Patents

Literature

201results about "Laminated bus-bars" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

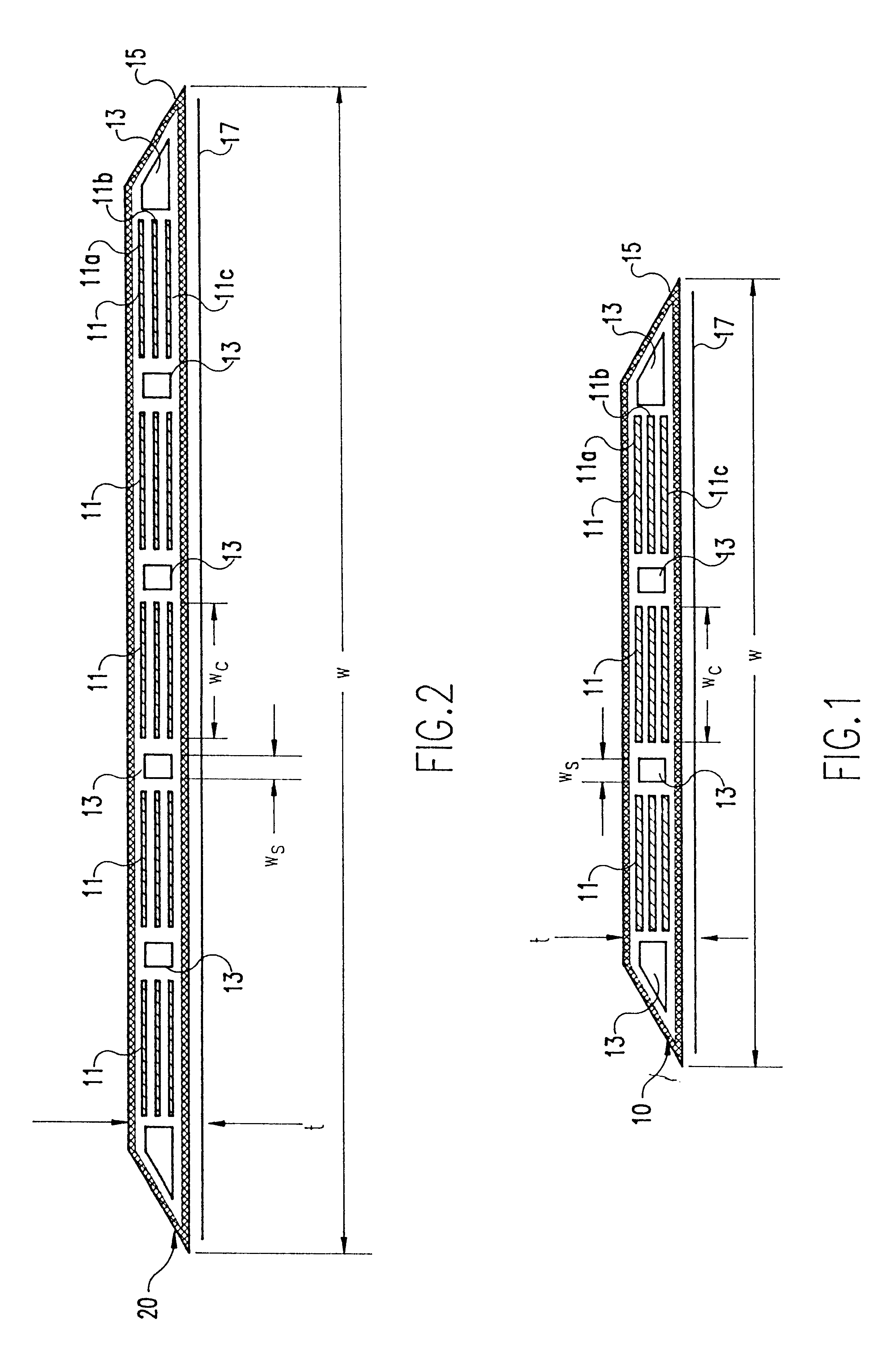

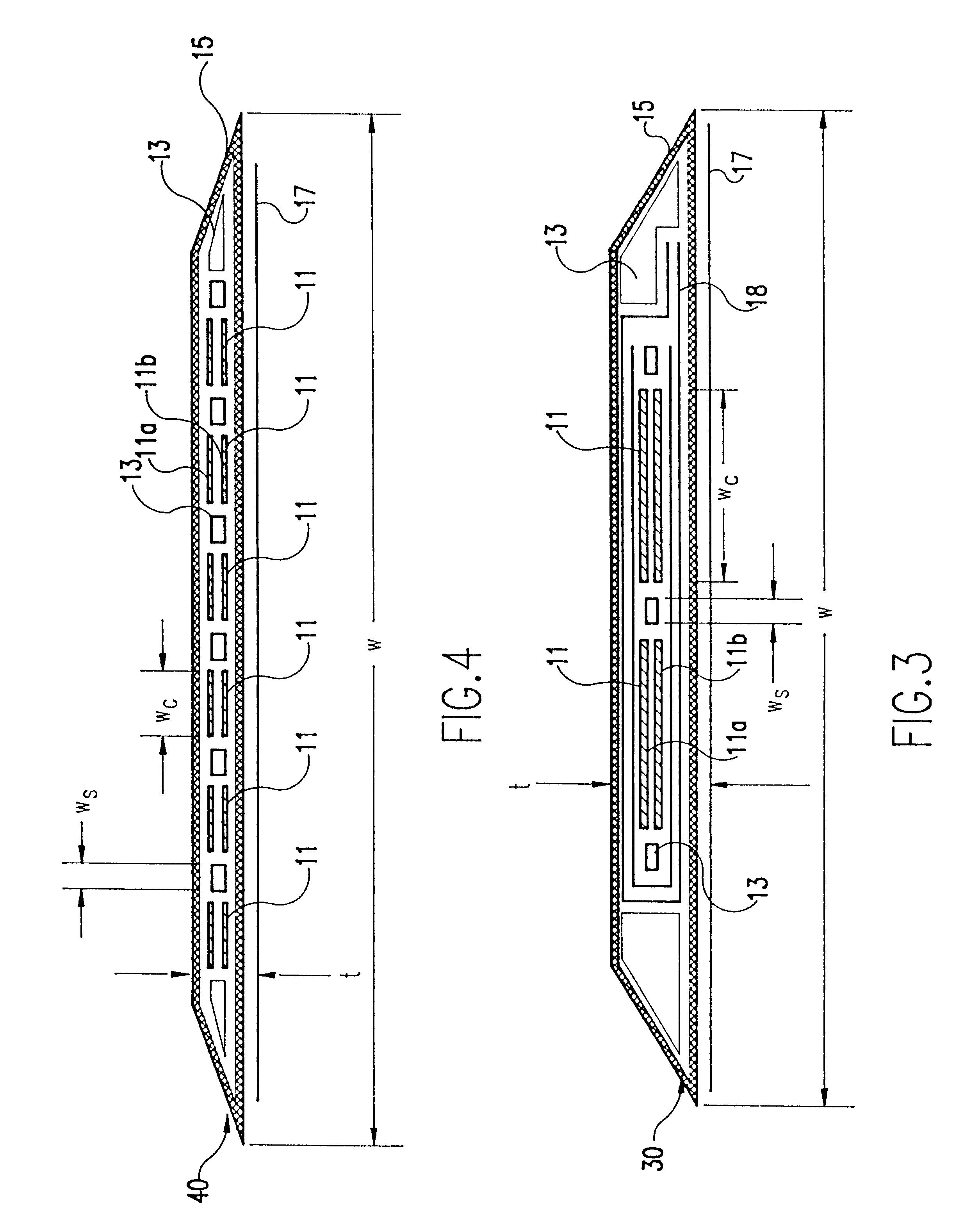

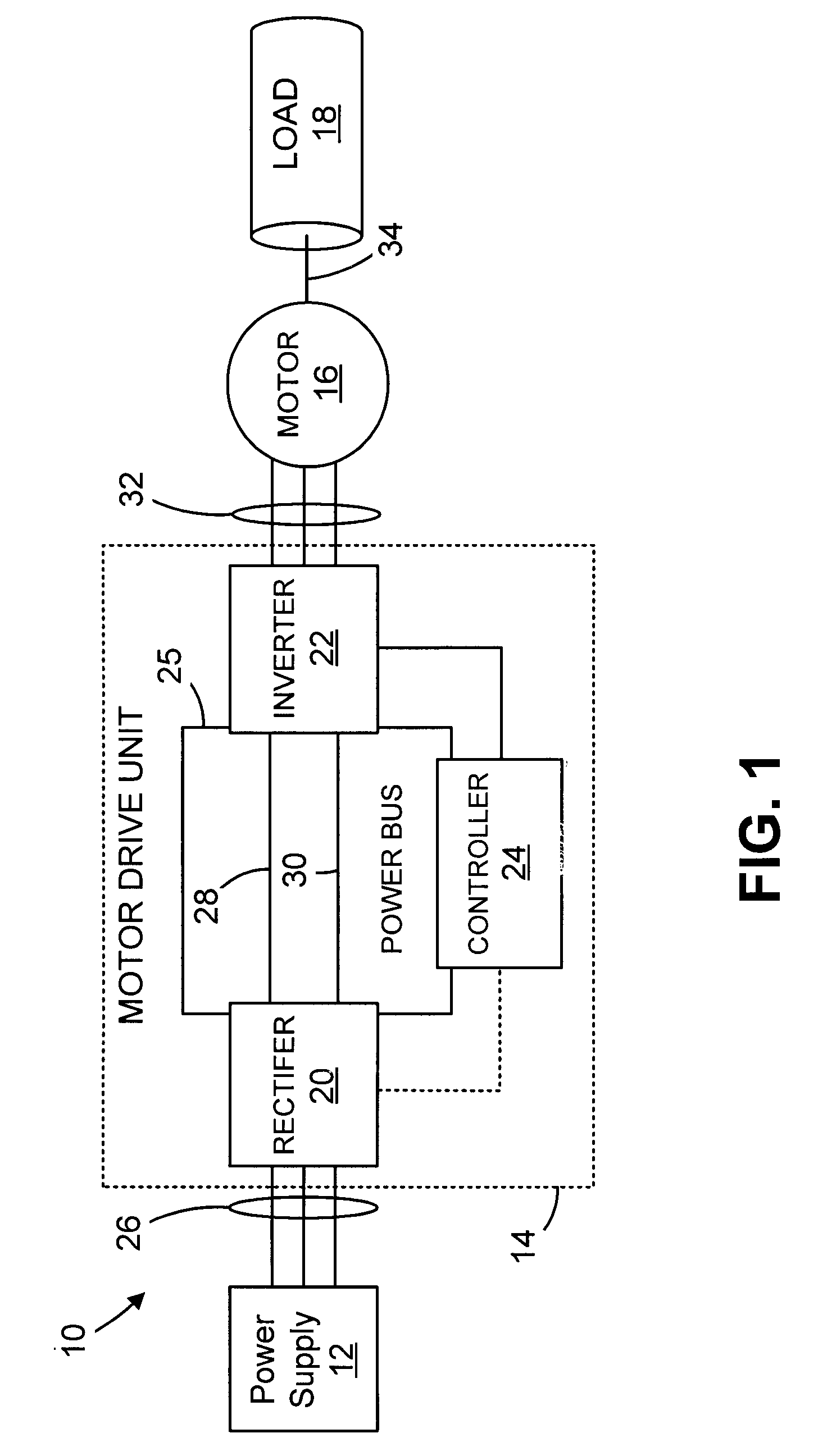

Power electronics interconnection for electric motor drives

ActiveUS20120305283A1Improve performanceReduce resistanceLine/current collector detailsElectrolytic capacitorsElectricityElectrical conductor

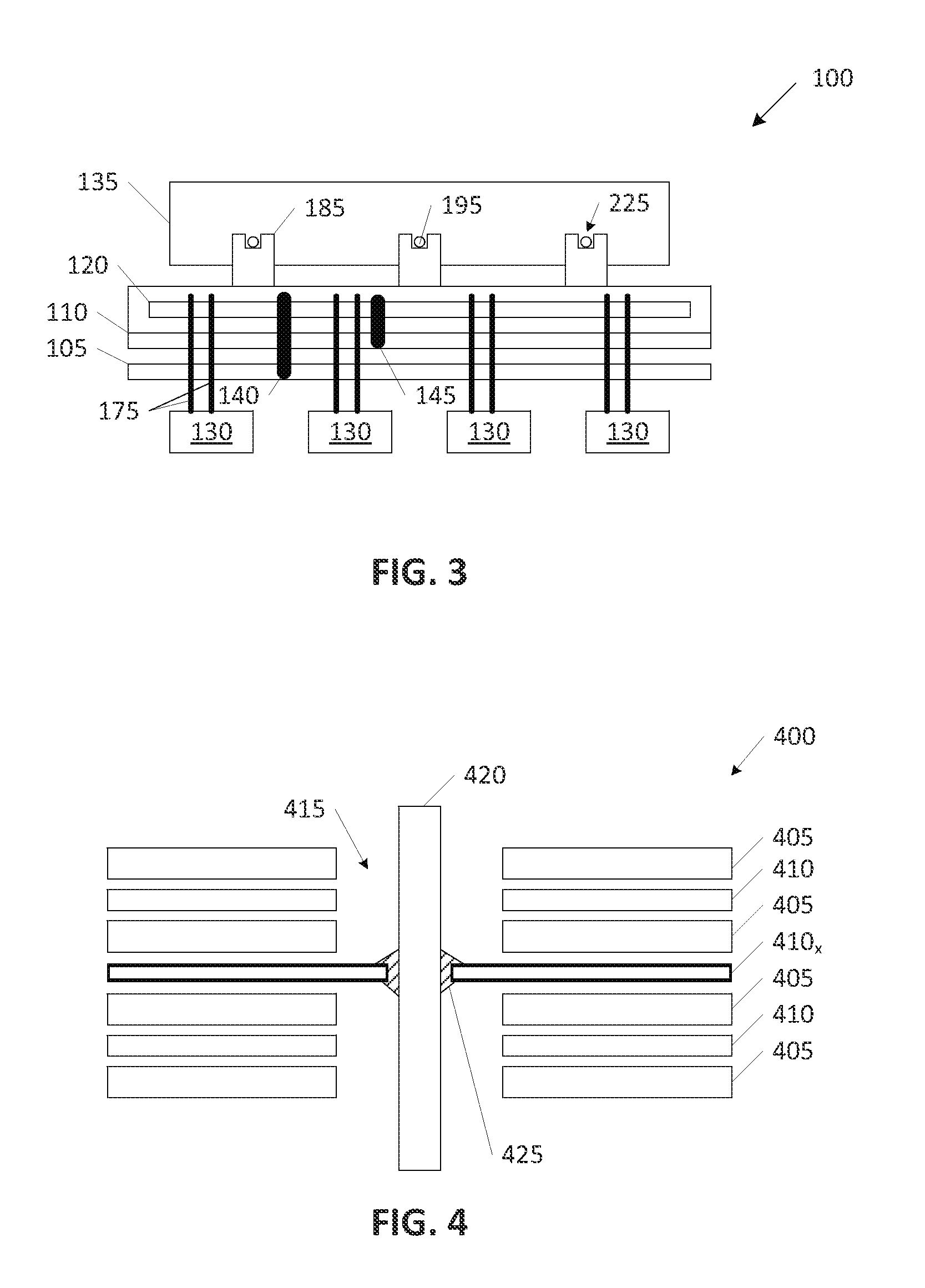

The bus bar includes a first bus bar layer formed of a first generally uniform thickness of a first bus bar conductor; a first dielectric layer overlying a top surface of the first bus bar layer; and a second bus bar layer formed of a second generally uniform thickness of a second bus bar conductor overlying a top surface of the first dielectric layer and the top surface of the first bus bar layer wherein: the first bus bar layer includes a first via for receipt of a first electrical lead of an electrical component and a second via for receipt of a second electrical lead of the electrical component and wherein: the first dielectric layer and the second bus bar layer each include a via aligned with the first via wherein the first electrical lead is extendable from beneath the first bus bar layer through the first dielectric layer and through the second bus bar layer.

