Method for making copper oxygen gun nozzle

A manufacturing method and copper-oxygen technology, applied in the direction of manufacturing converters, etc., can solve the problems of reduced cooling space and effective cooling area, reduced service life, small welding area, etc., to reduce production costs, improve service life, and thermal conductivity. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

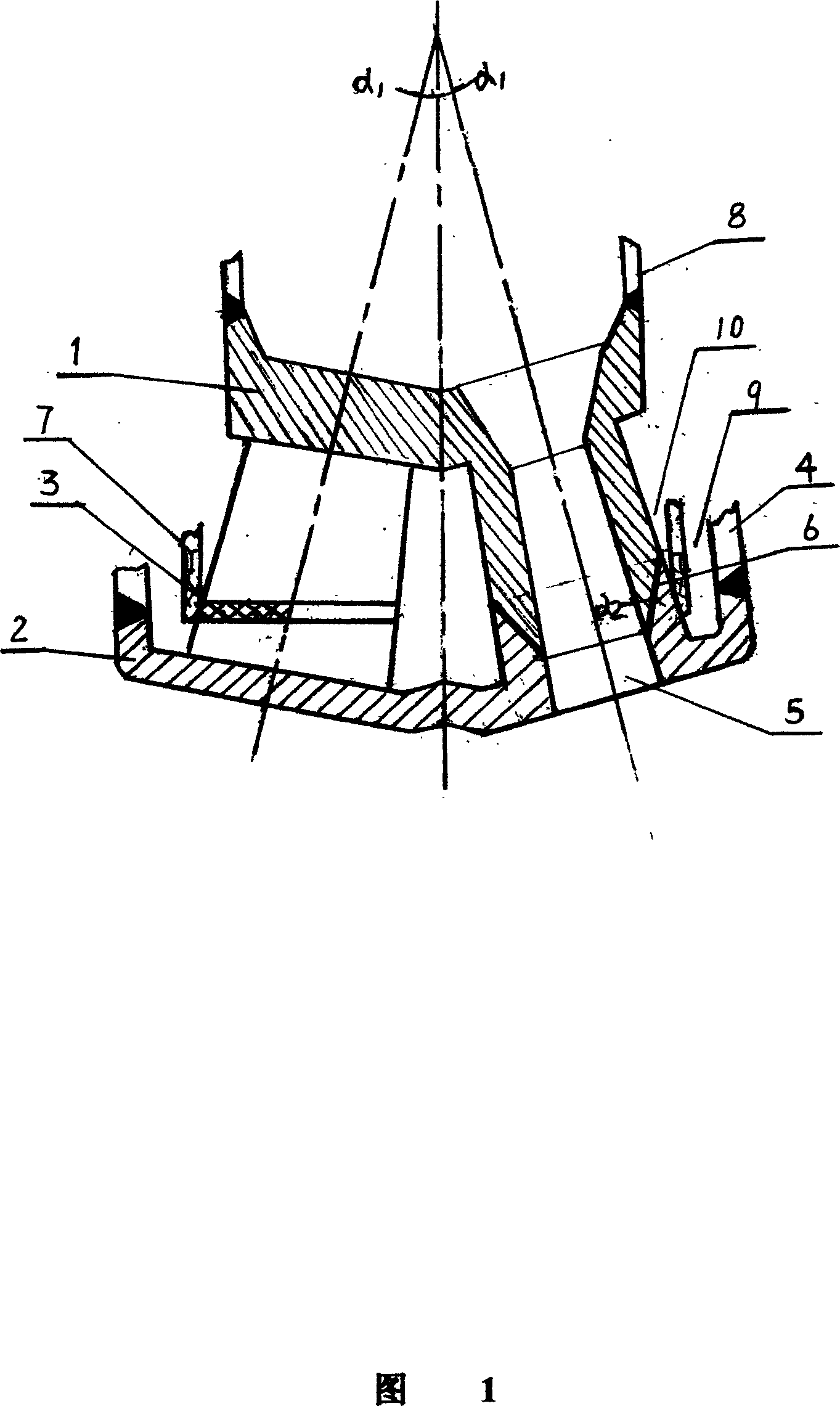

[0010] The manufacturing method of the copper-oxygen lance nozzle of the present invention is realized in this way, which will be described in detail below in conjunction with the accompanying drawings. As shown in Figure 1, the copper-section oxygen lance nozzle is composed of: oxygen inlet end 1, oxygen blowing end 2, water barrier 3, oxygen lance outer tube 4, oxygen blowing hole 5, welding groove 6, oxygen lance middle tube 7, oxygen lance The gun tube 8, the water inlet channel 9, and the water outlet channel 10 are composed. Since the oxygen blowing end 2 has a high temperature when working in the converter and requires high thermal conductivity, the oxygen blowing end is made of copper die forging. Because the oxygen blowing end 1 is soaked In cooling water, the oxygen inlet is made of cast steel, steel or a low cost alloy such as brass. Arrange 3 to 8 oxygen blowing holes 5 in the circumferential direction of the oxygen blowing end 2, and the angle α formed by the axis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com