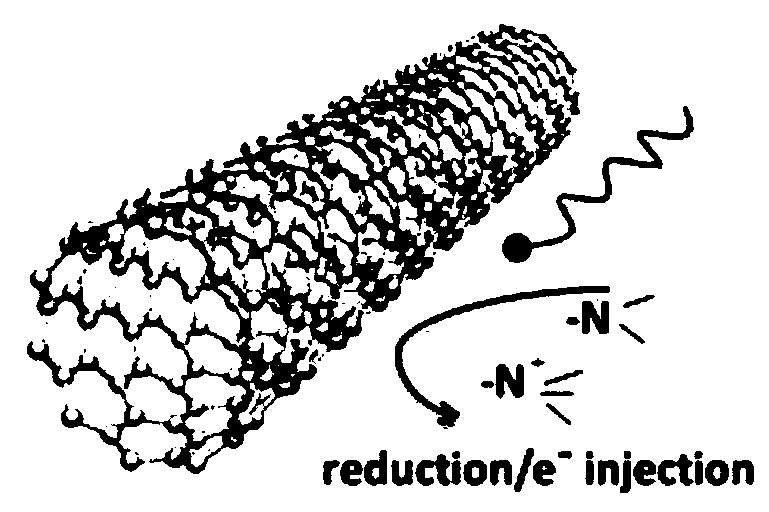

A kind of oleylamine-doped n-type carbon nanotube thermoelectric material and its preparation method and application

A technology of carbon nanotubes and thermoelectric materials, which is applied in the directions of thermoelectric device junction lead-out materials and thermoelectric device manufacturing/processing, etc., can solve the problems of low n-type conversion efficiency of carbon nanotubes, etc. , high conductivity, good application and development prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] (1) Dissolve 3.15 g of oleylamine in 10 mL of ethanol, stir magnetically for 30 min, and sonicate for 10 min to obtain a dopant with a concentration of 0.315 g / mL.

[0035] (2) Dissolve 10 mg of sodium dodecylbenzene sulfonate in 20 mL of ethanol, add 6 mg of multi-armed carbon nanotube yarn prepared by a floating gas-phase catalytic method, and let stand for 120 min of impregnation.

[0036] (3) Add the dopant with a concentration of 0.315g / mL prepared in step (1) dropwise into the product obtained in step (2), let it stand for immersion for 30min, then carry out vacuum filtration of the resulting reaction mixture, and use ethanol After washing 3 times, a black product was obtained, which was dried in an oven at 60° C. for 1 hour to obtain oleylamine-doped carbon nanotube fibers.

[0037] (4) Put the product obtained in step (3) into the crucible, then place the crucible in the tube furnace, close the intake valve and exhaust valve, open the vacuum device until the vac...

Embodiment 2

[0041] (1) Dissolve 1.50 g of oleylamine in 10 mL of ethanol, stir magnetically for 30 min, and sonicate for 10 min to obtain a dopant with a concentration of 0.15 g / mL.

[0042] (2) Dissolve 10 mg of sodium dodecylbenzene sulfonate in 20 mL of ethanol, add 6 mg of multi-armed carbon nanotube yarn prepared by a floating gas-phase catalytic method, and let stand for 120 min of impregnation.

[0043](3) Add the dopant with a concentration of 0.15 g / mL prepared in step (1) dropwise into the product obtained in step (2), let it stand for immersion for 30 min, then carry out vacuum filtration of the resulting reaction mixture, and use ethanol After washing 3 times, a black product was obtained, which was dried in an oven at 60° C. for 1 hour to obtain oleylamine-doped carbon nanotube fibers.

[0044] (4) Put the product obtained in step (3) into the crucible, then place the crucible in the tube furnace, close the intake valve and exhaust valve, open the vacuum device until the vacu...

Embodiment 3

[0048] (1) Dissolve 3.15 g of oleylamine in 10 mL of ethanol, stir magnetically for 30 min, and sonicate for 10 min to obtain a dopant with a concentration of 0.315 g / mL.

[0049] (2) Dissolve 10 mg of sodium dodecylbenzene sulfonate in 20 mL of ethanol, add 6 mg of multi-armed carbon nanotube yarn prepared by a floating gas-phase catalytic method, and let stand for 120 min of impregnation.

[0050] (3) Add the dopant with a concentration of 0.315g / mL prepared in step (1) dropwise into the product obtained in step (2), let it stand for immersion for 10min, then carry out vacuum filtration of the resulting reaction mixture, and use ethanol After washing three times, a black product was obtained, which was placed in an oven and dried at 60° C. for 6 hours to obtain oleylamine-doped carbon nanotube fibers.

[0051] (4) Put the product obtained in step (3) into the crucible, then place the crucible in the tube furnace, close the intake valve and exhaust valve, open the vacuum devi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com