Owner:TESLA INC

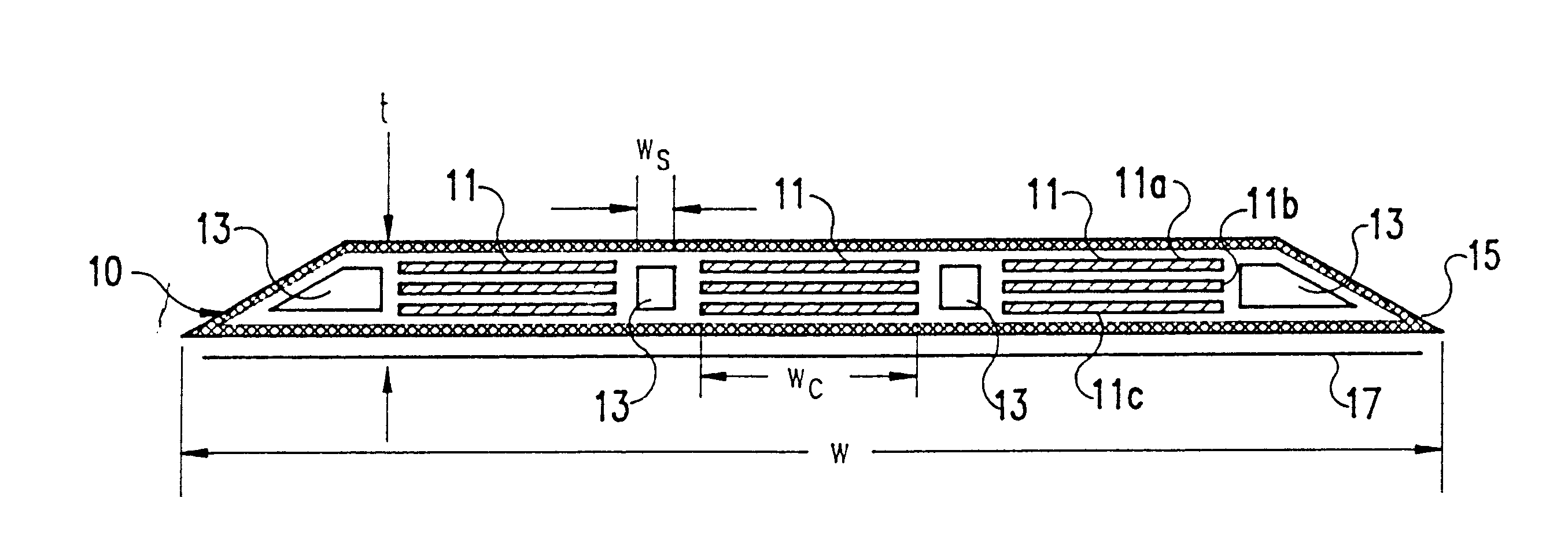

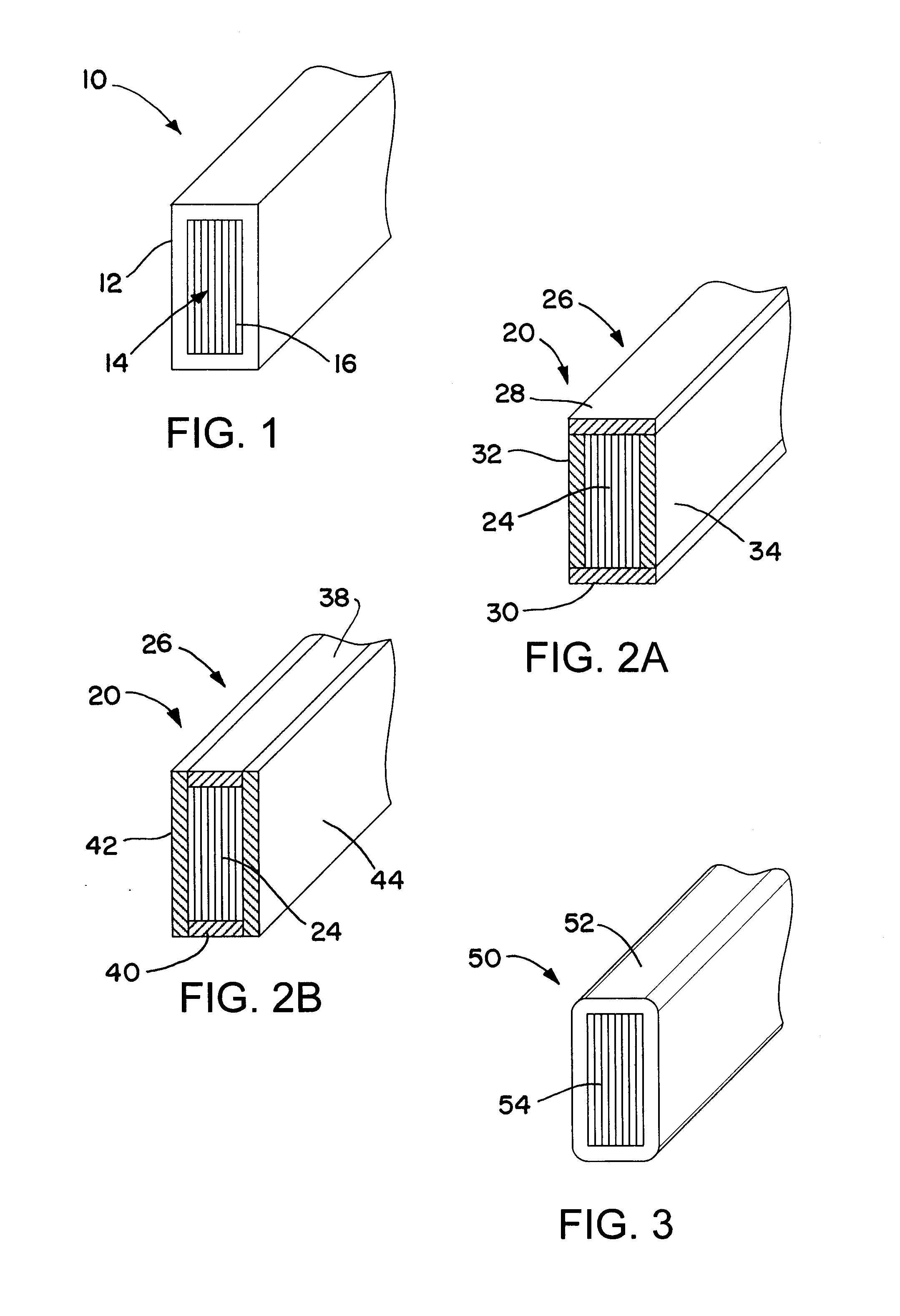

Flat surface-mounted multi-purpose wire

InactiveUS6492595B2Strip/foil conductorsCoupling device connectionsInsulation layerElectrical conductor

A multi-purpose wire includes at least one elongated conductor having a width of at least 0.125 inches. The conductor includes at least one conductive layer having a thickness no greater than about 0.0200 inches. The wire also includes a bonding material between each conductor, and an insulation layer surrounding the conductor and bonding material.

