Manufacturing method of interior container of low-temperature container based on austenitic stainless steel low-temperature property

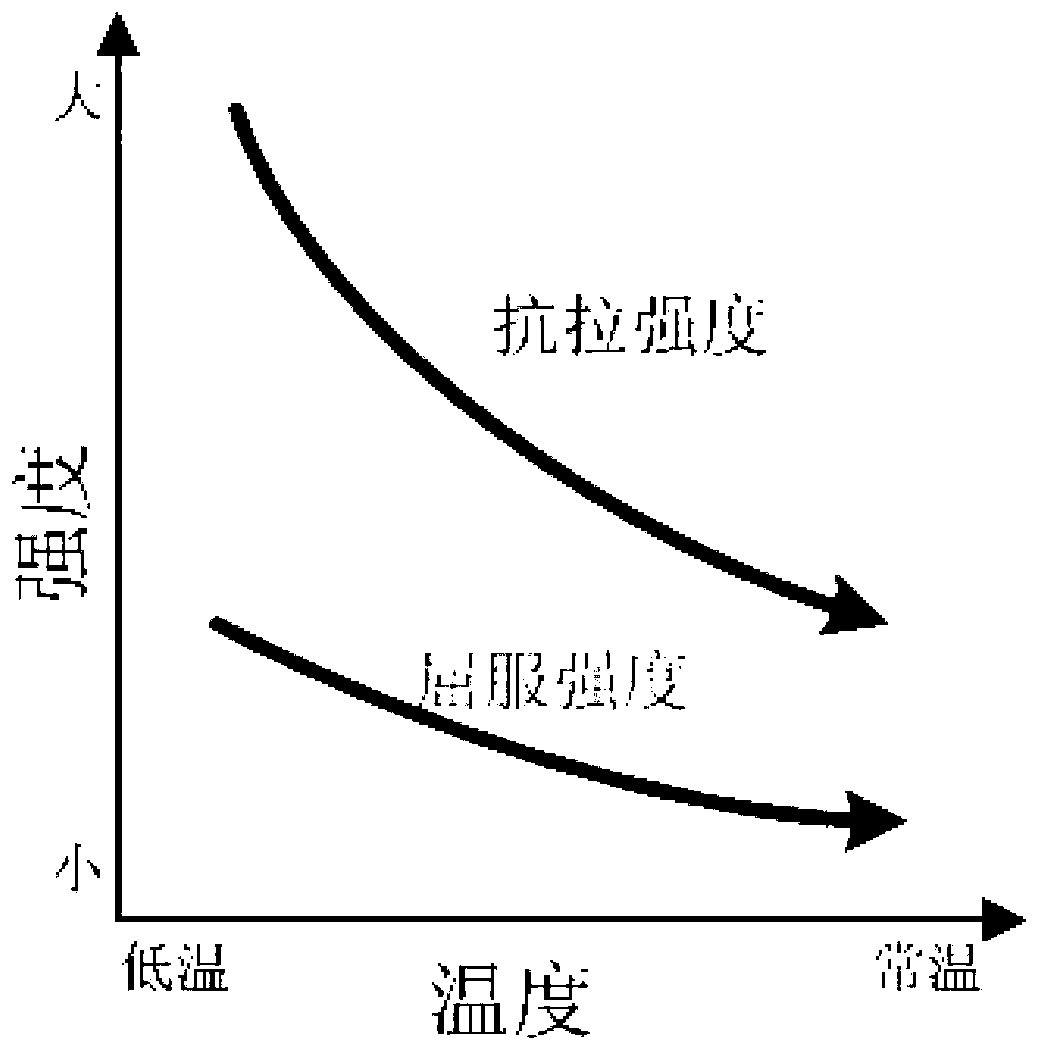

A technology for austenitic stainless steel and low-temperature containers, which is applied in pressure vessels, instruments, scientific instruments, etc., can solve problems such as material strength strengthening without considering material properties, achieve increased strength values and allowable stresses, and strong international competitiveness , the effect of thinning the wall thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Taking the fixed low-temperature vessel inner container designed and manufactured by the typical domestic austenitic stainless steel S30408 as an example, the method mentioned in this patent is used to design and manufacture to increase its light weight. compare the results.

[0026] The design parameters of the cryogenic container inner container are shown in Table 1:

[0027] Table 1 Design parameter list of cryogenic vessel

[0028] Design temperature T d

[0029] (1) Austenitic stainless steel S30408 materials with more than three furnace batch numbers are subjected to a tensile mechanical property test at -196°C. The test reference standard is GB / T13239:2006 "Metallic Materials Low Temperature Tensile Test Method", the sample axis Perpendicular to the rolling direction of the plate, the quasi-static rate is used in the test process, and the yield strength and tensile strength of the material are finally determined.

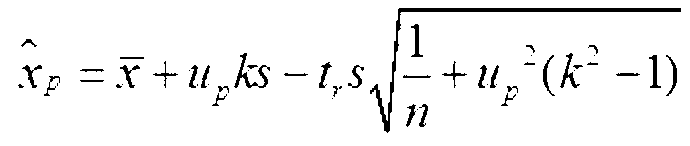

[0030] (2) Under the condition...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com