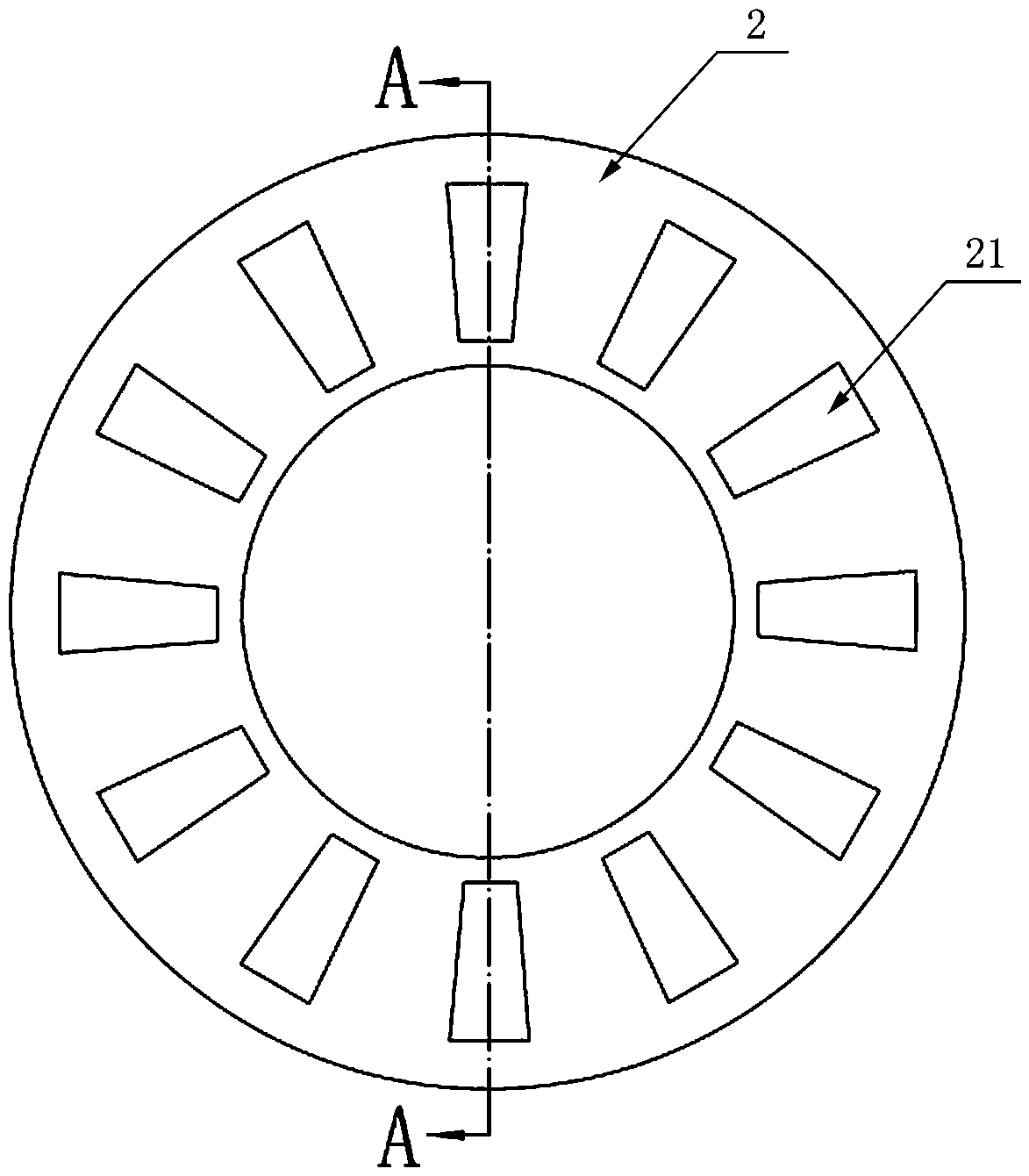

Insulating single-inserting sheet of in-phase double-circuit parallel connection transition conductor