Owner:SOUTHWIRE CO LLC

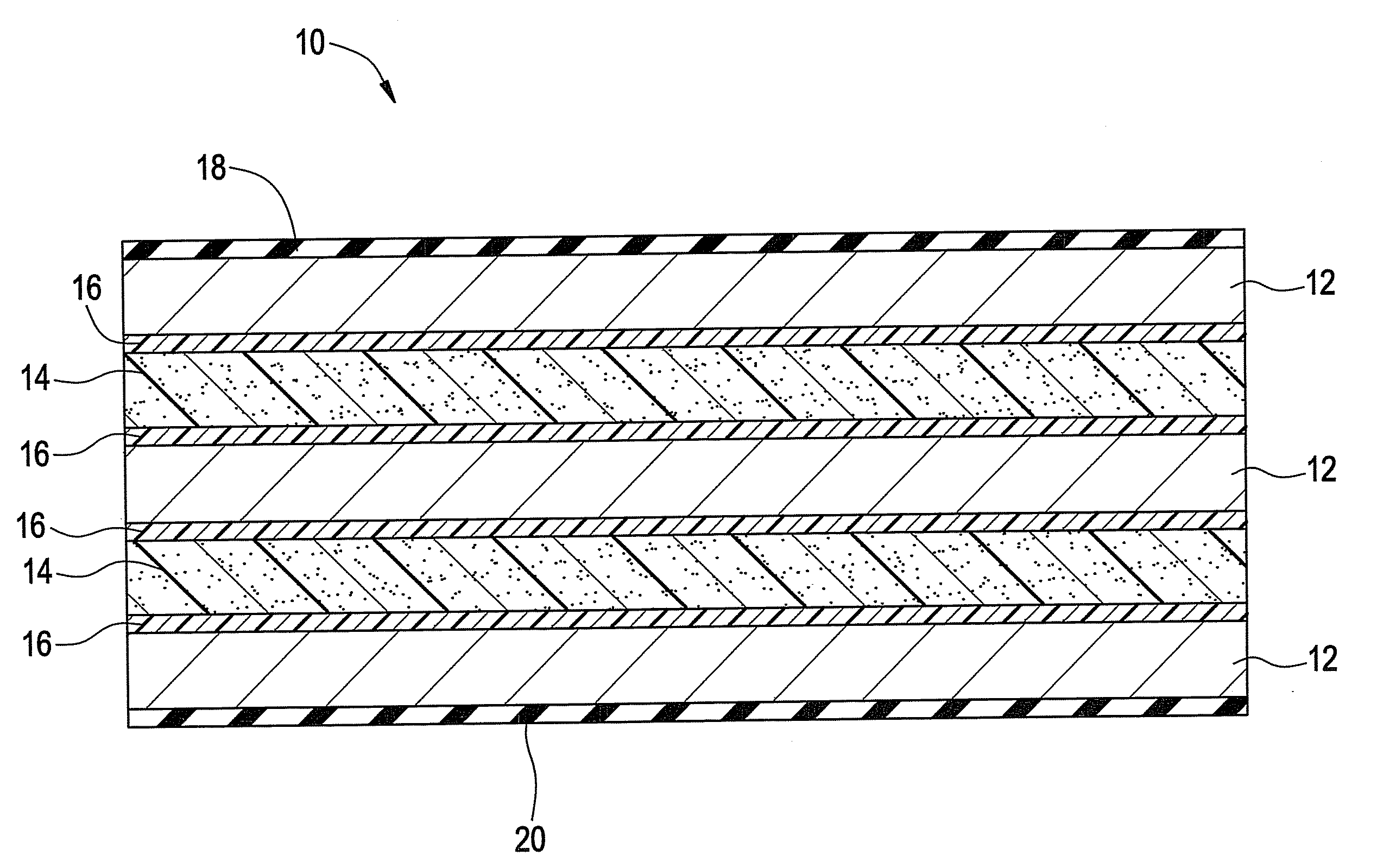

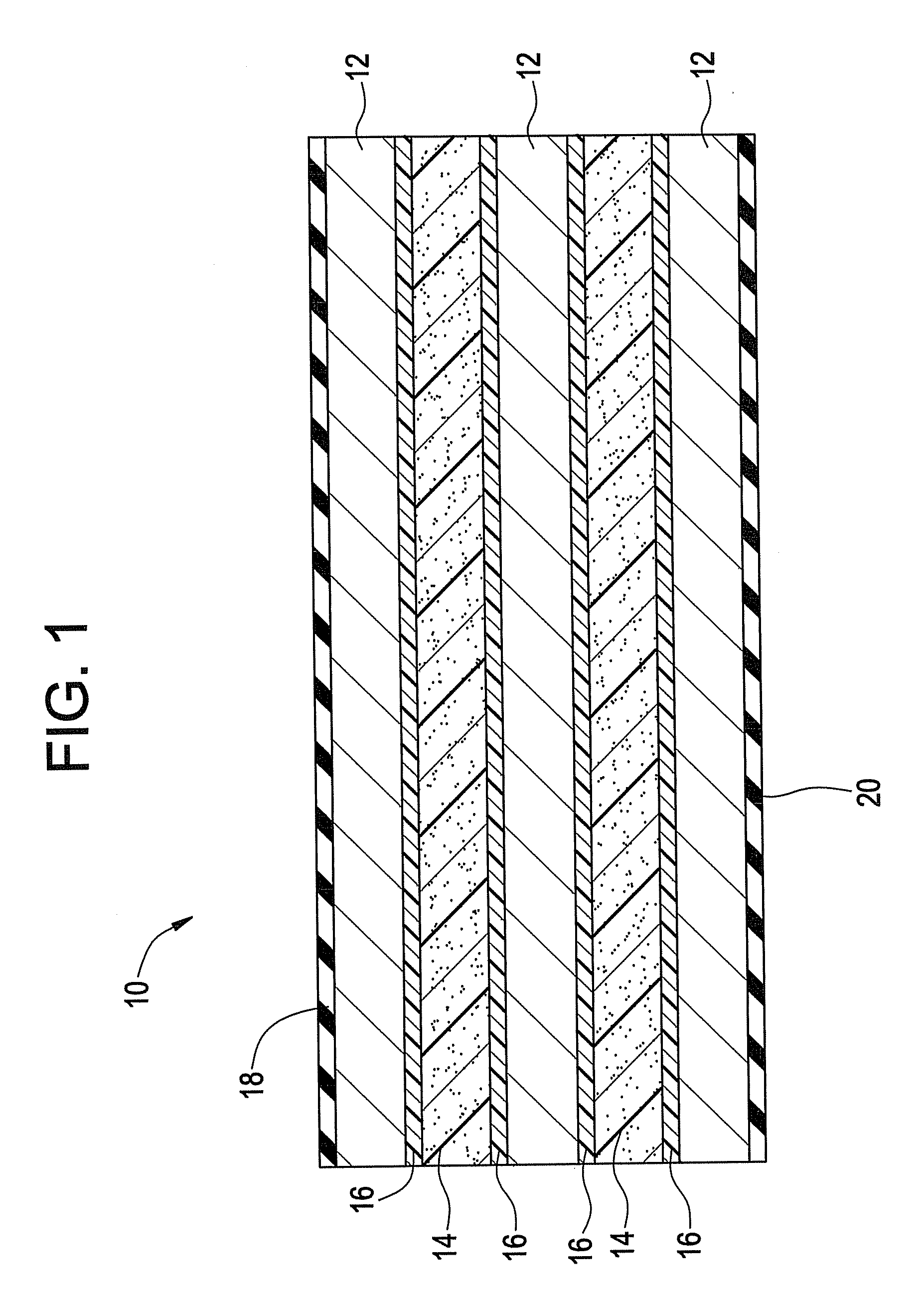

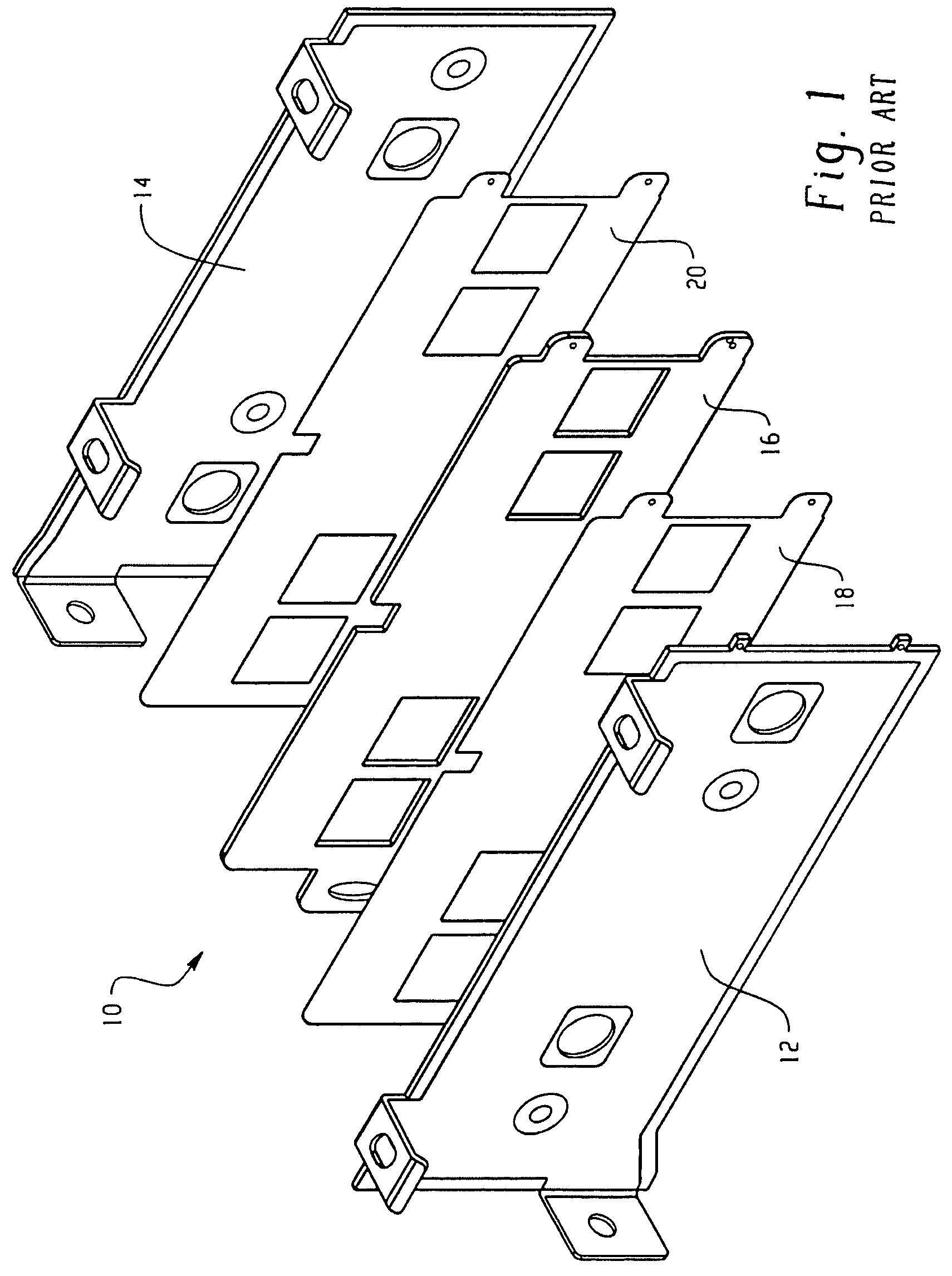

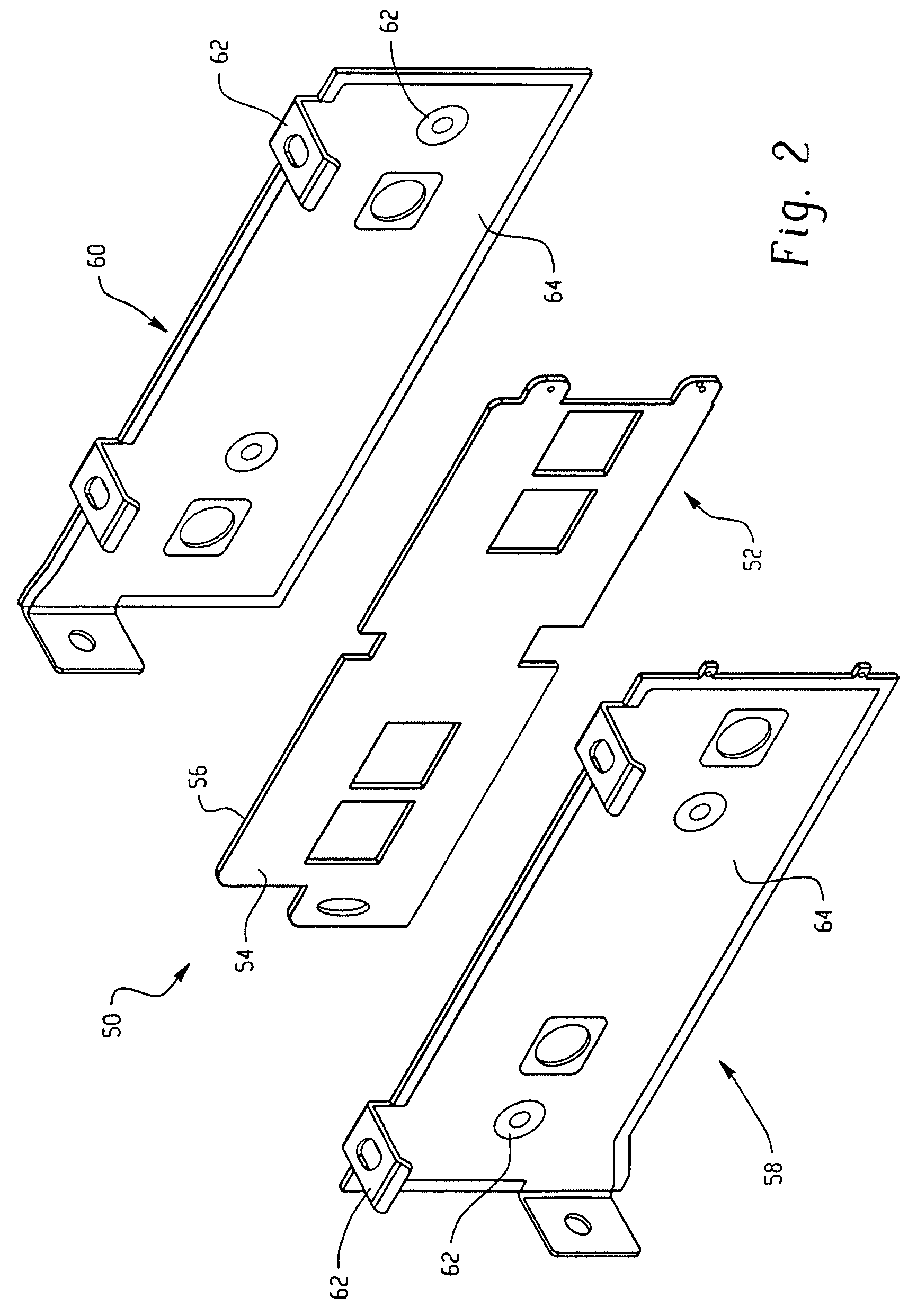

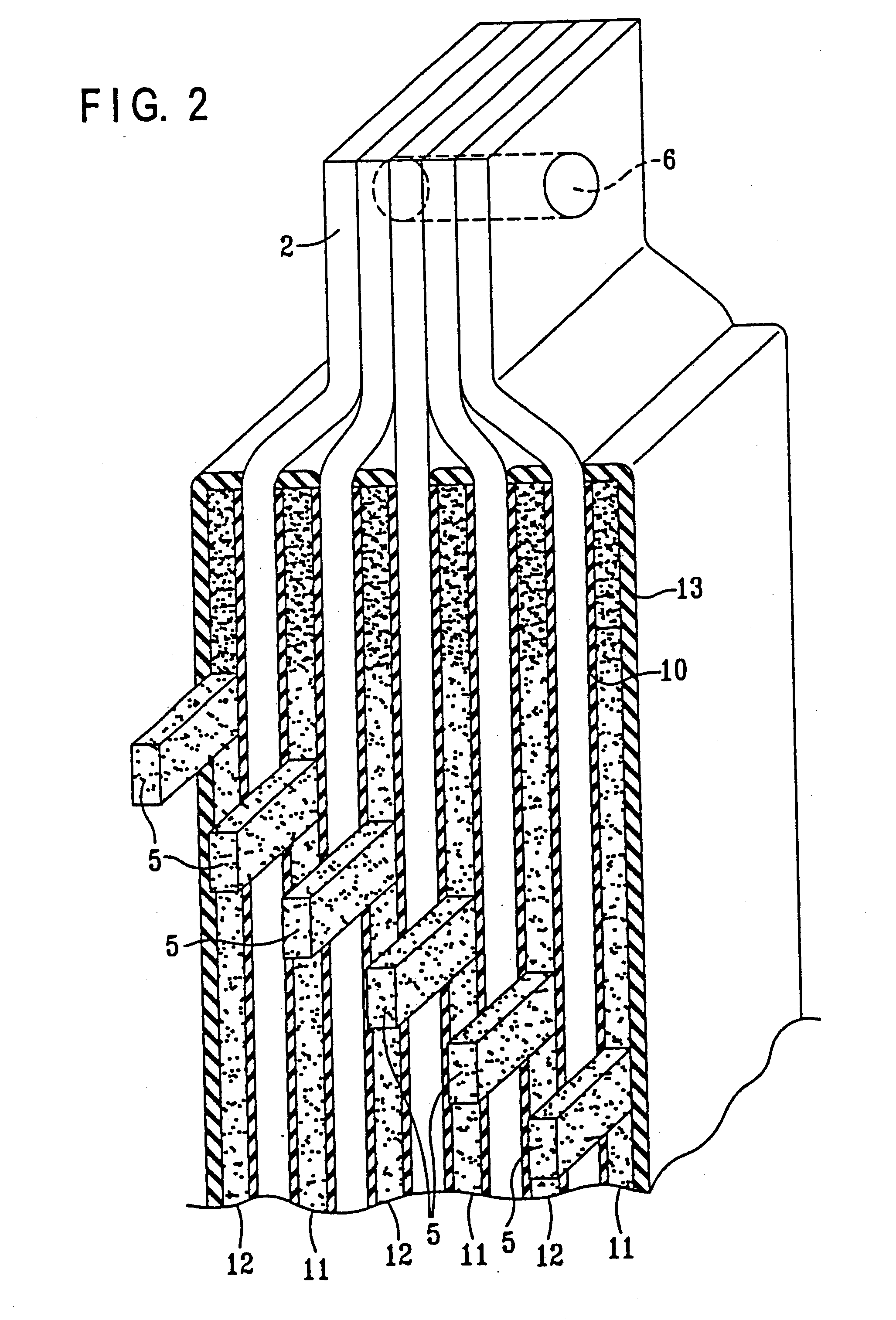

Laminated bus bar assembly

InactiveUS7557298B2Electrical apparatus contructional detailsLaminated bus-barsElectricityDistribution system

A laminated bus bar assembly comprises alternating layers of a conductive layer and a foam dielectric layer. The foam dielectric layer has a dielectric constant greater than a solid non-porous dielectric constant of the same material, the use of which increases the partial discharge inception and extinction voltage levels, provides vibration resistance, decreases inductance and the like. The bus bar assembly of laminar construction is useful for power distribution systems, high power transistor modules, and the like.

