Rotor cage of squirrel cage motor

A squirrel-cage motor and rotor technology, which is applied to asynchronous induction motors, electrical components, electromechanical devices, etc., can solve the problems of high cost of copper rotor squirrel cages and difficulty in guaranteeing the quality of aluminum rotor squirrel cages, etc., to make up for the difficulty in casting quality Guaranteed, saving silver solder, quality easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

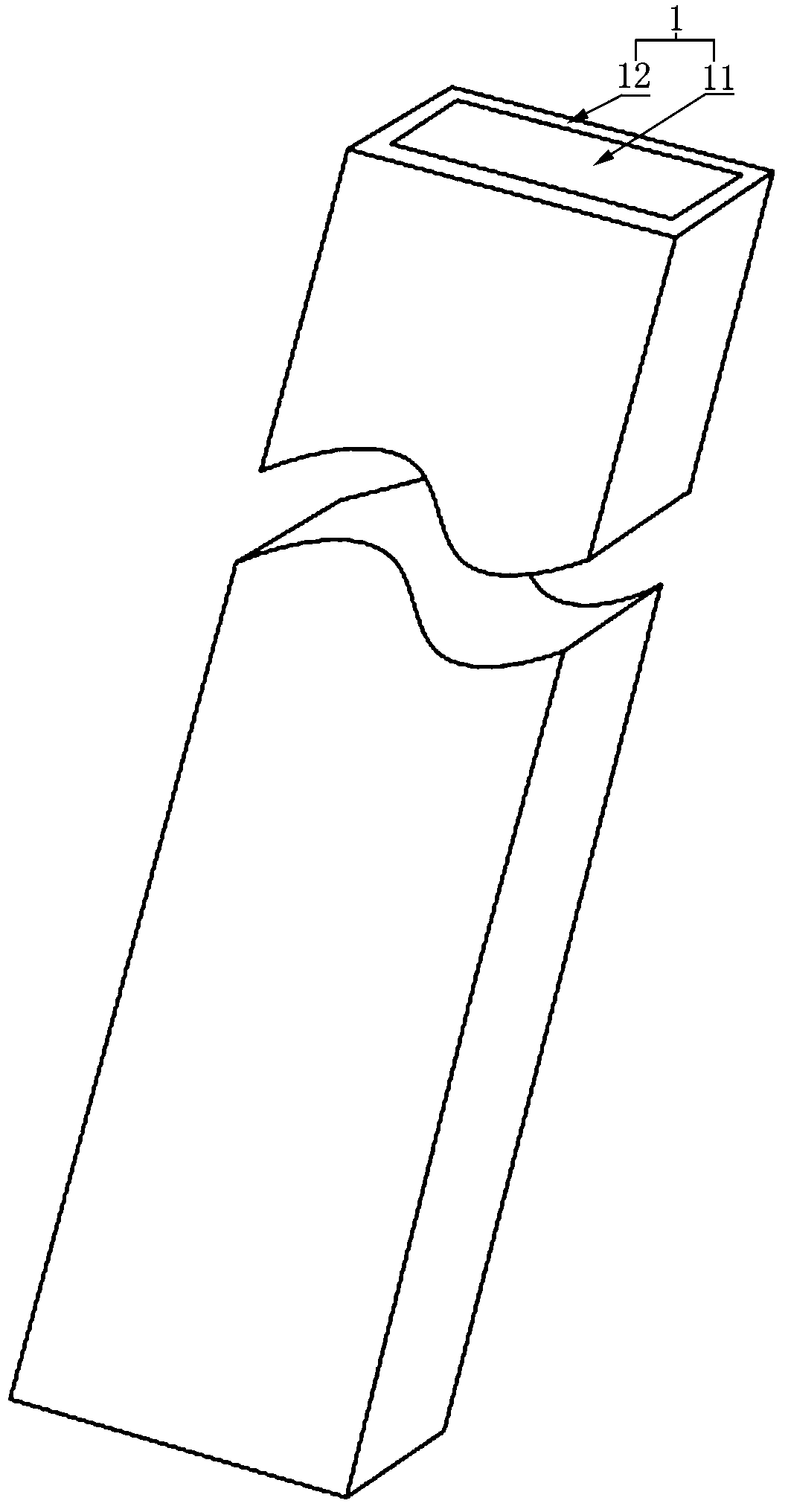

[0010] Reference figure 1 The squirrel cage of a squirrel cage motor of the present invention includes a plurality of composite guide bars 1 and two aluminum end rings 2 connected to the two ends of the composite guide bar 1. The composite guide bar 1 is composed of aluminum bars 11 and The copper layer 12 around the aluminum strip 11 is composed. This structure mainly utilizes the skin effect of current transfer, that is: when the conductor passes alternating current, most of the current density is concentrated on the surface of the conductor, and most of the current passes through the copper layer 12, making full use of the copper guide strip The advantages of good electrical conductivity, and at the same time the center of the guide bar is set as an aluminum bar 11, which reduces the overall mass of the guide bar, makes it lighter, and makes full use of the advantages of the aluminum guide bar.