ActiveCN104505615ASave materialTroubleshoot transition issuesSecuring/insulating coupling contact membersCoupling contact membersElectrical conductorEngineering

The invention discloses an insulating single-inserting sheet of an in-phase double-circuit parallel connection transition conductor. In the insulating single-inserting sheet, a single-side contact connecting sheet (2) of the in-phase double-circuit parallel connection transition conductor is arranged on one side of an insulating plate (1), and is composed of a first transition parallel connection conductor (21) and a second transition parallel connection conductor (22) in a parallel connection mode, and a transition conductor insulating layer (23) is arranged between the first transition parallel connection conductor (21) and the second transition parallel connection conductor (22); a locating insulating block (3) is arranged on the outer side of the single-side contact connecting sheet (2) of the in-phase double-circuit parallel connection transition conductor, an insulating sleeve (4) penetrates through the center of the insulating plate (1), the center of the single-side contact connecting sheet (2) of the in-phase double-circuit parallel connection transition conductor and the center of the locating insulating block (3), and an insulating bolt hole (5) is formed in the middle of the insulating sleeve (4). Due to the fact that a two-phase insulating double-inserting sheet of the in-phase double-circuit parallel connection transition conductor is utilized, the conductor material is saved, and the current-carrying capacity is improved.

Owner:JIANGSU ONEQ ELECTRICAL APPLIANCE GRP

Copper-clad aluminum-magnesium wire for communication cable and manufacturing method thereof

ActiveCN101916617AReasonable structureAdvanced technologySingle bars/rods/wires/strips conductorsConductive materialElectrical conductorEngineering

The invention relates to a copper-clad aluminum-magnesium wire for a communication cable and a manufacturing method thereof. The copper-clad aluminum-magnesium wire for the communication cable comprises an aluminum-magnesium core rod and a copper layer, wherein the copper layer is uniformly and concentrically clad on the surface of the aluminum-magnesium core rod; the copper layer accounts for 18 to 22 percent of the volume of the copper-clad aluminum-magnesium wire for the communication cable. The manufacturing method of the copper-clad aluminum-magnesium wire for the communication cable comprises: 1, melting; 2, cladding and welding; and 3, wire-drawing and annealing. The structural reasonableness, electrical properties, mechanical properties and environmental properties of the copper-clad aluminum-magnesium wire for the communication cable all meet the technical standards for internal wires of the common communication cables, the signal, image and data transmission performance of the copper-clad aluminum-magnesium wire for the communication cable is in complete accordance with high-frequency transmission line skin effect, the copper-clad aluminum-magnesium wire for the communication cable saves copper resource by replacing copper with aluminum, is in accordance with the trend of energy conservation and emission reduction and can greatly reduce the cost of raw materials.

Owner:SHENZHEN SHENZHOU CABLE

Reinforced aluminium alloy compressive cable

InactiveCN105405508AHigh tensile strengthSolve the problem of breakingFlexible cablesFlexible conductorsInsulation layerElectrical conductor

The invention discloses a reinforced aluminium alloy compressive cable. The reinforced aluminium alloy compressive cable comprises a tubular aluminium alloy conductor; a carbon fibre composite reinforced core is arranged in the centre of the tubular aluminium alloy conductor; a thin copper strip is arranged between the carbon fibre composite reinforced core and the tubular aluminium alloy conductor; an insulation layer is wrapped outside the tubular aluminium alloy conductor in an extruded manner; a single-wire layer, which is formed by a plurality of conductive single wires in a parallel winding manner, is wound outside the insulation layer; a buffer layer and an outer sheath are lapped outside the single-wire layer; and a metal compressive tube is also arranged between the buffer layer and the outer sheath. The reinforced aluminium alloy compressive cable disclosed by the invention is high in compressive strength and mechanical strength, good in moisture resistance, sealing performance and flexibility, low in cost and long in service life.

