Patents

Literature

63results about How to "High degree of lightweight" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

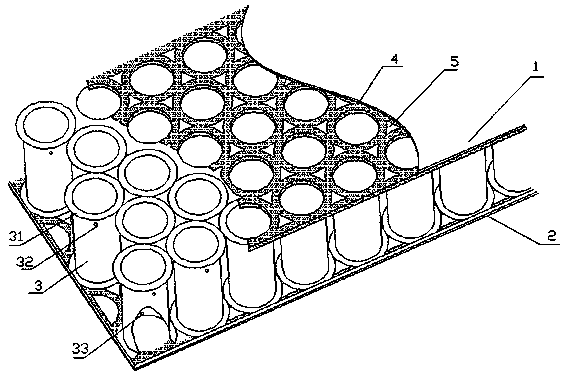

Honeycomb interlayer structure prepared through added material manufacturing method

InactiveCN109317677AHigh degree of lightweightIncrease profitAdditive manufacturing apparatusHoneycombImpact resistance

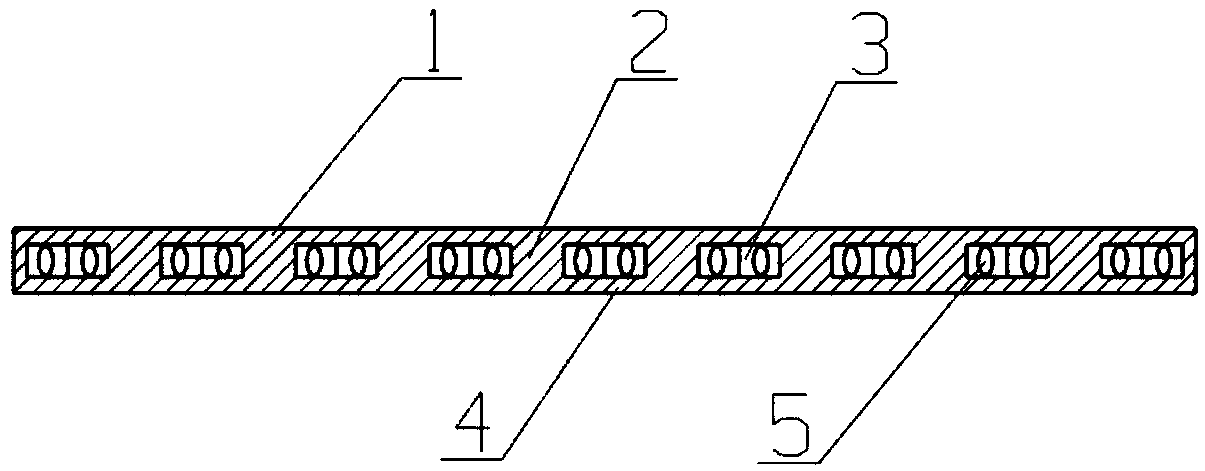

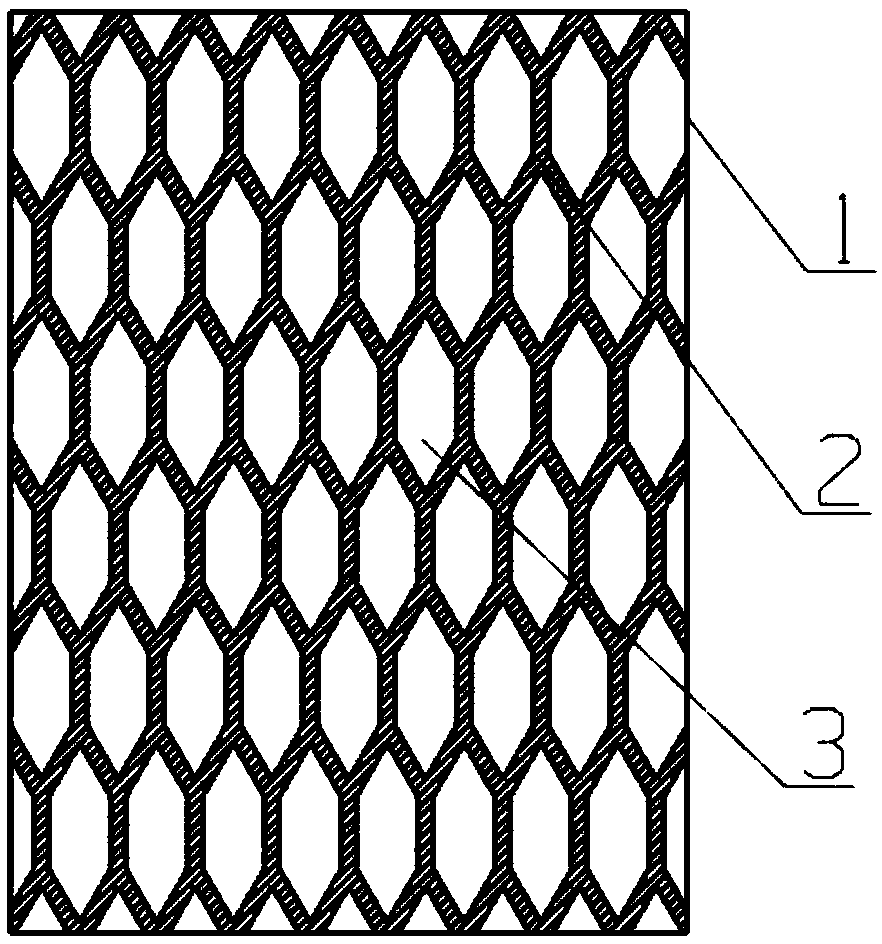

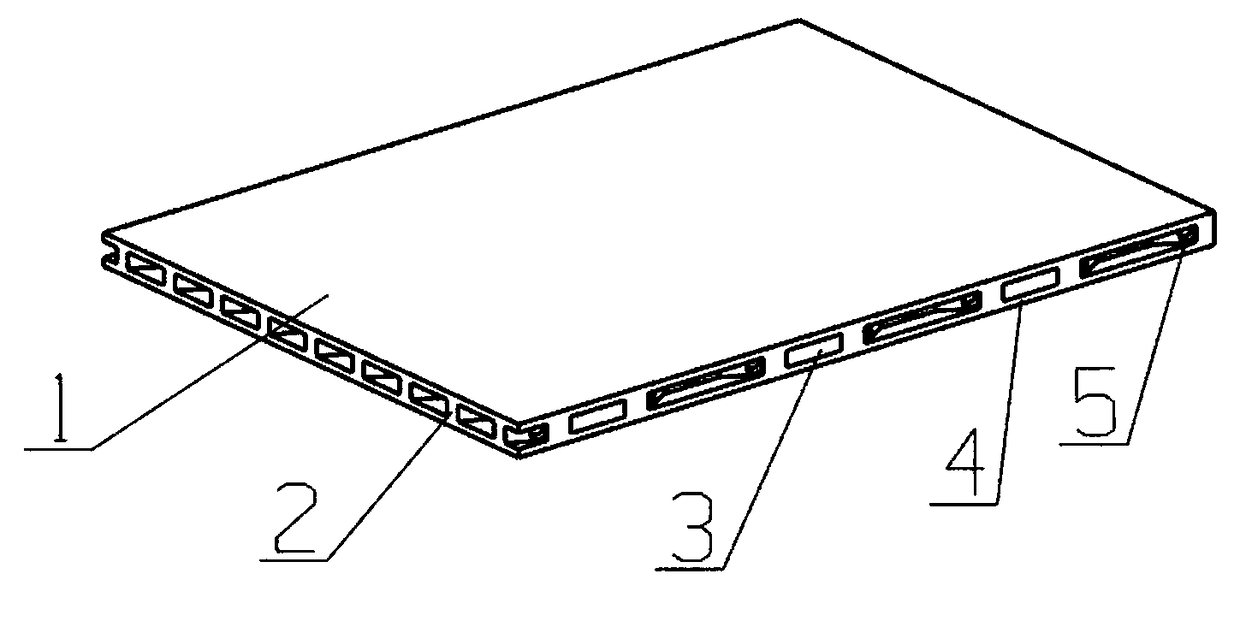

The invention belongs to the technical field of added material manufacturing, and in particular, relates to a honeycomb interlayer structure prepared through an added material manufacturing method inthe aerospace field. The honeycomb interlayer structure is prepared through a metal powder added material manufacturing method, and comprises a first panel, a honeycomb reinforcing rib, a honeycomb cavity, a second panel and a powder removing process hole, wherein the honeycomb reinforcing rib is positioned between the first panel and the second panel; the first panel, the second panel and the honeycomb reinforcing rib are in metallurgic bonding; the honeycomb cavity is formed in the honeycomb reinforcing rib; and the powder removing process hole is formed in the honeycomb reinforcing rib. Asthe first panel, the second panel and the honeycomb reinforcing rib are in metallurgic bonding, the honeycomb interlayer structure has the characteristics of high lightness degree, high impact resistance, excellent vibration resistance, excellent bending resistance, excellent fatigue resistance and high specific strength. As the honeycomb interlayer structure is prepared through the added materialmanufacturing method, the forming size precision is high, and the surface quality is excellent; and a non-assembled surface is once formed through added material manufacturing, so that the subsequentmachining is not needed, the material utilization rate is high, and the production efficiency is high.

Owner:BEIJING XINGHANG MECHANICAL ELECTRICAL EQUIP

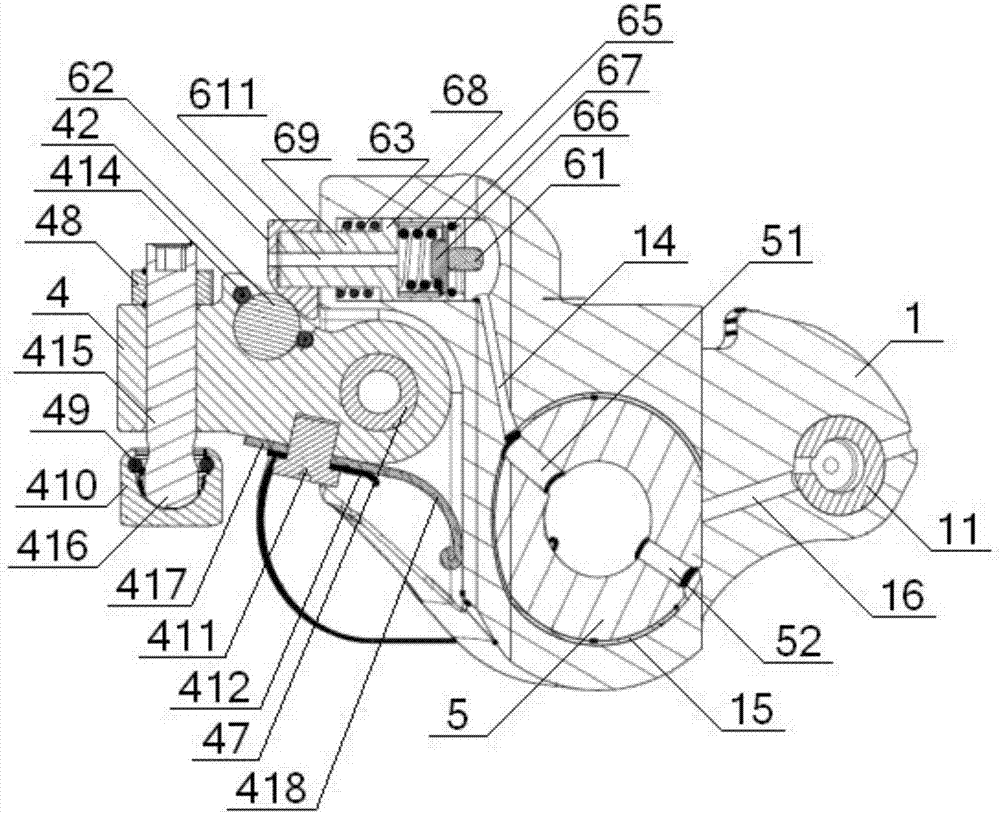

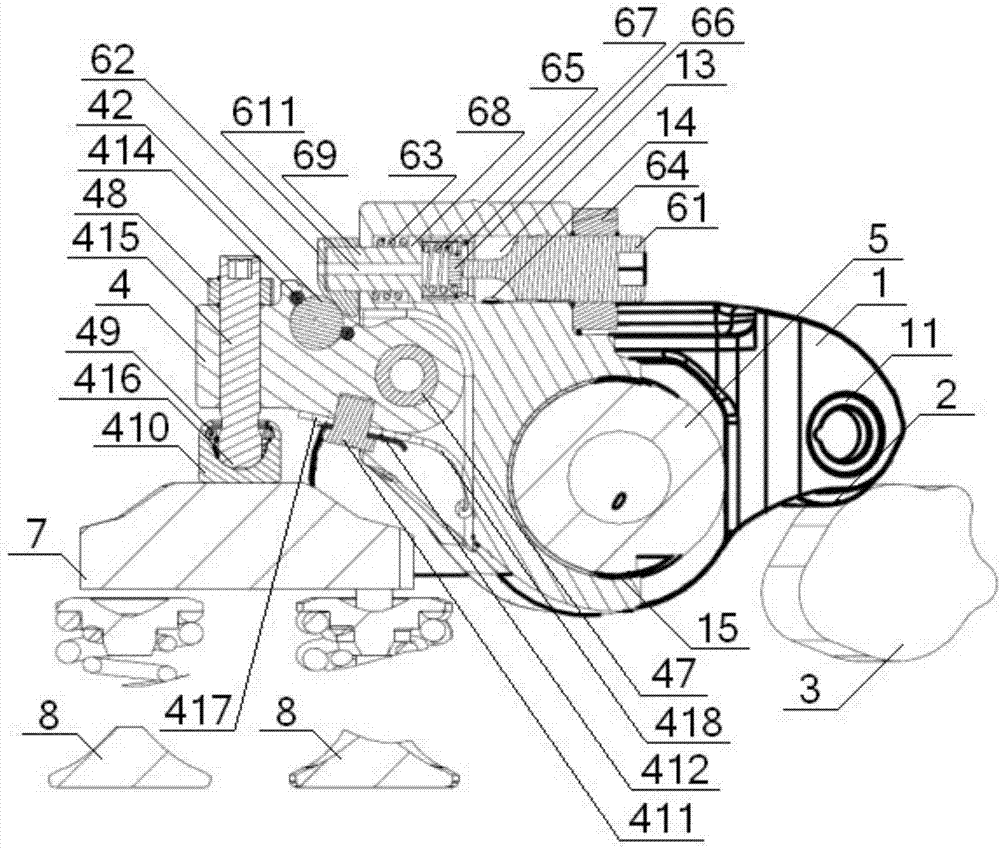

Heavy-duty diesel engine split type rocker arm brake mechanism for commercial vehicle

ActiveCN107143394AReduced processing performanceShorten the lengthValve arrangementsLubrication of auxillariesDieselingCam

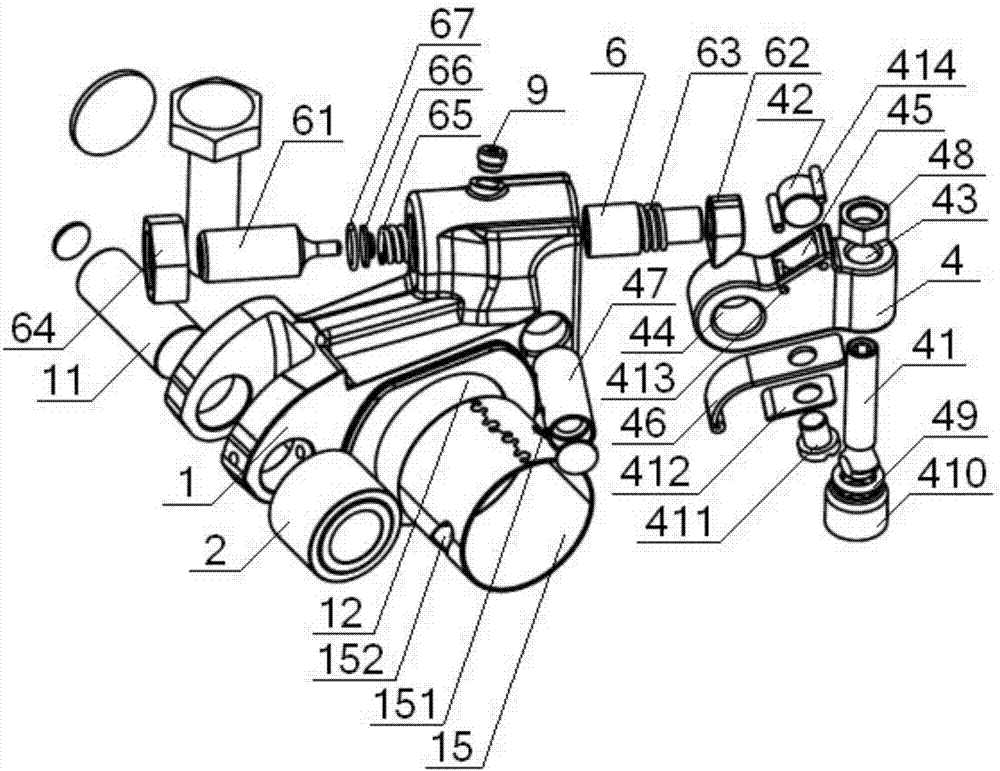

A heavy-duty diesel engine split type rocker arm brake mechanism for a commercial vehicle comprises a rocker arm body, a swing mechanism and a hydraulic drive system; the rocker arm body is mounted on a rocker arm shaft through a main mounting hole, the swing mechanism comprises a swing head, a first adjusting bolt and a rolling column, the swing head is mounted on the rocker arm body, a sheet-shaped spring is arranged at the bottom of the swing head, and is pressed on the bottom of the rocker arm body, a ball head of the first adjusting bolt is mounted in a ball socket in an elephant foot shape, the hydraulic drive system comprises a hydraulic plunger with a return spring sleeved, a second adjusting bolt in contact with the hydraulic plunger and a rocker arm cam in threaded connection with the hydraulic plunger, the hydraulic plunger is mounted in a drive cavity of the rocker arm body, the rocker arm cam makes contact with the rolling column, a brake hydraulic oil way communicated with the main mounting hole, the drive cavity and a swing arm shaft hydraulic oil hole is arranged in the rocker arm body, and the heavy-duty diesel engine split type rocker arm brake mechanism is high in reliability, low in cost, high in lightweight degree, simple in structure, convenient to assemble and maintain and good in brake effect.

Owner:DONGFENG COMML VEHICLE CO LTD

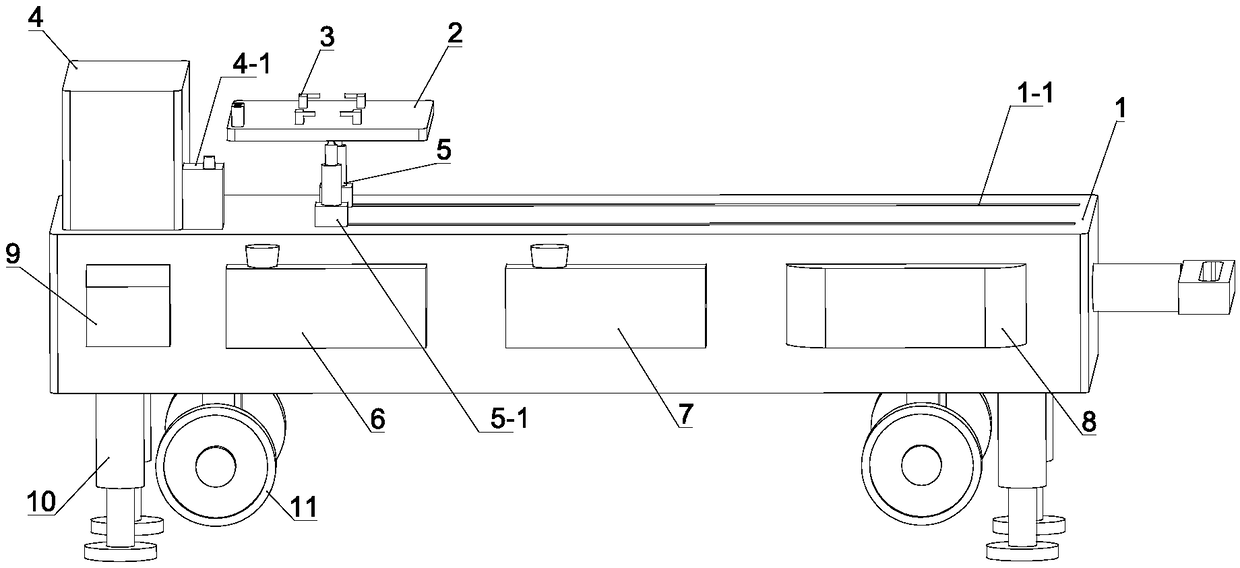

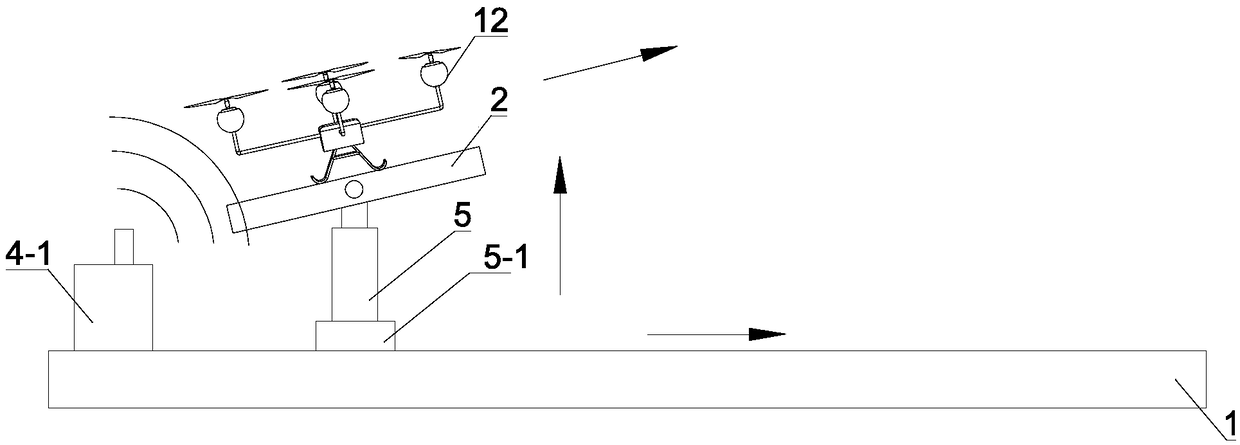

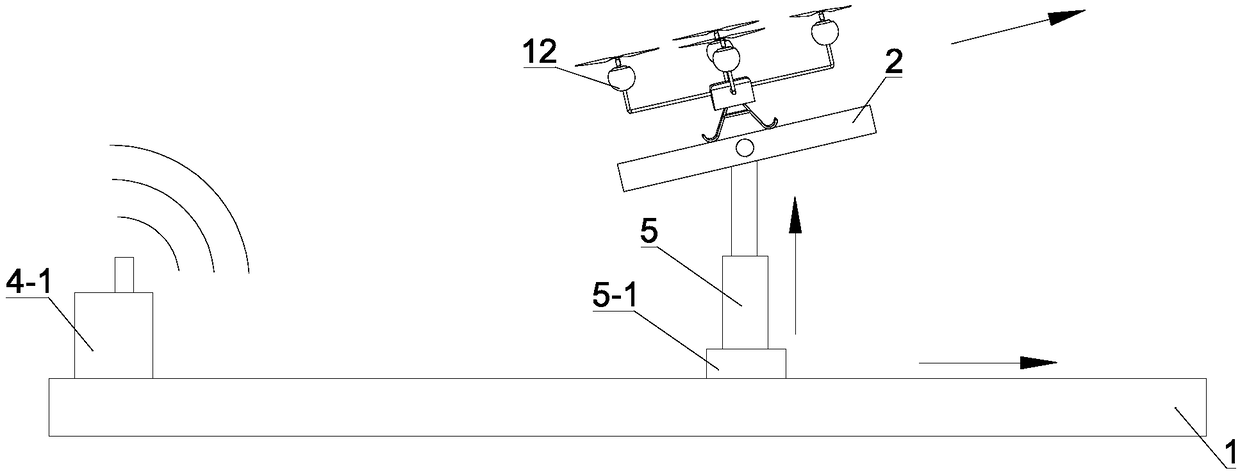

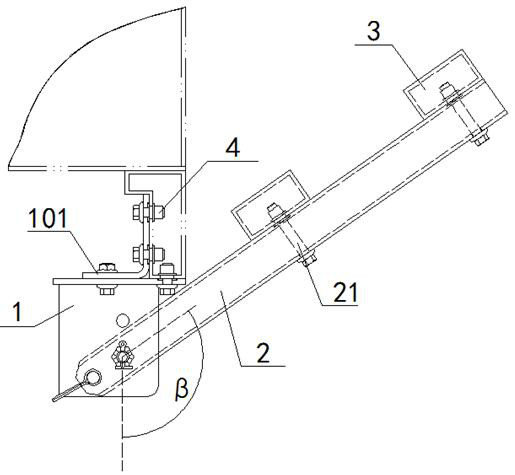

Auxiliary take-off and landing flight platform of unmanned aerial vehicle and auxiliary take-off and landing flight method

ActiveCN108860637ASpeed up take offReduce energy consumptionLaunching/towing gearElectric vehicle charging technologyUncrewed vehicleUnmanned air vehicle

The invention discloses an auxiliary take-off and landing flight platform of an unmanned aerial vehicle and an auxiliary take-off and landing flight method. The auxiliary take-off and landing flight platform of the unmanned aerial vehicle comprises a platform main body and an auxiliary take-off device arranged on the platform main body, wherein the auxiliary take-off device comprises a take-off and landing board used for placing the unmanned aerial vehicle, a horizontal pushing mechanism and a vertical pushing mechanism; the horizontal pushing mechanism is used for driving the take-off and landing board to horizontally move from one end of the platform main body to the other end of the platform main body, and the take-off and landing board is arranged above the platform main body; an electric fixed clamping position is arranged on the take-off and landing board. When the electric fixed clamping position is in a closed state, the unmanned aerial vehicle breaks away from the constraint of the electric fixed clamping position. The auxiliary take-off and landing flight platform of the unmanned aerial vehicle can help the electric unmanned aerial vehicle to complete a take-off task, sothat the self energy consumption of the unmanned aerial vehicle in the take-off stage is reduced, the endurance time of the unmanned aerial vehicle is prolonged, and the operation radius of the unmanned aerial vehicle is increased.