Owner:WORLD PROPERTIES

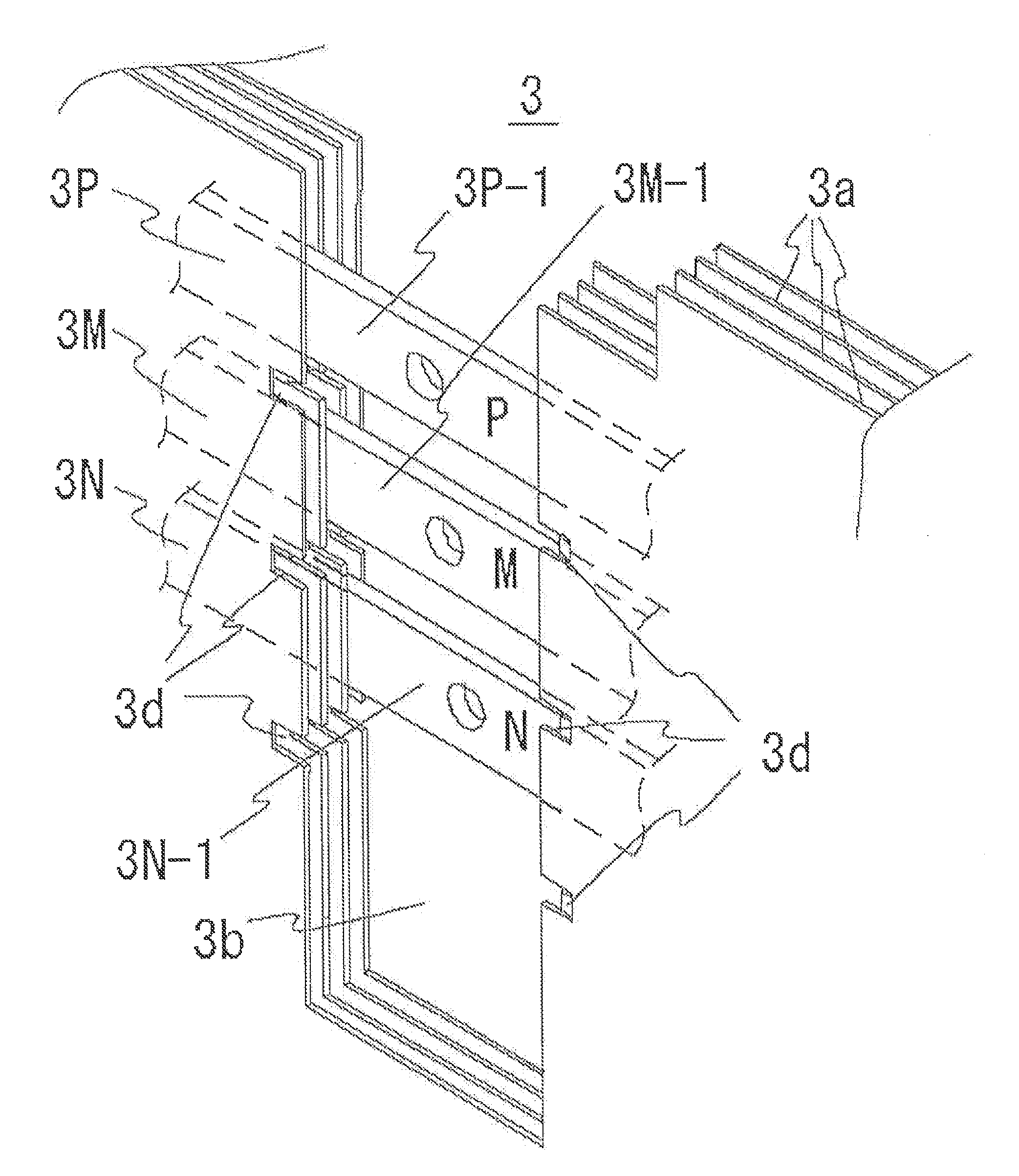

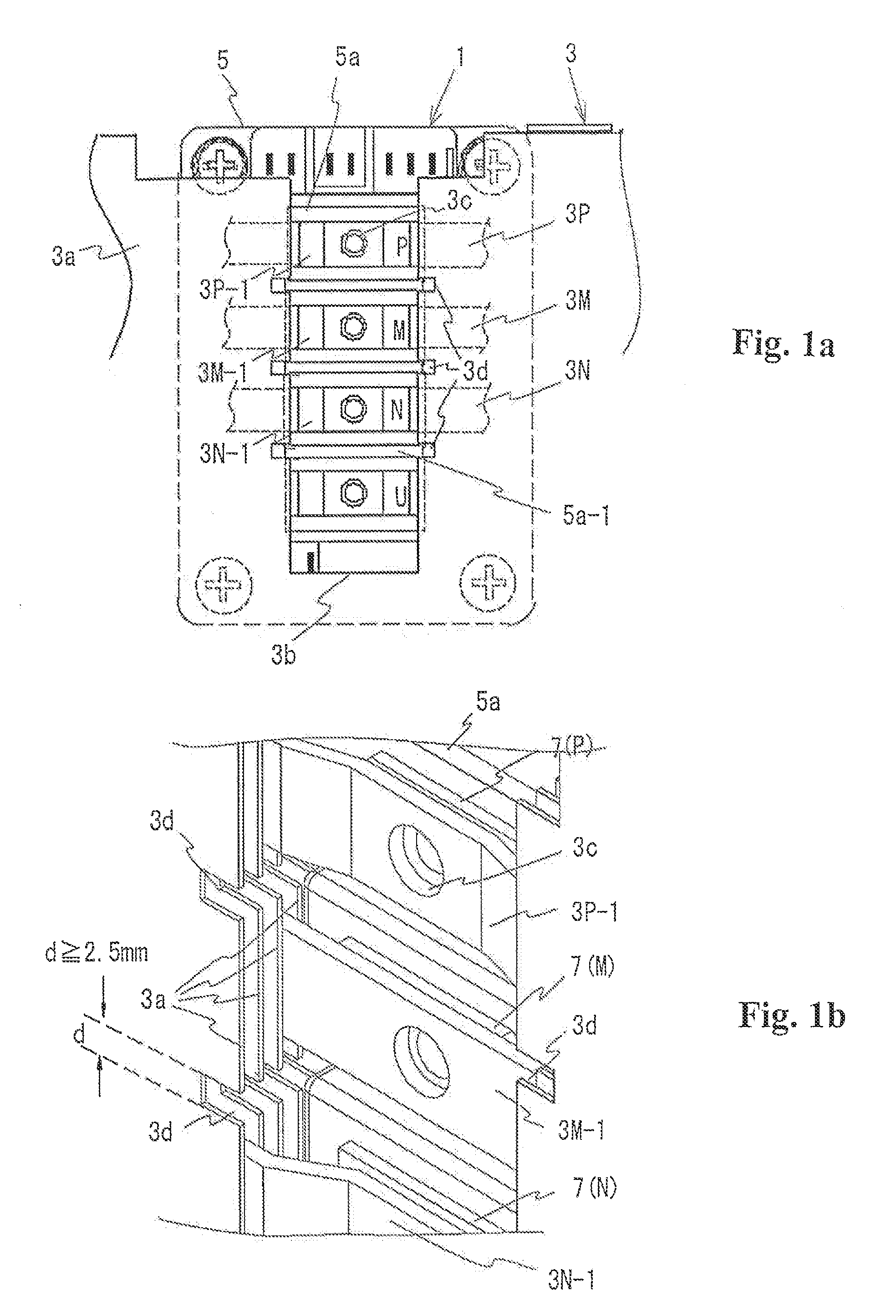

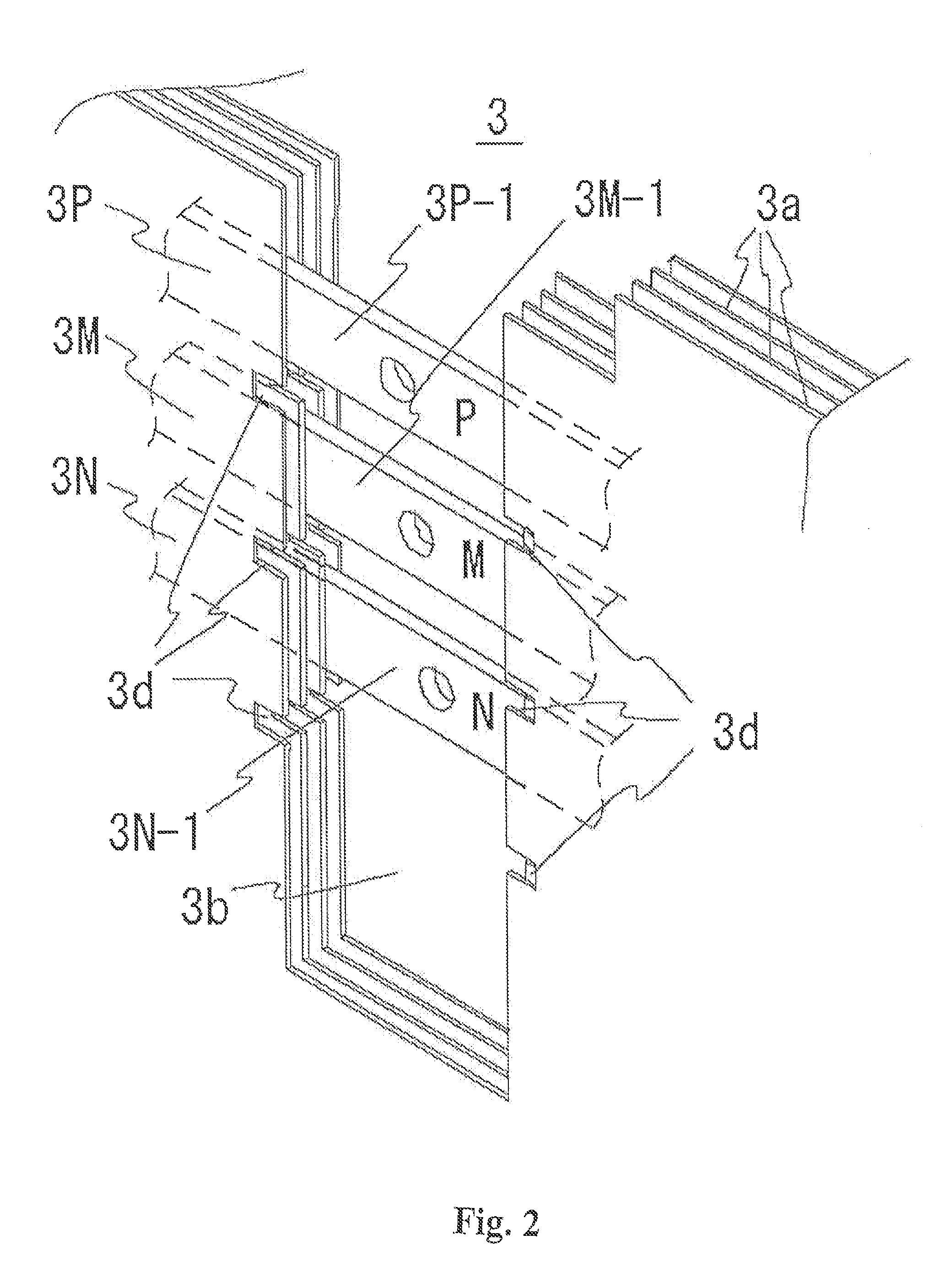

Laminated bus bar

ActiveUS20110308834A1Improve insulation performanceConversion constructional detailsElectrical apparatus contructional detailsElectrical conductorEngineering

A laminated bus bar is applied to a main wiring circuit of an electric power converter and connected to a semiconductor module. The laminated bus bar includes insulator plates laminated together, and conductors interposed between the insulator plates. Each conductor includes a connection terminal section led out in accordance with an arrangement of a main circuit terminal on the semiconductor module. A creepage groove is formed on an edge of each of the insulator plates in accordance with a position between the connection terminal sections. The laminated bus bar facilitates elongation of the creepage distance between the connection terminals.