Owner:JIANGSU LONG E CABLE

Copper and aluminum composite pipe of refrigerating machine and processing technology thereof

InactiveCN104138926ALow costReduce processing costsMetal layered productsMetallic bondingProcessing cost

The invention discloses a copper and aluminum composite pipe of a refrigerating machine and a processing technology of the copper and aluminum composite pipe. The processing technology of the copper and aluminum composite pipe is characterized by comprising the steps of continuous casting of a copper and aluminum pipe blank; rolling process; stretching; flaw detecting; and annealing. Defects in the prior art are overcome; the outer side of the provided copper and aluminum composite pipe is provided with an anti-rust aluminum alloy, the inner side of the provided copper and aluminum composite pipe is provided with oxygen-free copper, and an interatomic metallic bonding layer is arranged between copper and aluminum, the pipe blank is cast by using a continuous casting technology for the copper and aluminum pipe blank, and then, a metallurgical bonding layer is formed on a copper and aluminum composite surface by using a hot rolling technology; and the copper and aluminum composite pipe is low in processing cost and can be widely applied into the refrigerating machine such as an air conditioner, a refrigerator to replace a copper pipe, so that a great number of copper resources are saved, and the cost of the refrigerating machine is reduced.

Owner:HEFEI GREAT WALL REFRIGERATION TECH

Fin aluminum foil for high-corrosion-resistance and low-potential heat exchanger and manufacturing method of fin aluminum foil

ActiveCN112605147AMeet the flanging requirementsImprove mechanical propertiesFurnace typesHeat treatment furnacesAluminum foilHeat exchanger

The invention belongs to the field of aluminum alloy foil rolling, and discloses a fin aluminum foil for a high-corrosion-resistance and low-potential heat exchanger and a manufacturing method of the fin aluminum foil. The aluminum foil comprises the following components by mass percentage: 0.40-0.50% of Fe, 0.12-0.20% of Si, less than or equal to 0.03% of Cu, less than or equal to 0.01% of Mn, less than or equal to 0.005% of Mg, 0.8-1.1% of Zn, 0.025-0.05% of Ti , less than or equal to 0.03% of Zr, and the balance of aluminum. The full-process technology for producing the high-Zn heat exchanger fin aluminum foil through the continuous cast rolling and cold rolling method, a produced novel aluminum fin is used in cooperation with a drawing internal thread aluminum round pipe and can serve as an anode sacrificial material to protect an air conditioner heat exchanger aluminum alloy pipe, and the service corrosion penetration life of the air conditioner heat exchanger drawing aluminum pipe is prolonged; and therefore, a heat exchanger of an air conditioner outdoor unit can be fully aluminized and is possible to be high in corrosion resistance and long in service life.

Owner:JIANGSU DINGSHENG NEW MATERIAL JOINT STOCK CO LTD

Fixing structure of secondary hanger for plating PCB (Printed Circuit Board)

InactiveCN102220624AAvoid being platedEasy to optimizeElectrolysis componentsEngineeringPrinted circuit board

The invention discloses a fixing structure of a secondary hanger for plating a PCB (Printed Circuit Board). The secondary hanger is capable of rotating around a first fixed point by setting two fixed points on the secondary hanger and setting two locating points on a copper medal; when the secondary hanger is rotated to the second fixed point and is overlapped with the first locating point on the copper medal, the secondary hanger is firmly connected with the copper medal; at the moment, the secondary hanger is vertically downwards for normal electroplating; when the secondary hanger is not fixed with a board, the secondary hanger is rotated to the second fixed point and is overlapped with the second locating point on the copper medal, and then the secondary hanger is firmly connected with the copper medal; at the moment, the secondary hanger is fixed horizontally; when in electroplating, the secondary hanger which is not fixed with the board is fixed horizontally, and the secondary hanger is prevented from soaking in electroplating liquid and participating the electroplating; therefore, the secondary hanger which is not fixed with the board is prevented from plating copper, the problem of copper slag can be effectively improved, the copper resource is saved, the uniformity of plating can be further guaranteed, and the product quality is improved.

