Novel transposition aluminum conductor

A technology of transposition wires and aluminum wires, applied in the direction of conductors, insulated conductors, cables, etc., can solve problems such as discharge, accidents, and wire flow loss, and achieve the effects of improving the withstand voltage level, reducing eddy current loss, and avoiding eddy current loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

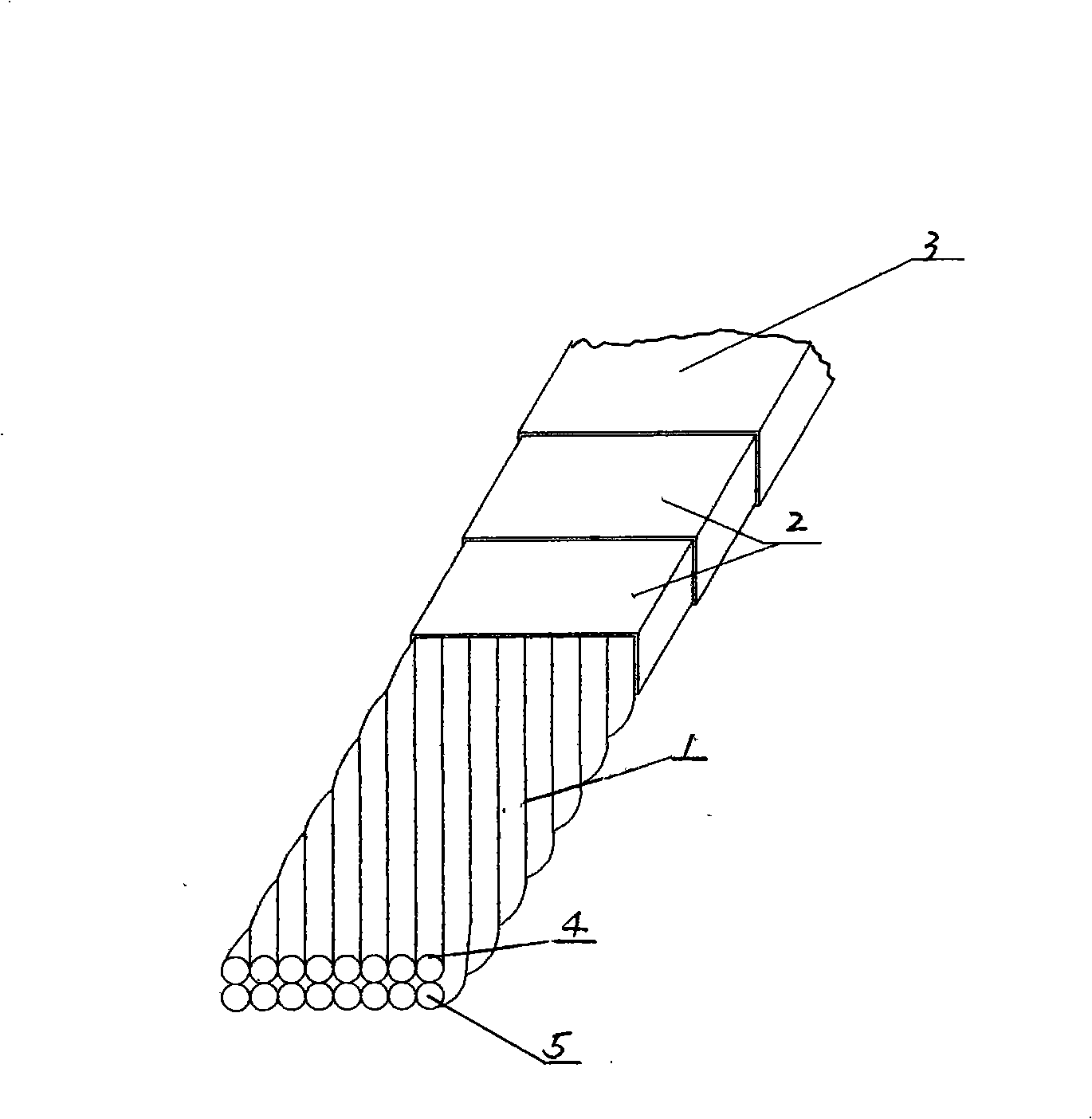

[0019] Taking the present invention applicable to UHV as an example, it includes a flat transposition wire 1, a film insulation layer 2 and a composite insulation layer 3; Double-layered transposition rectangular stranded wires composed of single-strand round aluminum wires 5; the film insulation layer 2 is an insulation film wrapping layer 4; the composite insulation layer 3 is a composite non-woven fabric wrapping with an insulation film layer; the film insulating layer 2 is coated on the outside of the flat transposed wire 1, and the composite insulating layer 3 is coated on the outside of the film insulating layer 2; the insulating films used for the film insulating layer 2, the composite insulating layer 3 and the insulating film wrapping layer 4 are all made of Class H insulating material.

[0020] After 16 non-defective single-strand round aluminum wires 5 with a diameter of 4.0mm are shaped by a special new-type transposition device and a new type of pressure roller, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com