Owner:SOUTH CHINA AGRI UNIV

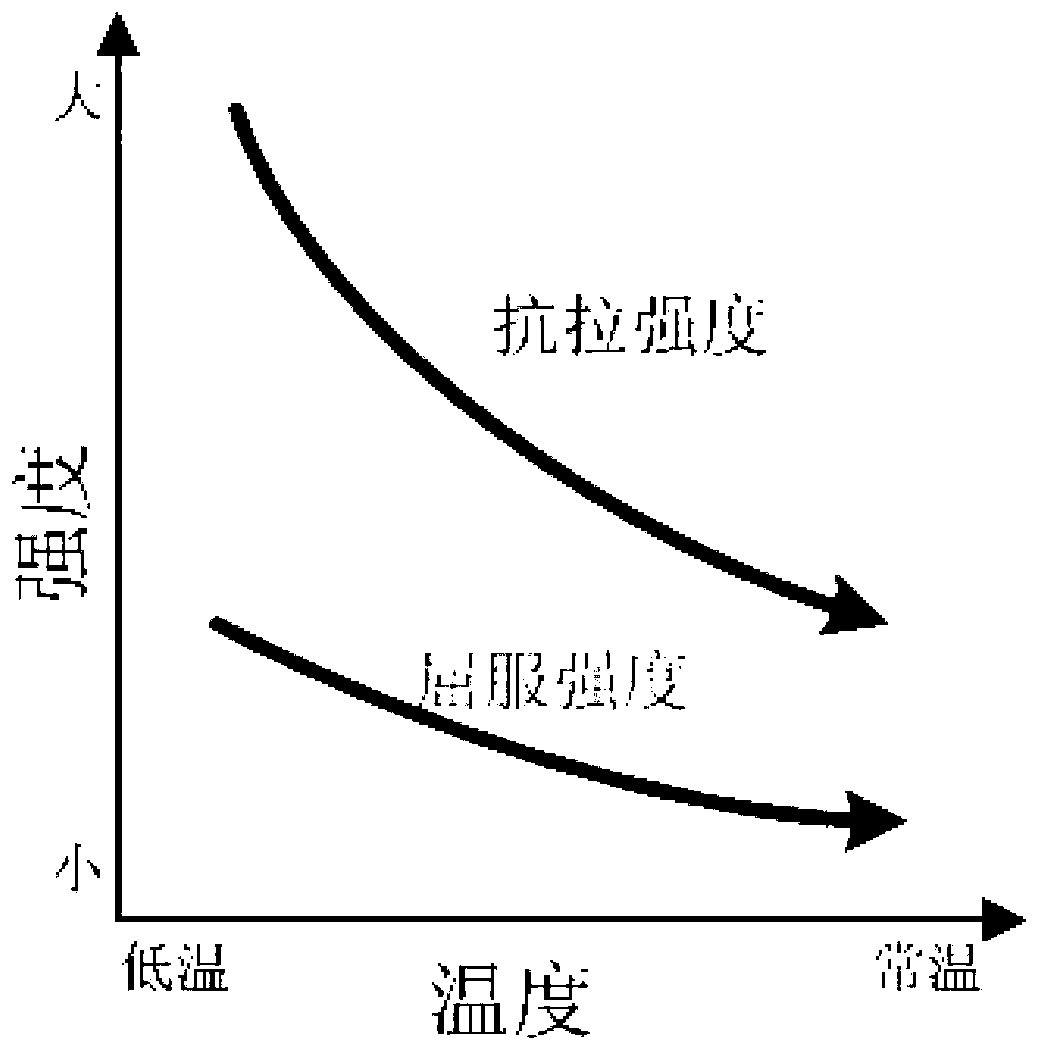

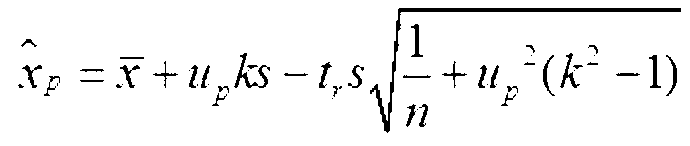

Manufacturing method of interior container of low-temperature container based on austenitic stainless steel low-temperature property

ActiveCN103278375AHigh degree of lightweightHigh strengthPressure vesselsStrength propertiesUltimate tensile strengthAustenite

The invention relates to the design and manufacture of low-temperature containers, in order to provide a manufacturing method of an interior container of a low-temperature container based on an austenitic stainless steel low-temperature property. The method comprises the following steps of: acquiring the variation rule of the austenitic stainless steel mechanical property from the normal-temperature to low-temperature environment; determining the minimum guarantee value of the austenitic stainless steel mechanical property at low temperature environment; selecting the intensity value for design according to the design temperature of the interior container of the low-temperature container; determining the allowable stress value for the design of the container in the low-temperature container; and designing and calculating each relevant parameter and manufacturing. Through the manufacturing method provided by the invention, the intensity value and the allowable stress of the interior container can be improved further based on the manufacturing method of the existing low-temperature container (including a conventional low-temperature container and a strain strengthening low-temperature container); the wall thickness of the interior container is thinned, and the weight of the interior container is relieved, thereby achieving a better energy-saving and emission-reduction effect and a higher light weight degree of the low-temperature container.