Owner:竞陆电子(昆山)有限公司

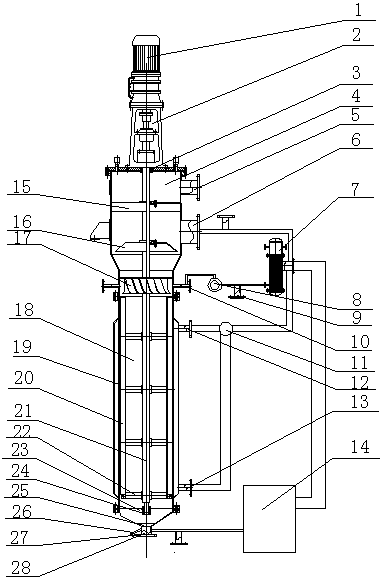

Duplex centrifugal-film evaporator for preparing basic cupric carbonate

InactiveCN103007559AEasy to separateQuick responseEvaporationCopper compoundsBASIC CUPRIC CARBONATEBasic copper carbonate

The invention relates to a duplex centrifugal-film evaporator for preparing basic cupric carbonate, which includes a drive system, a vapor treatment chamber, an evaporation chamber and a tapered discharging chamber, wherein a gas-liquid filter and a gas-liquid separator are arranged inside the vapor treatment chamber; the outer wall of the vapor treatment chamber is provided with a tail gas collecting opening and a secondary vapor recovering opening; a distributing device is arranged at the top end of the vapor treatment chamber; a material inlet is formed in the outer wall of the distributing device; the secondary vapor recovering opening is communicated with the material inlet sequentially through a condenser and a feeding pump; a jacket is arranged inside the evaporation chamber; the outer wall of the jacket is provided with a vapor outlet and a condensate water outlet; the vapor outlet and the condensate water outlet are communicated with each other, and are communicated with the material inlet sequentially through a vacuum pump, the condenser and the feeding pump; one side of a discharge valve of the tapered discharging chamber is connected with a sample collector; the other side of the discharge valve is connected with a screw rod feeder; and the screw rod feeder is communicated with the material inlet sequentially through the condenser and the feeding pump. The duplex centrifugal-film evaporator realizes on-line production detection and treatment as well as on-line recovery and utilization of gas, liquid and residues, thereby improving the product quality and yield.

Owner:TAIXING SMELTING PLANT

Method for making copper oxygen gun nozzle

This invention involves a manufacture method for copper-saved oxygen lance nozzle. It is characterized in: copper-saving oxygen lance nozzle comprises the upper oxygen-in-end and the subjacent oxygen blow end, fix 3-8 oxygen blow hole at circumferential direction of the oxygen blow end, the included anglealpha1of oxygen lance nozzle axial ray and the oxygen blow hole is 7- 18degree, water-blocking plate surrounds the lateral wall of oxygen blow hole and connects with oxygen lance tube, the included angle of oxygen lance nozzle axial ray of the connection of the upper oxygen-in-end and the subjacent oxygen blow end and welding slope groove isalpha2,alpha2>= alpha1. The oxygen-in-end of the copper-saved oxygen lance sprayer in this invention adopts cast steel, steel or low-cost alligation such as brass and other materials, which not only improves the service life but also lowers the cost of production and saves copper resources. The invention has the advantages of high mechanical strength, good thermal conductivity, reasonable design and simple structure. The service life of the nozzle is 3 times of cast copper oxygen lance nozzle.the method can save about 50% copper.

