Method for preparing graphene film on low-temperature substrate

A graphene film and substrate technology, applied in the field of graphene film preparation, can solve the problems of unsuitable graphene industrial production and high substrate temperature, and achieve the advantages of large-scale large-scale production, fast growth speed and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

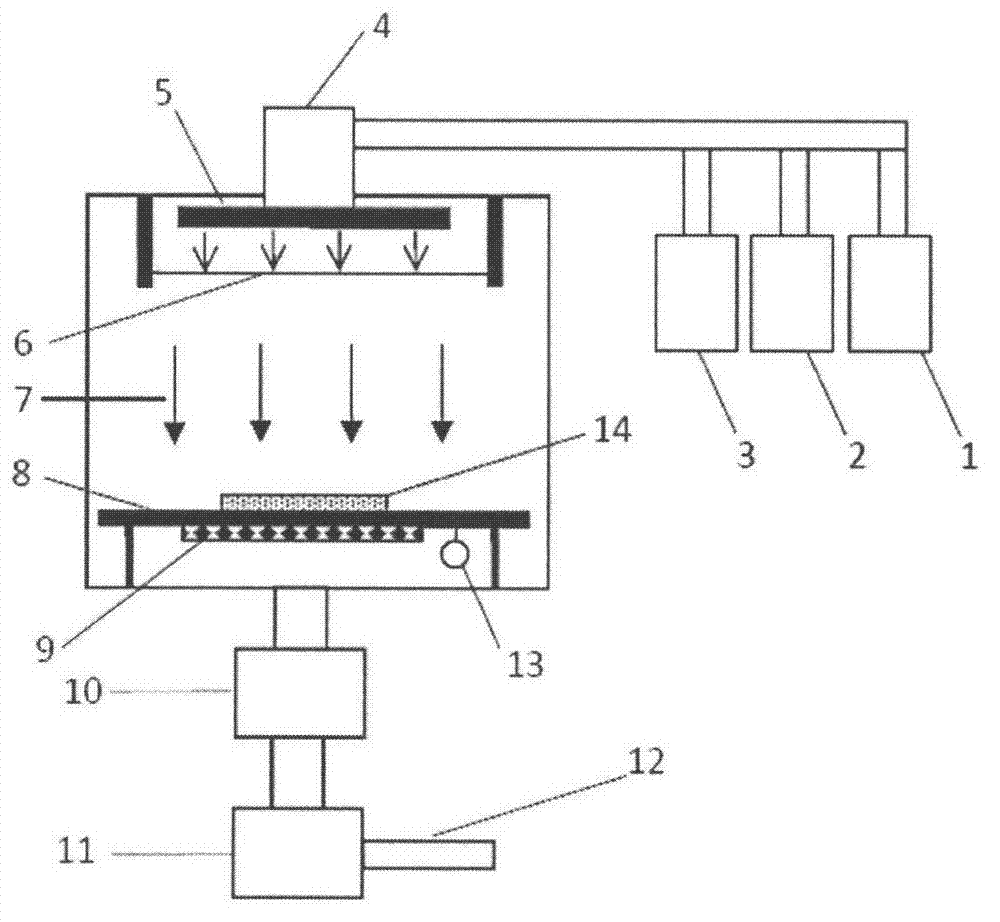

Method used

Image

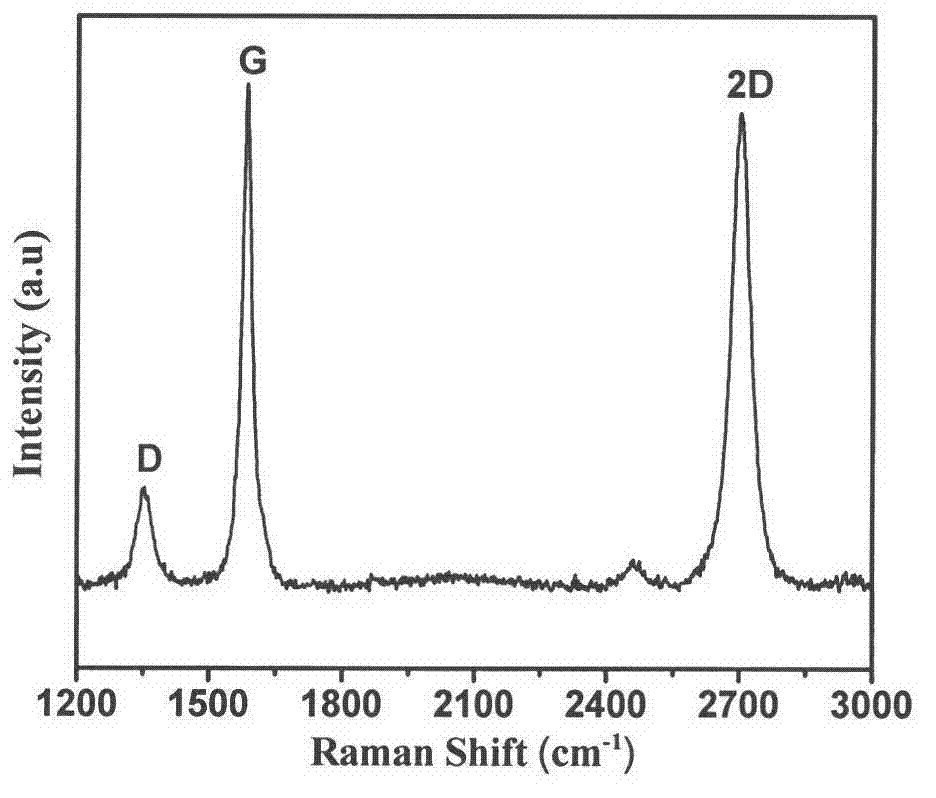

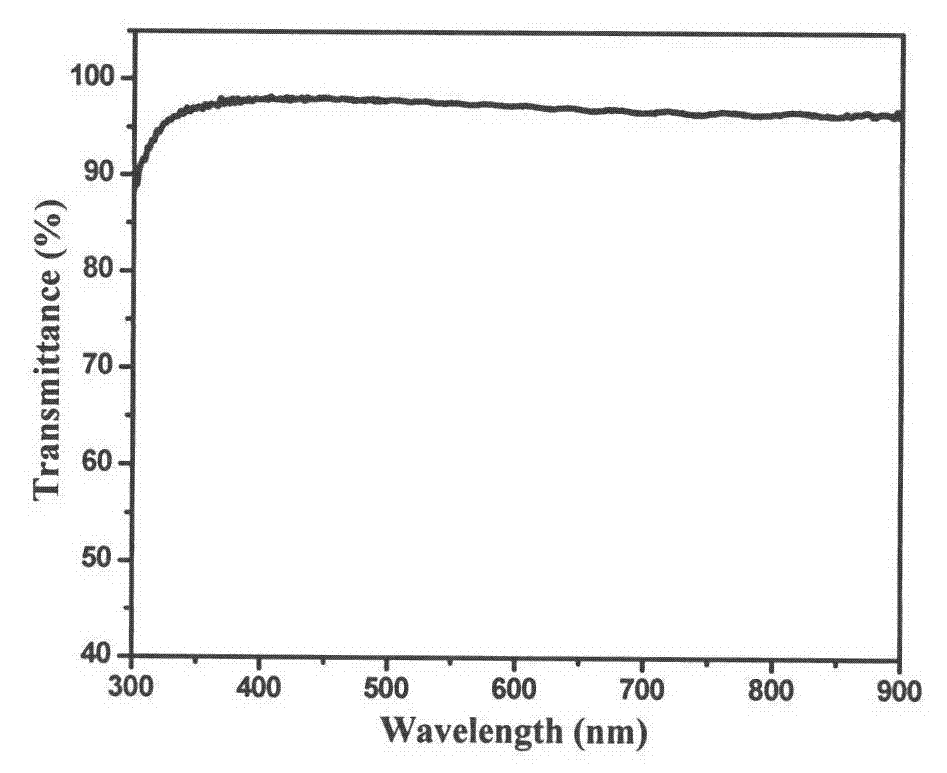

Examples

Embodiment 1

[0027] (1) Use 4cm×4cm high-purity quartz as the substrate, clean it ultrasonically with acetone, alcohol and deionized water, and place it in a magnetron sputtering chamber. The vacuum in the sputtering chamber is pumped to 6×10 -4 pa, turn on the RF power source of the copper target (purity: 99.99%) and preheat it for 10 minutes; start to control the rotation of the substrate support (20r / min), and feed Ar gas 30sccm; add RF voltage to make the gap between the target material and the anode cover To generate glow, set the sputtering power of the copper target to 150W, and pre-sputter for 10 minutes to remove surface oxidation and contamination; then open the baffle to start depositing a film, and grow a copper film with a thickness of 2 μm; after the growth is completed, turn the baffle Close quickly, and take out the sample after turning off the vacuum equipment.

[0028] (2) Putting the copper film substrate into a tube furnace and annealing at normal pressure in a hydroge...

Embodiment 2