Owner:FUJI ELECTRIC CO LTD

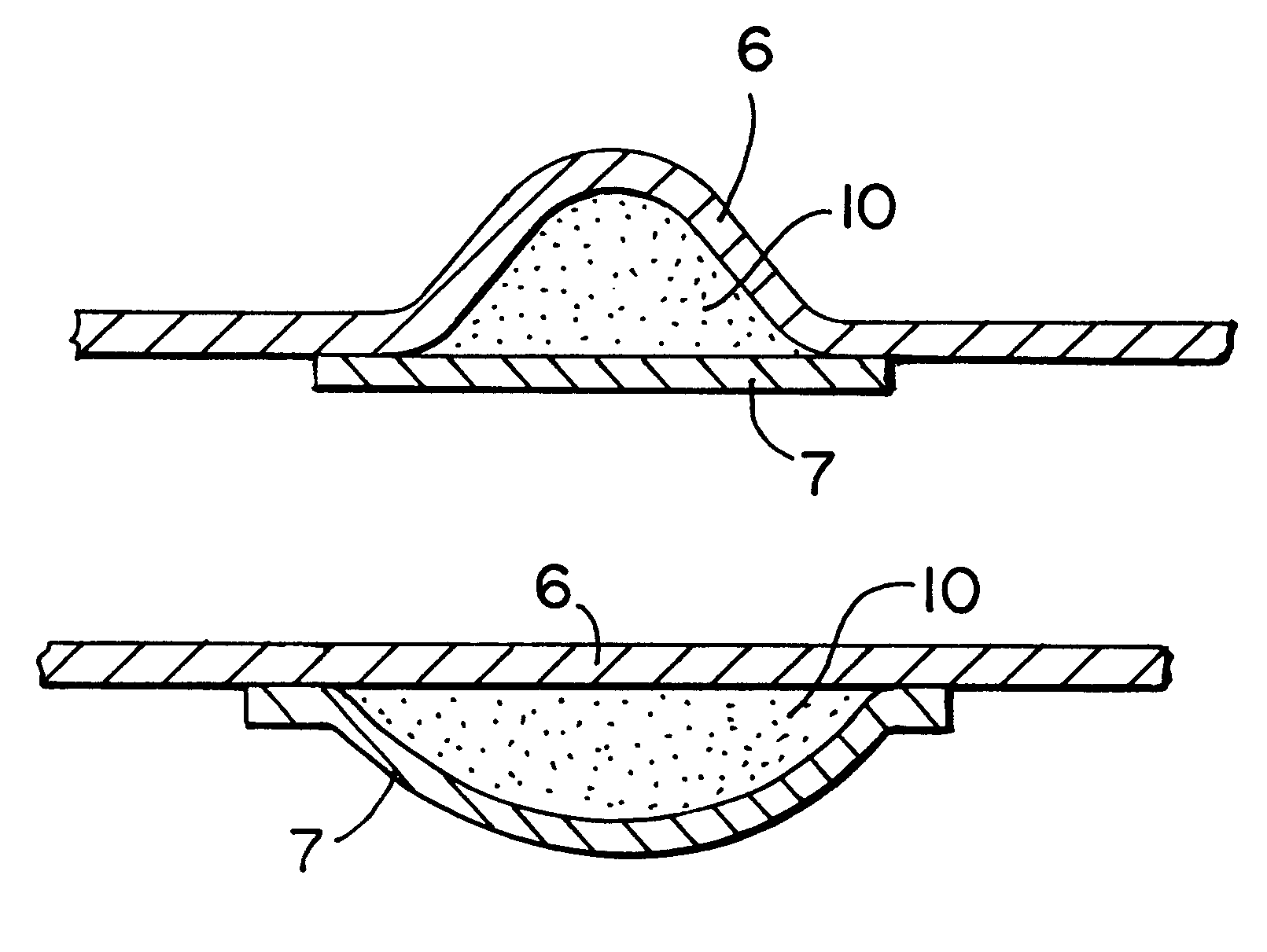

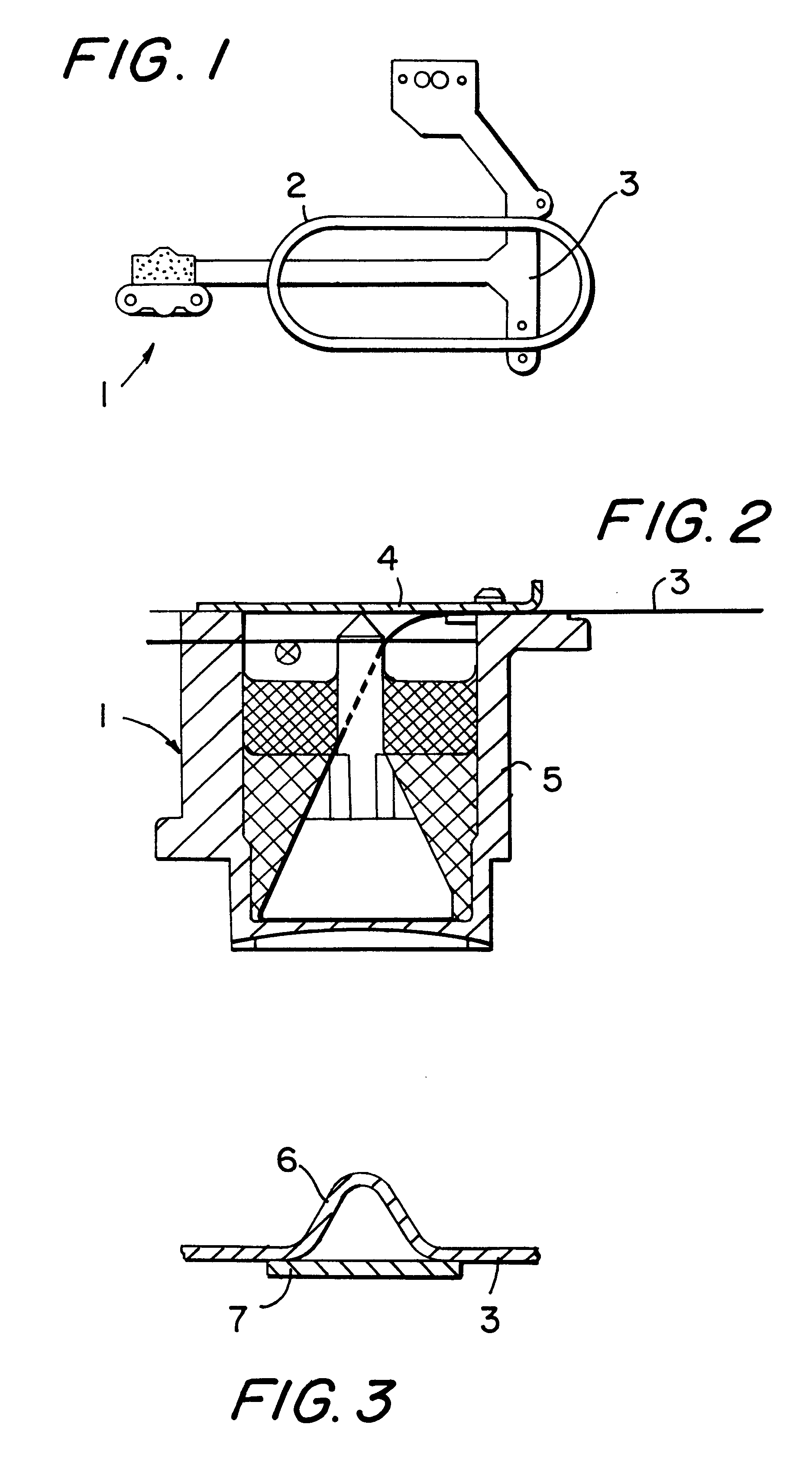

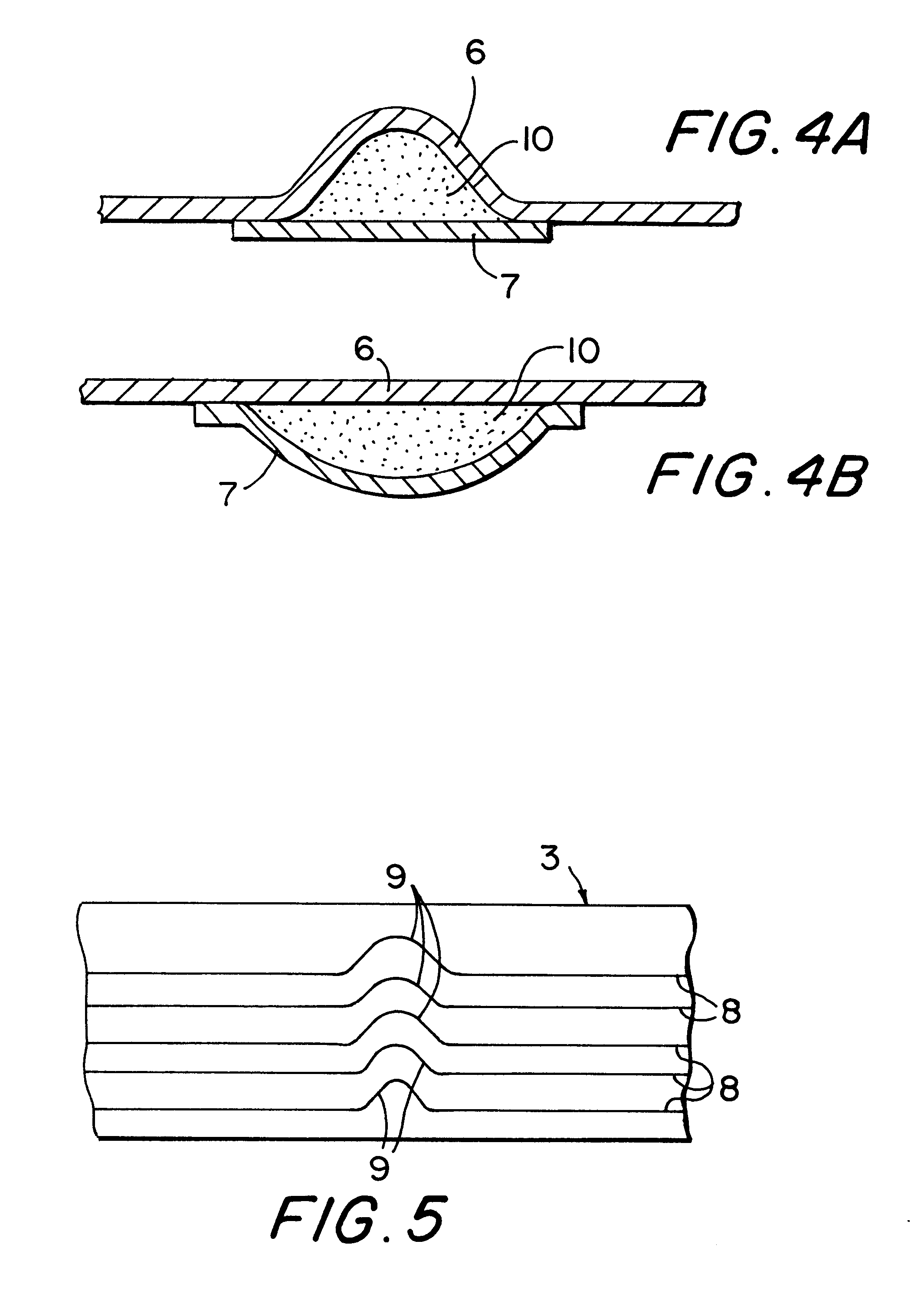

Insulation of busbars using insulating members having corrugated sections

ActiveUS20100319958A1Minimize and eliminate air gapSolve the low heat dissipation efficiencyBus-bar/wiring layoutsLine/current collector detailsBusbarThermal contact

Busbars of a busway system are insulated so as to minimize or eliminate air gaps between busbars. In an embodiment, an insulating sheath is provided with corrugations in regions corresponding to busbar bends. The corrugations allow the sheath to follow the busbar bends without the need to cut or interrupt the sheath. Busbars may therefore be fully insulated without the need for further insulating materials (e.g., tape). Good thermal contact between busbars throughout their length is achieved, improving heat dissipation and efficiency.