Owner:梁璐

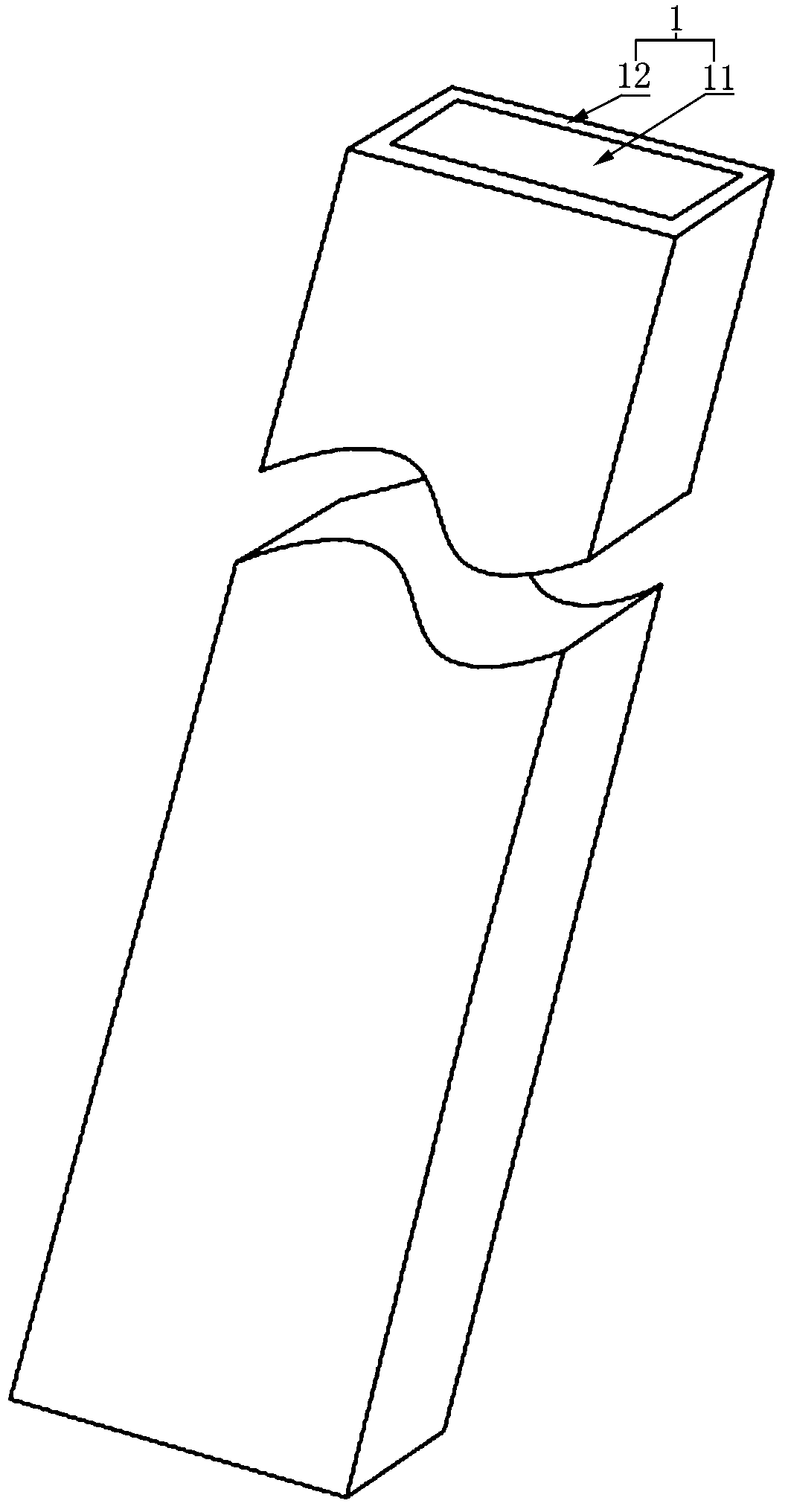

Rotor cage of squirrel cage motor

PendingCN108448851AEasy to detectSave copper resourcesAsynchronous induction motorsEngineeringCopper