Owner:ZHEJIANG UNIV

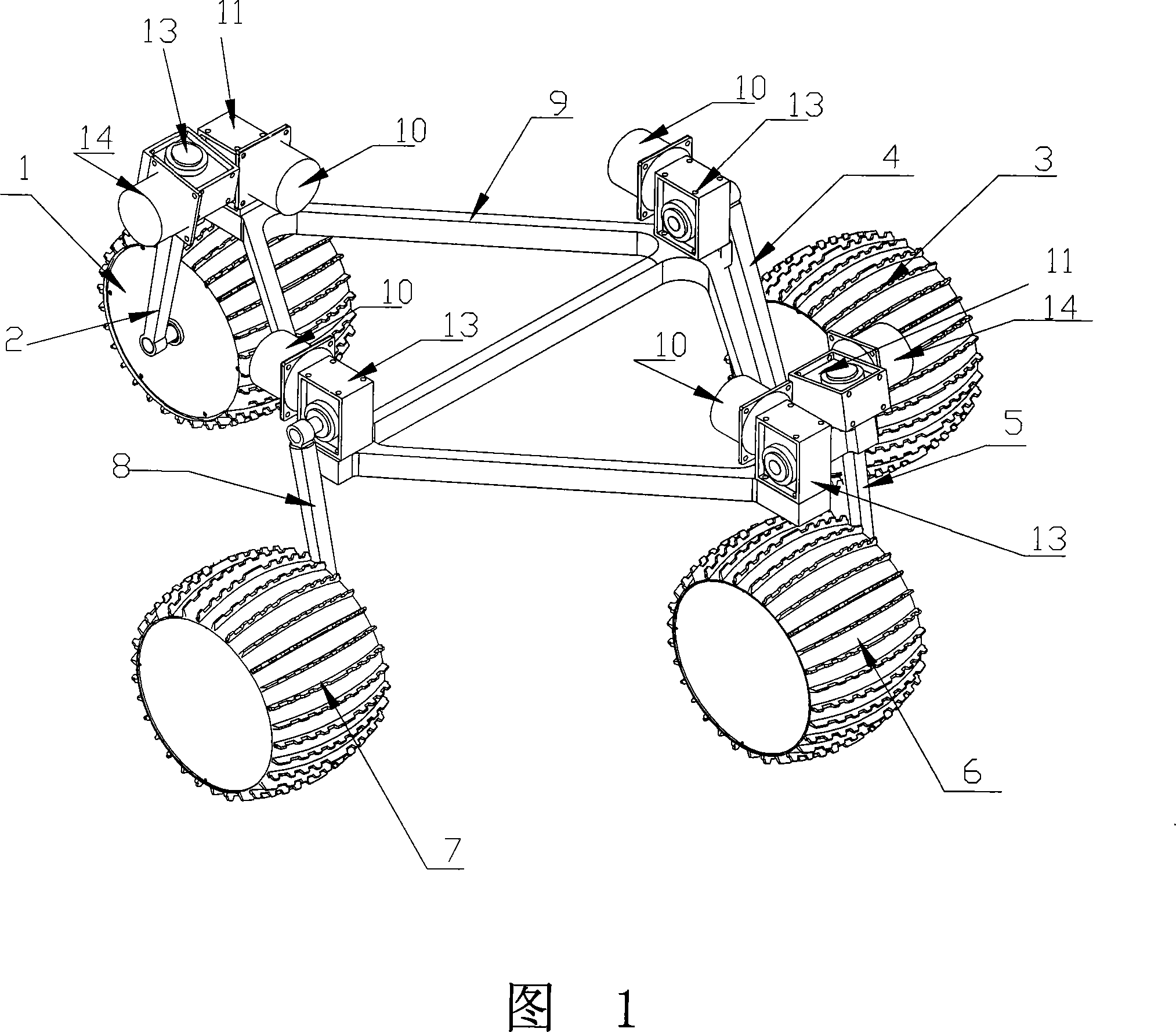

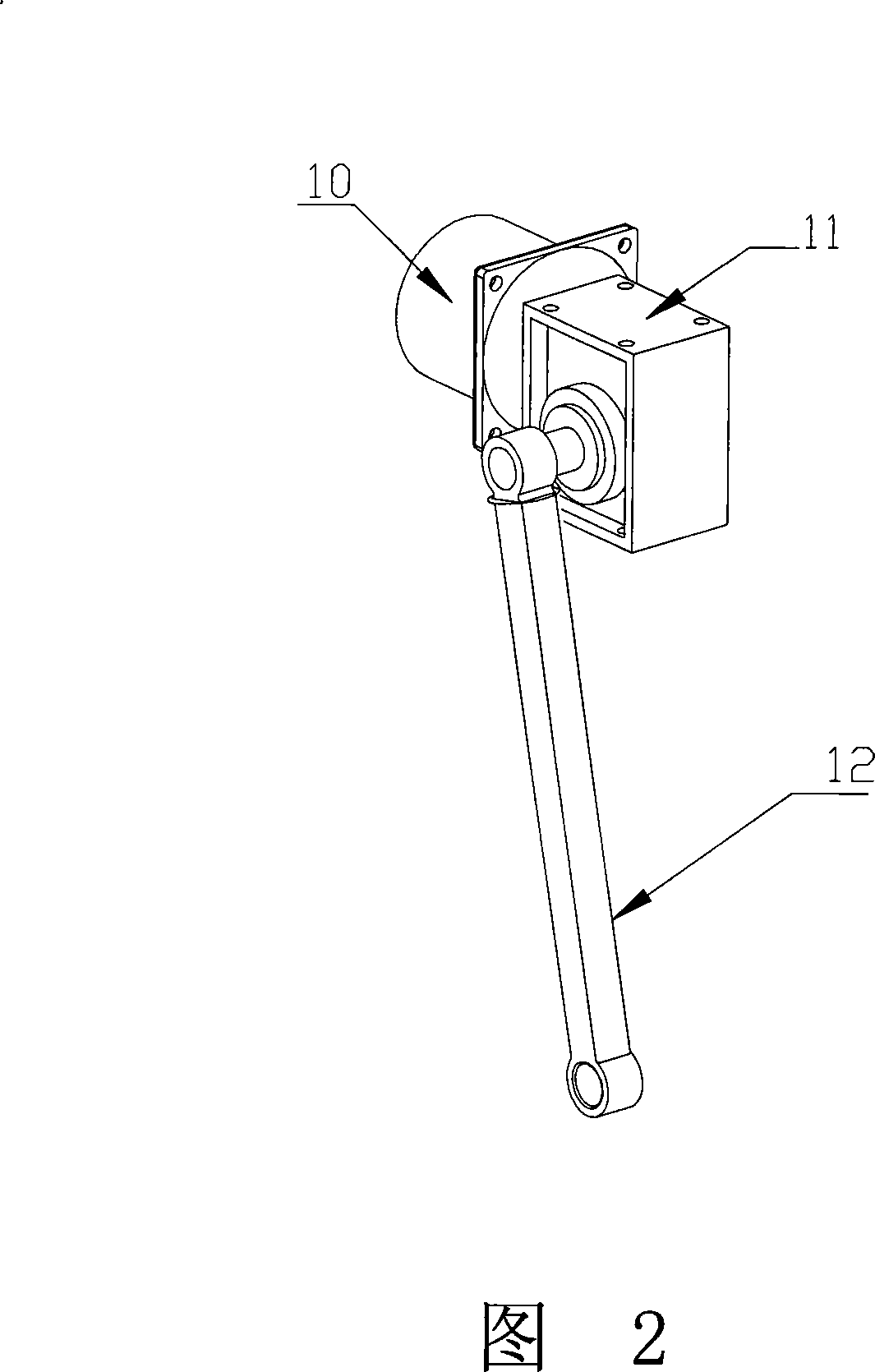

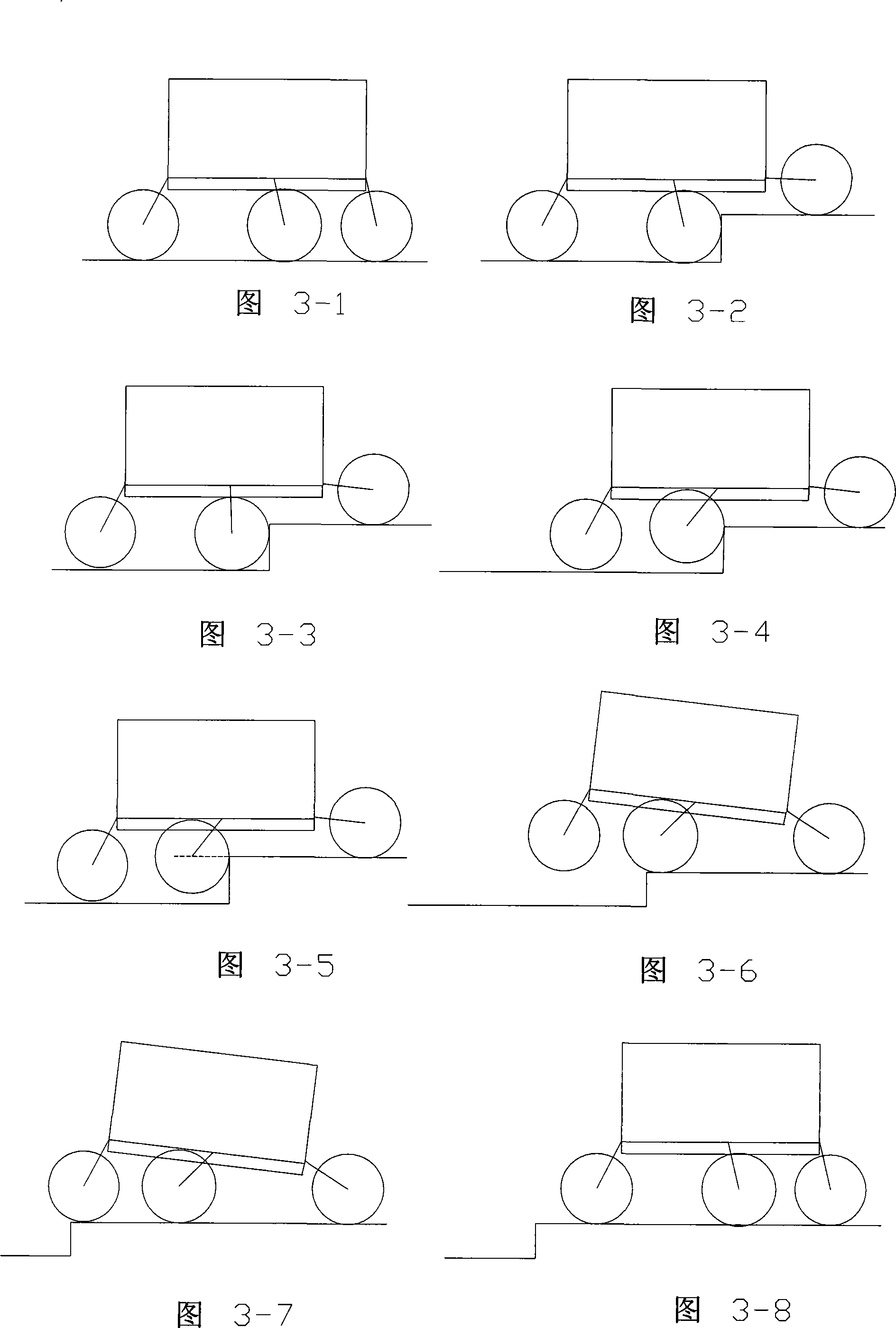

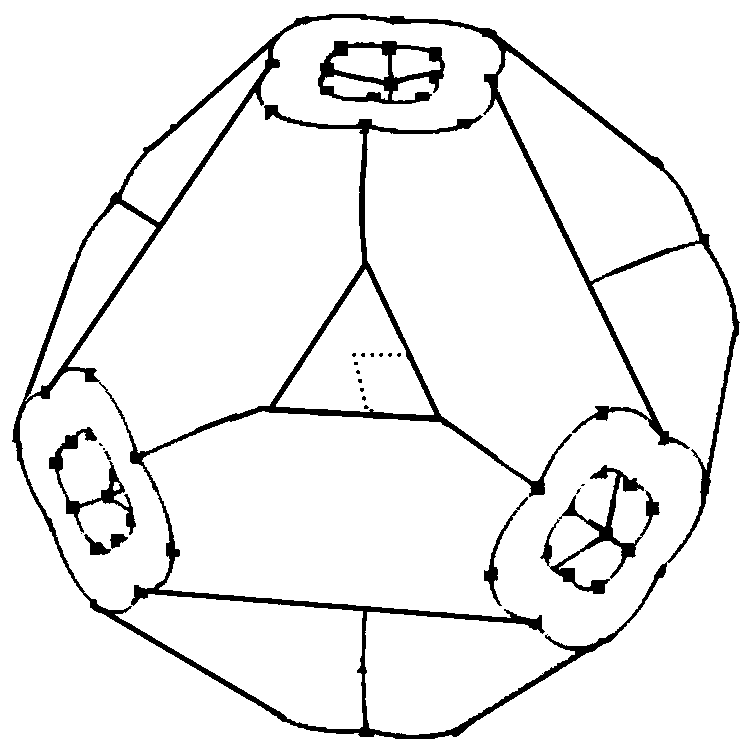

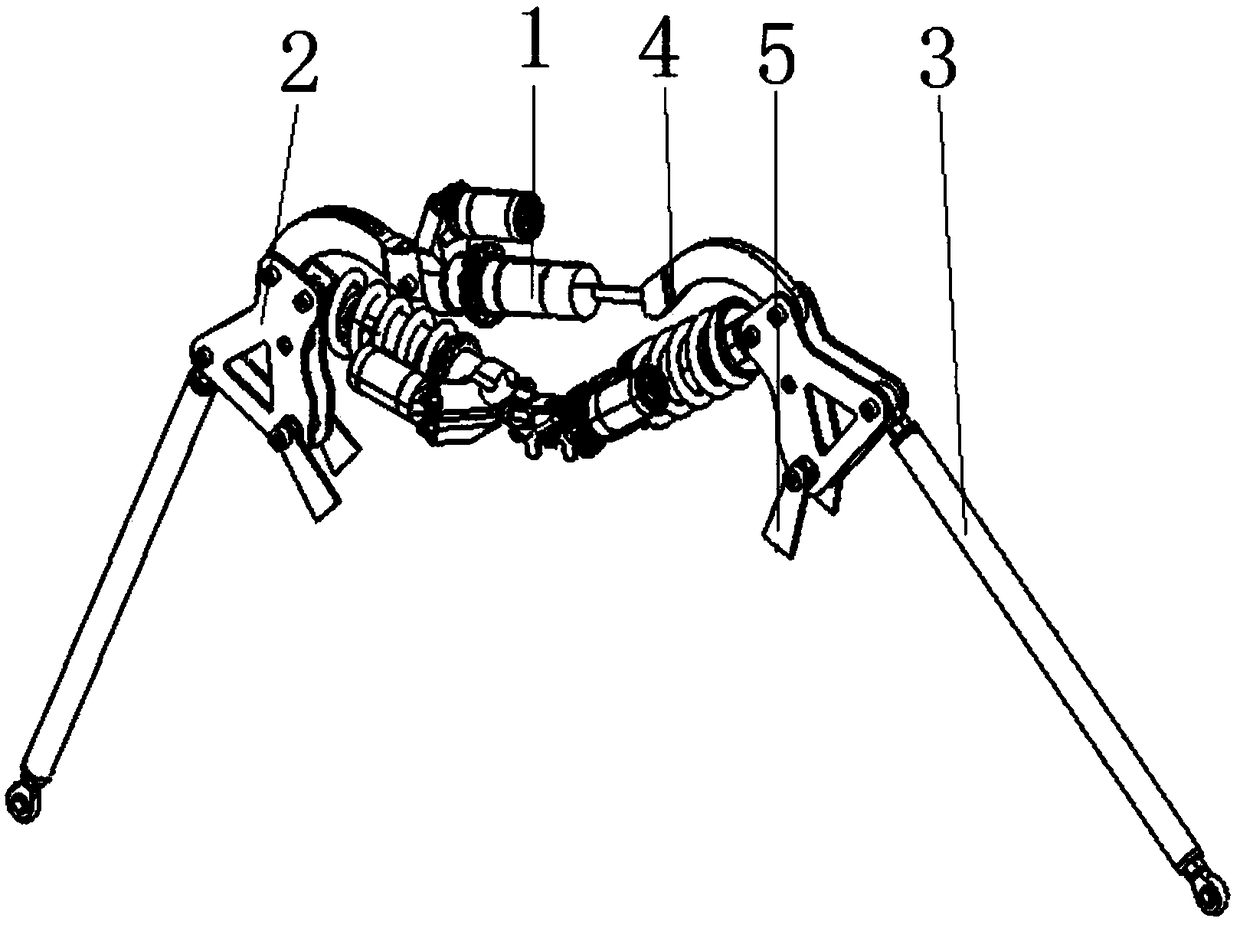

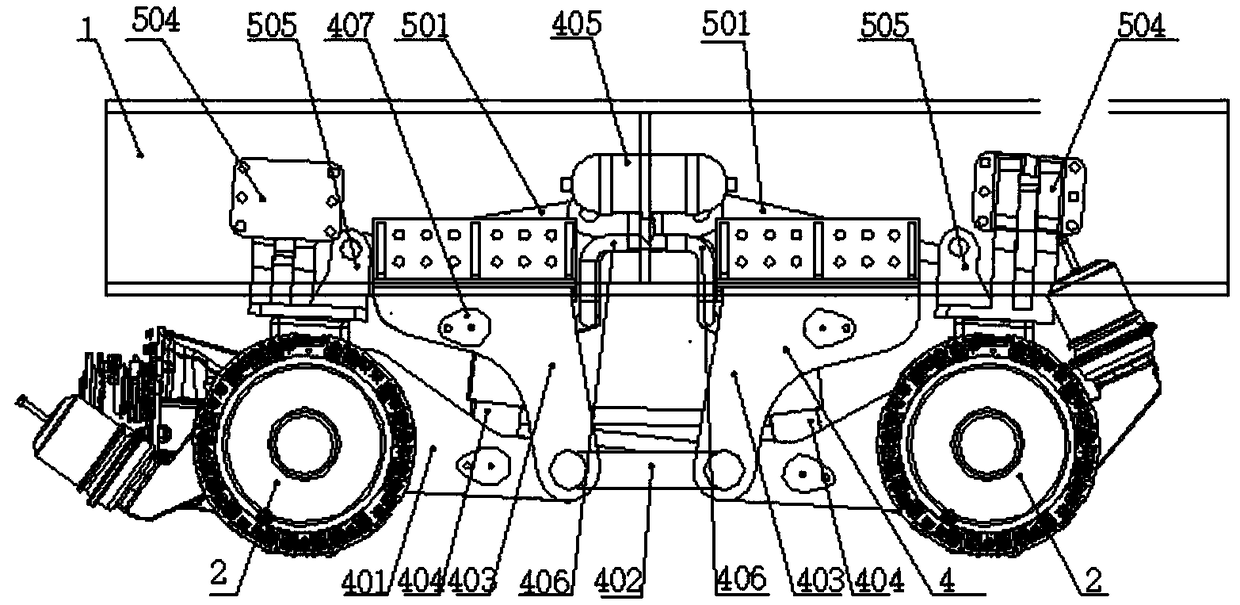

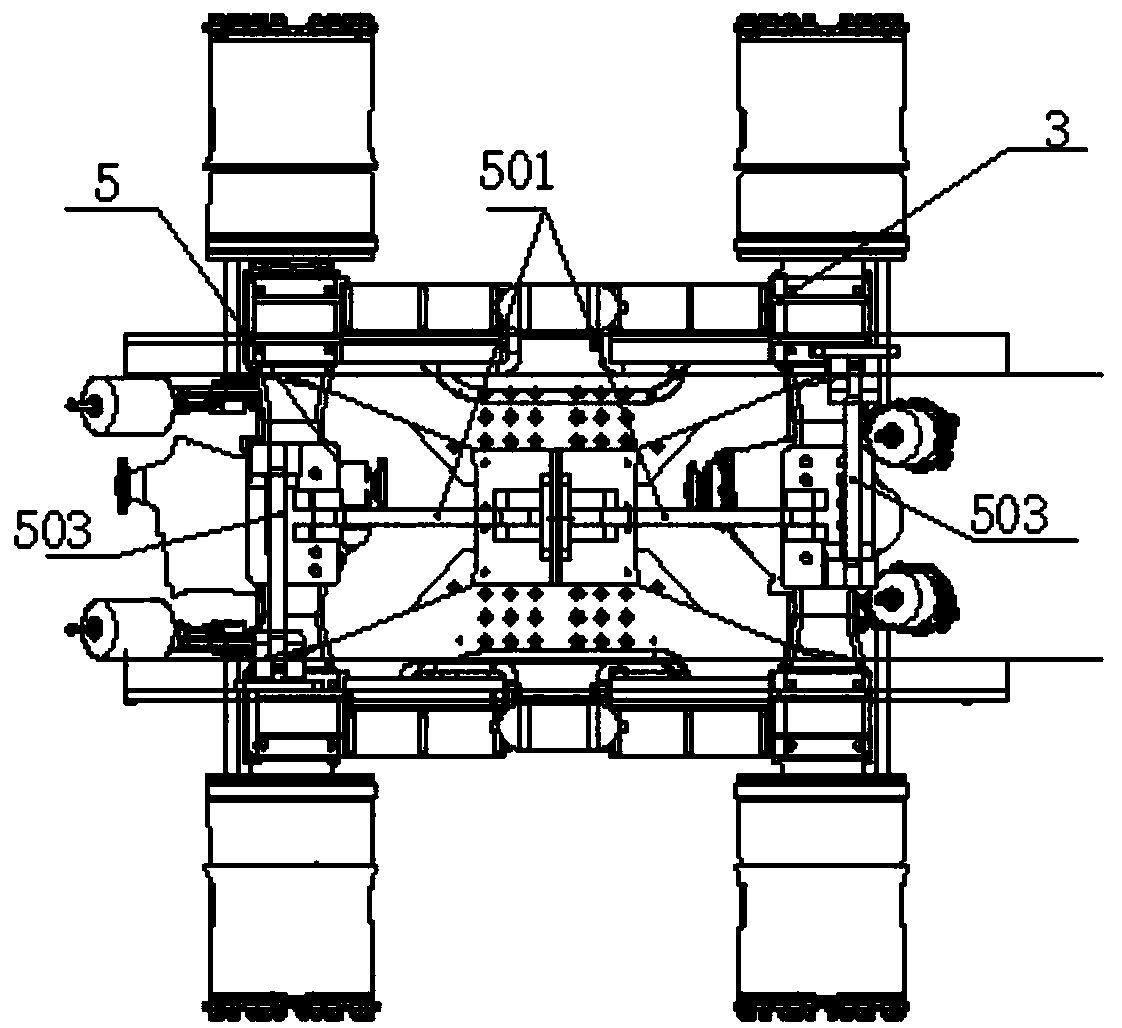

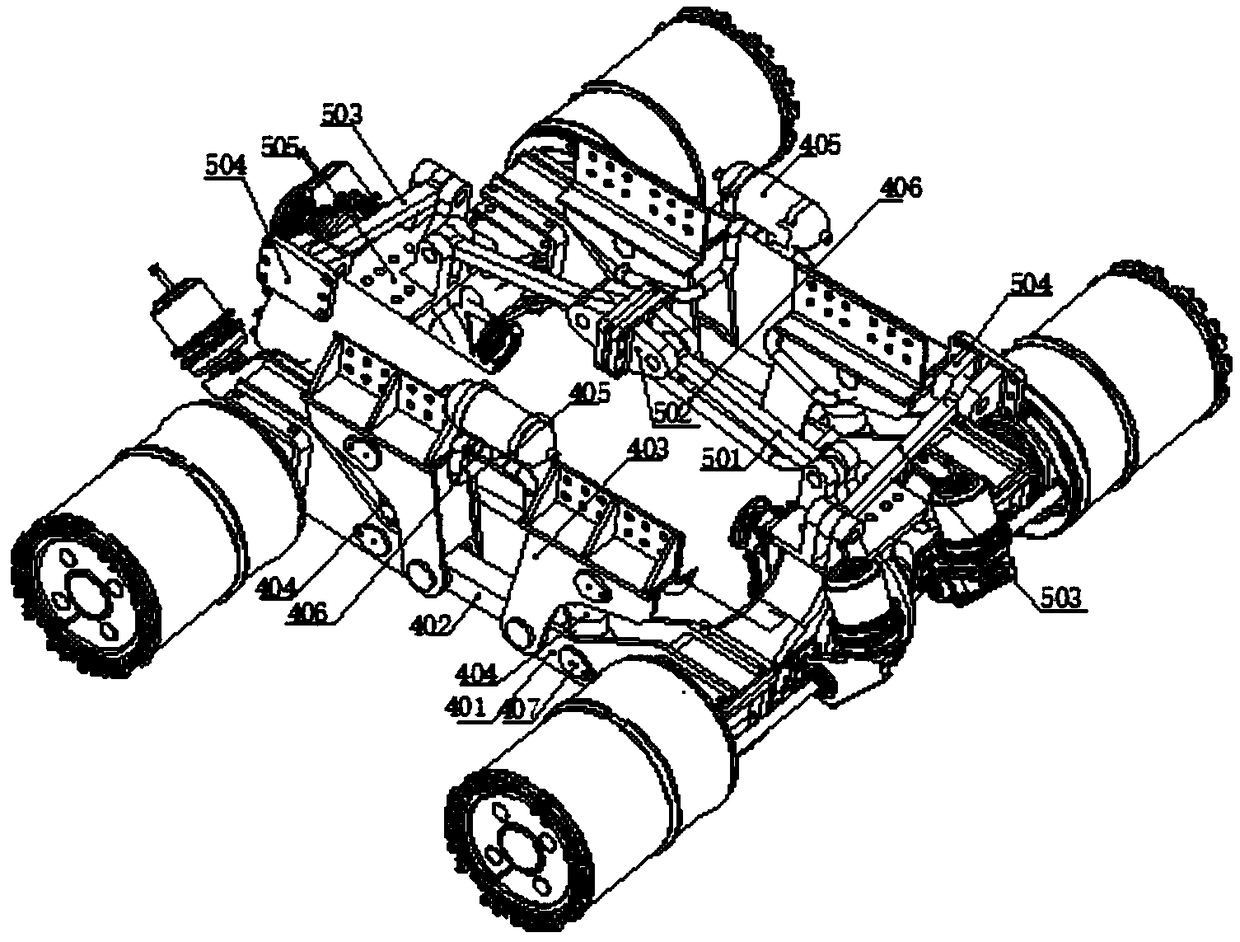

Initiatively rocking arm variable diamond-type four-wheel lunar rover moving system

InactiveCN101214833ATake full advantage of efficient mobilityGive full play to crawling abilityVehiclesVehicle frameEngineering

The invention discloses an active swing arm type variable diamond four-wheel lunar rover moving system. The system comprises a diamond like vehicle frame, a front wheel, a rear wheel, a left wheel and a right wheel with an independent driving system positioned on the vehicle frame. The front wheel and the rear wheel are fixedly positioned on the vehicle frame via a front suspension system and a rear suspension system. The left wheel and the right wheel are fixedly positioned on the vehicle frame via the left suspension system and the right suspension system. The front suspension system and the rear suspension system comprise a swing arm type power mechanism and a steering mechanism. The front wheel and the rear wheel change direction in linkage. The left suspension system and the right suspension system comprise a swing arm type power mechanism. Adopting the structure of the four-wheel three-axis diamond chassis and the active swing arm, the invention initially plays the high-efficient mobility of wheel type driving mode and the crawling ability of foot type moving system, and the invention relates to the active swing arm type variable diamond four-wheel lunar rover moving system with simple and compact structure, low cost, being suitable for operation under various severs environments, wide application, good stability, high reliability and strong flexibility of steering.

Owner:HUNAN UNIV

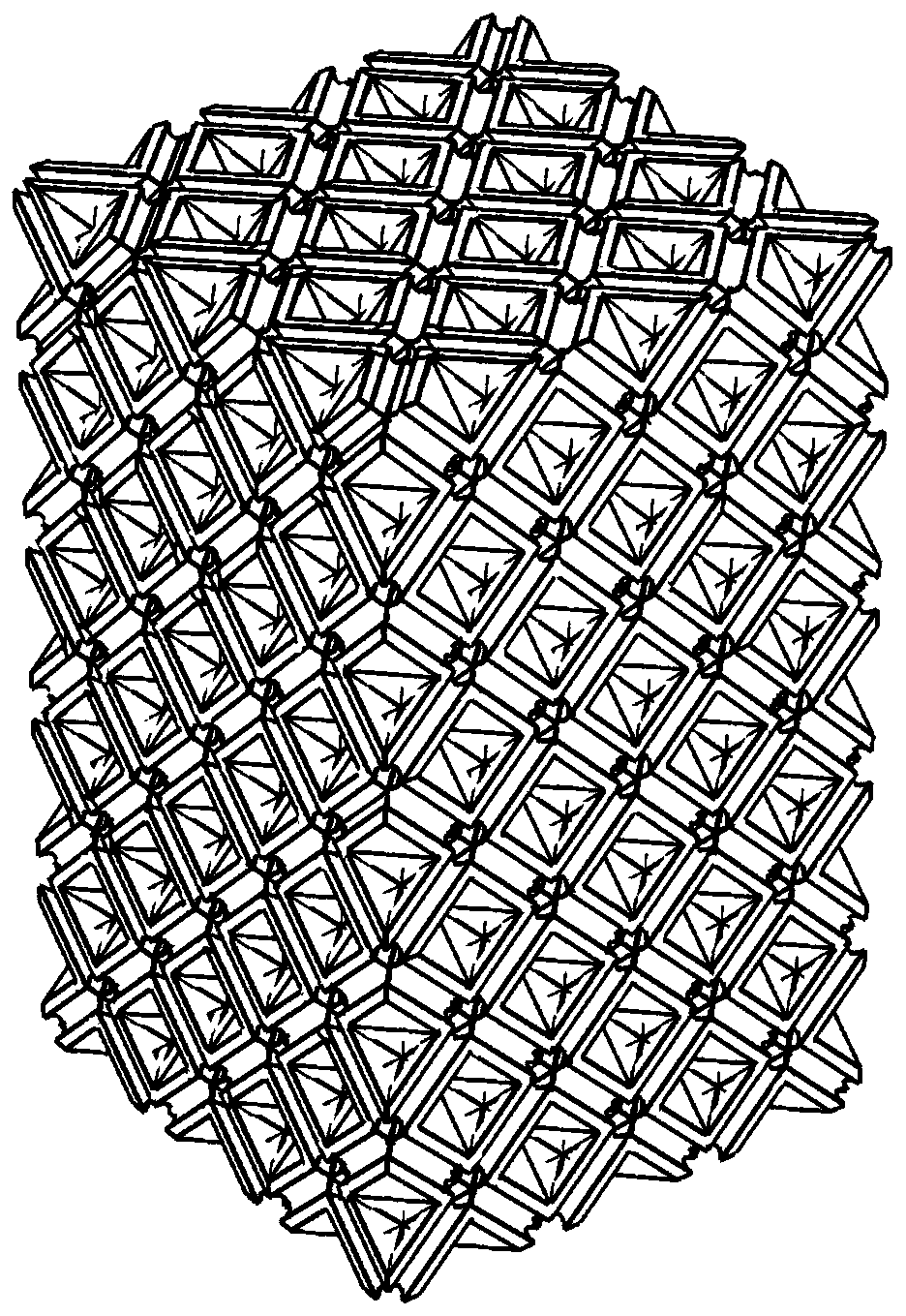

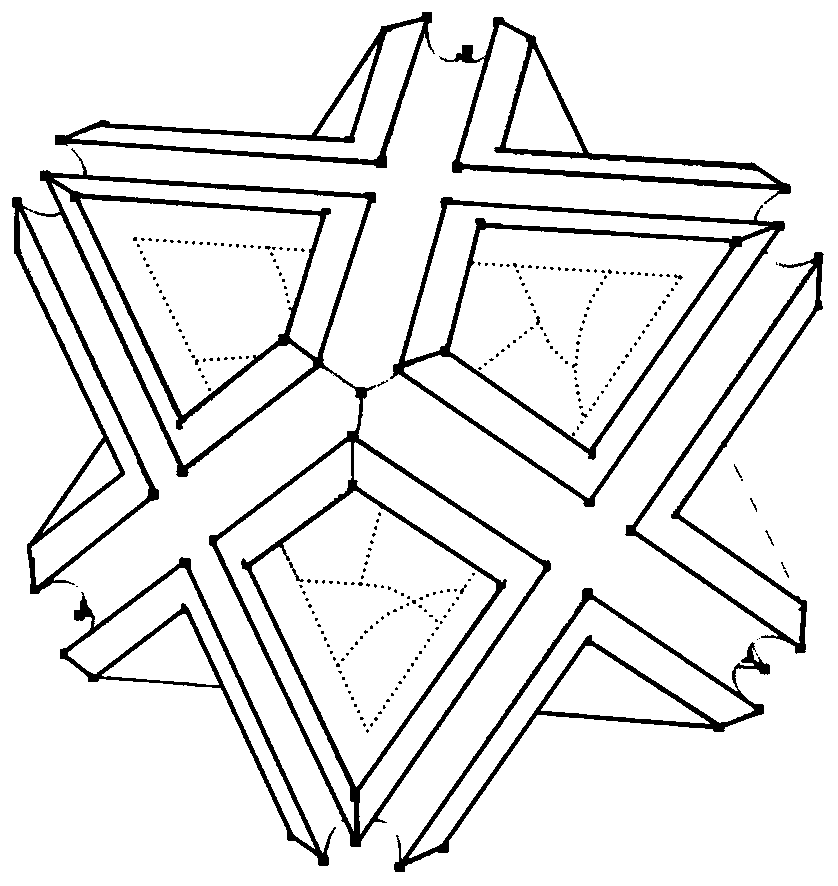

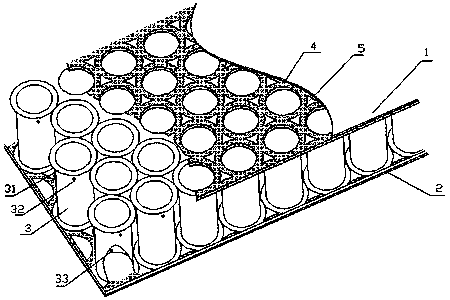

Enhanced superimposed hollow lattice structure and application thereof

ActiveCN111425543AHigh degree of lightweightHigh strengthSpringsWingsEngineeringMechanical engineering

The invention belongs to the field of lattice structures, and specifically discloses an enhanced superimposed hollow lattice structure and an application thereof. The enhanced superimposed hollow lattice structure comprises a plurality of enhanced hollow lattice unit cells arranged periodically and repeatedly in three dimensions, the enhanced hollow lattice unit cells comprise peripheral base hollow unit cells and inner core support hollow unit cells, the centers of gravity of the peripheral base hollow unit cells are coincided with that of the inner core support hollow unit cells, and the connecting rods and connecting points of the inner core support hollow unit cells are coincided with the central points of the connecting rods of the peripheral base hollow unit cells. According to the invention, partial solid is removed from the middle of the connecting rod body of the solid unit cell structure to form a hollow lattice unit cell and achieve light weight; the produced enhanced superimposed hollow unit cell is composed of two hollow unit cells, the volume of the superimposed lattice structure is lower than the sum of the volumes of the two base lattice structures under separate implementation, but the strength is higher than the sum of the strength of the two base lattice structures working separately, and the maximum bearing displacement is higher than the maximum bearing displacement characteristic under the sole action of the basic structure.