Owner:SCHNEIDER ELECTRIC USA INC

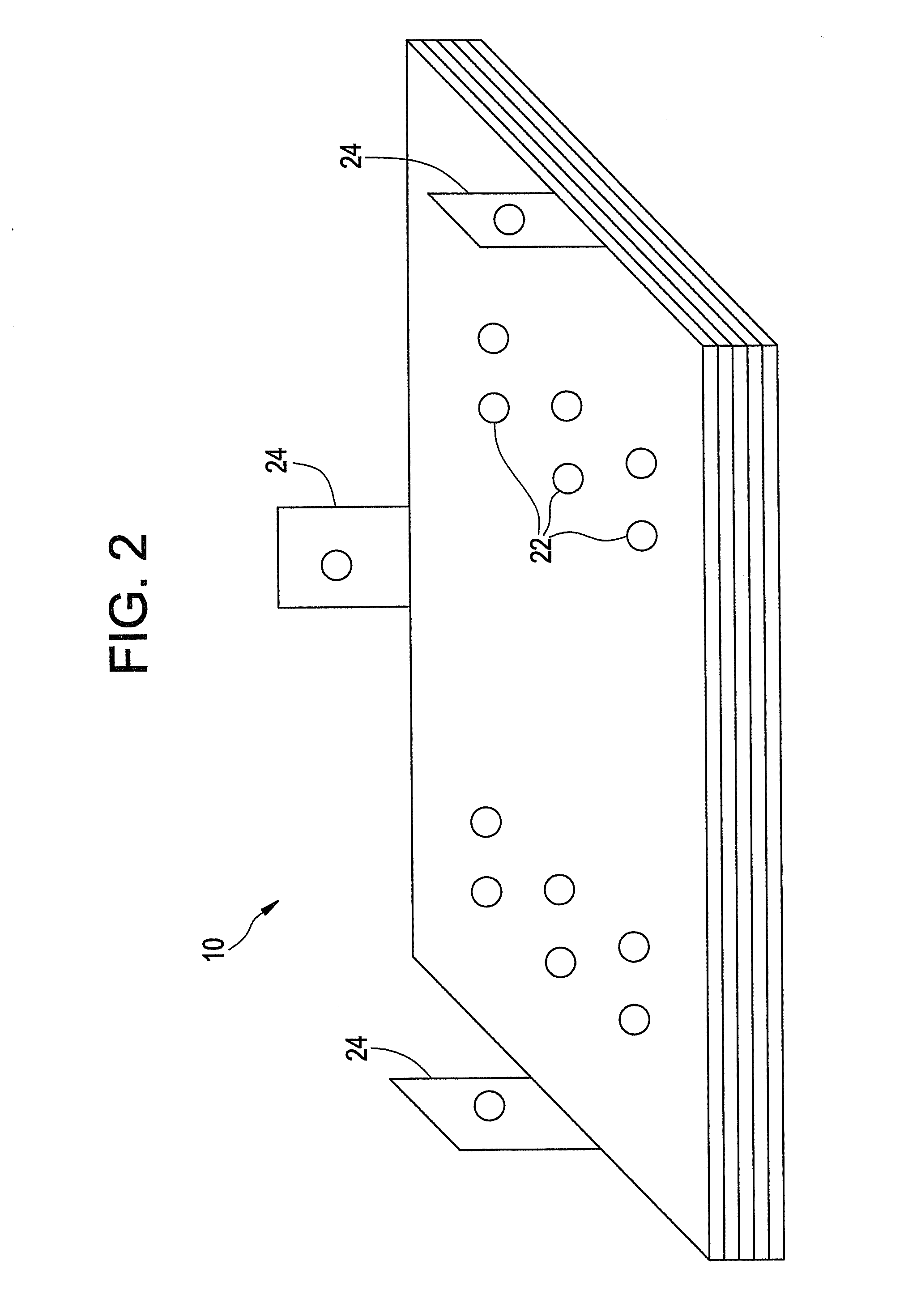

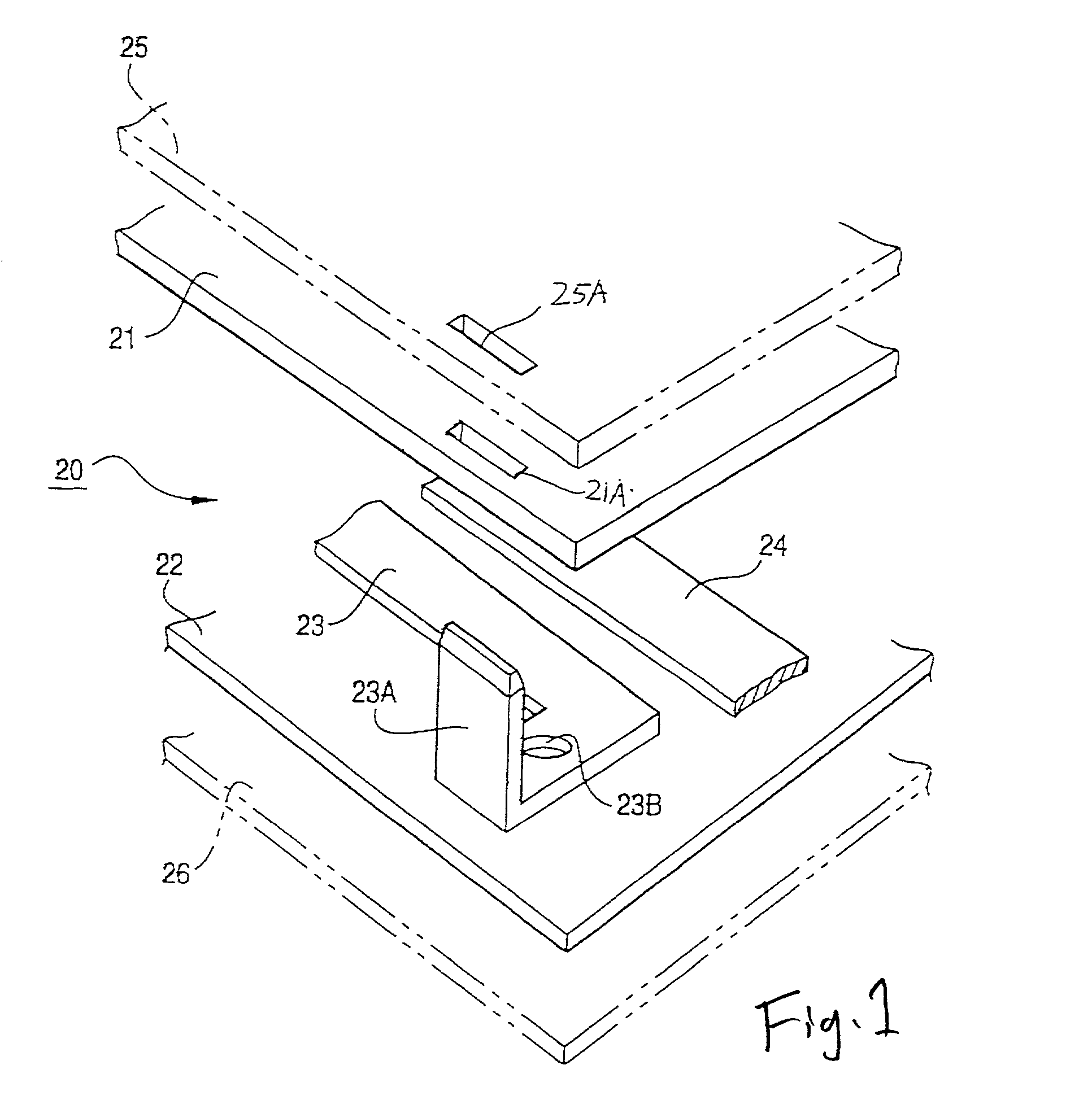

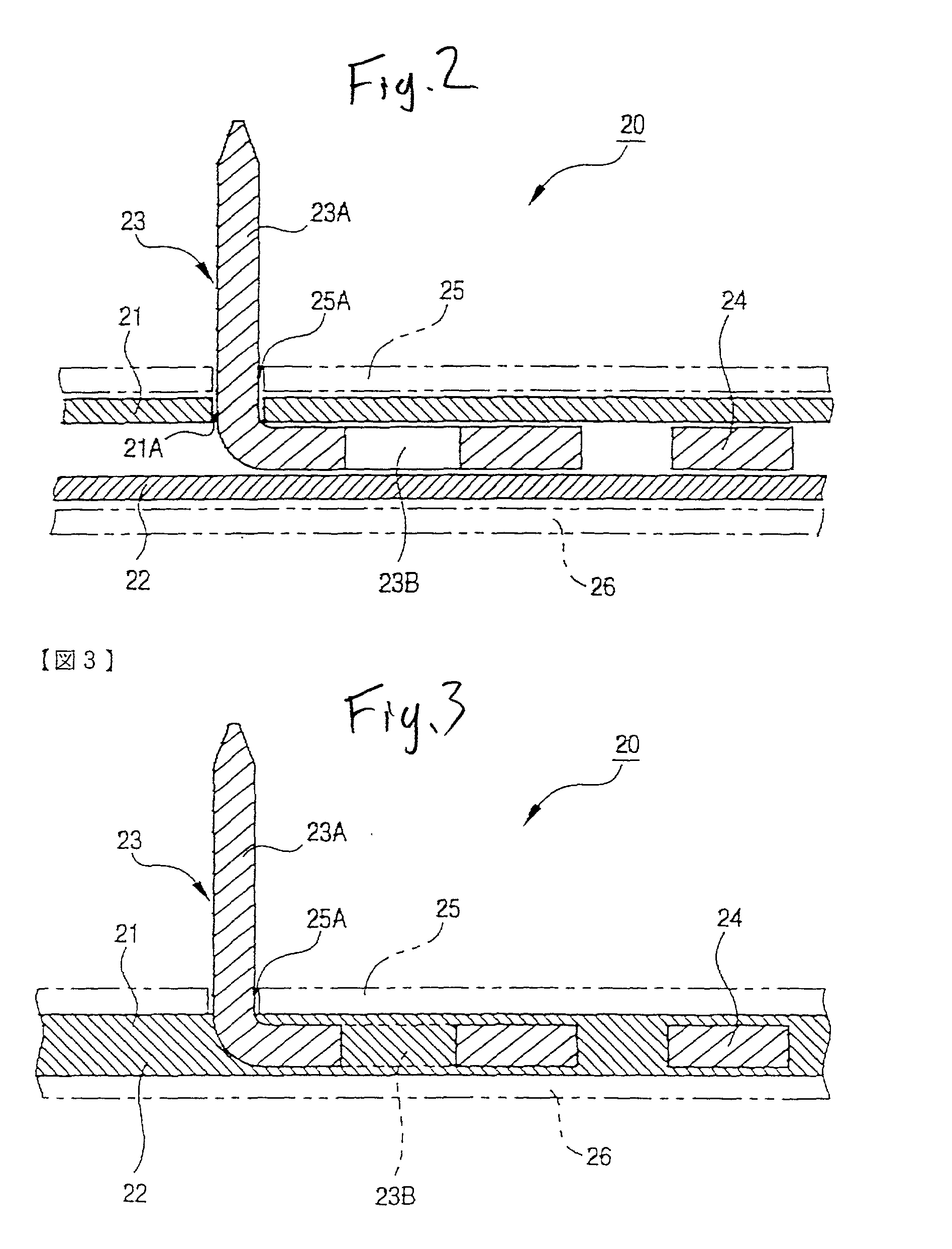

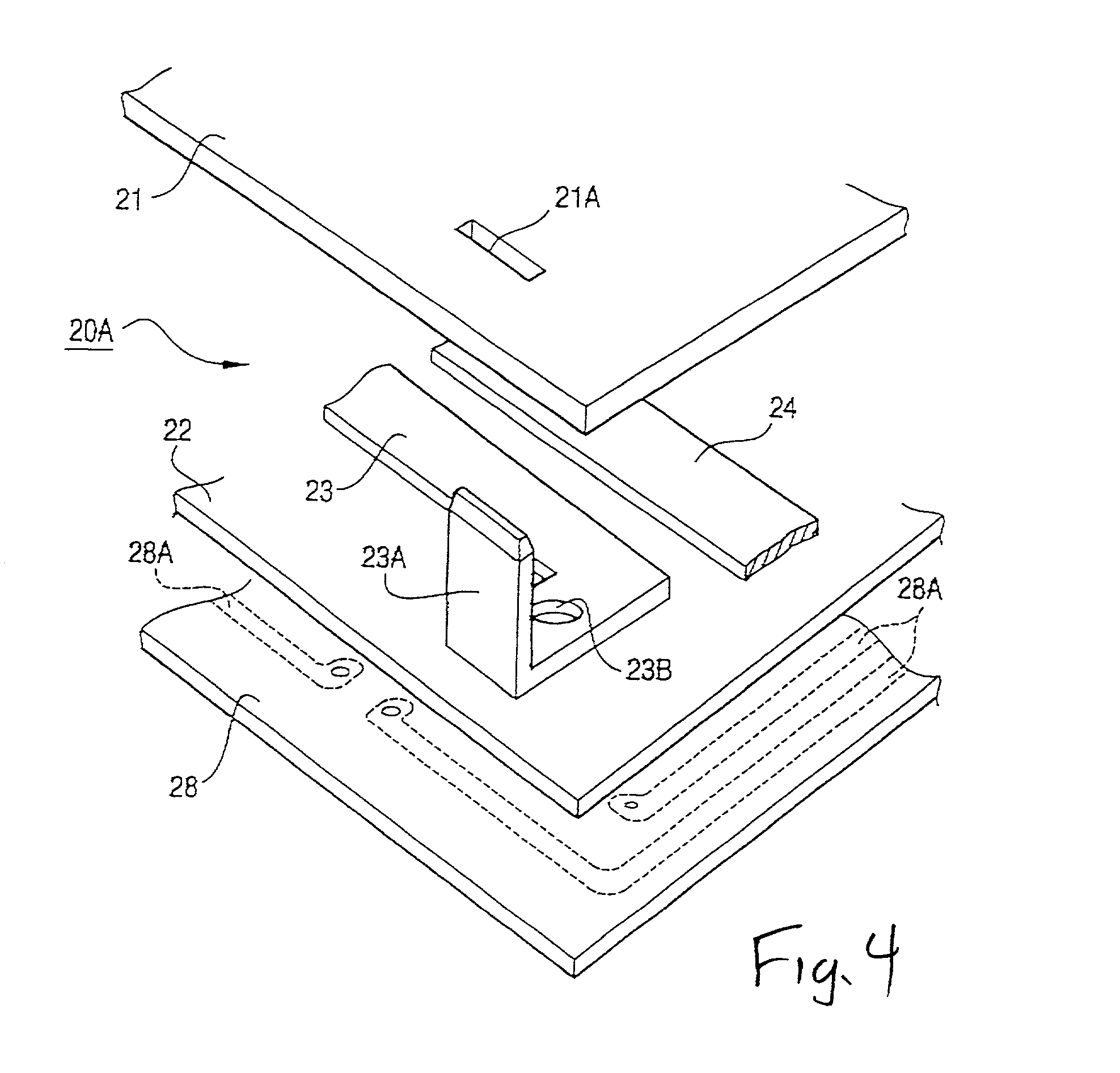

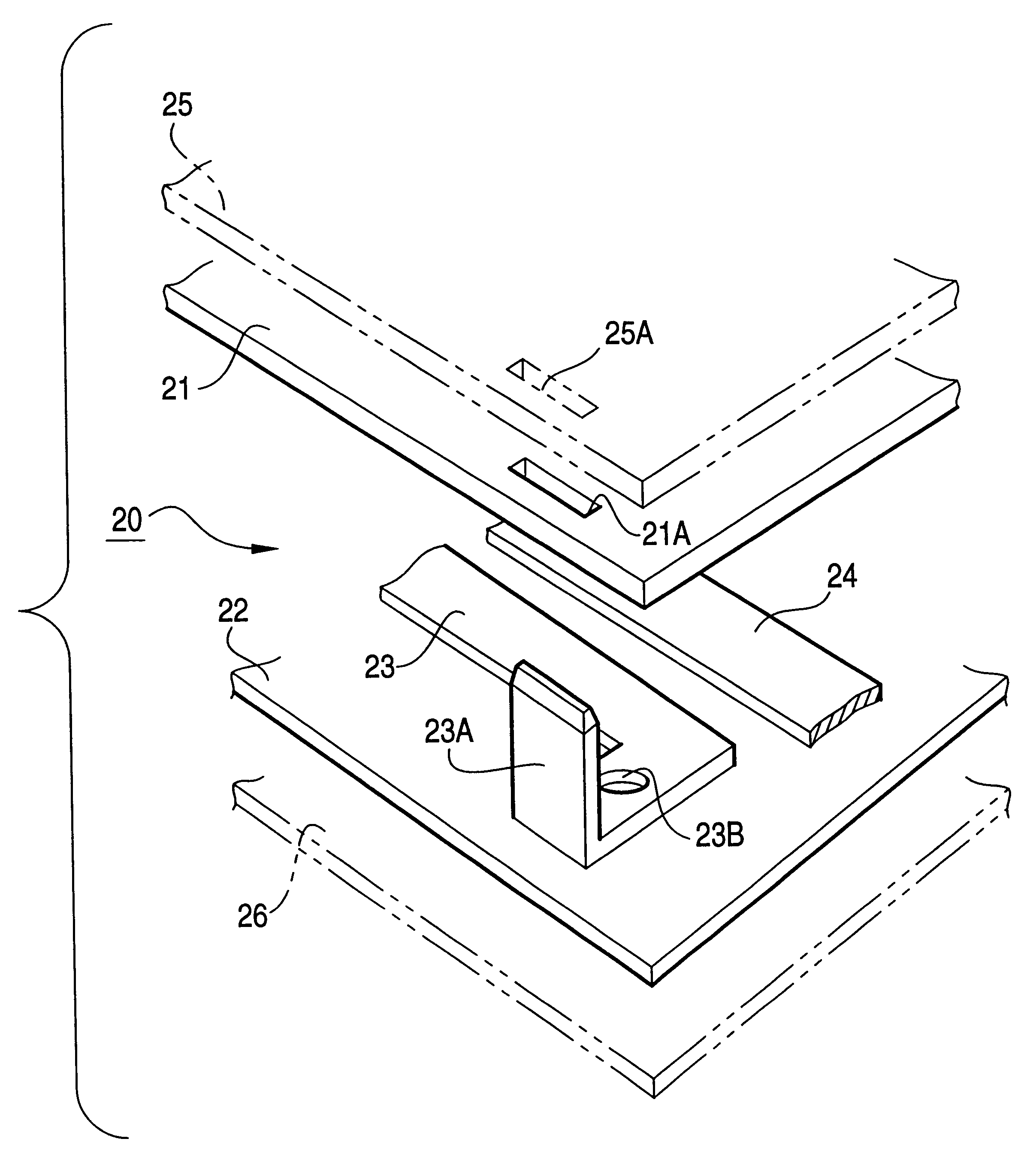

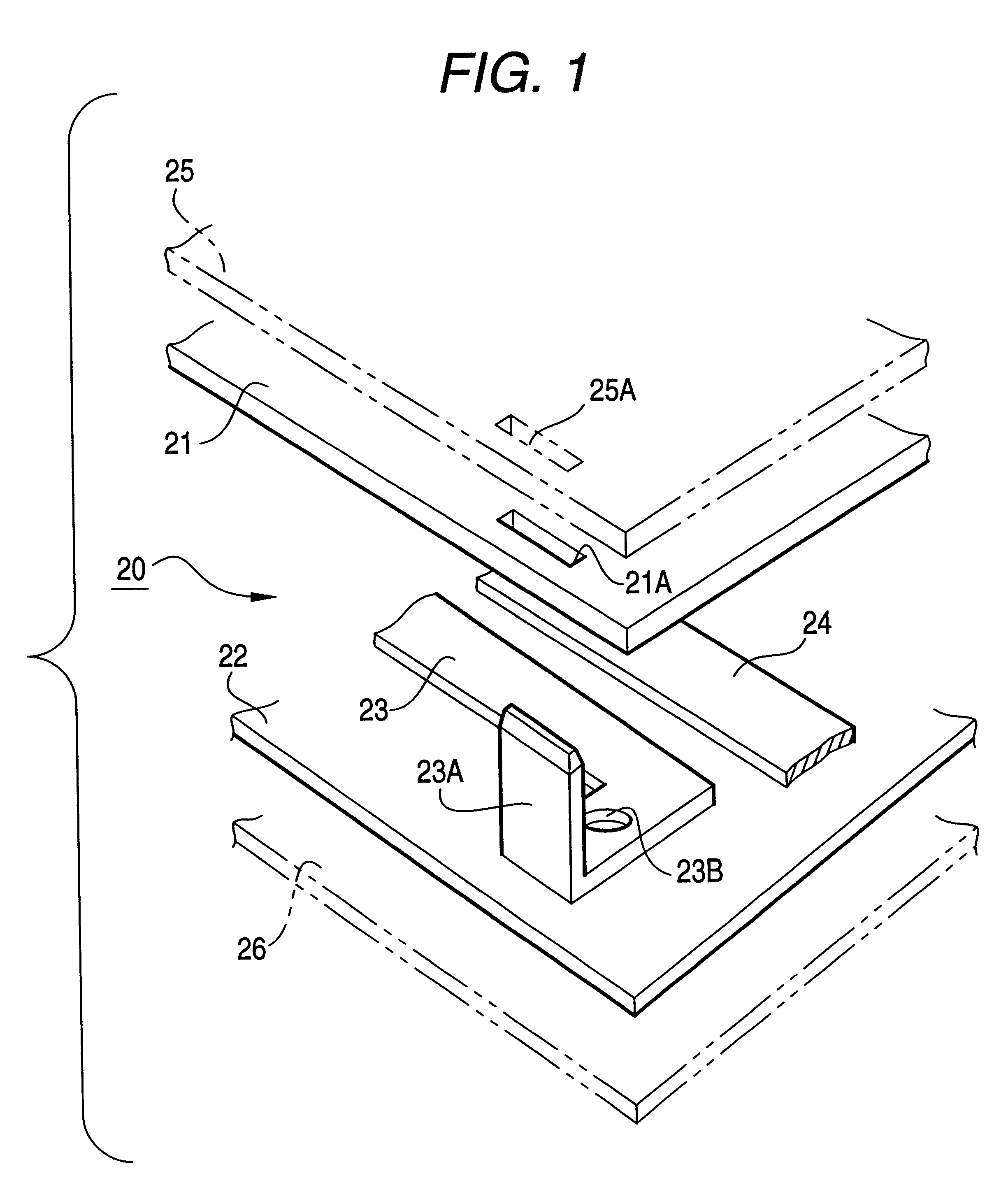

Bus bar wiring plate body for electric coupling box

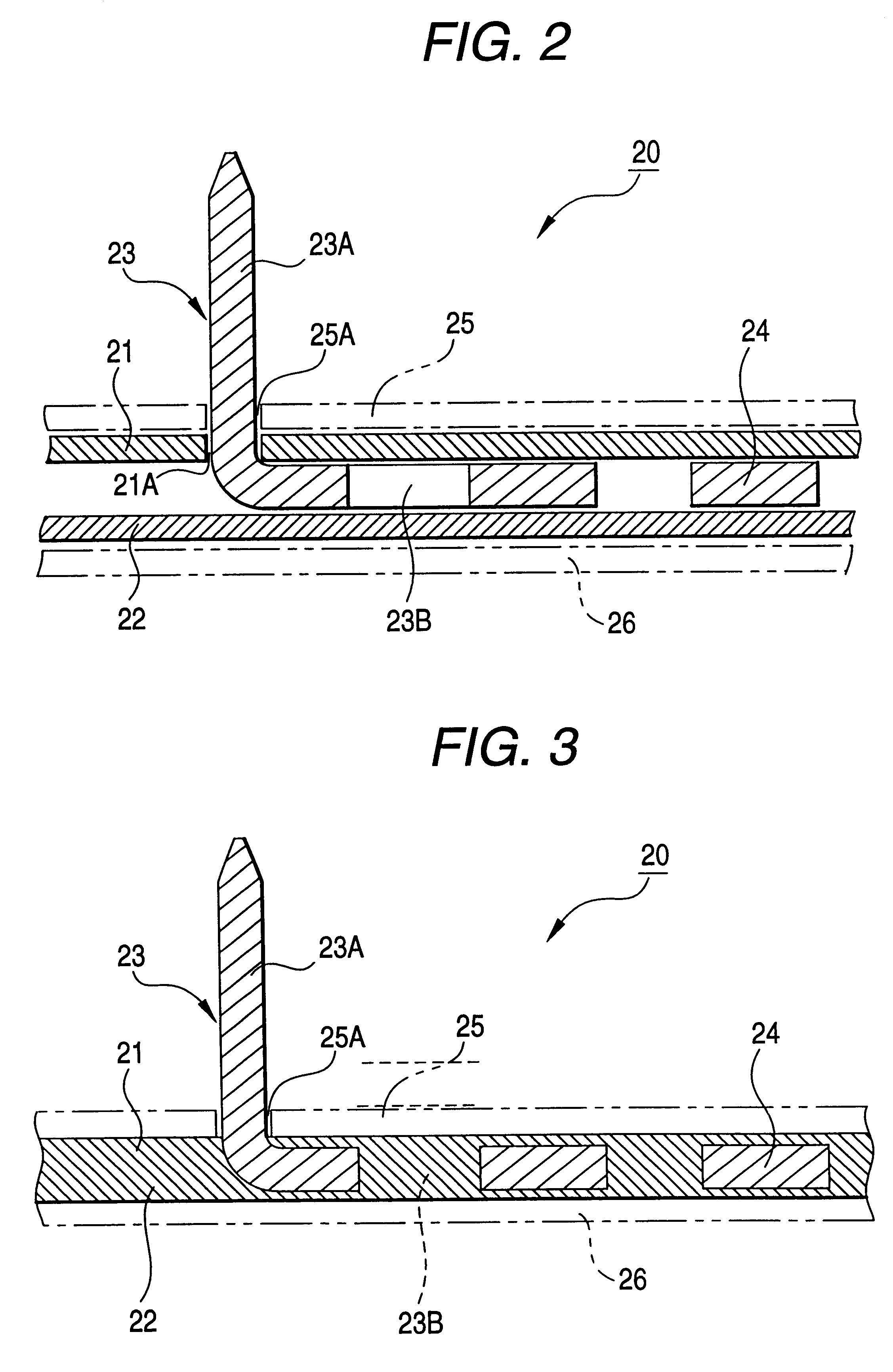

The bus bar wiring plate body (20) for an electric coupling box according to the present invention is arranged in a manner that bus bar members (23, 24) are wired between pre-hardening epoxy resin plates (21, 22) and these pre-hardening epoxy resin plates are subjected to the heat pressing process to thereby integrate the pre-hardening epoxy resin plates (21, 22) and the bus bar members (23, 24) in a laminated state. When hardened epoxy resin plates (25, 26) are disposed at the outsides of the pre-hardening epoxy resin plates (21, 22) as shown by phantom lines, respectively, the strength of the bus bar wiring plate body (20) can be improved. Thus, since the bus bar members (23, 24) are sealed in an insulated state, leak current can be reduced surely. Further, the thickness of the bus bar wiring plate body (20) can be reduced to a large extent, so that the electric coupling box can be miniaturized and lightweighted.