The invention relates to the field of squirrel cage motor accessories and particularly relates to a rotor cage of a squirrel cage motor, mainly to solve the technical problems that a copper rotor cagein the prior art is high in cost and the quality of an aluminum rotor cage is hard to ensure. The below technical scheme is mainly adopted and the rotor cage of the squirrel cage motor comprises a plurality of composite guide bars and two aluminum end rings connected at two ends of the composite guide bars, wherein the composite guide bar is formed by an aluminum bar and a copper layer coating the periphery of the aluminum bar. The rotor cage is mainly applicable to a squirrel cage motor, in particularly, a squirrel cage-type asynchronous motor, and is used as a rotor cage structure of the squirrel cage motor.

Owner:永济市贝特电气机械有限公司

Copper-clad aluminum-magnesium wire for communication cable

ActiveCN101916617BReasonable structureAdvanced technologySingle bars/rods/wires/strips conductorsConductive materialElectrical conductorSkin effect

The invention relates to a copper-clad aluminum-magnesium wire for a communication cable. The copper-clad aluminum-magnesium wire for the communication cable comprises an aluminum-magnesium core rod and a copper layer, wherein the copper layer is uniformly and concentrically clad on the surface of the aluminum-magnesium core rod; the aluminum-magnesium core rod consists of 98.65% aluminum, 1.2% magnesium and 0.15% cadmium. The structural reasonableness, electrical properties, mechanical properties and environmental properties of the copper-clad aluminum-magnesium wire for the communication cable all meet the technical standards for internal wires of the common communication cables, the signal, image and data transmission performance of the copper-clad aluminum-magnesium wire for the communication cable is in complete accordance with high-frequency transmission line skin effect, the copper-clad aluminum-magnesium wire for the communication cable saves copper resource by replacing copper with aluminum, is in accordance with the trend of energy conservation and emission reduction and can greatly reduce the cost of raw materials.