Owner:HUAZHONG UNIV OF SCI & TECH

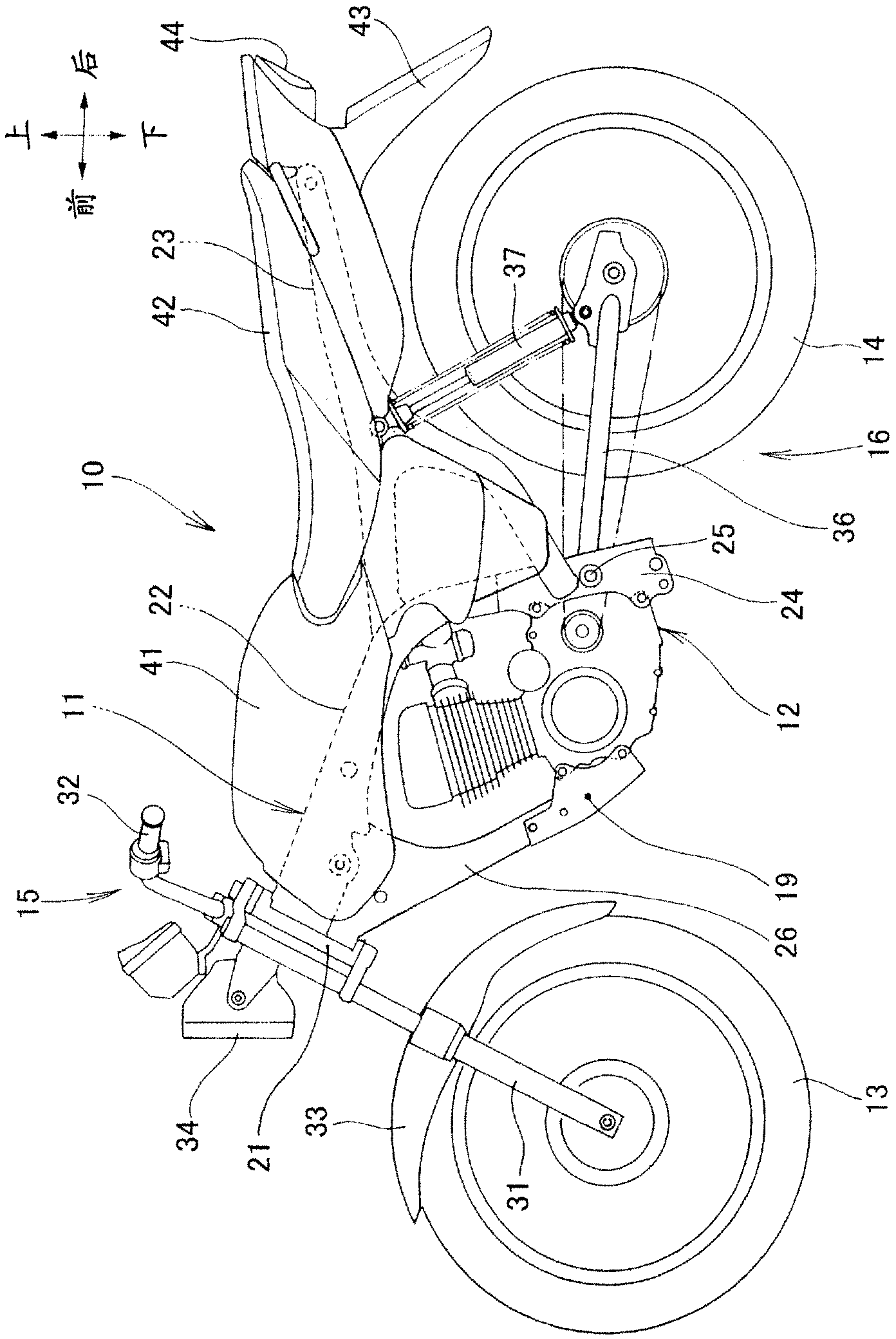

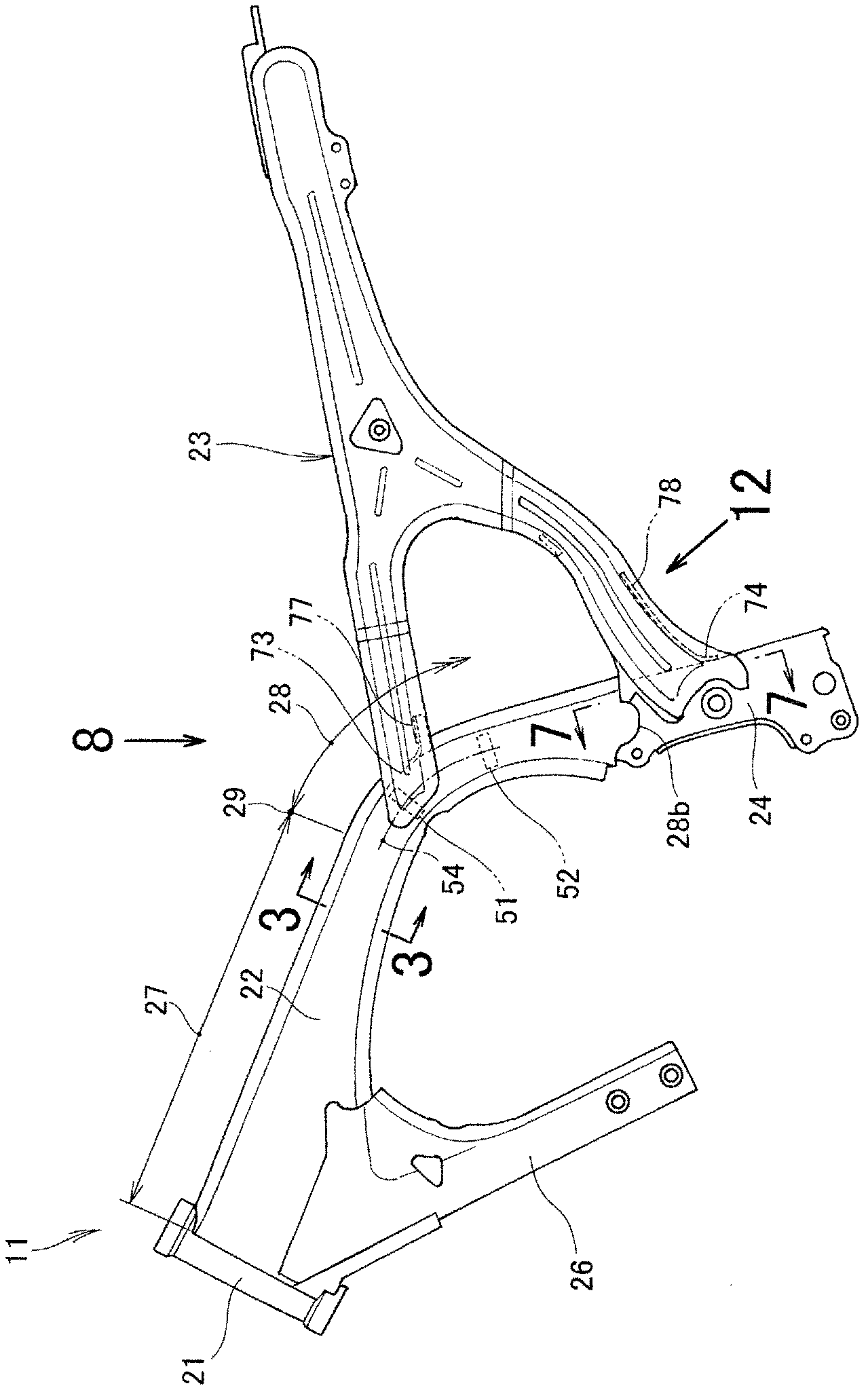

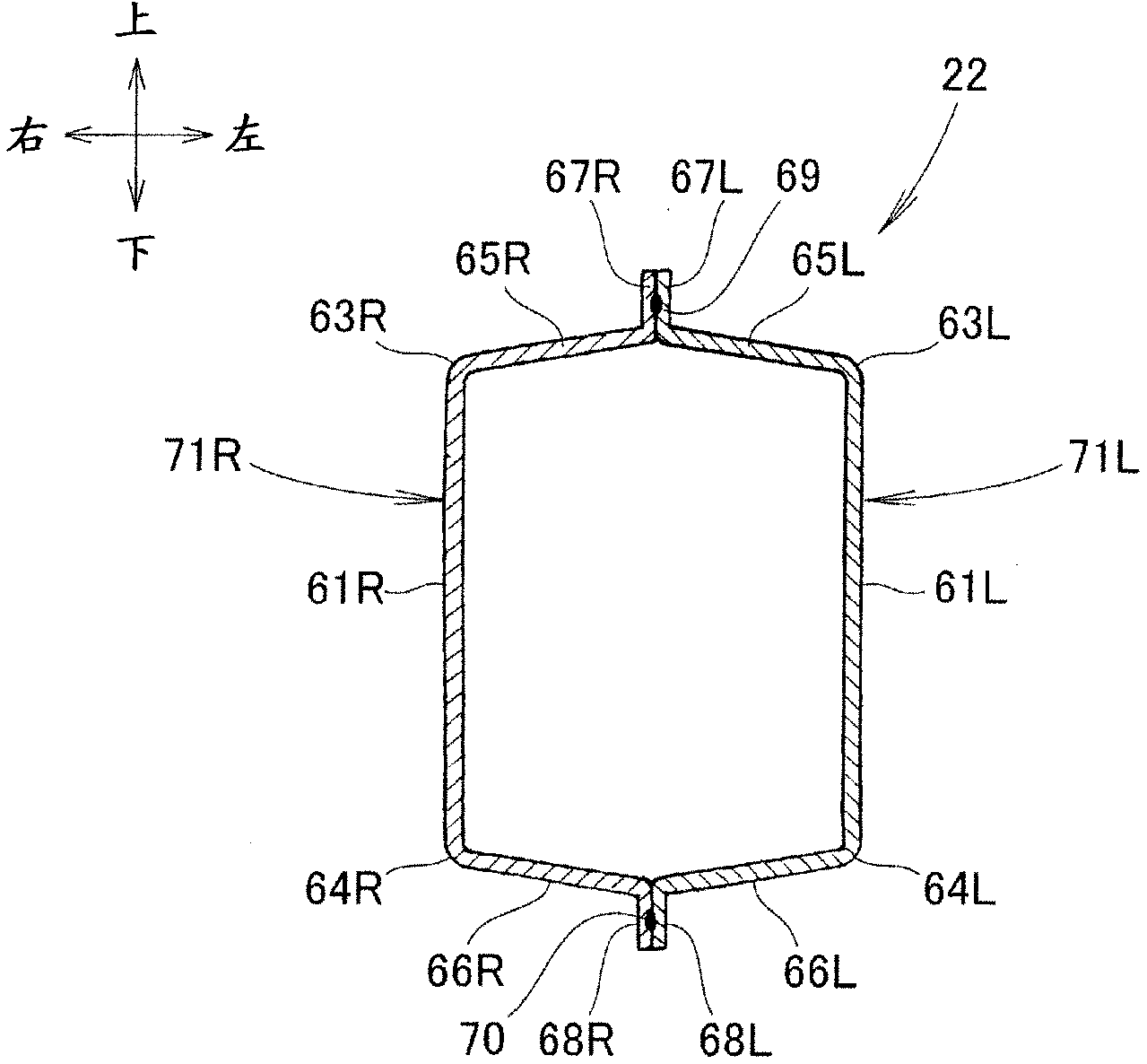

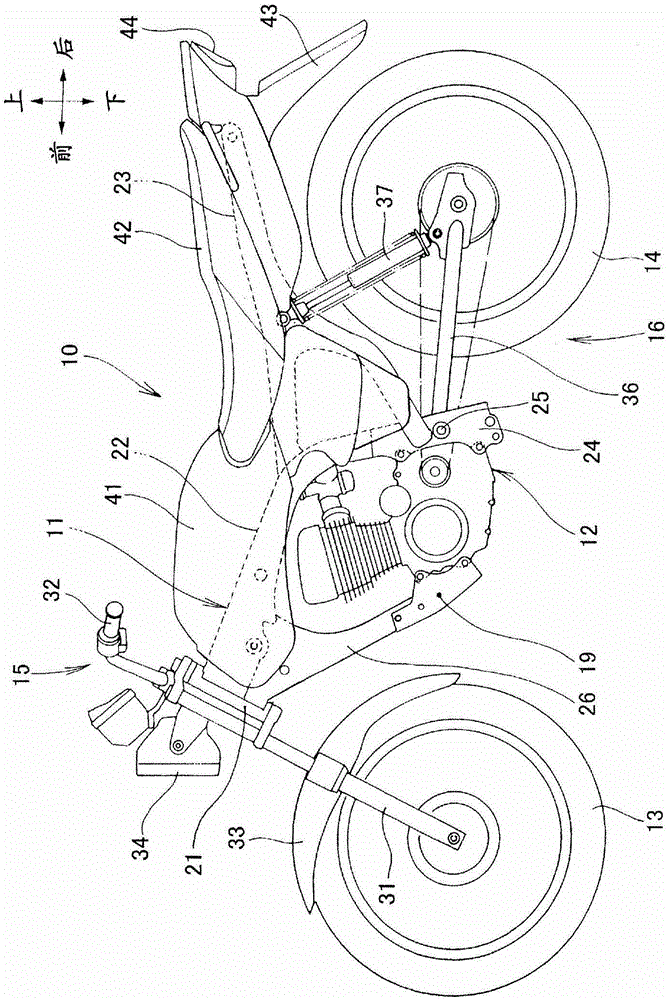

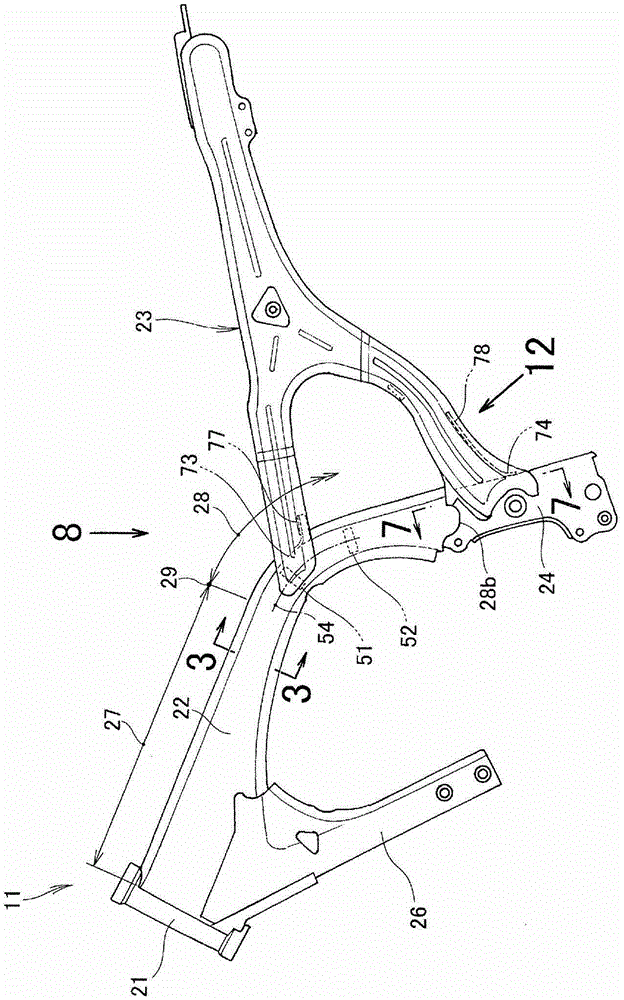

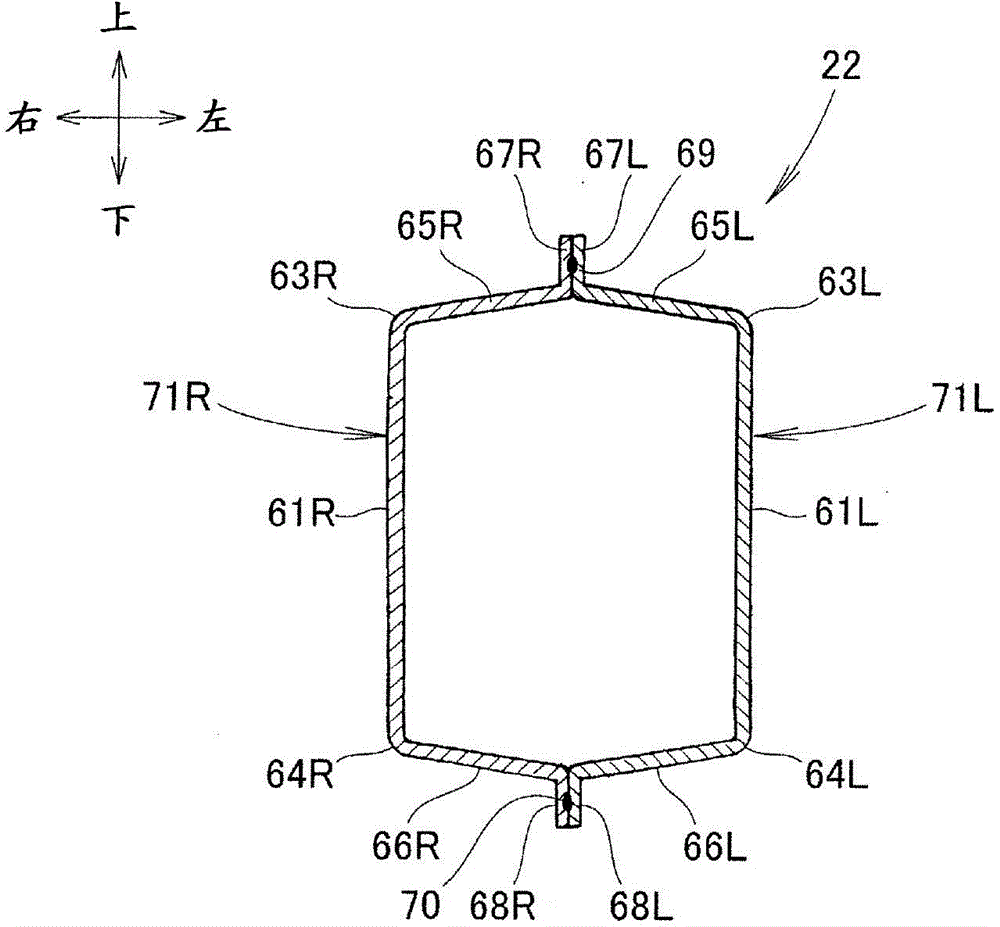

Vehicle body framework of two-wheeled motorcycle

The invention aims at proving a vehicle body framework made of press working drip mouldings of a two-wheeled motorcycle. The vehicle body framework not only satisfies a requirement of light weight but also has relatively high rigidity. On the vehicle body framework, a main framework (22) is composed of a straight line extension portion (27) and a bending portion (28) which bends from a rear end of the straight line extension portion (27) and is extended downwards. A rear framework (23) is a part whose head end is connected with the left and right lateral surfaces of the bending portion (28) in a vehicle width direction and a part that is extended backwards. Reinforcement members (77, 78) that are generally rectangular in an overlook view are disposed between the bending portion (28) and a front portion inner surface of the rear framework (23). Front edges of the reinforcement members (77, 78) are connected with a rear surface of the bending portion (28) and a pivot framework portion (24) respectively.

Owner:HONDA MOTOR CO LTD

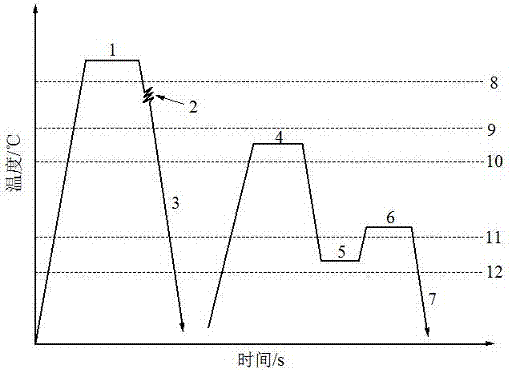

Manufacturing method for reverted austenite hot-stamped steel plate

InactiveCN107245554AEasy to operateIncreased strength and plasticityQuenching agentsMartensite transformationHot stamping

The invention relates to a manufacturing method for a reverted austenite hot-stamped steel plate. The method comprises the following steps: (1) heating materials to a certain temperature of greater than Ac3 (a finishing temperature of austenite transformation) at a certain heating speed and insulating heat for a certain time; (2) carrying out primary quenching: transferring a steel plate into a stamping die and carrying out hot-stamping formation, and then carrying out water quenching to achieve room temperature; (3) carrying out heat insulation in a reverted austenite area: re-heating the steel plate quenched to the room temperature to a certain temperature between As (a beginning temperature of reverted austenite formation) and Ac1 (a beginning temperature of austenite transformation) and keeping constant temperature for a period of time; (4) carrying out secondary quenching: rapidly quenching the steel plate to a certain temperature between Ms (a beginning temperature of martensite phase transformation) and Mf (a finishing temperature of martensite phase transformation) and insulating heat for a certain time; (5) partitioning: heating the steel plate to a temperature of greater than Ms and insulating heat for element partitioning; and (6) carrying out tertiary quenching: quenching the steel plate to room temperature.

Owner:SHANDONG JIANZHU UNIV

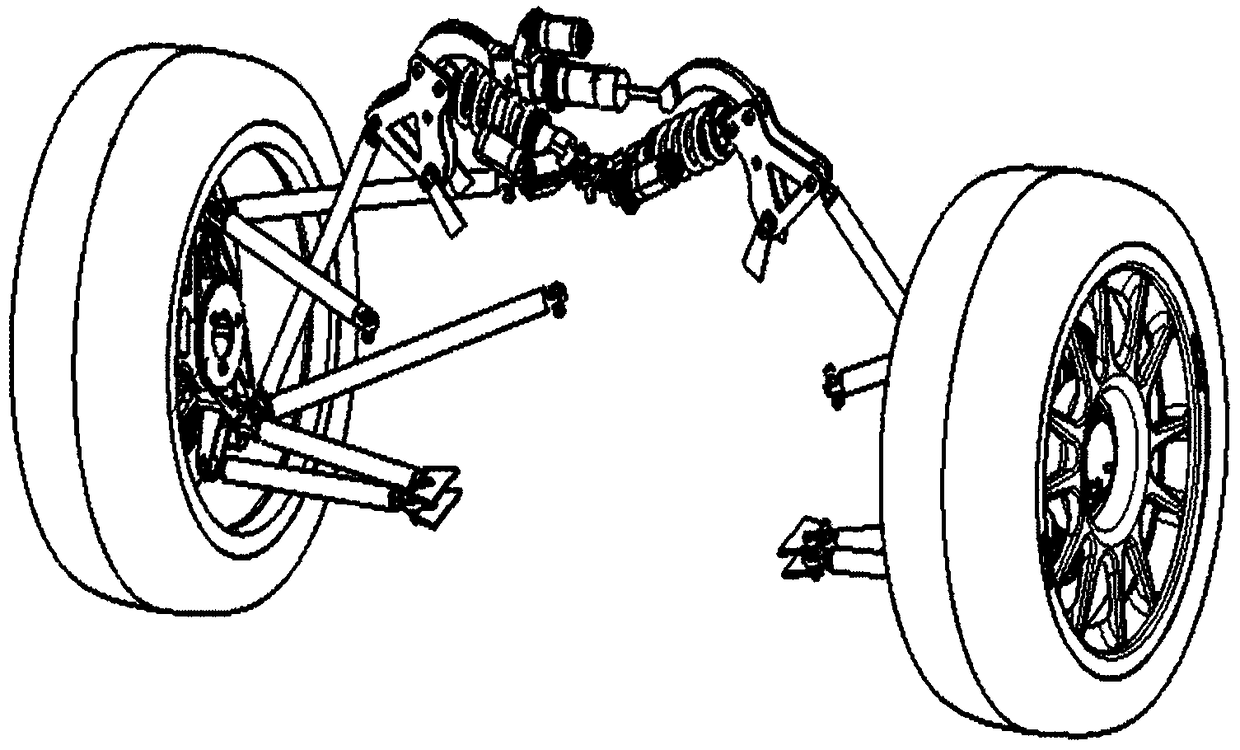

Vehicle longitudinal trim control device

InactiveCN108859649AImprove powerImprove fuel economyResilient suspensionsEngineeringIndependent suspension

The invention discloses a vehicle longitudinal trim control device. The device comprises a damping mechanism, lever mechanisms are symmetrically arranged on the two sides of the damping mechanism androtationally connected with the damping mechanism, transmission rods are connected to one ends of the lever mechanisms on the two sides, and the transmission rods are rotationally connected with the lever mechanism. The device has the advantages that by arranging the damping mechanism of an independent suspension, the damping mechanism can only take effect when wheels hop in the same direction simultaneously for twice, that is to say, the damping mechanism can only take effect when a longitudinal trim tendency exists, and then the purpose that individual control over the longitudinal trim characteristic is conducted while the vehicle longitudinal trim characteristic is not affected can be achieved; therefore, by means of the device, good longitudinal trim control can be provided for a vehicle under the condition of not affecting the vehicle longitudinal trim characteristic; in addition, the device is compact in structure, simple in layout and easy to disassemble, install and adjust, and has an extremely high application value.

Owner:HEFEI UNIV OF TECH

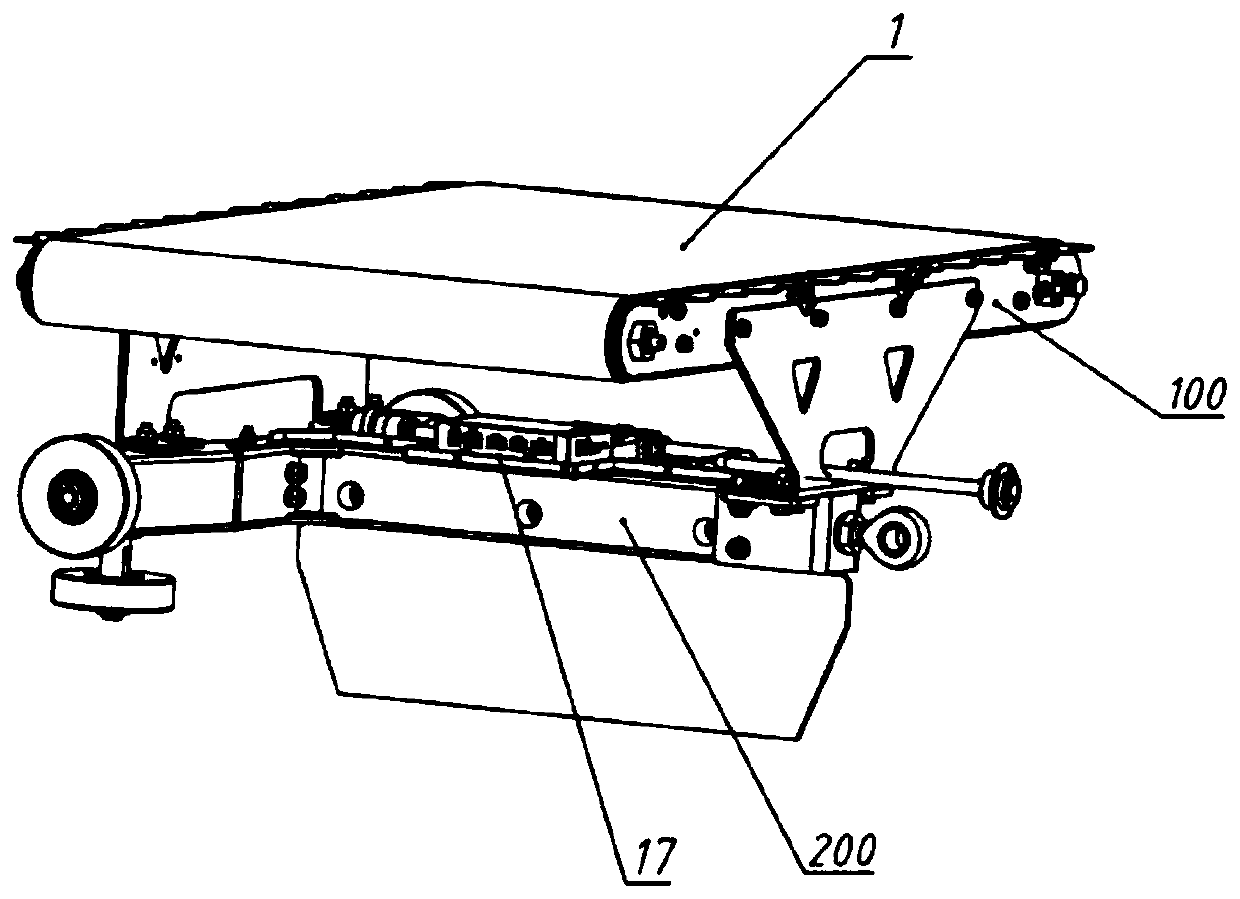

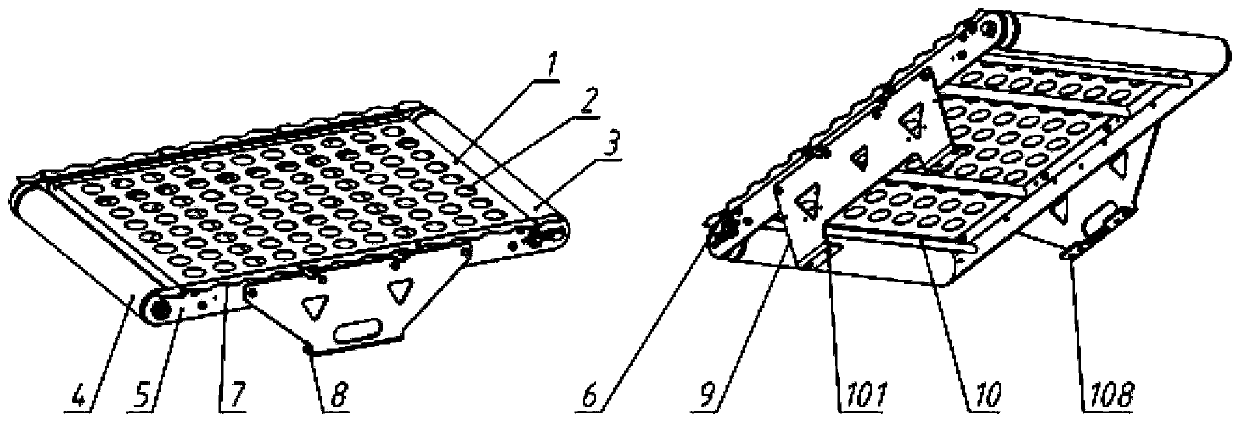

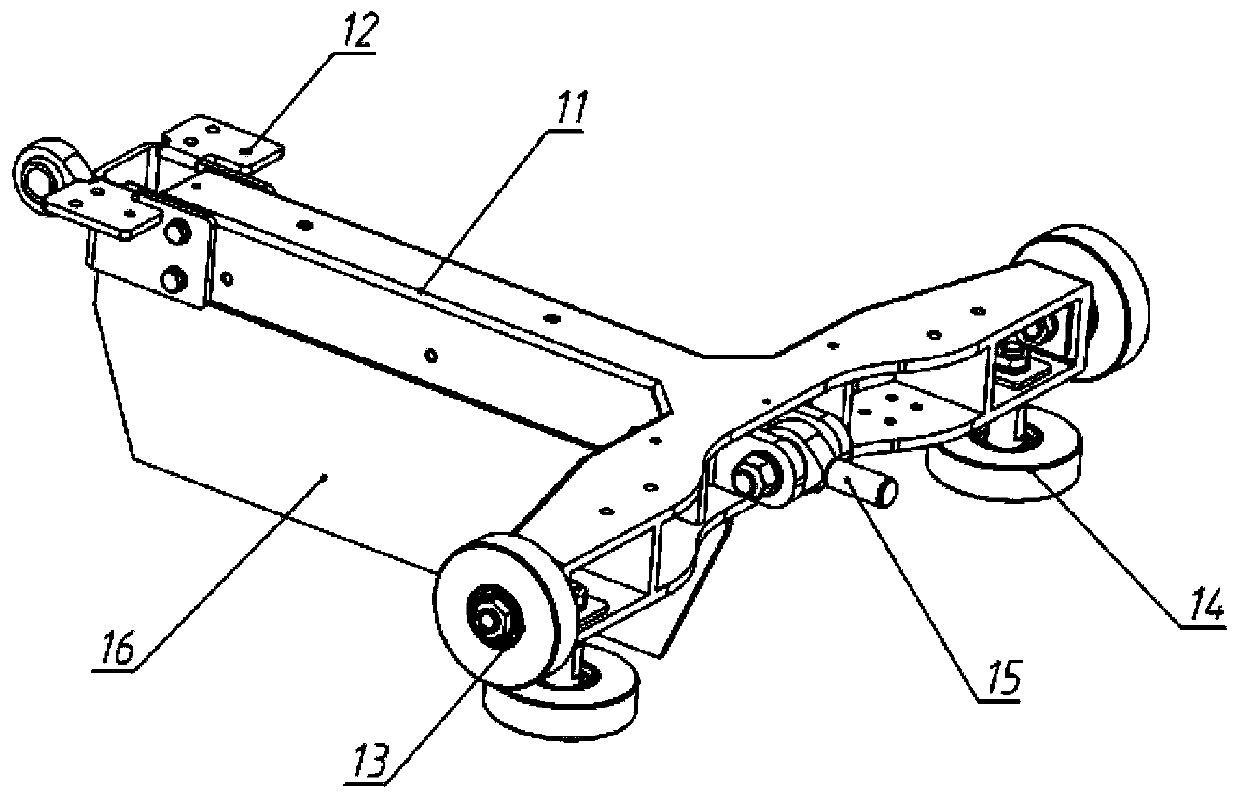

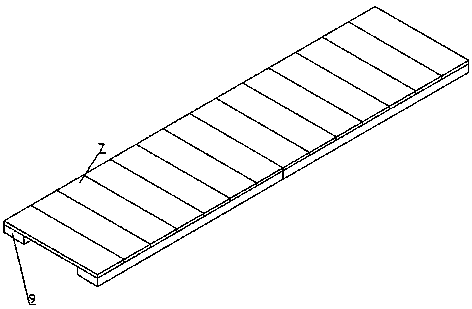

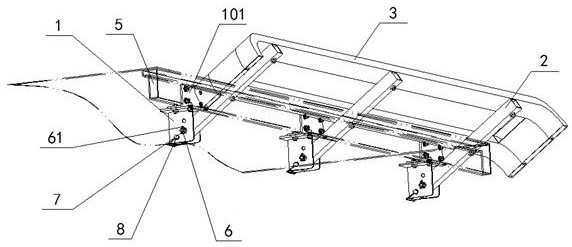

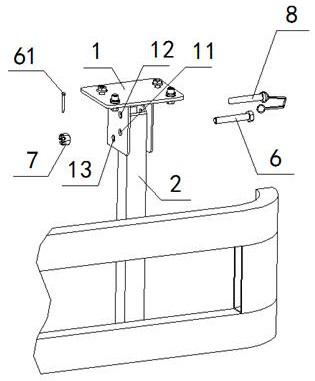

Crossed belt sorting trolley assembling method

InactiveCN111590314ACompact structureHigh degree of lightweightAssembly machinesStructural engineeringMechanical engineering

The invention provides a crossed belt sorting trolley assembling method. The improvement design on respective modular structures and assembling methods of an upper conveying unit and a lower frameworkis adopted, and accordingly the purposes that the installing stability and assembling and disassembling accuracy of module structures of various assemblies are improved, the disassembling and assembling operation efficiency is simplified, and component abrasion and running noise are reduced are expected to be achieved. A sorting trolley is divided into an upper conveying unit and a lower framework, and after respective independent assembling, integral installation is implemented. A folding plate is horizontally and fixedly arranged on each side plate of the upper conveying unit, and a first bending connecting plate and a second bending connecting plate are vertically and fixedly arranged on each side plate. A plurality of uniform arc sections are arranged on the outer side edges of the folding plates. When a front sorting trolley and a rear sorting trolley are connected in series, the arc sections of the respective folding plates of the front sorting trolley and the rear sorting trolley are engaged, and a certain gap is reserved. The folding plates are fixedly connected with folding plate fixing plates arranged at the side portions of the side plates. The part between the side plates on the two sides is transversely connected with multiple pull rods, and the two ends of the pull rods are fixedly connected with the side plates through bolts from the outer sides. The first bending connecting plates and the second bending connecting plates are connected with the side plates on one sides correspondingly.