Owner:YAZAKI CORP

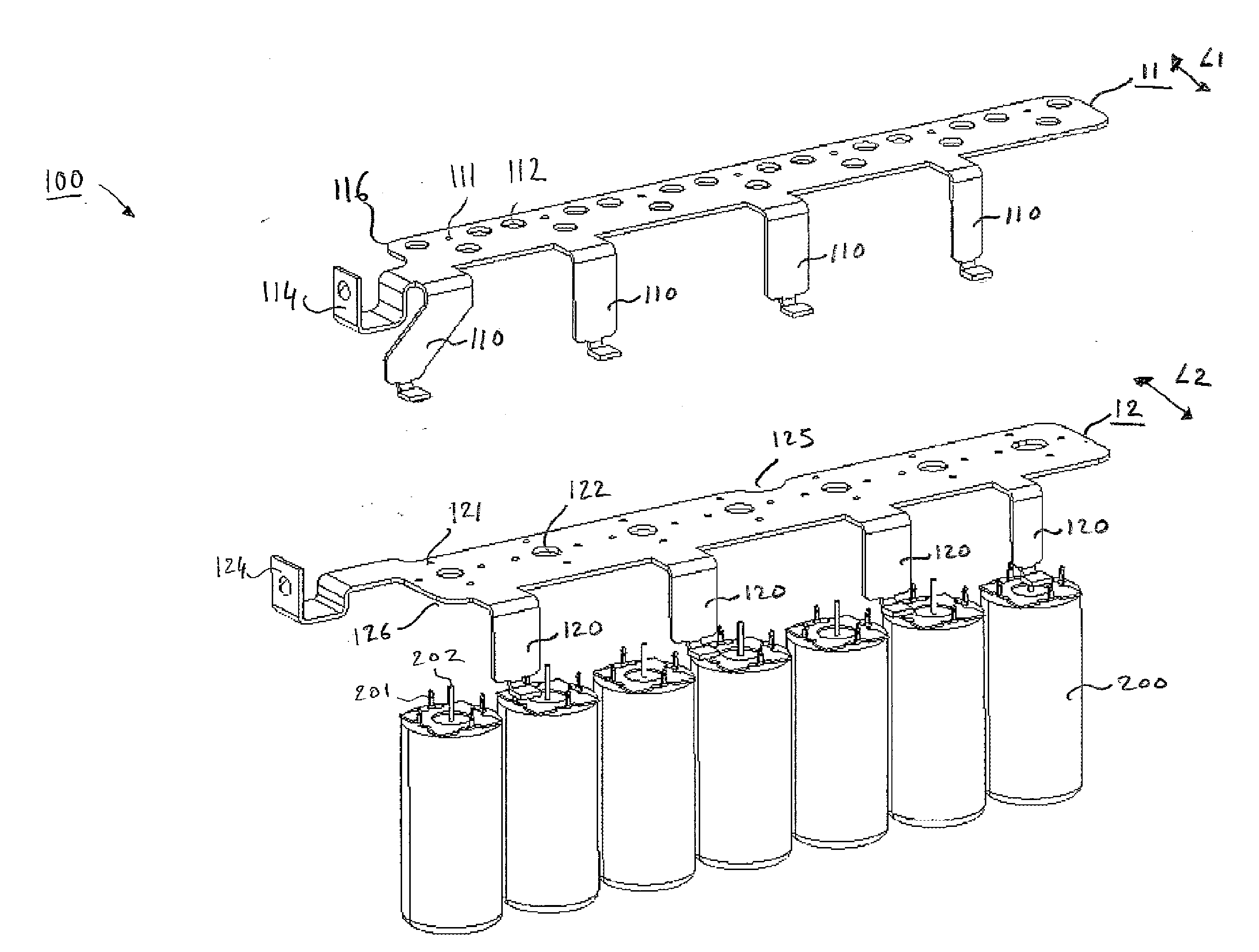

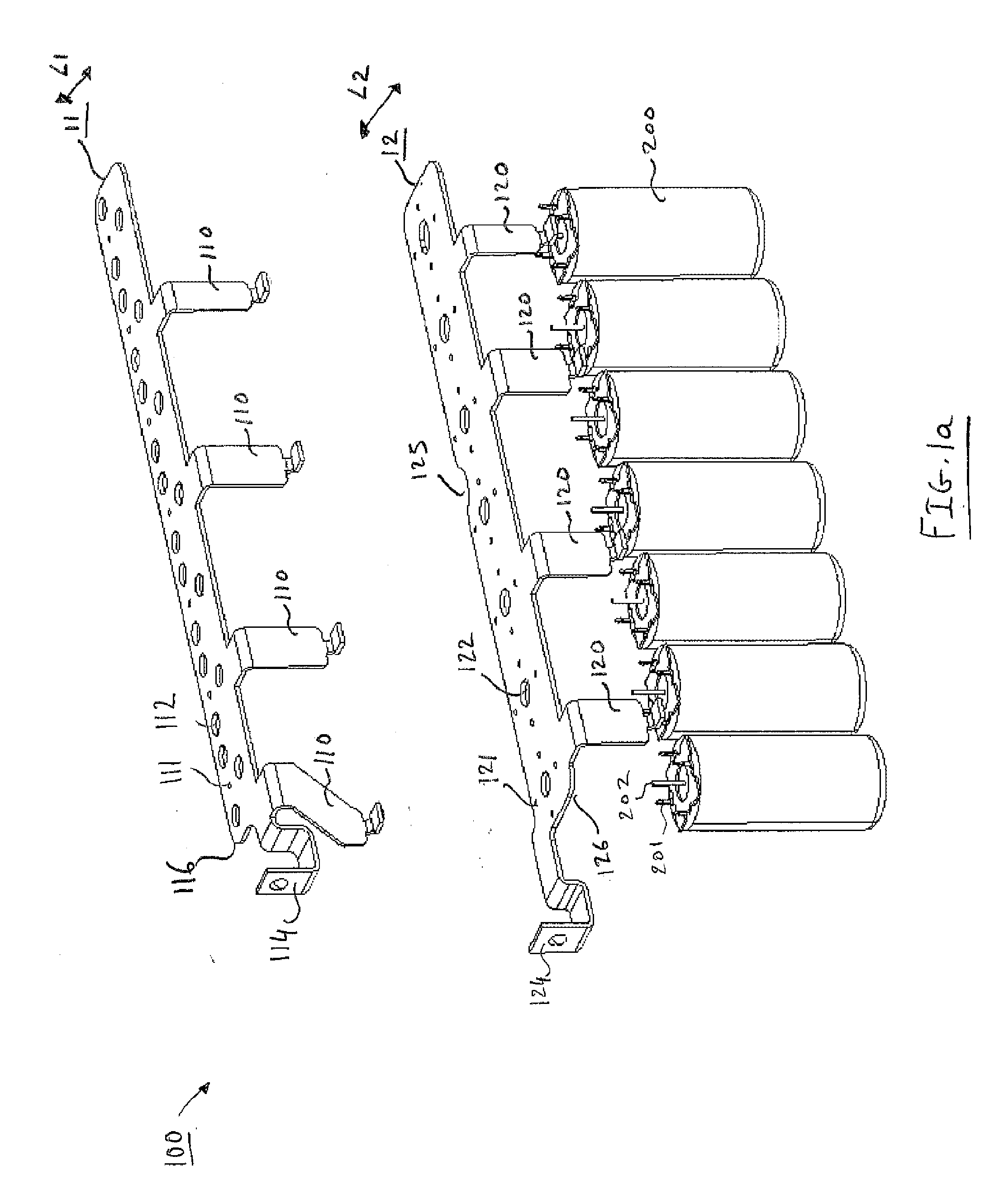

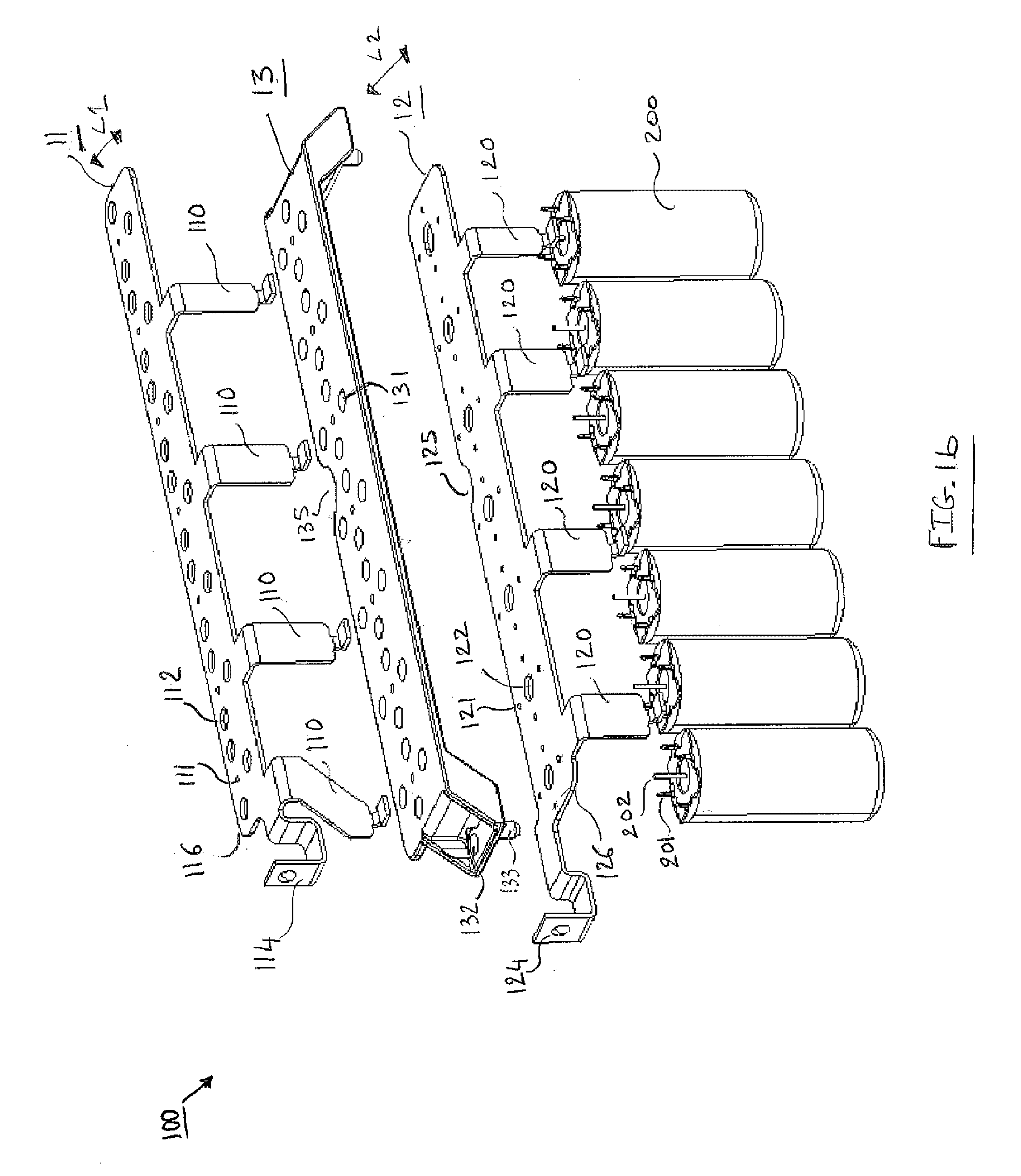

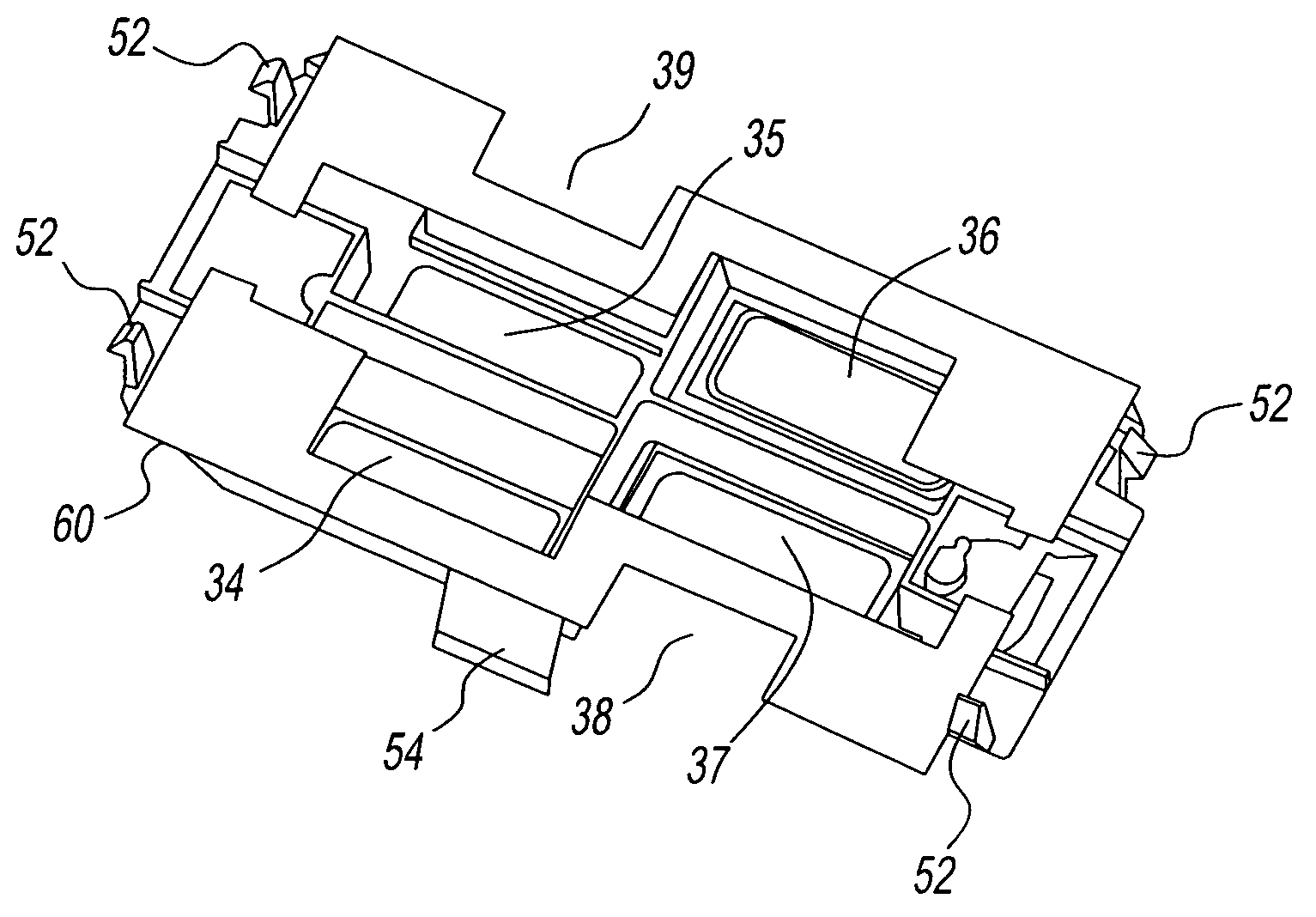

Device for assembling capacitors for an electronic converter

ActiveUS20140321090A1Reduce inductancePrinted circuit assemblingLine/current collector detailsGlass fiberPlastic materials