Owner:SHENZHEN SHENZHOU CABLE

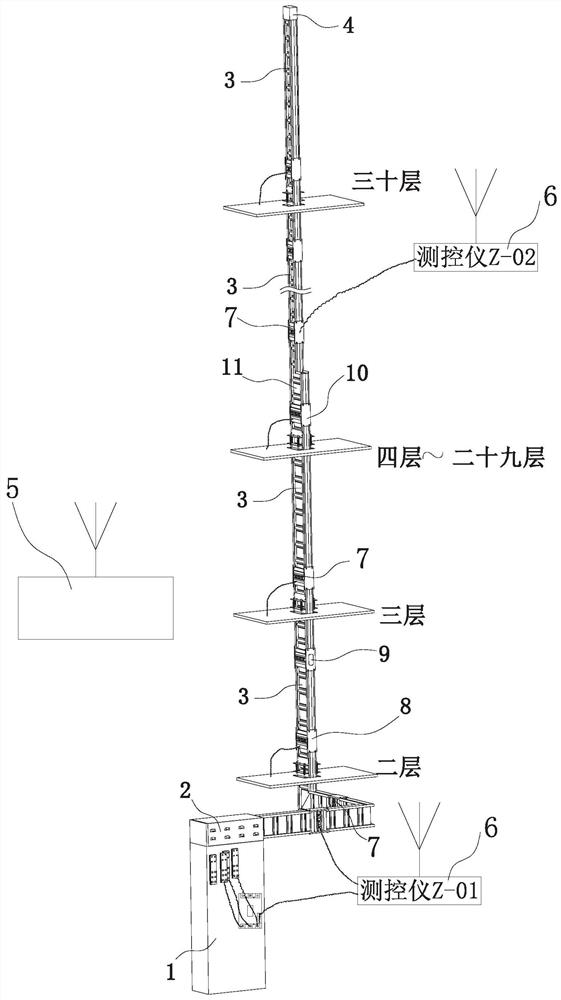

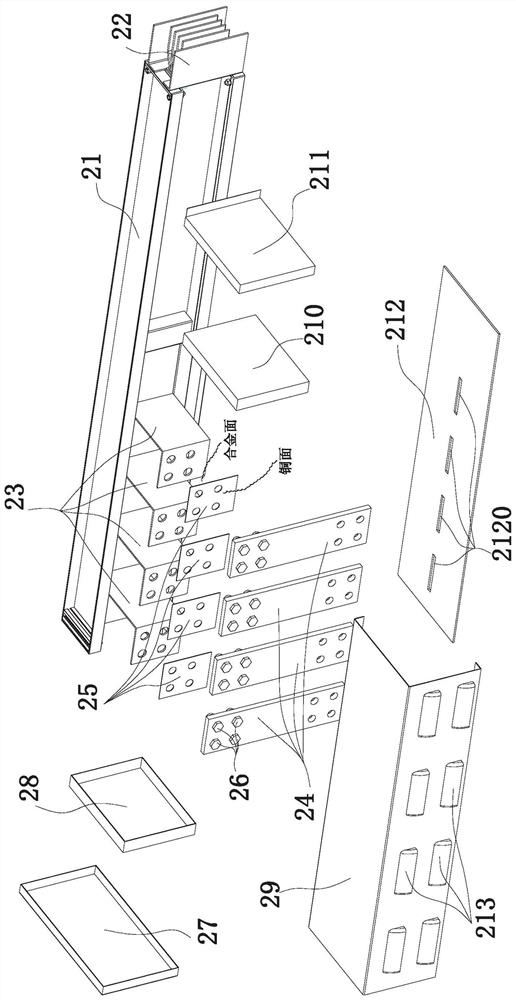

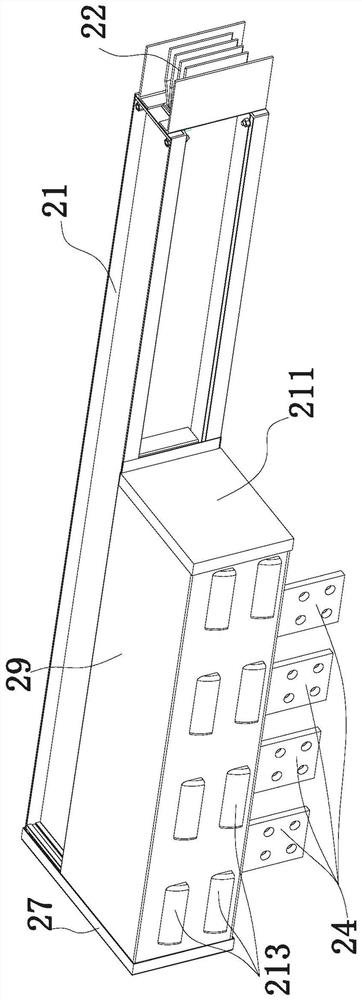

Copper-aluminum alloy smart bus trunk system

ActiveCN113097952BLow costImprove securityCircuit arrangementsCoupling contact membersCapacitanceBusbar

The copper-aluminum alloy smart bus trunk system disclosed by the present invention is used for power transmission trunk and power distribution in construction projects, and includes a bus duct start end section, a bus body, a variable capacitance section, a branch unit and a bus duct terminal, and at the bus duct start end section And the variable capacity section is equipped with temperature detection, over-temperature alarm, over-limit cut-off power circuit and circuit for detecting the voltage of the busbar casing, and automatically cuts off the power supply circuit when the voltage of the busbar casing exceeds the personal safety voltage; the busbar body is composed of the busbar casing , bus bar, the bus bar housing and bus bar connection in adjacent sections are respectively provided with bus slots, or \and bus bar connectors, or \and bus bar connectors with tap function, or\ And busbar connectors with equipotential terminals, or\and variable capacitance busway; copper and aluminum alloys are used for effective transition and perfect combination between the connections of the busway, saving copper resources, reducing engineering costs, and improving the safety of the power supply system performance.

Owner:珠海光乐电力母线槽有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com