Owner:QINGDAO KENGIC AUTOMATION EQUIP CO LTD

Body frame of a two-wheeled motorcycle

Owner:HONDA MOTOR CO LTD

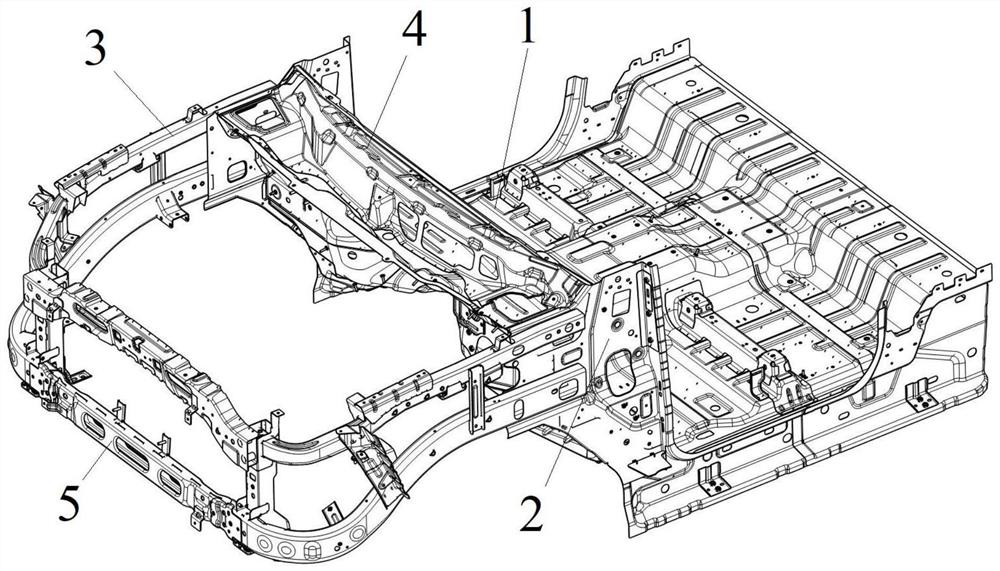

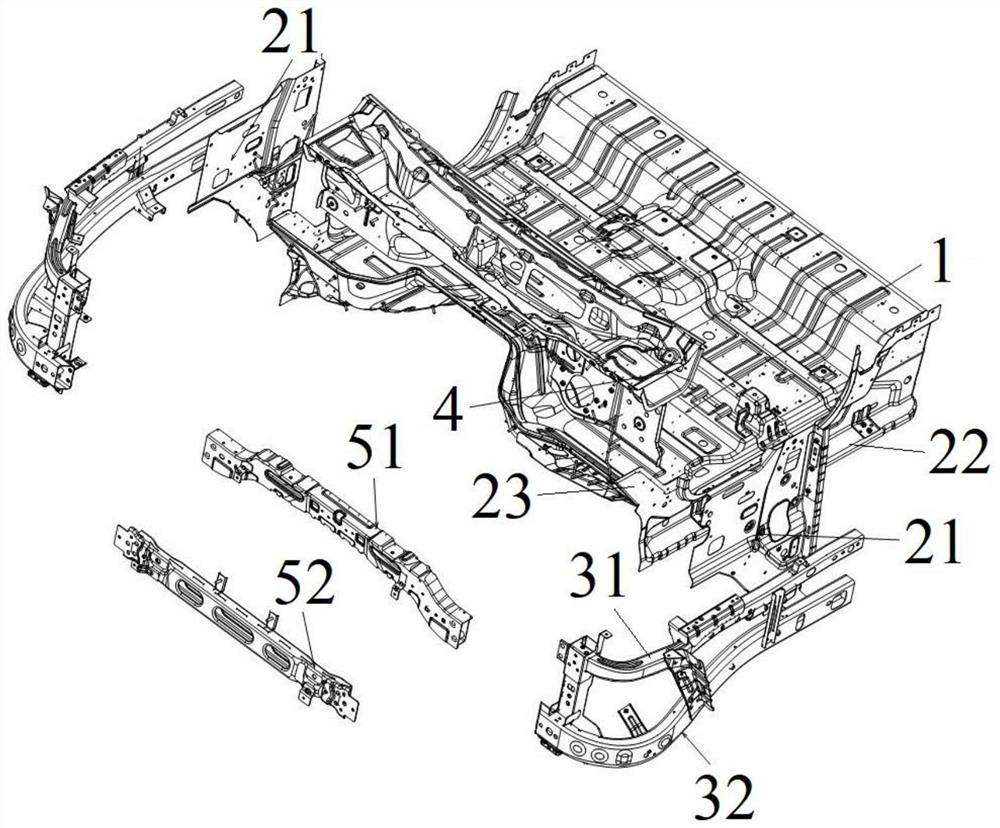

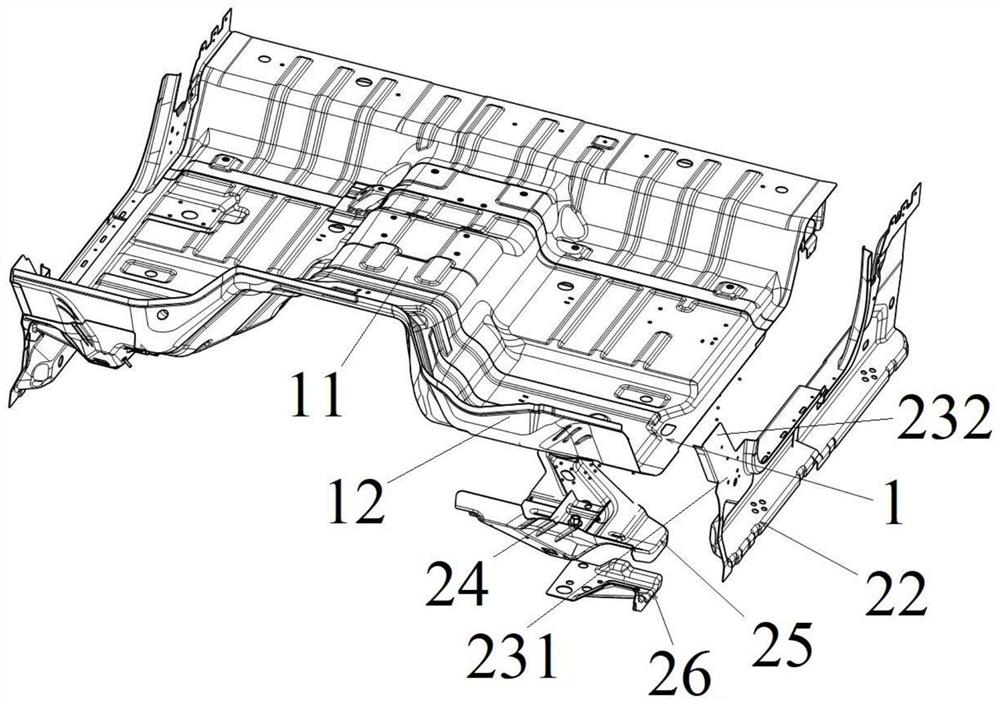

Front cabin structure of off-road vehicle body

ActiveCN113968285AControl force transmissionSimple structureSuperstructure subunitsBumpersClassical mechanicsEngineering

The invention relates to the technical field of automobile structures, in particular to a front cabin structure of an off-road vehicle body. The structure comprises a floor assembly, side reinforcing assemblies are arranged on the two transverse sides of the floor assembly in the vertical direction, and the lower ends of the side reinforcing assemblies are fixed to the transverse sides of the floor assembly; a cabin longitudinal beam assembly which is arranged in the longitudinal direction, and the end, close to the floor assembly, of the cabin longitudinal beam assembly is fixed to the upper end of the side reinforcing assembly; a front wall assembly which is arranged in the transverse direction, and the two ends of the front wall assembly are fixedly connected with the side reinforcing assemblies on the two sides respectively; a water tank cross beam assembly which is transversely arranged, and the two ends of the water tank cross beam assembly are fixedly connected with the cabin longitudinal beam assemblies on the two sides; the lower end of the front wall assembly is fixed to the floor assembly, and the lower end of the front wall assembly, the side reinforcing assemblies on the two sides and the floor assembly form a stress cavity space for dissipating the bending moment and torque of the cabin longitudinal beam assembly. The front cabin is simple in structure, can bear large longitudinal stress by constructing a frame type structure, and is good in structural stability and high in lightweight degree.

Owner:DONGFENG OFF ROAD VEHICLE CO LTD

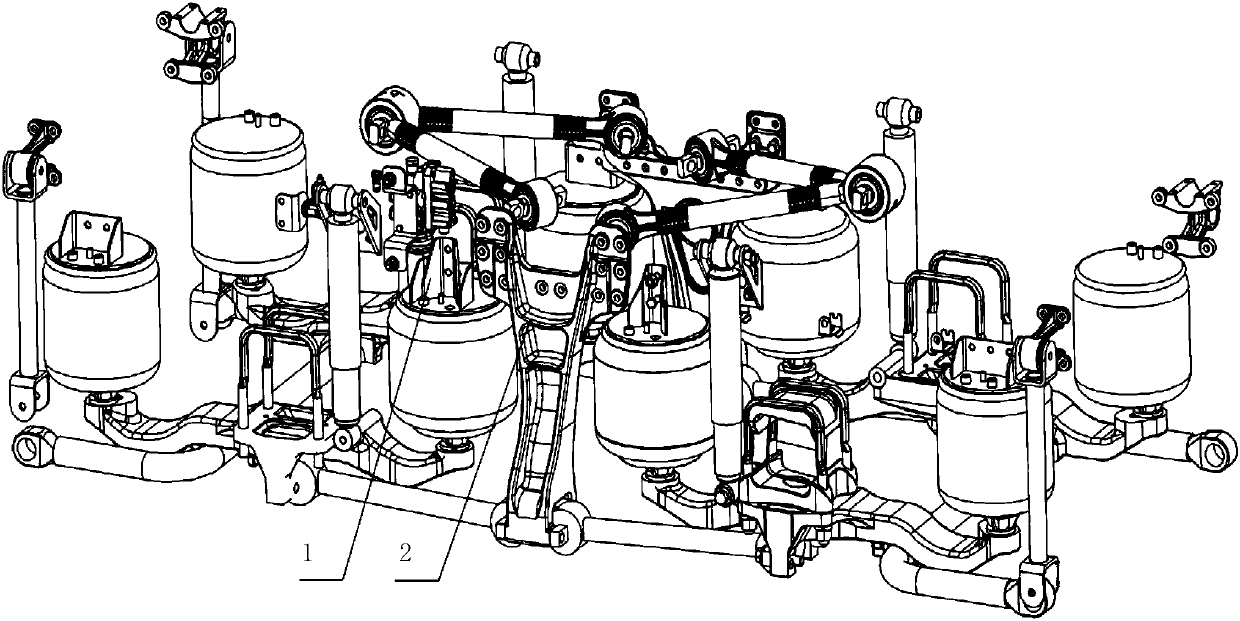

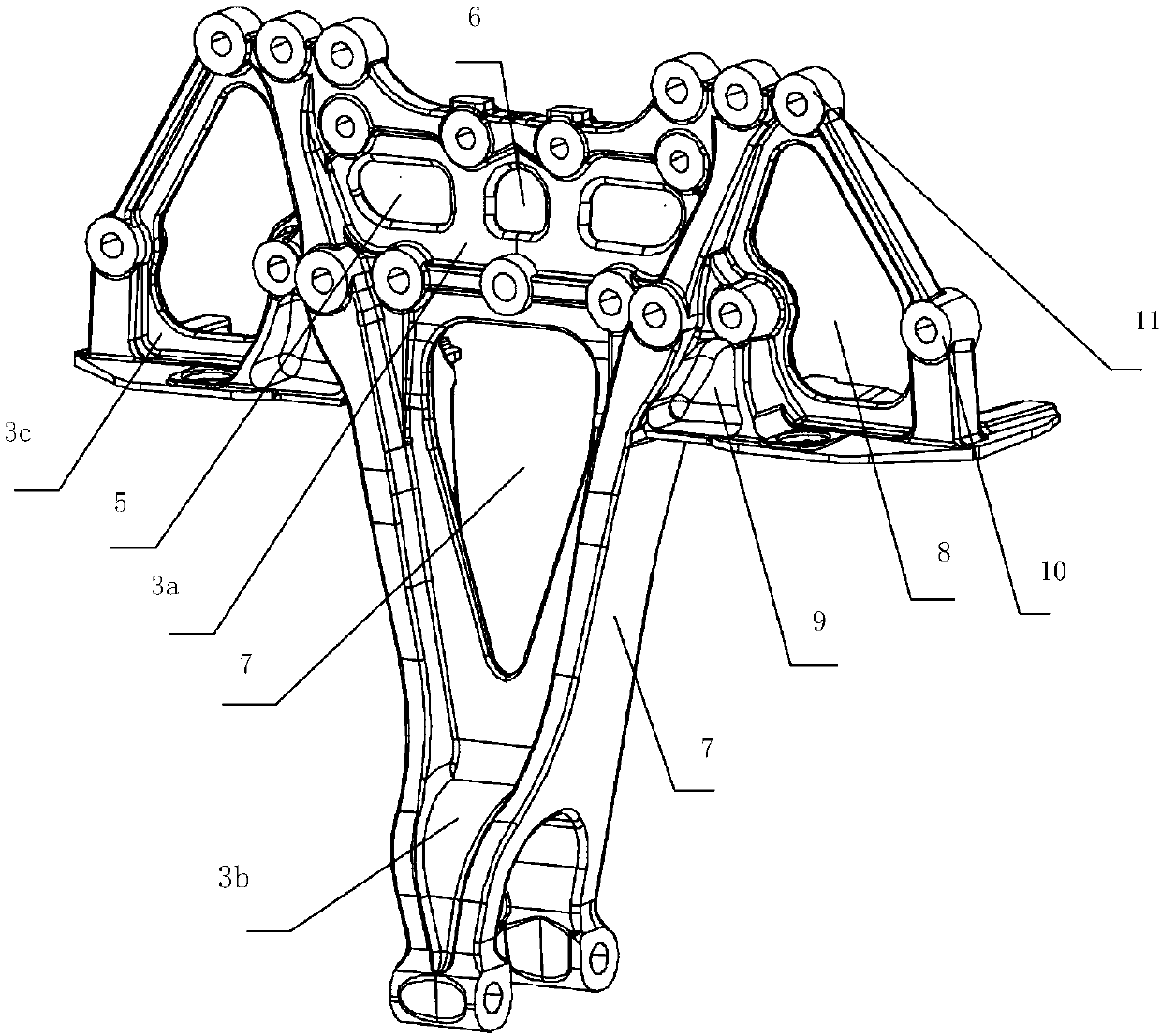

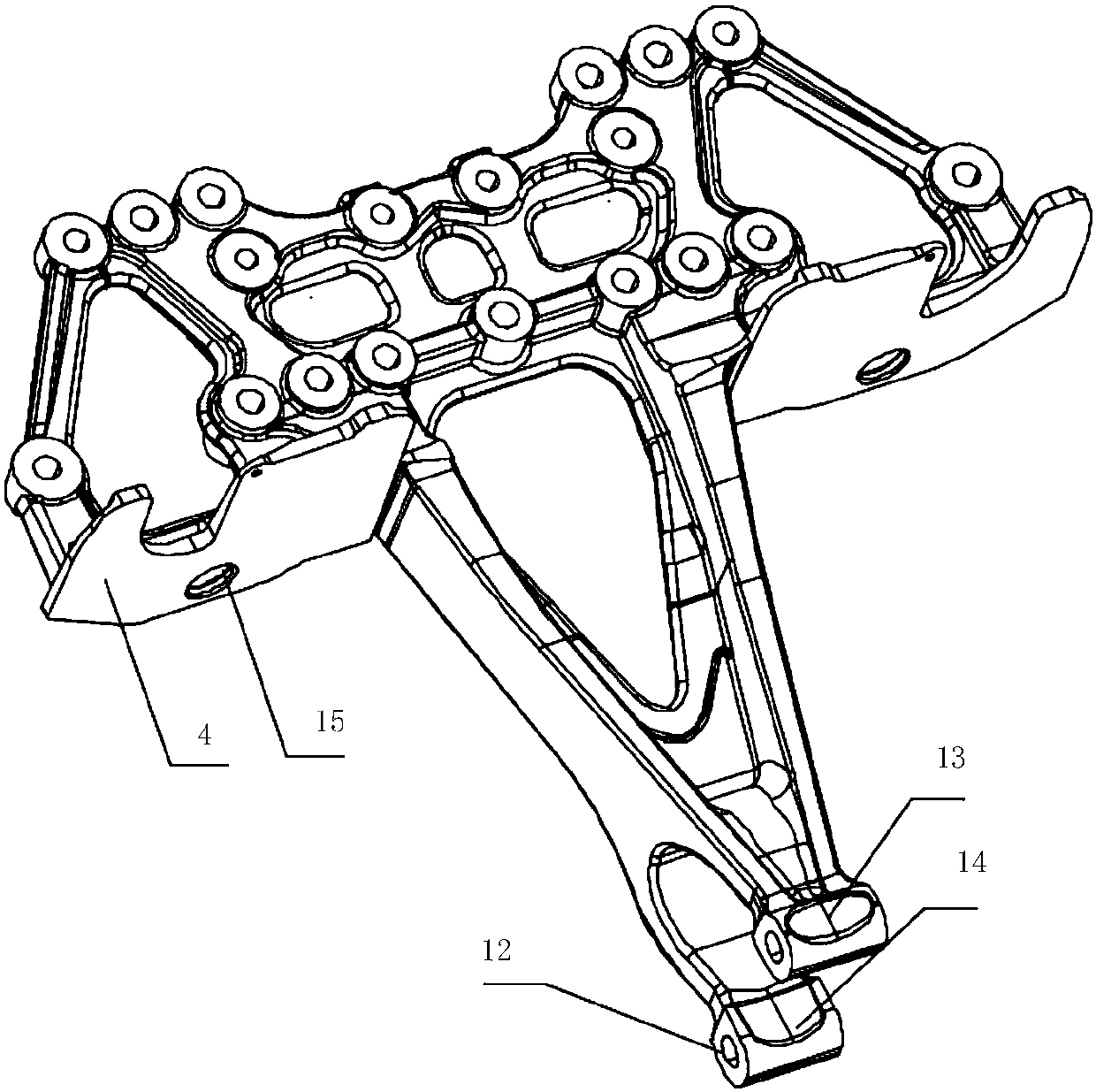

Function integrated support of air suspension and special high-strength cast-state ductile iron material of support

ActiveCN107699784AMeet material performance requirementsHigh yield strengthResilient suspensionsPunchingChemical composition

The invention relates to a support of an air suspension and special high-strength cast-state ductile iron of the support. The high-yield-strength cast-state ductile iron comprises chemical componentsincluding C, S, P, Mn, Si, Cr, Sn, Mg, Re and the balance Fe. The support comprises a support body, an air spring supporting face and a middle and rear axle thrust rod base, and the support is of an integral casting structure. Compared with the prior art, according to the cast-state performance, the tensile strength sigma b is larger than or equal to 600 MPa, sigma 0.2 is larger than or equal to 400 MPa, delta is larger than or equal to 10%, the brinell hardness HB is equal to 245-287, the content of a cast-state base body is 80%, the content of cementite is 1%, the yield strength is improved,and the material performance requirement of a structure bearing piece with the medium heavy truck fatigue resisting strength can be met. In addition, the support is of the integral casting structure,welding, forging, punching and other technologies are not needed, respective assembling is not needed neither, cost is greatly reduced, and time is greatly shortened; the effective strength is guaranteed, and meanwhile material stacking is reduced as well; and the space is more compact, the lightweight degree is higher, and the fuel economy of a whole vehicle can be better improved.

Owner:CHINA FIRST AUTOMOBILE

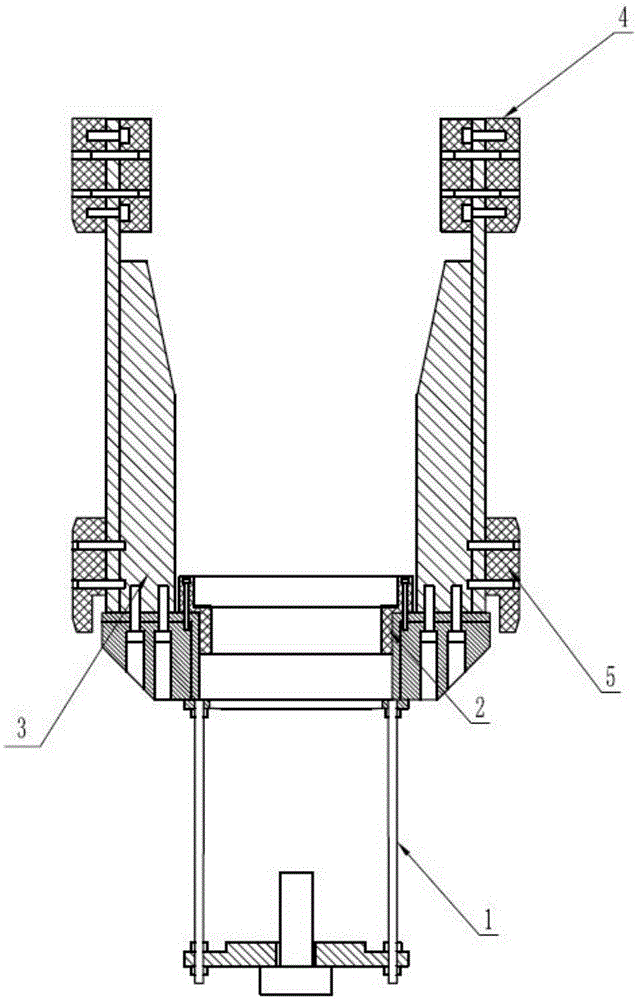

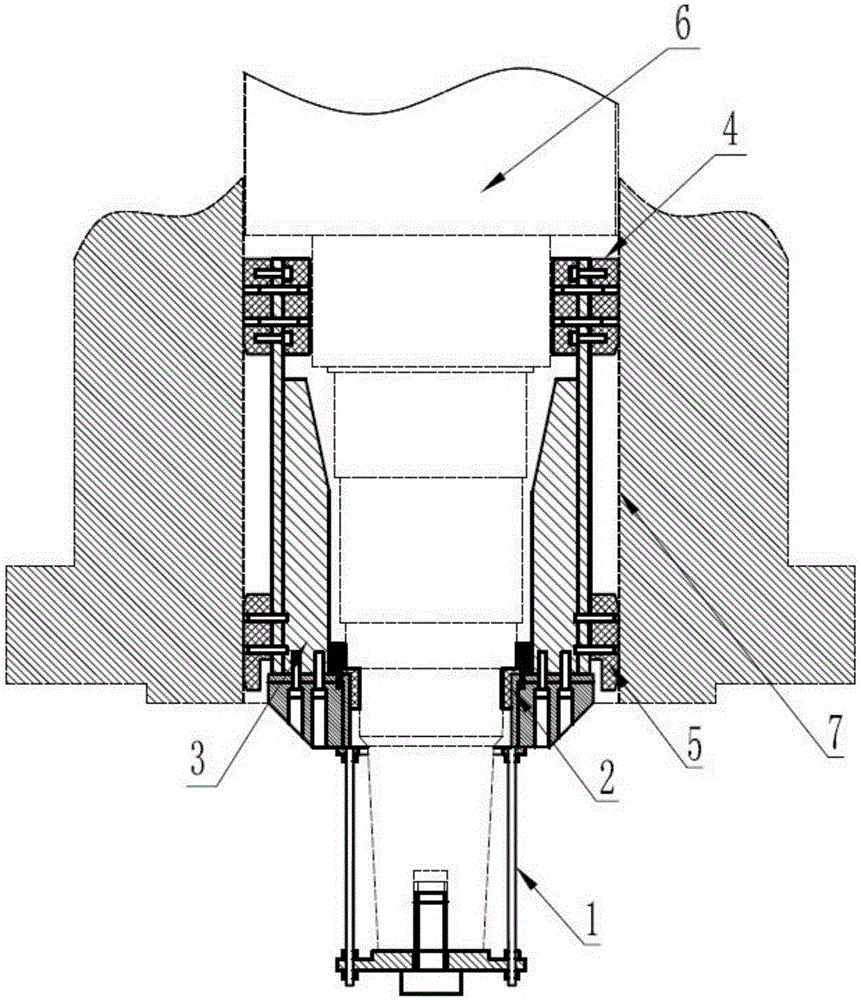

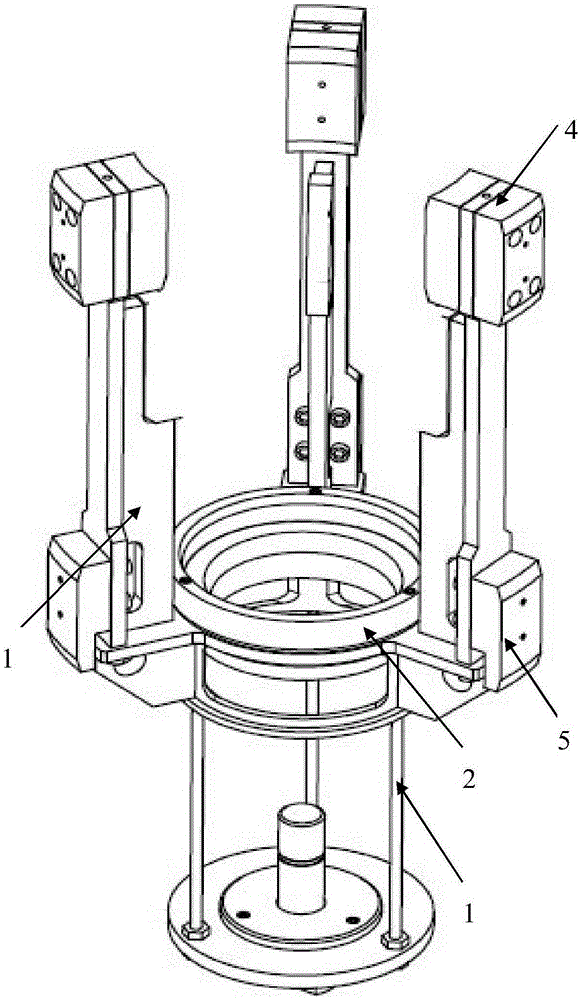

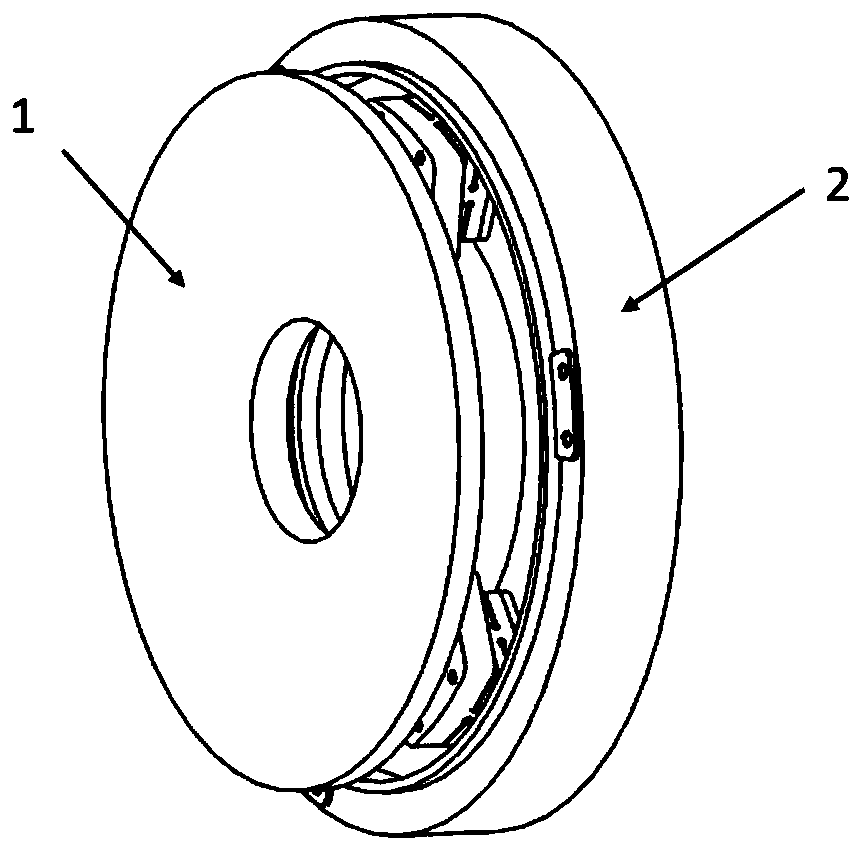

Tooling device used for assembly of rotor and stator in shielding electric motor

ActiveCN105305745AEasy to bumpAssembly risk is highCentering/balancing rotorsEngineeringElectric motor

