An infrared transparent window with electromagnetic shielding function

A transparent window, electromagnetic shielding technology, applied in the manufacture of circuits, electrical components, cables/conductors, etc., can solve the problems of reducing the electromagnetic shielding performance of materials, increasing the resistivity of materials, etc., to prevent the decrease of infrared transmittance and high electromagnetic shielding. , the effect of good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Using existing MOCVD equipment, using organometallic trimethyl indium as the indium source, organometallic tetrakis(dimethylamino)tin as the doping source, oxygen with a purity of 99.9999% or more as the oxygen source, and argon with a purity of 99.999% or more as the source A protective atmosphere is grown to prepare an infrared transparent window.

[0037] The preparation method of the infrared transparent window of this embodiment is as follows:

[0038]1) Sapphire substrate pretreatment: A double-sided polished sapphire substrate with a thickness of 430 μm is selected as the main body of the infrared window, and there is a 0.2° deviation angle between the surface of the substrate and the sapphire c-crystal plane. After cleaning the surface of the sapphire substrate with organic and inorganic acid and alkali, put it into the MOCVD reaction chamber, control the temperature at 600° C., and control the pressure at 10 Torr for 30 minutes.

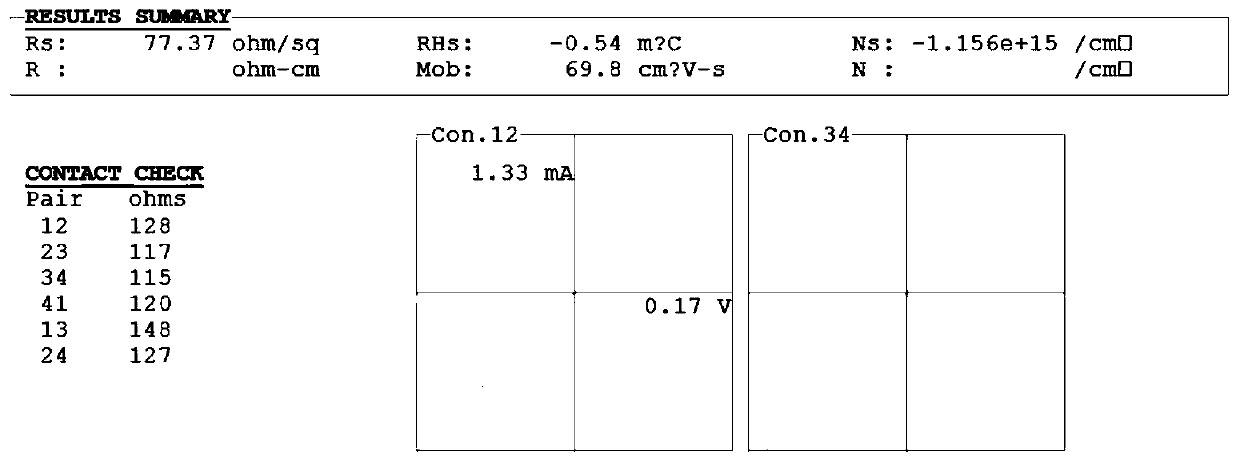

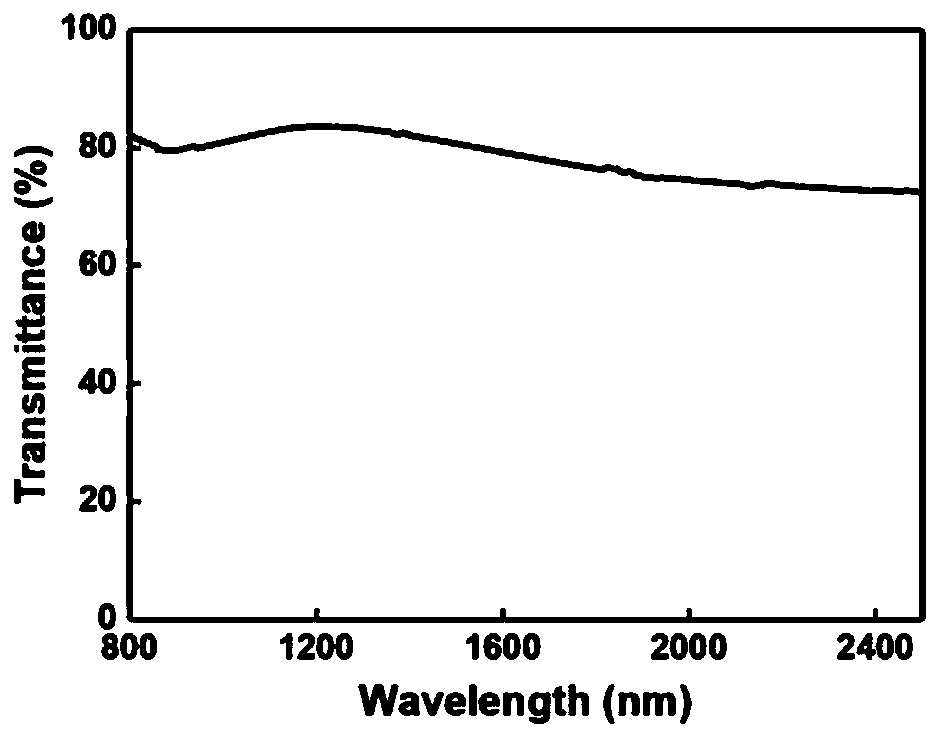

[0039] 2) Growth of indium ox...

Embodiment 2

[0045] The preparation method of the infrared transparent window of this embodiment is as follows:

[0046] 1) Sapphire substrate pretreatment: A double-sided polished sapphire substrate with a thickness of 430 μm is selected as the main body of the infrared window, and there is a 0.2° deviation angle between the surface of the substrate and the sapphire c-crystal plane. After cleaning the surface of the sapphire substrate with organic and inorganic acid and alkali, put it into the MOCVD reaction chamber, control the temperature at 600° C., and control the pressure at 10 Torr for 30 minutes.

[0047] 2) Growth of indium oxide-based transparent conductive film: the growth temperature is adjusted to maintain at 530° C., the pressure of the reaction chamber is controlled at 9 Torr, and argon gas is introduced as a protective atmosphere. The organometallic trimethylindium and oxygen were fed, and the flow rates were controlled at 6.0×10 -5 mol / min and 2.2×10 -2 mol / min, and dope...

Embodiment 3

[0050] The preparation method of the infrared transparent window of this embodiment is as follows:

[0051] Sapphire substrate pretreatment: A double-sided polished sapphire substrate with a thickness of 100 μm is selected as the main body of the infrared window, and the surface of the substrate has a 0° deviation angle from the sapphire c-crystal plane. After cleaning the surface of the sapphire substrate with organic and inorganic acid and alkali, put it into the MOCVD reaction chamber, control the temperature at 300° C., and control the pressure at 3 Torr for 60 minutes.

[0052] Indium oxide-based transparent conductive film growth: adjust the growth temperature to 400°C, control the reaction chamber pressure at 760Torr, and feed argon as a protective atmosphere. Introduce organometallic trimethyl indium and laughing gas, the flow rates are controlled at 6.0×10 -5 mol / min and 2.2×10 -2 mol / min, and doped with organometallic tetramethyltin, the flow control is the same as...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com