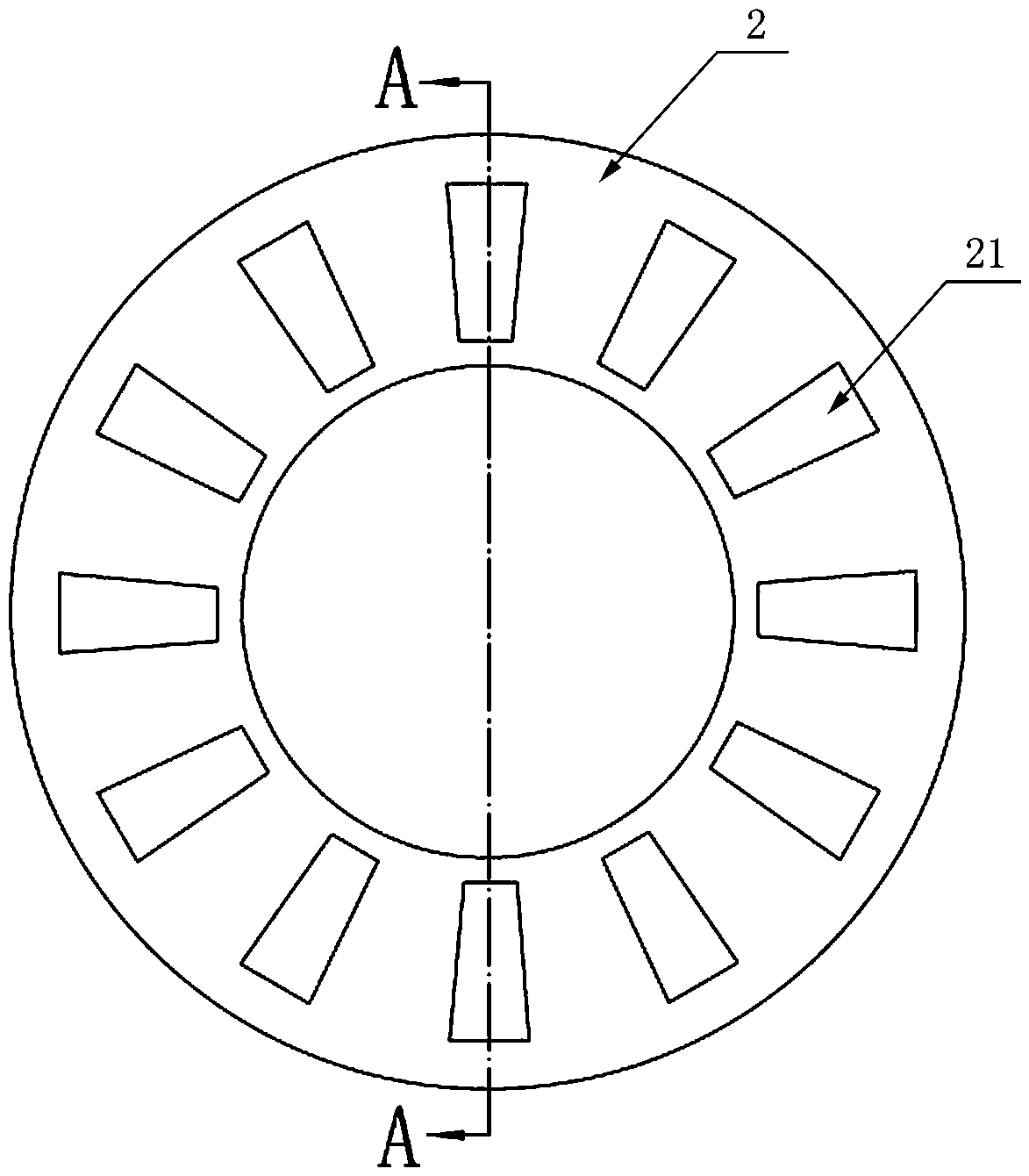

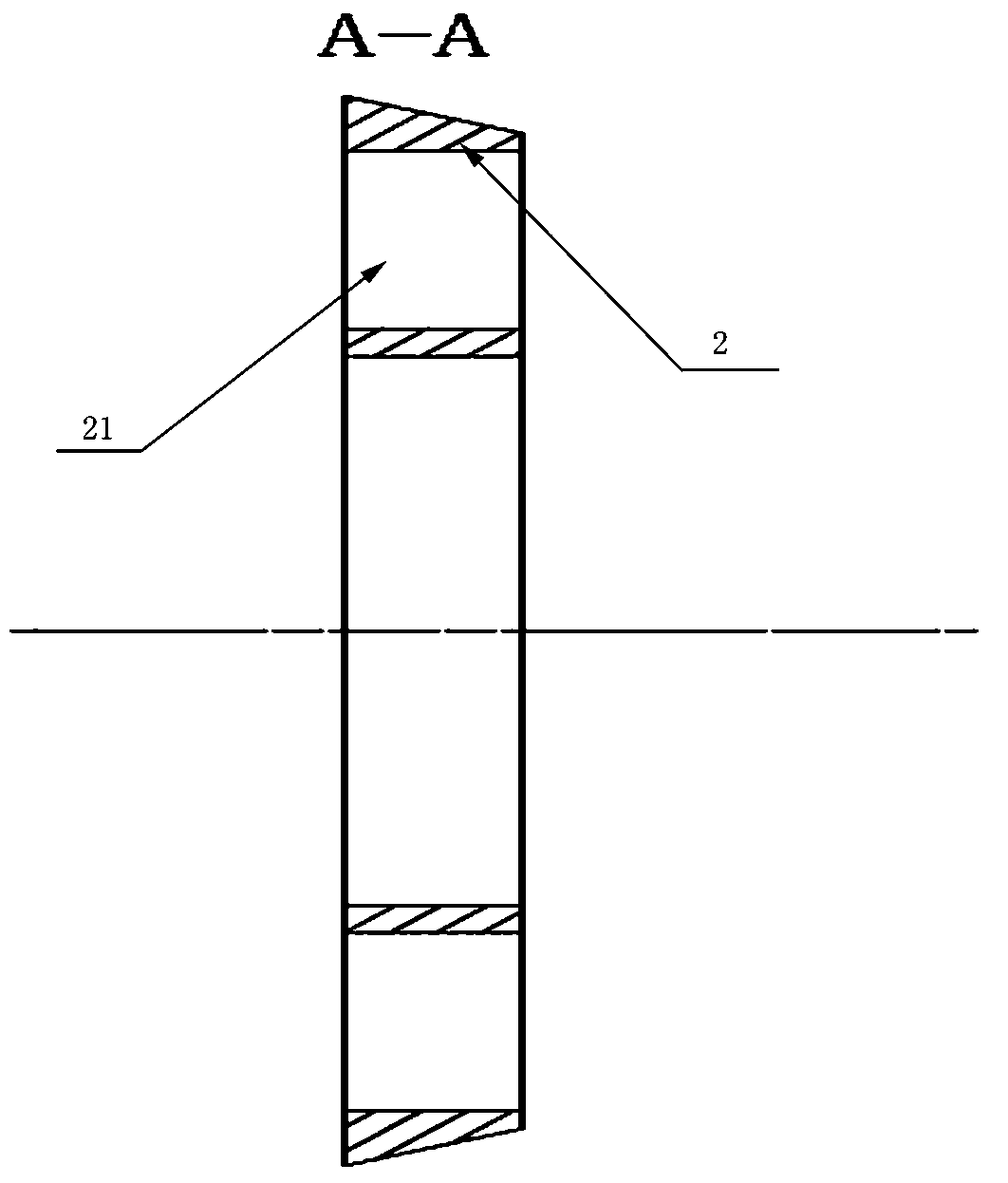

[0011] Reference Figure 2-4 The aluminum end ring 2 is provided with an axial t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com