The invention relates to a tooling device used for assembly of a rotor and a stator in a shielding electric motor, wherein three aluminum supports uniformly distributed on a tooling bracket and a nylon block fixed on the surface of the same are used to realize positioning guidance, a whole set of tool is connected to the rotor by an axial end threaded hole, radial positioning is realized by a stepped shaft small circle, and thus the objective to assemble the rotator into the stator is realized. In tooling device used for the assembly of the rotor and the stator in the shielding electric motor provided by the invention, lightweight design is adopted, so that tool assembly and disassembly are convenient; and the guiding and positioning of a non-metal material are adopted, so that scratches to a product surface during the assembly are avoided. The tooling device has high accuracy of the positioning guiding, can realize requirements of the rotor with a small volume for the assembly and the positioning, is simple in the assembly and disassembly, can greatly reduce time cost, and can shorten a product manufacture period.

Owner:HARBIN ELECTRIC POWER EQUIP

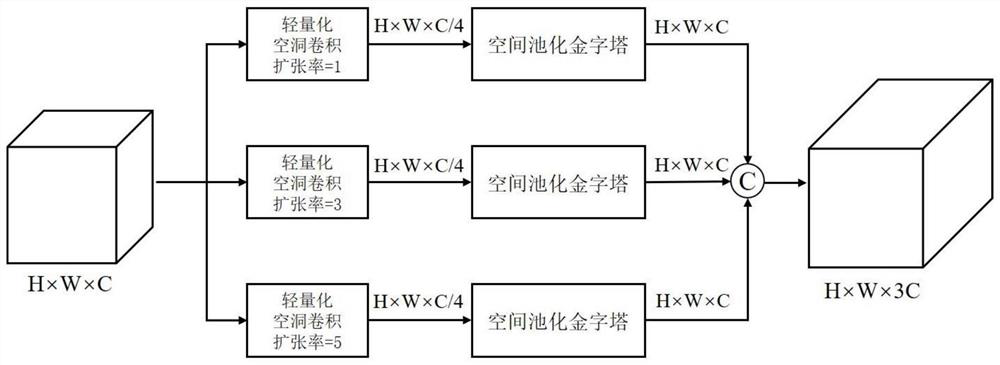

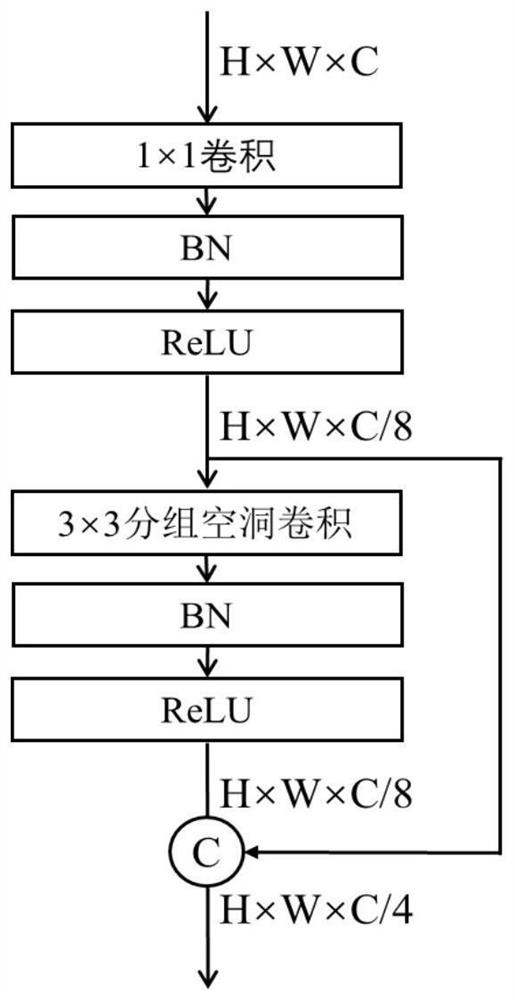

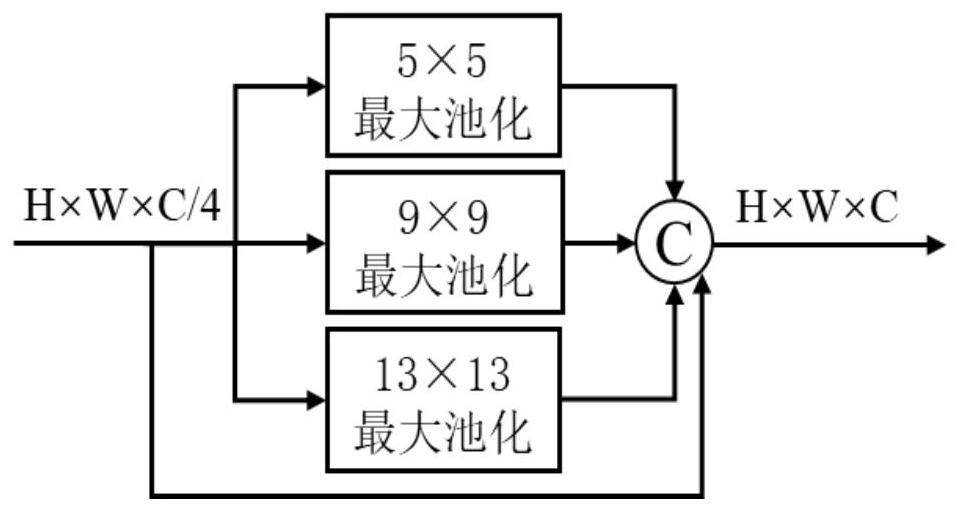

Weld defect multi-scale feature extraction module based on lightweight cavity convolution

ActiveCN113205501AEnhance expressive abilityImprove robustnessImage enhancementImage analysisFeature extractionAlgorithm

The invention discloses a weld defect multi-scale feature extraction module and method based on lightweight cavity convolution, and belongs to the related technical field of weld defect detection. The module comprises a plurality of branches and a first superposition layer which are connected in parallel, each branch comprises the lightweight cavity convolution and a space pooling pyramid which are connected, the lightweight cavity convolution is used for extracting weld defect features of different receptive fields from the weld defect feature map to generate a first feature map, and the spatial pooling pyramid is used for enhancing the expression ability of the first feature map for the weld defect features of different scales through pooling layers of different sizes and then generating a second feature map; the expansion rates of the lightweight cavity convolution of different branches are different; and the first superposition layer is used for superposing the second feature maps output by all the branches to generate a final feature map. According to the method, lightweight improvement is carried out on the model, the robustness of the neural network model for large size change of the weld defect is enhanced, and the neural network model can be conveniently and quickly embedded into various models.

Owner:HUAZHONG UNIV OF SCI & TECH +1

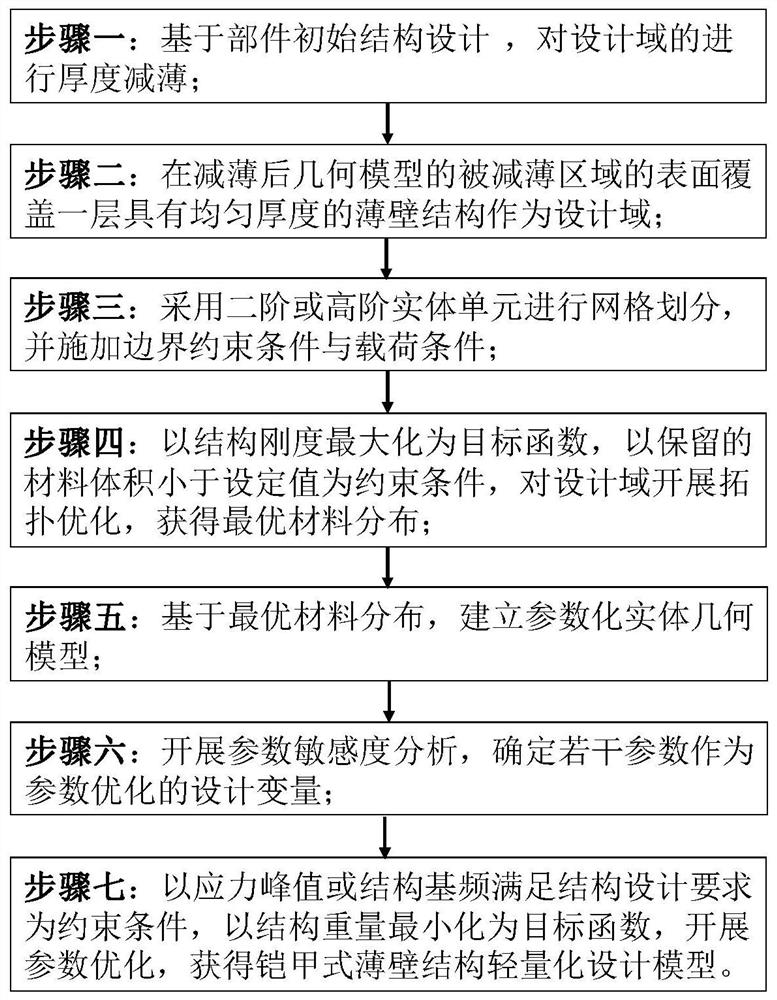

Lightweight design method for armor type thin-wall structure

ActiveCN111859483AReduce volumeShort timeGeometric CADDesign optimisation/simulationAlgorithmElement analysis

The invention discloses a lightweight design method for an armor type thin-wall structure, which belongs to the field of aerospace equipment and comprises the following steps: covering a layer of thin-wall structure with uniform thickness on the surface of a thinned area of a thinned geometric model on the basis of an initial structure design of an internal pressure part to obtain a geometric model to be optimized; performing mesh generation by adopting a second-order or high-order entity unit, and applying a boundary constraint condition and a load condition to obtain a finite element analysis model; obtaining optimal material distribution in a design domain; establishing a parameterized entity geometric model of the internal pressure component after topological optimization; and obtaining an optimal parameter optimization design variable value, and finally obtaining an armor type thin-wall structure lightweight design model of the design object component. The method completely comprises a conceptual design stage and a detailed design stage, meanwhile, a geometric model processing method required by topological optimization and a parameterized geometric model modeling method required by parameter optimization are provided, and the methods have good operability and convenience.

Owner:DALIAN UNIV OF TECH

Mining vehicle hydro-pneumatic spring rear suspension system

ActiveCN109367340AWith variable stiffnessReduce shockResilient suspensionsVehicle springsVehicle frameVertical load

The invention discloses a mining vehicle hydro-pneumatic spring rear suspension system. The mining vehicle hydro-pneumatic spring rear suspension system comprises a vehicle frame and a suspension mechanism mounted on a vehicle axle. The suspension mechanism is mounted on the vehicle frame and comprises four hydro-pneumatic springs, two high-low pressure energy accumulators and a guiding mechanism.The four hydro-pneumatic springs are arranged at the two ends of an intermediate axle and a rear axle correspondingly and connected with the high-low pressure energy accumulators through oil pipes. Variation of the empty load and the full load is achieved through variation of the oil pressure; the hydro-pneumatic springs bear the vertical load; the hydro-pneumatic springs on the intermediate axleand the rear axle are inter-linked through oil pipes, and the function that a suspension is balanced is achieved; a guiding mechanism is mounted in the vehicle frame; and by means of the mining vehicle hydro-pneumatic spring rear suspension system, the problems that in the prior art, a vehicle is low in bearing capacity and comfort level, and the service life of the vehicle is short are solved.

Owner:潍柴(扬州)特种车有限公司

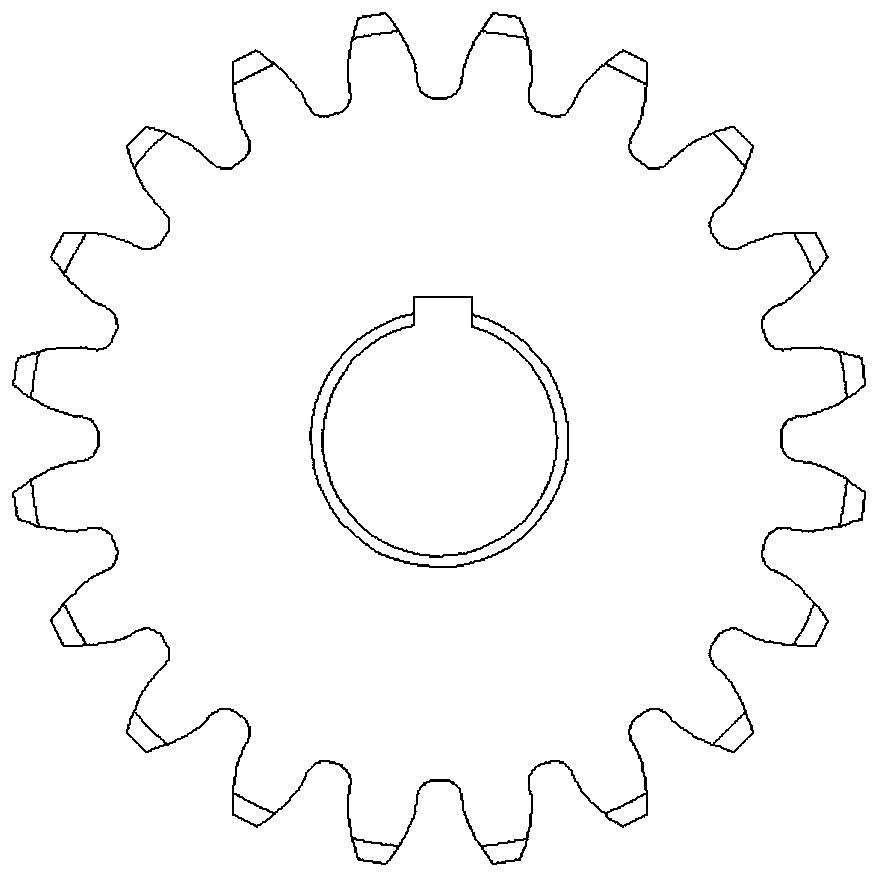

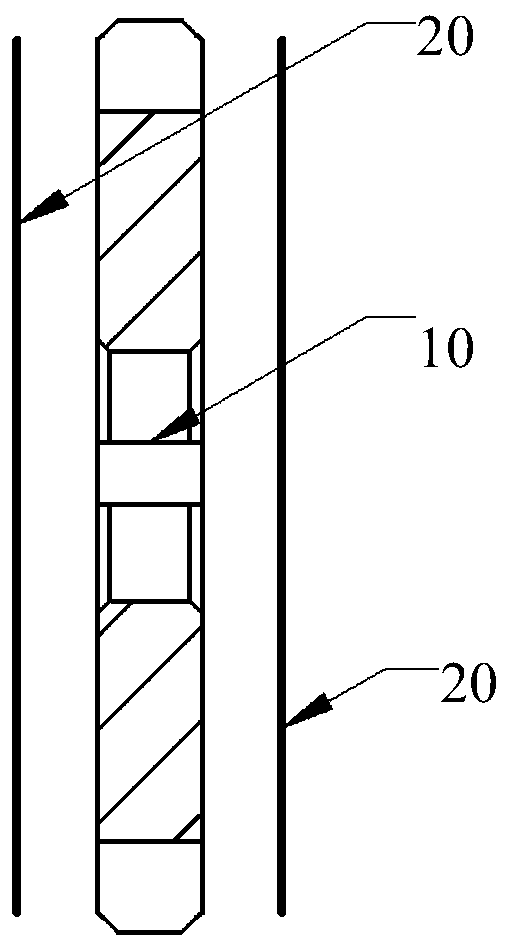

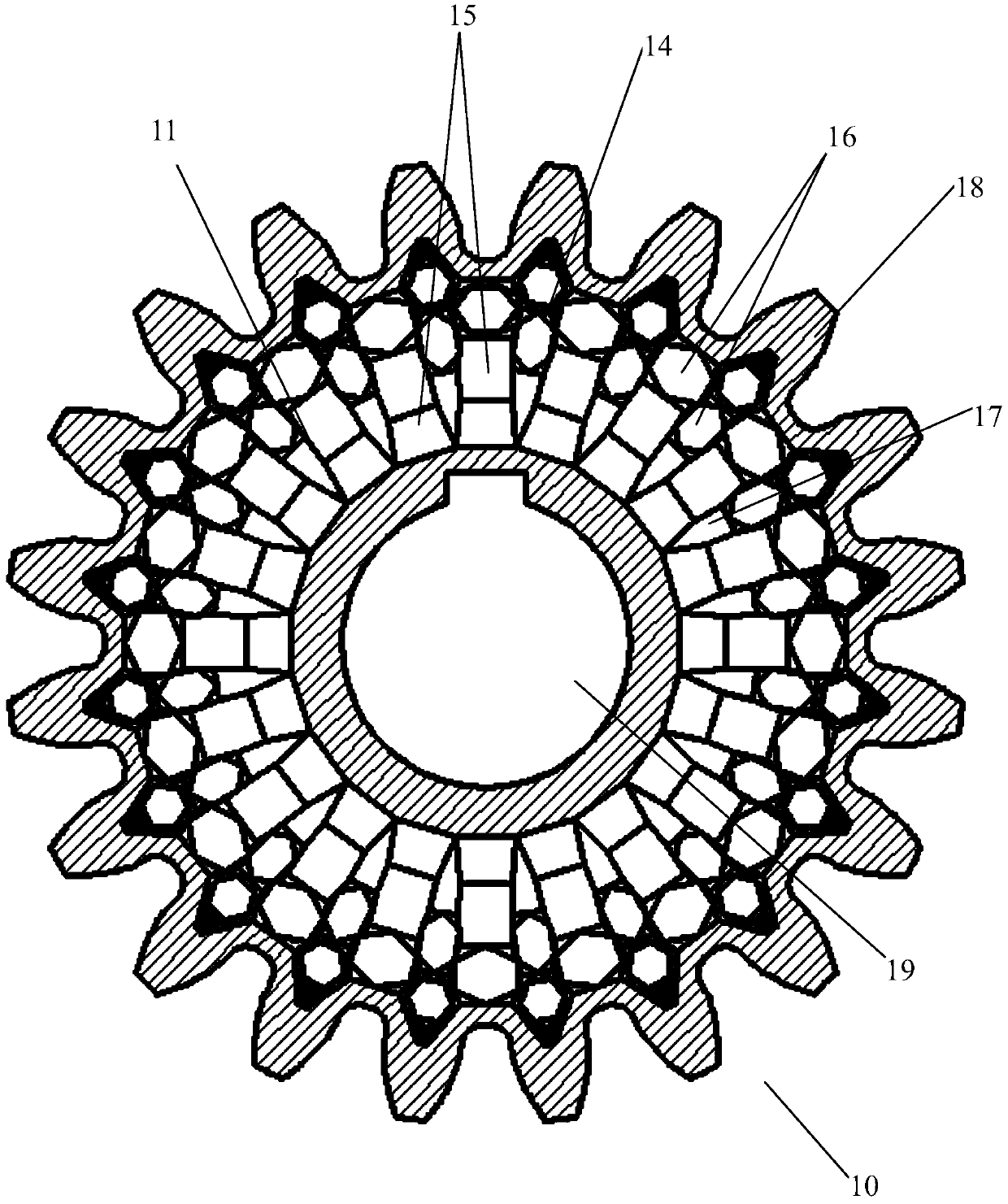

Lightweight fractal gradient gear

PendingCN111140639AImprove mechanical performanceGuaranteed fatigue strengthPortable liftingGearing elementsGear wheelManufacturing engineering

The invention discloses a lightweight fractal gradient gear. The lightweight fractal gradient gear comprises a gear body and is characterized by further comprising two plate bodies, wherein the platebodies are fixed to the two sides of the gear body; and the gear body is of a porous lightweight structure, wherein the porous lightweight structure at least is composed of a first-stage gradient holegroup, a second-stage gradient hole group and a third-stage gradient hole group which are constructed in a staggered mode. According to the lightweight fractal gradient gear, a honeycomb type multi-cell structure serves as a prototype, and gradient type, split type and multi-type design is carried out, so that the maximum lightweight of the gear is achieved, and manufacturing is convenient.

Owner:HUAQIAO UNIVERSITY

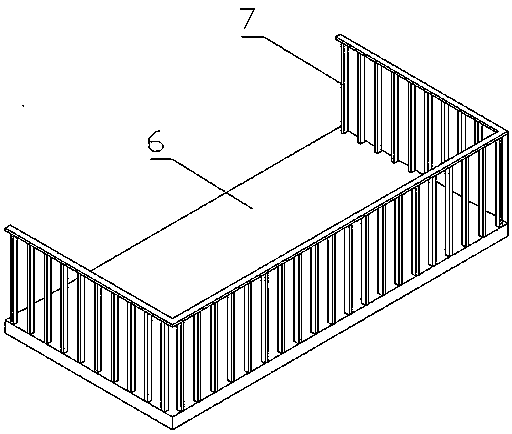

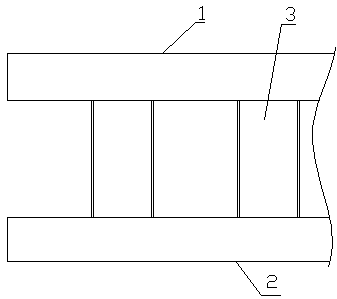

Balcony

The invention provides a balcony which comprises a balcony board stretching out of a building, and a guardrail mounted on the balcony board. The balcony board is formed by splicing of a plurality of composite boards, and each composite board comprises an upper panel, a lower panel, a plurality of pipe bodies in the middle, and brazing layers between the pipe bodies and the upper panel as wells asbetween the pipe bodies and the lower panel. The balcony has the characteristics of being low in self-weight, low in construction cost, high in structural strength, and good in heat-insulating, sound-insulating and vibration-insulating effects.