[0033] (1) Use 4cm×4cm high-purity quartz as the substrate, clean it ultrasonically with acetone, alcohol and deionized water, and place it in a magnetron sputtering chamber. The vacuum in the sputtering chamber is pumped to 6×10 -4 Pa, turn on the RF power source of the copper target (purity: 99.99%) and preheat for 10 minutes; start to control the rotation of the substrate support (20r / min), and feed 30 sccm of Ar gas; add RF voltage to make the gap between the target material and the anode cover To generate glow, set the sputtering power of the copper target to 150W, pre-sputter for 10 minutes, remove surface oxidation and contamination; then open the baffle to start depositing a film, and grow a copper film with a thickness of 5 μm; after the growth is completed, turn the baffle Close quickly, and take out the sample after turning off the vacuum equipment.

[0034] (2) Putting the copper thin film substrate into a tube furnace and annealing at normal pressure in a hydroge...

Embodiment 3

[0039] (1) Use 4cm×4cm high-purity quartz as the substrate, clean it ultrasonically with acetone, alcohol and deionized water, and place it in a magnetron sputtering chamber. The vacuum in the sputtering chamber is pumped to 6×10 -4 pa, turn on the RF power source of the copper target (purity: 99.99%) and preheat it for 10 minutes; start to control the rotation of the substrate support (20r / min), and feed Ar gas 30sccm; add RF voltage to make the gap between the target material and the anode cover Generate a glow, set the sputtering power of the copper target to 150W, and pre-sputter for 10 minutes to remove surface oxidation and contamination; then open the baffle to start depositing a film, and grow a copper film with a thickness of 1 μm; after the growth is completed, turn the baffle Close quickly, and take out the sample after turning off the vacuum equipment.

[0040] (2) Putting the copper thin film substrate into a tube furnace and annealing at normal pressure in a hyd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com