Duplex centrifugal-film evaporator for preparing basic cupric carbonate

A thin-film evaporator and copper carbonate technology, applied in evaporation, copper compounds, separation methods, etc., can solve the problems of insufficient utilization of vapor, liquid and residue, low yield of processed products, energy consumption, etc., to avoid direct steam Emissions, save copper resources, reduce the effect of production energy consumption and production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in further detail below with reference to the accompanying drawings and an embodiment taking the production of basic copper carbonate as an example.

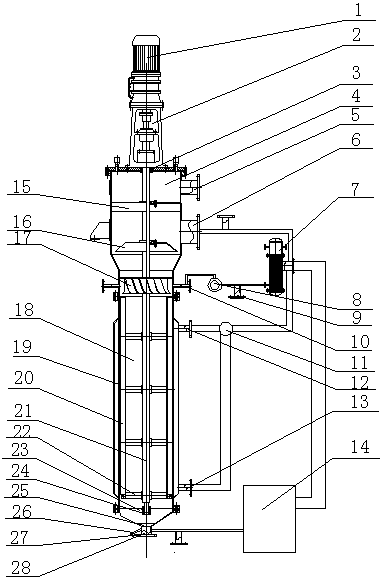

[0016] Such as figure 1 The shown compound centrifugal thin film evaporator for preparing basic copper carbonate includes a servo motor reducer transmission system, a steam treatment chamber 4, an evaporation chamber 18, and a conical discharge chamber 23. The servo motor reducer transmission system is located in the evaporator The upper end of the reducer includes the servo motor 1, the reducer 2 and the rotating shaft 21. The output shaft of the reducer 2 is connected to the rotating shaft 21. The rotating shaft 21 penetrates the steam treatment chamber 4, the evaporation chamber 18, and the conical discharge chamber 23. The lower end of the reducer is connected to the steam The treatment room 4 is connected, and a mechanical seal 3 is arranged between the reducer and the steam treat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com