Owner:张跃

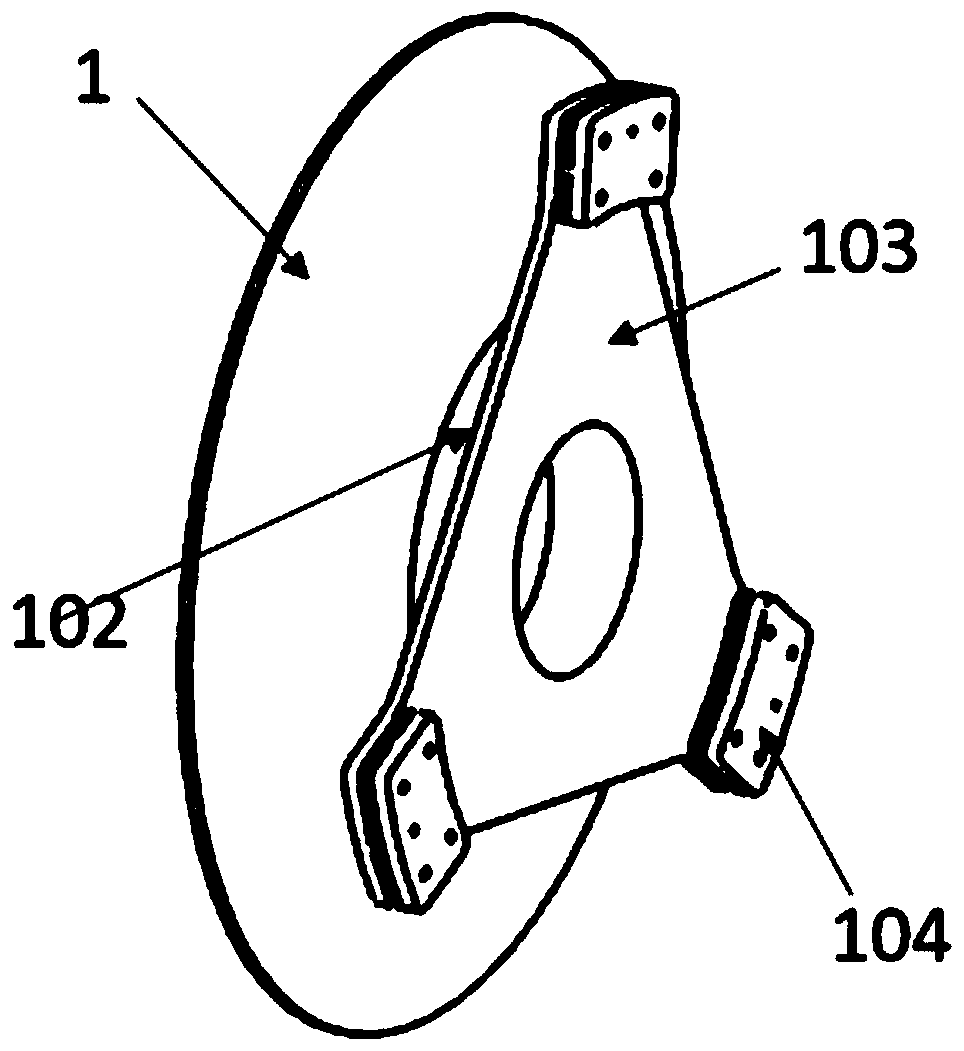

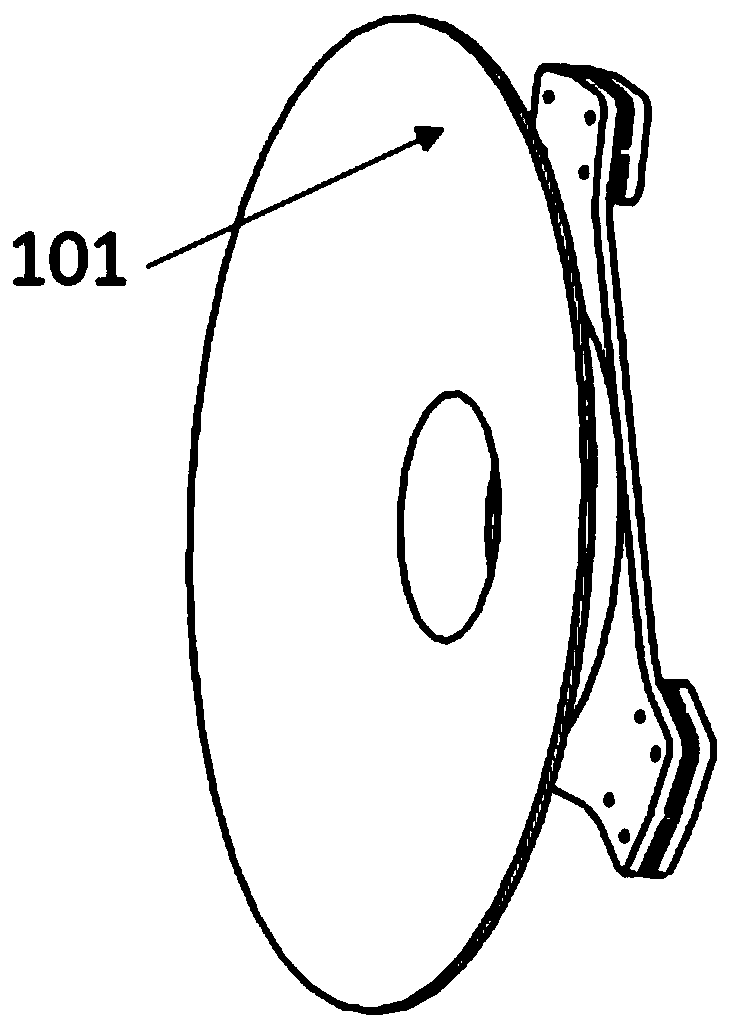

Flexible aluminum reflector

InactiveCN110716279AHigh degree of lightweightReduce instabilityMountingsIntegrated designMechanical engineering

The invention relates to a flexible aluminum reflector. The flexible aluminum reflector comprises a mirror body, a connecting piece and a flexible supporting piece, wherein the flexible supporting piece comprises a low-rigidity triangular plate and a biaxial flexible hinge arranged on the triangular plate, the biaxial flexible hinge can deflect in two directions perpendicular to the axis of the mirror body, and the triangular plate and the connecting piece can generate displacement and deflection along the axis of the mirror body. The flexible aluminum reflector is high in lightweight degree;by the adoption of integrated design, the reflector can be directly connected with a reflector backboard, a flexible transition piece is omitted, the installing and debugging process is simplified, and the instability of connection between all pieces is lowered; and the processing cycle can be shortened, and cost can be lowered.

Owner:JIHUA LAB

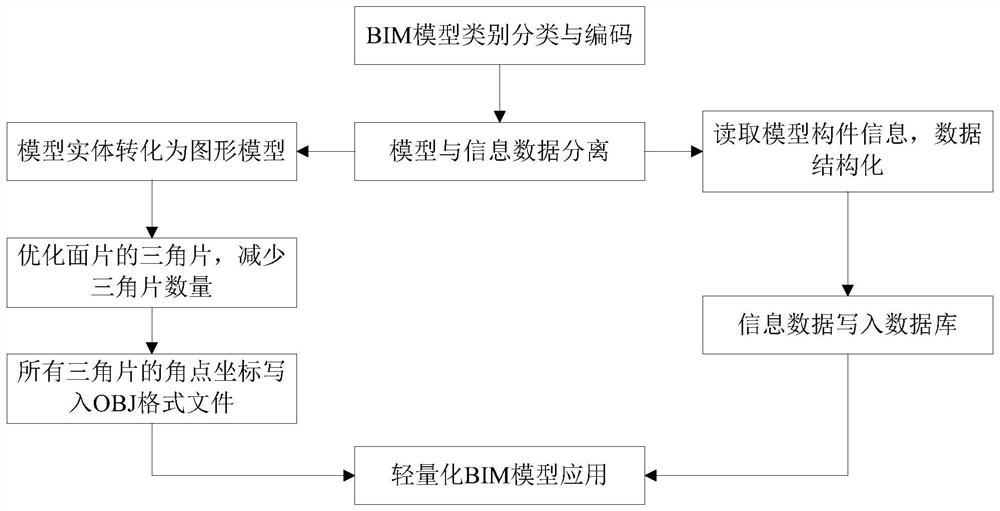

BIM model lightweight method based on digital-analog separation

PendingCN112818429AQuality is easy to controlEasy to operateGeometric CADDesign optimisation/simulationGraphicsAlgorithm

The invention discloses a BIM (Building Information Modeling) lightweight method based on digital-analog separation, which is characterized by comprising the following steps of: classifying existing components in a BIM according to a given rule and different categories, and endowing each category with different category codes; reading information data according to different information structures of each category of components of the BIM model, and uploading the information data to a database; an entity of the BIM model being converted into a graphic model, all patches of the graphic model being triangularly sliced, and angular point coordinates of the triangular patches being obtained; automatically optimizing the number of the triangular plates of the surface patch according to the angular point coordinates of the triangular plates, and reducing the number of the triangular plates; the category codes and the component IDs serving as set names of triangular plates of all the components and being used for associating the model components with database model information data. By means of the method, the weight of the weight-level BIM model can be reduced, and great technical convenience is provided for building full-life-cycle BIM application.

Owner:CHINA CONSTR EIGHT ENG DIV CORP LTD

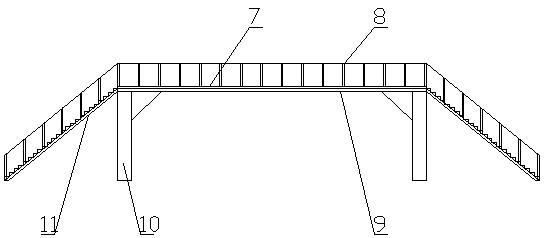

Pedestrian overpass

InactiveCN108193584AImprove lightweightReduce stressBridge structural detailsMetal layered productsEngineeringComposite plate

The invention discloses a pedestrian overpass. The pedestrian overpass comprises an overpass body, an overpass face arranged on the overpass body and guardrails arranged on the overpass face, the overpass face is composed of one or a plurality of composite plates by splicing, and the composite plates comprise upper panels, lower panels, a plurality of pipe bodies in the middle, and brazing layersbetween the pipe bodies and the upper panels as well as the lower panels. On the one hand, the pedestrian overpass has four functions of heat preservation, fire prevention, sound insulation and vibration isolation; on the other hand, under the same strength, the amount of used material is least; under the same weight, the strength is largest; and the pedestrian overpass has the characteristics ofbeing quick to assemble and disassemble and easy to replace and maintain.

Owner:张跃

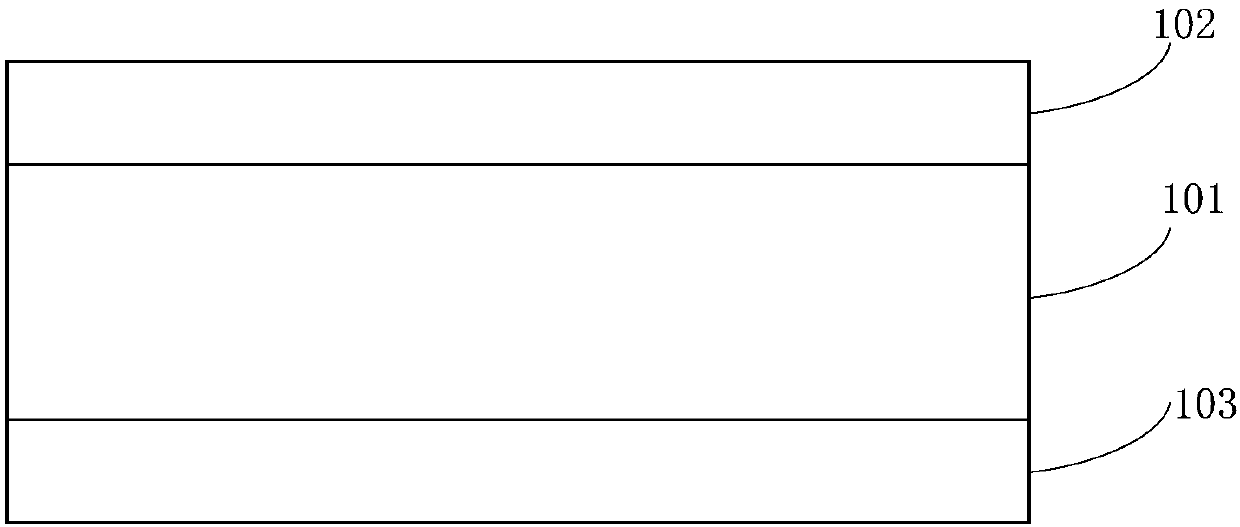

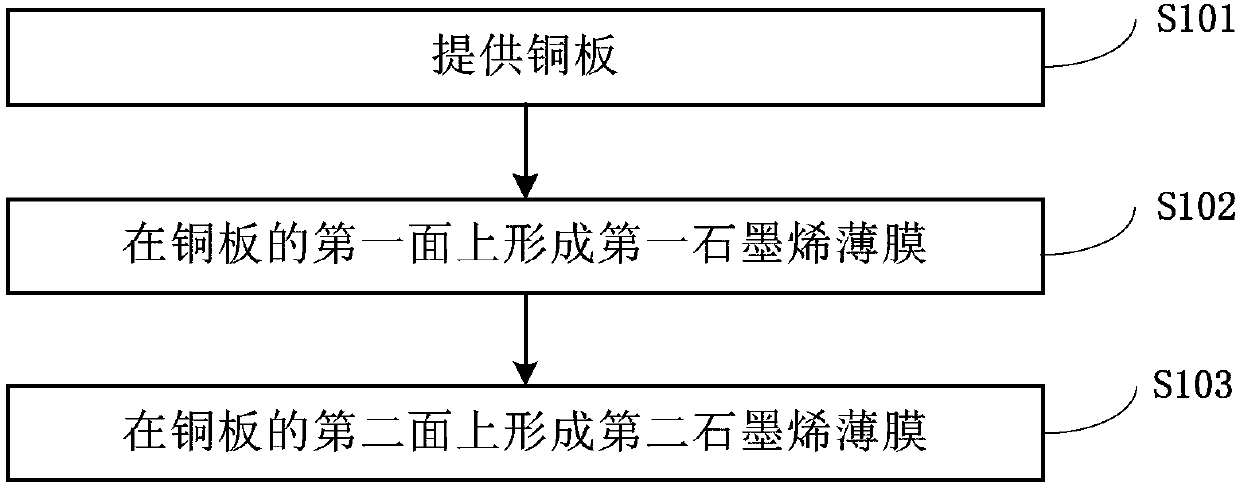

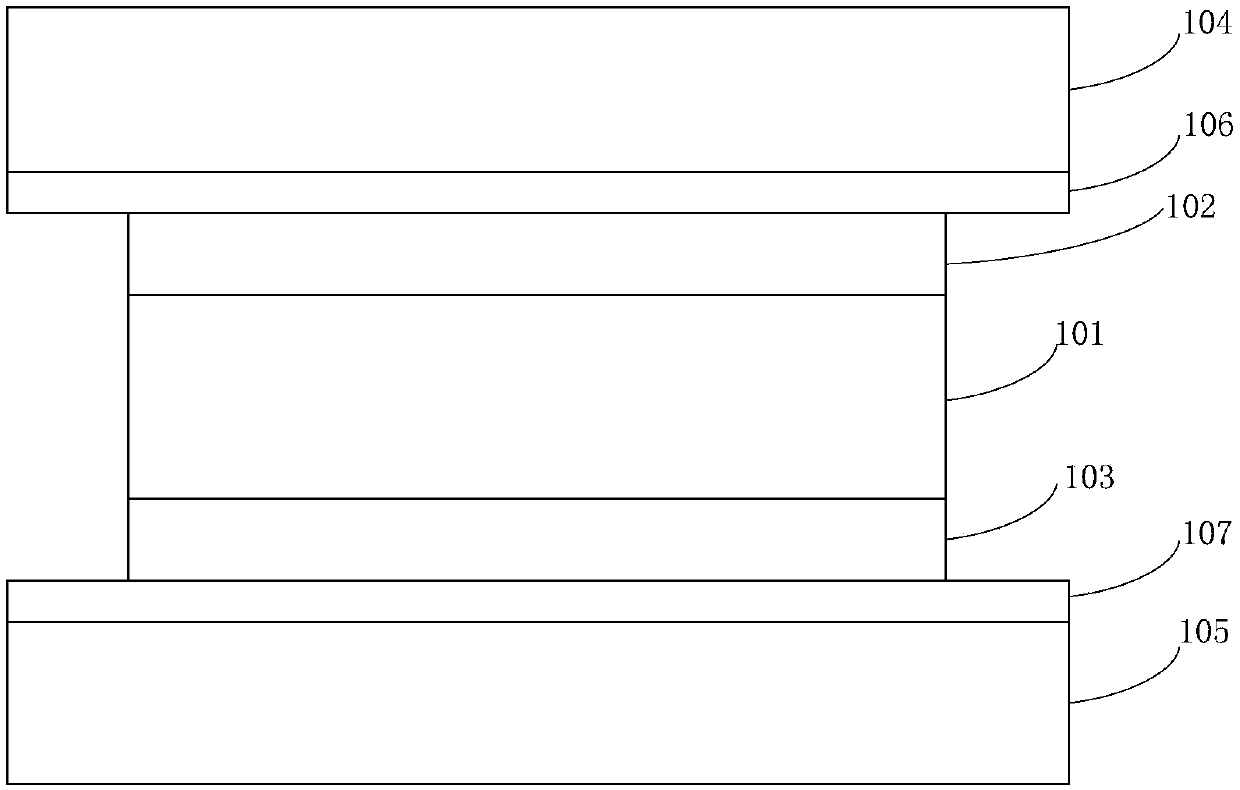

Copper-based graphene low-sensitivity composite busbar and manufacturing method thereof

InactiveCN110391624AImprove current carrying capacityReduce temperature riseLaminated bus-barsInsulation layerElectrical conductor

The invention discloses a copper-based graphene low-sensitivity composite busbar and a manufacturing method thereof. The copper-based graphene low-sensitivity composite busbar includes a copper-basedgraphene composite conductor layer, a first insulation layer disposed on a first surface of a first graphene film of the copper-based graphene composite conductor layer, and a second insulation layerdisposed on a second surface of a second graphene film of the copper-based graphene composite conductor layer. Wherein, the copper-based graphene composite conductor layer includes: a copper plate, the first graphene film disposed on the first surface of the copper plate, and a second graphene film disposed on the second surface of the copper plate, and the first surface is disposed opposite to the second surface. Since the copper-based graphene low-sensitivity composite busbar of the invention utilizes the copper-based graphene composite conductor layer as a conductor layer, temperature riseof the low-sensitivity composite busbar can be effectively reduced, parasitic inductance of the low-sensitivity composite busbar can be reduced, the switching frequency of an IGBT can be further improved, and the degree of lightweight of the low-sensitivity composite busbar is significantly improved.

Owner:ZHUZHOU CSR TIMES ELECTRIC CO LTD

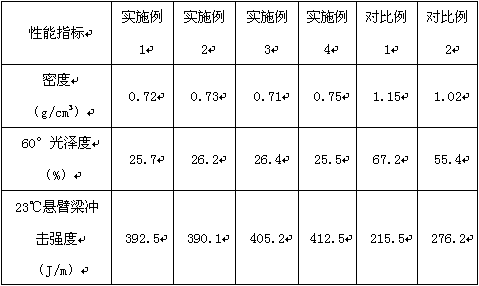

Lightweight extinction plastic master batch for automotive interior and preparation method of master batch

The invention relates to the field of automotive interior materials, and discloses a lightweight extinction plastic master batch for an automotive interior and a preparation method of the master batch. The preparation method comprises the following process: (1) adding sodium phosphate, a soluble polymer, nano mica sheets and a soluble calcium salt into water to prepare a precursor liquid; (2) performing a microwave hydrothermal reaction on the precursor liquid to form calcium phosphate on the nano mica sheets, and performing assembling to form composite loose particles; and (3) mixing polypropylene carrier resin, the composite loose particles, an elastomer toughening agent, an inorganic nano filler and an auxiliary agent, and performing extrusion granulation to obtain the lightweight extinction plastic master batch for the automotive interior. Compared with a traditional plastic master batch for an automotive interior, the lightweight extinction plastic master batch prepared by the invention has the advantages of good surface extinction property, high toughness, good fluidity, lower costs and a high degree of lightness; and the preparation method has a simple manufacturing procedure and low comprehensive costs, and is especially suitable for the field of the automotive interior.

Owner:CHENDU NEW KELI CHEM SCI CO LTD

Turnover type side protective fence for battery replacing vehicle type and using method thereof

PendingCN113232620AEasy to disassembleEasy to installVehicular safety arrangmentsStructural engineeringMechanical engineering

A turnover type side protective fence for a battery replacing vehicle type comprises a plurality of fixing supports, the fixing supports are U-shaped structures, the bottoms of the fixing supports are rotatably connected with a protective fence vertical beam through perforated shafts, a slotted nut is arranged at one end of each perforated shaft, and a protective fence cross beam is arranged above the protective fence vertical beam; and the top of each fixing support is connected with a cargo compartment side bottom beam through a riveting nut, and a lock pin is arranged on the fixing support to fix the protective fence vertical beam. The battery replacing efficiency is high, and the mounting and dismounting processes are simple and convenient.

Owner:DONGFENG AUTOMOBILE COMPANY

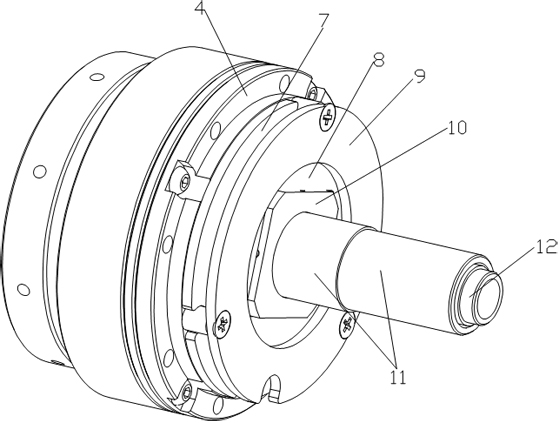

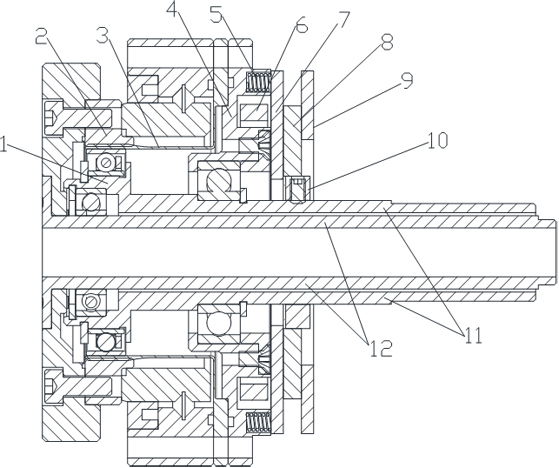

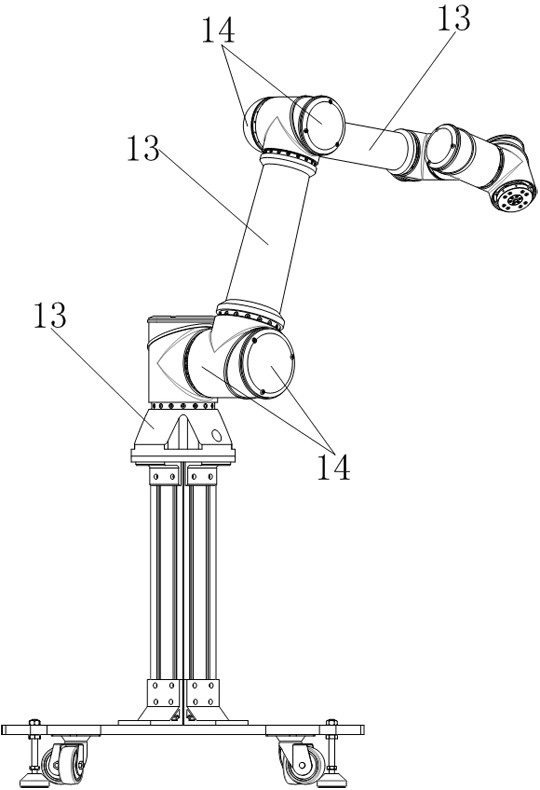

Robot joint embedded electromagnetic braking harmonic speed reduction device and joint system

InactiveCN114382861ADimensionally stableSmall sizeProgramme-controlled manipulatorGearboxesControl theoryMechanical engineering

The robot joint embedded electromagnetic braking harmonic speed reducer comprises an input shaft and an output shaft rotationally installed in the middle of the input shaft, one side of the input shaft is a wave generating end, the other side of the input shaft is a braking end, and the wave generating end of the input shaft is provided with a wave generator; the brake end of the input shaft is provided with a rear end cover and a friction brake assembly, the rear end cover is provided with a coil groove and a spring installation groove, an electromagnetic coil is installed in the coil groove of the rear end cover in a matched mode, a spring is installed in the spring installation groove of the rear end cover, the spring is fixedly connected with a brake armature, and the friction brake assembly comprises a friction plate corresponding to the brake armature. The spring elastically drives the brake armature to cling to the friction plate for friction braking; a flexible gear is installed outside the wave generator in a matched mode, and a rigid gear is installed outside the flexible gear in a matched mode and connected with the output shaft. The optimal matching scheme of harmonic speed reduction and electromagnetic braking is provided, the integration degree and the lightweight degree are high, and the positioning precision and performance are improved.

Owner:成都瑞迪智驱科技股份有限公司

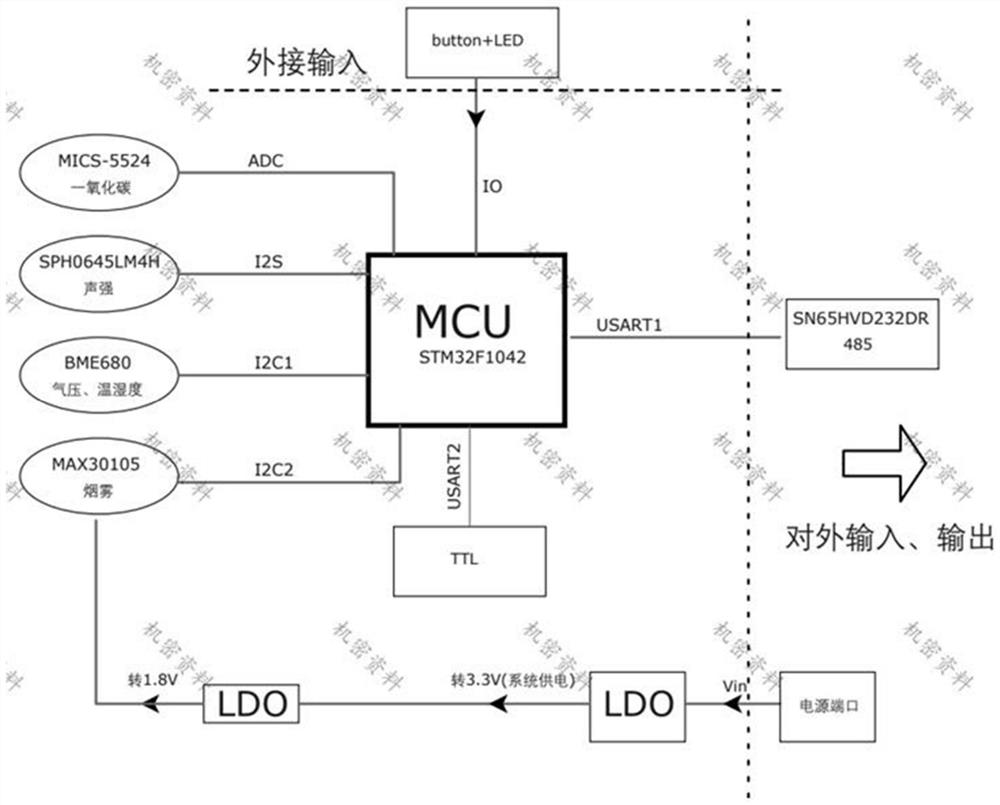

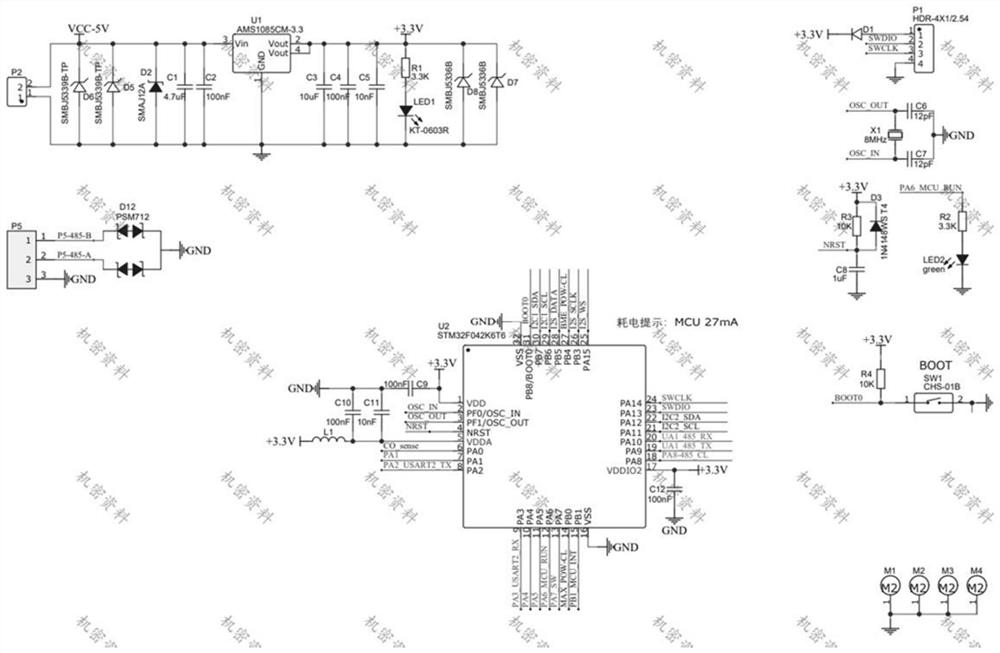

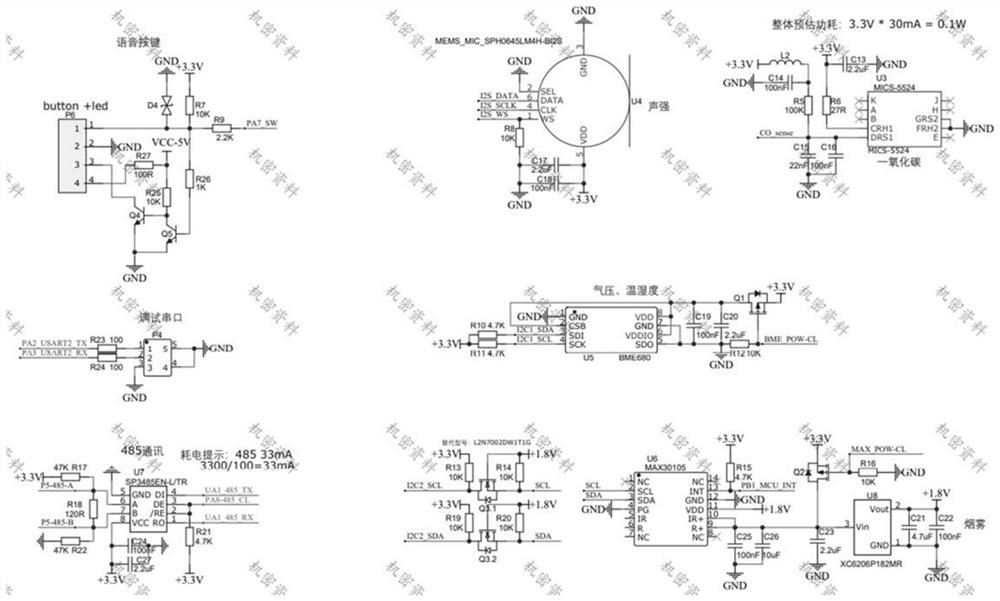

Acquisition circuit for intelligent inspection explosion-proof robot

PendingCN112711212AHigh degree of lightweightReduce manufacturing costProgramme controlMeasurement devicesSmoke EmissionComputer science

The invention discloses an acquisition circuit for an intelligent inspection explosion-proof robot, which comprises a control center, a voice control module, an air pressure, temperature and humidity acquisition module, a sound intensity acquisition module, a carbon monoxide acquisition module and a smoke acquisition module, wherein the control center is electrically connected with the voice control module, the air pressure, temperature and humidity acquisition module, the sound intensity acquisition module, the carbon monoxide acquisition module and the smoke acquisition module; the circuit also includes a power supply module used for providing electric energy for the control center, the voice control module, the air pressure and temperature and humidity acquisition module, the sound intensity acquisition module, the carbon monoxide acquisition module and the smoke acquisition module, and the control center is further electrically connected with an external master control center. The control center, the voice control module, the air pressure and temperature and humidity acquisition module, the sound intensity acquisition module, the carbon monoxide acquisition module and the smoke acquisition module are all placed in the distribution package acquisition shell. The method has the advantages of improving product light weight, reducing product cost and the like.

Owner:SHANGHAI XIANGHONG UNMANNED AERIAL VEHICLE NAVIGATION CONTROL TECH CO LTD

Panel structure for medical device housing

InactiveCN108174539AReduce stressHigh strengthCasings/cabinets/drawers detailsThermal insulationComposite plate

The invention provides a panel structure used for a medical device housing. A plurality of composite plates are spliced together so as to form the panel structure; the composite plate includes an upper panel, a lower panel, a plurality of tube bodies between the upper panel and the lower panel, and brazing layers between the tube bodies and the upper panel as well as between the tube bodies and the lower panel. The panel structure of the invention has the advantages of light weight, high structural strength, convenience in replacement, long service life, radiation protection, heat insulation,sound insulation and good vibration isolation effect.

Owner:张跃

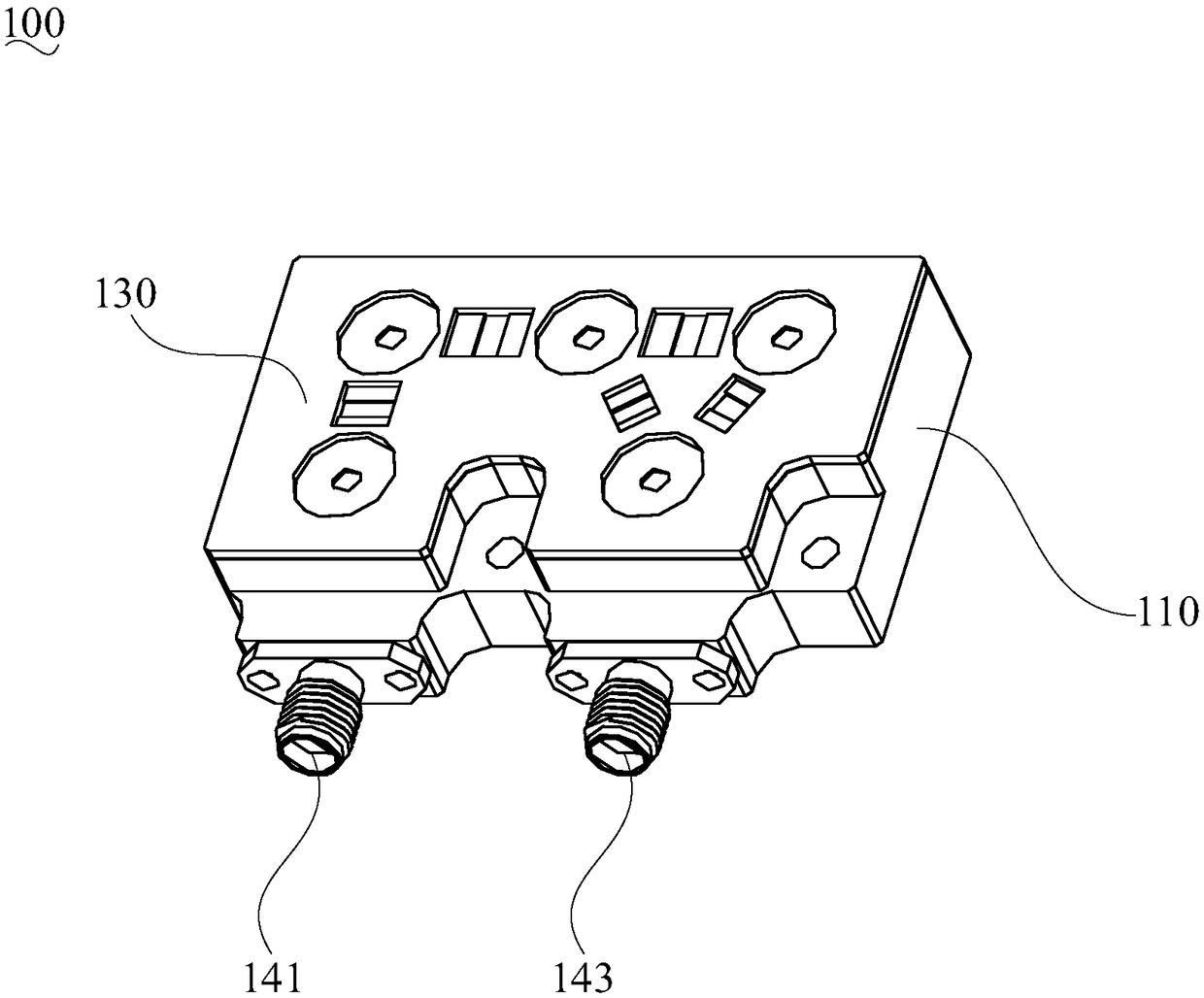

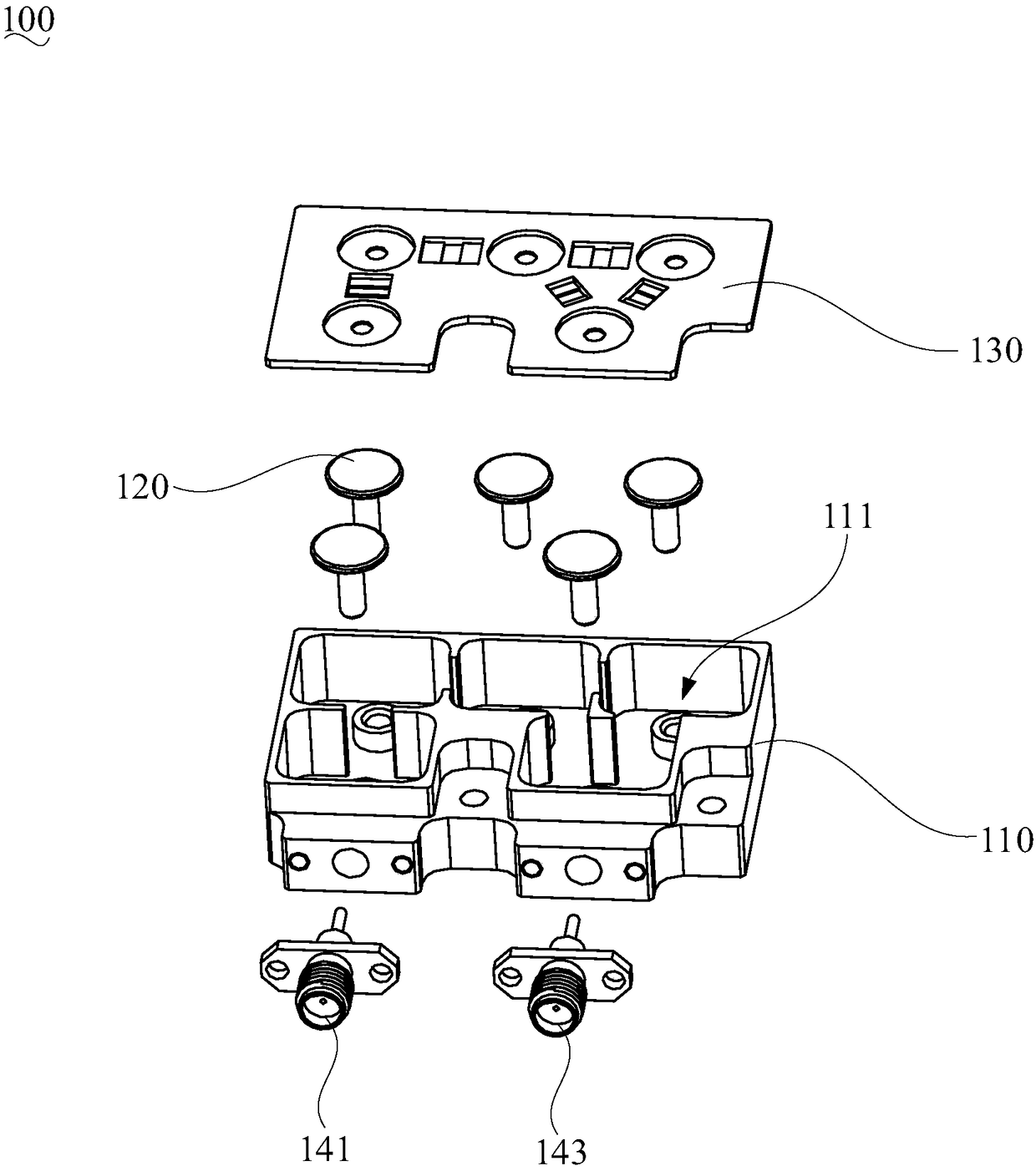

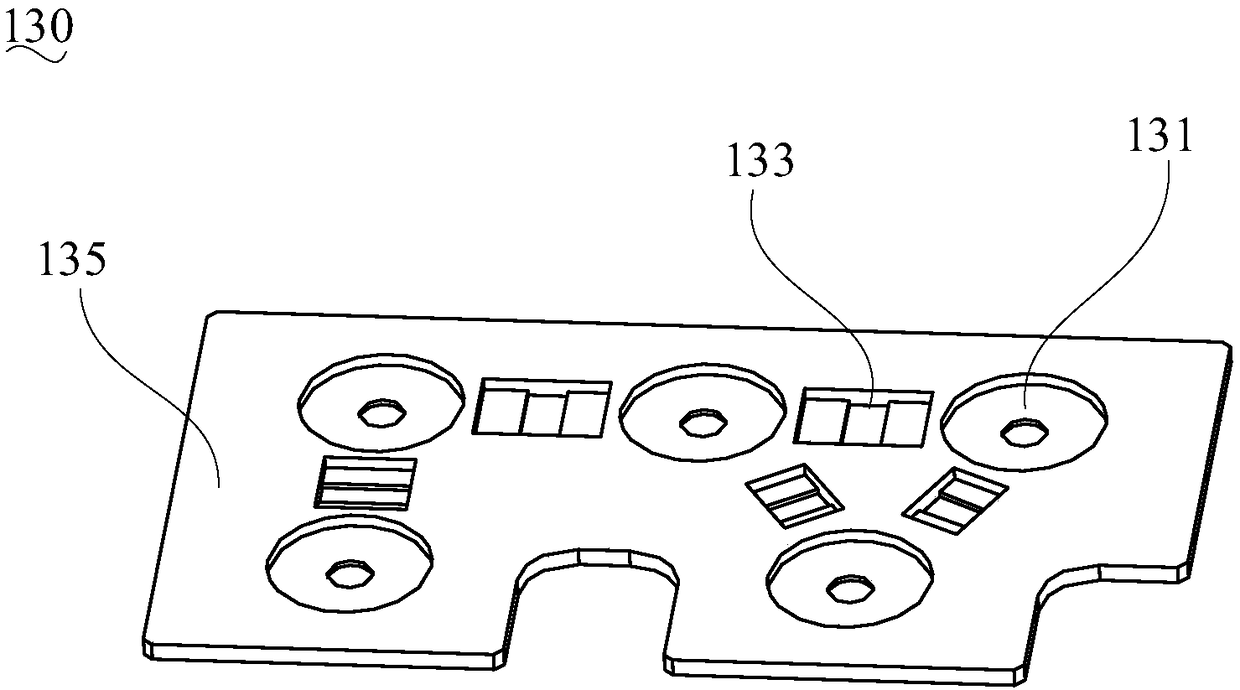

Cavity filter

ActiveCN108461879AHigh degree of lightweightReduce in quantityWaveguide type devicesCapacitanceResonant cavity

The present invention relates to a cavity filter. The cavity filter comprises a cavity internally provided with a plurality of resonant cavities, a cover plate capable of covering the cavity and a plurality of resonators respectively arranged in the resonant cavities and coupled to each other through preset coupling window. Frequency modulation areas are formed at positions of the cover plate corresponding to the resonators, coupling modulation areas are formed at positions of the cover plate corresponding to the coupling windows, and the frequency modulation areas and the coupling modulationareas can operably generate deformation. The frequency modulation areas and the coupling modulation areas respectively corresponding to the positions of the resonators and the coupling windows, capacitance and inductance parameters can be changed when the frequency modulation areas and the coupling modulation areas are convex upwards or concave downwards to achieve regulation of the frequency of the resonators and the coupling quantity between the resonators. Therefore, the cavity filter is provided with the frequency modulation areas and the coupling modulation areas on the cover plate to replace a traditional adjusting screw rod so as to effectively reduce the number of elements and simplify the structure, and the cavity filter is miniaturized and higher in light weight degree.

Owner:COMBA RF TECH GUANGZHOU LTD +1

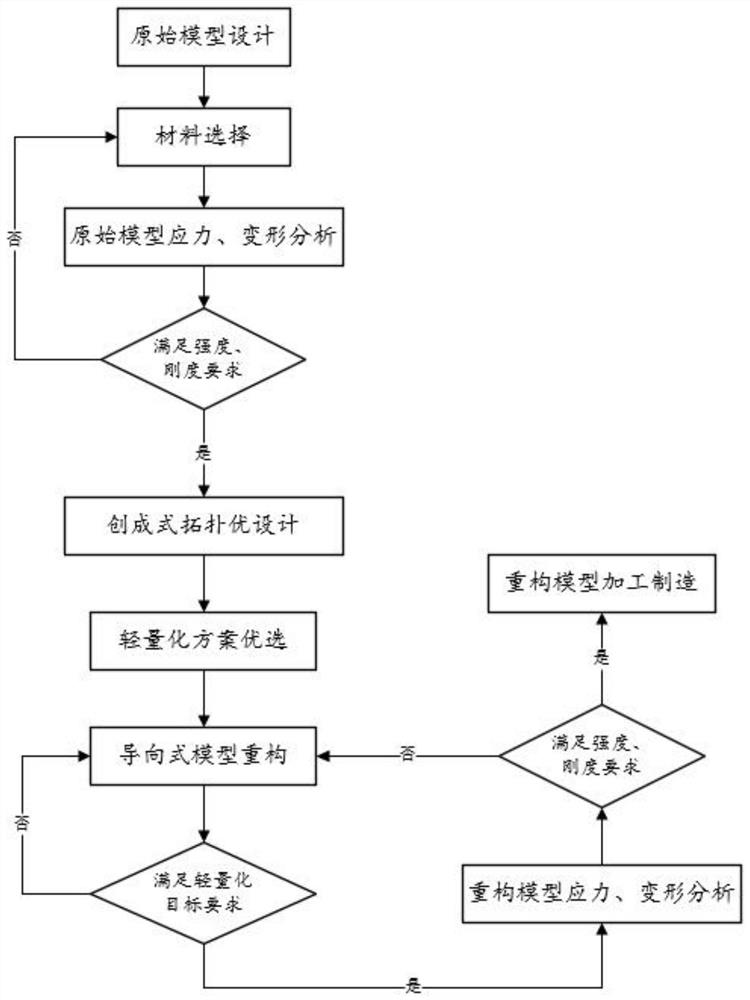

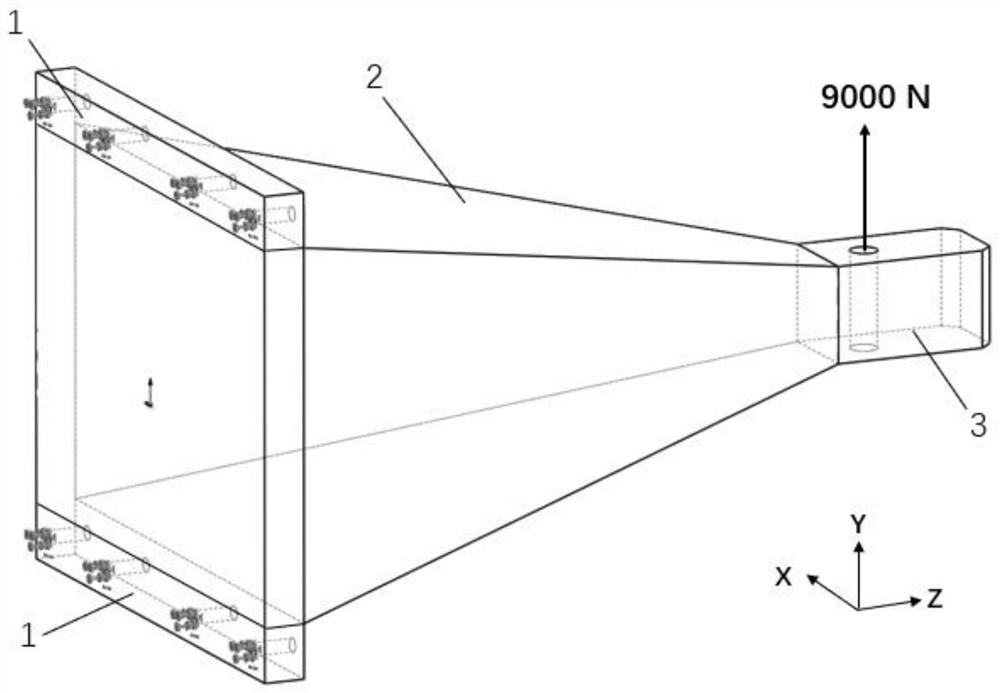

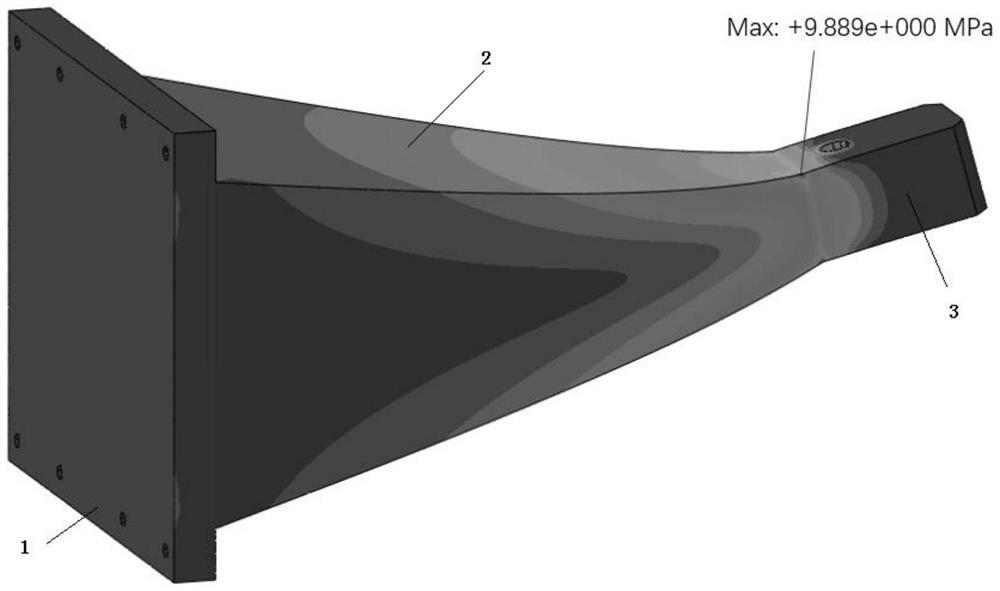

Large and medium-sized part lightweight design method based on generative optimization and guide reconstruction

ActiveCN112800655AEnsure reasonable distributionAchieve lightweight designGeometric CADDesign optimisation/simulationManufacturing technologyTopological optimization

Owner:UNIV OF SCI & TECH BEIJING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com