Owner:VALEO EQUIP ELECTRIC MOTEUR

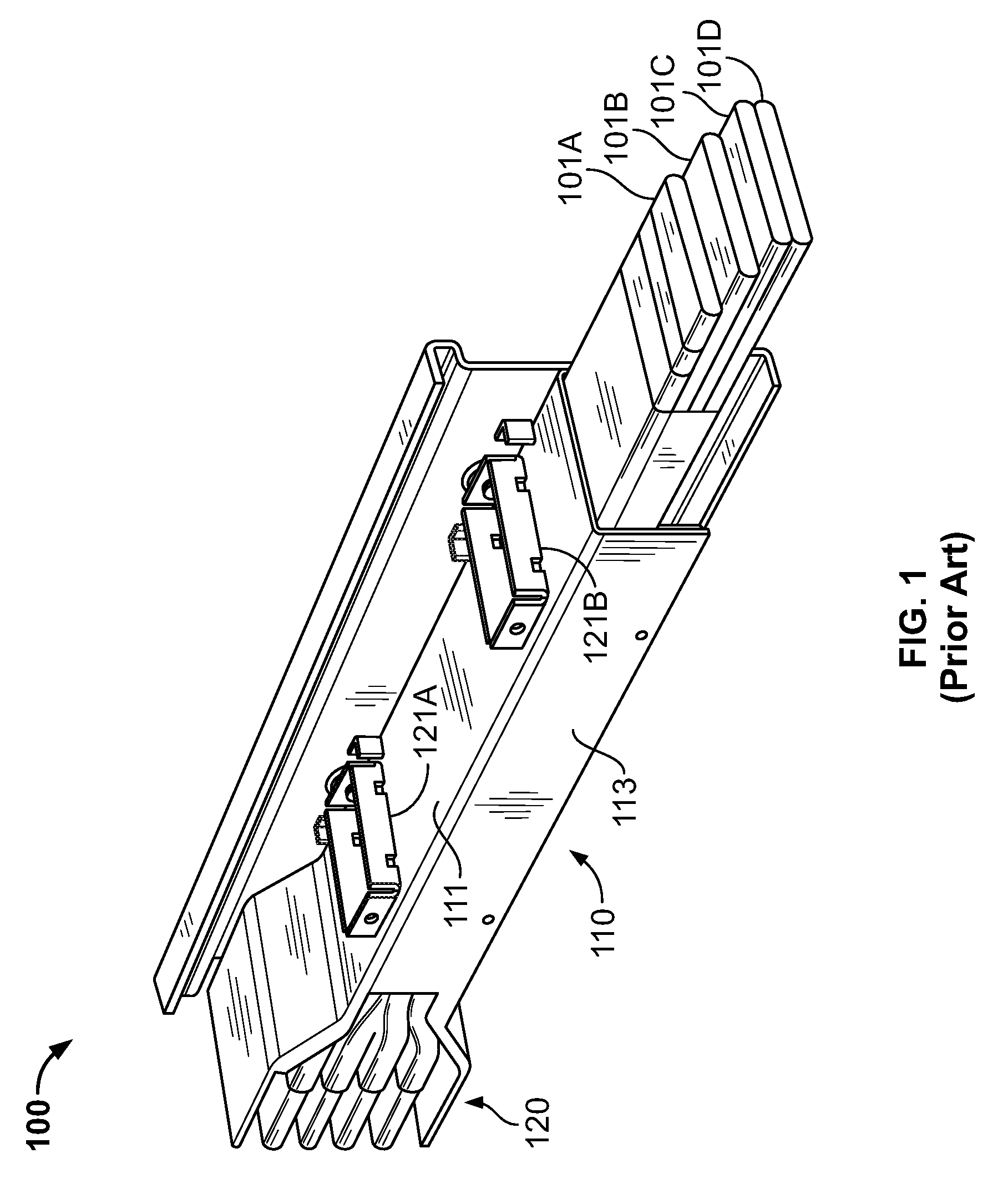

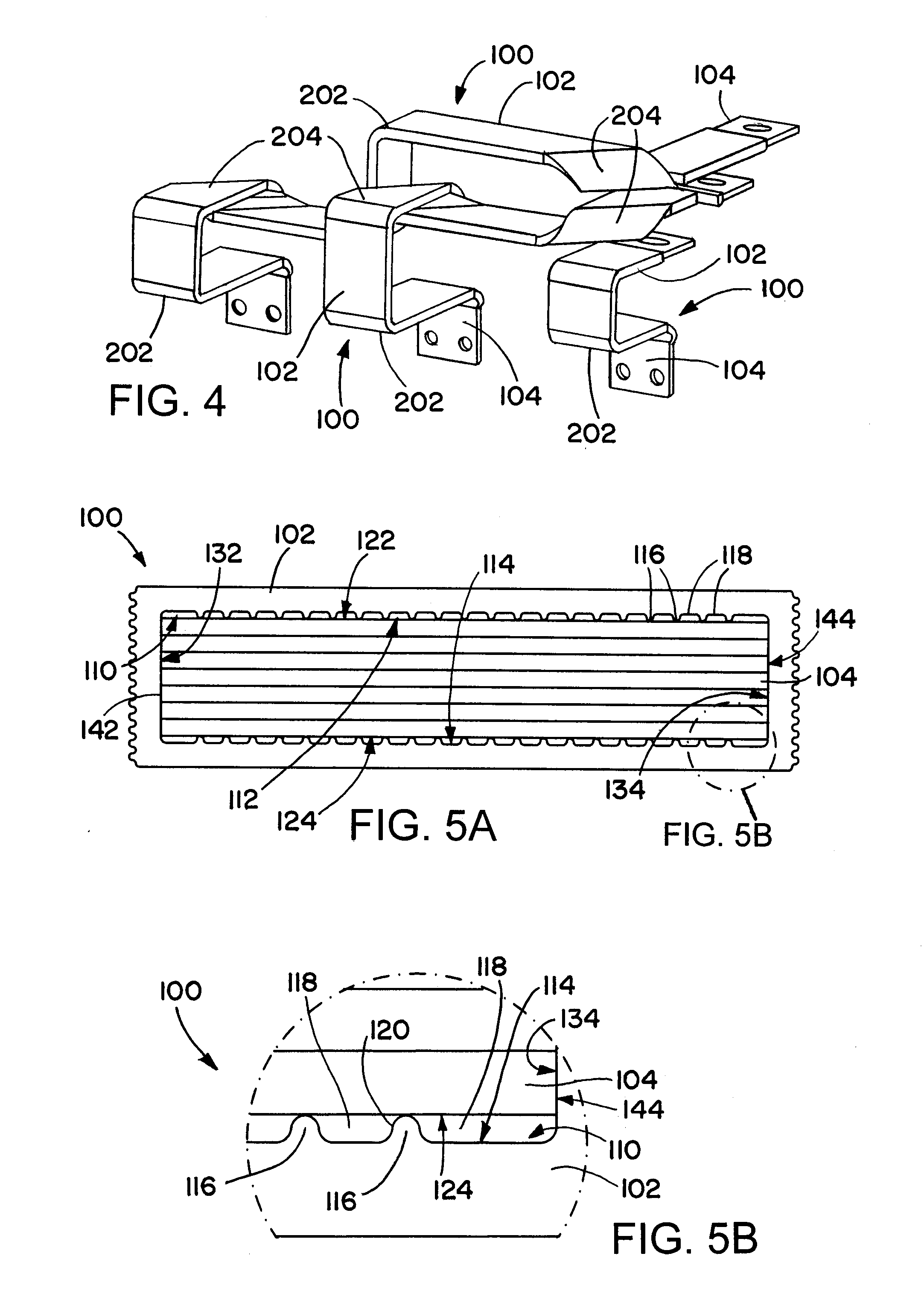

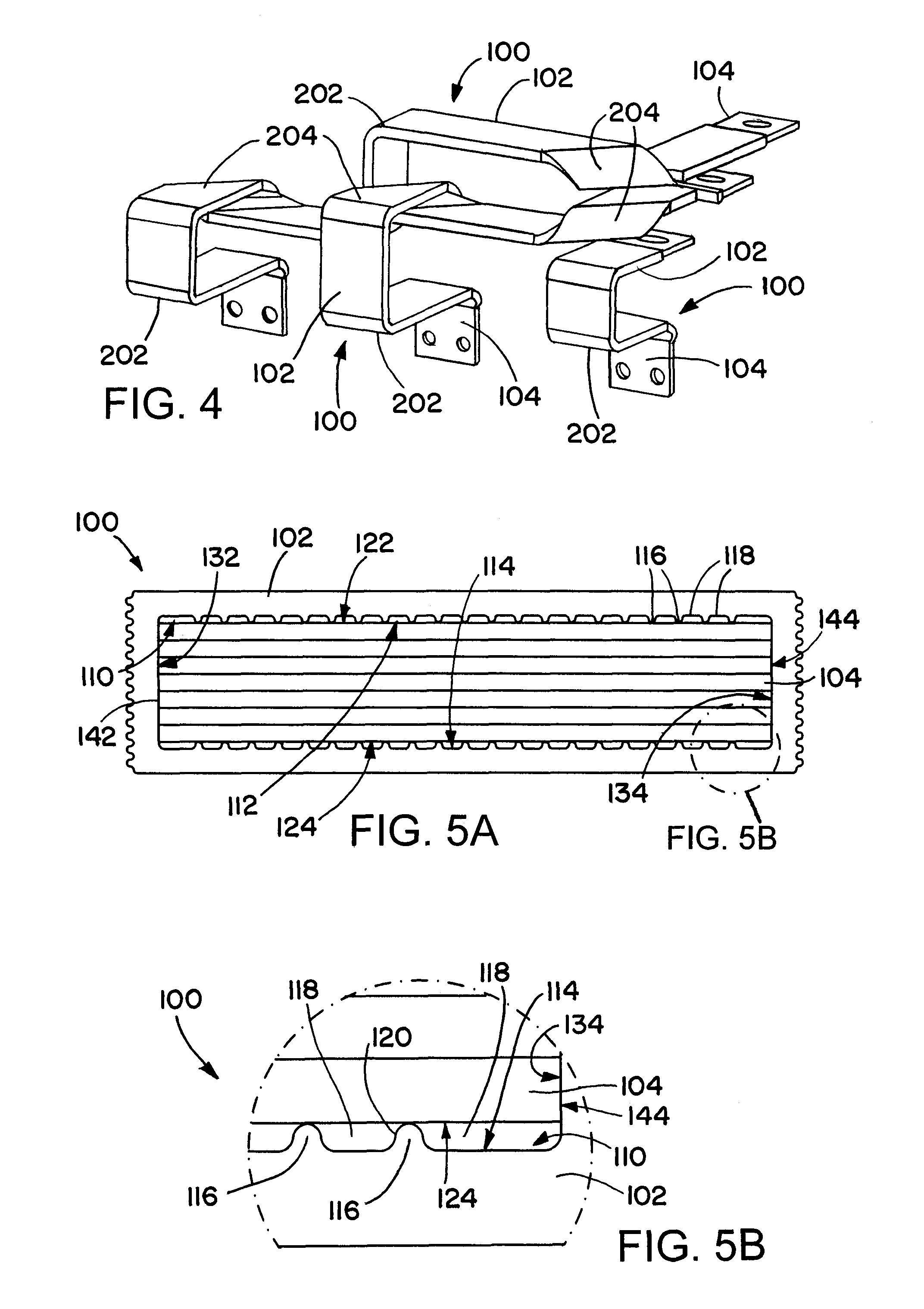

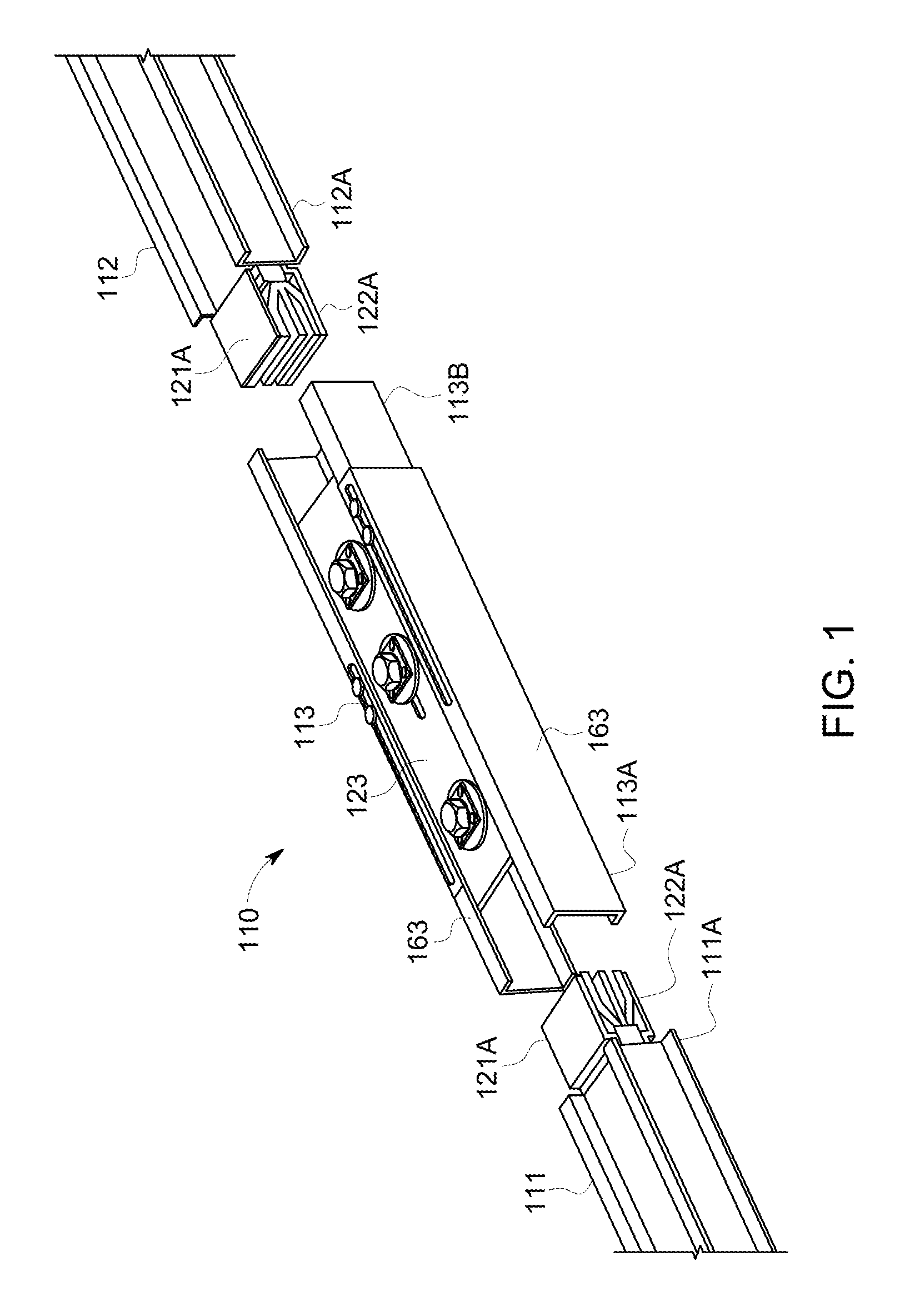

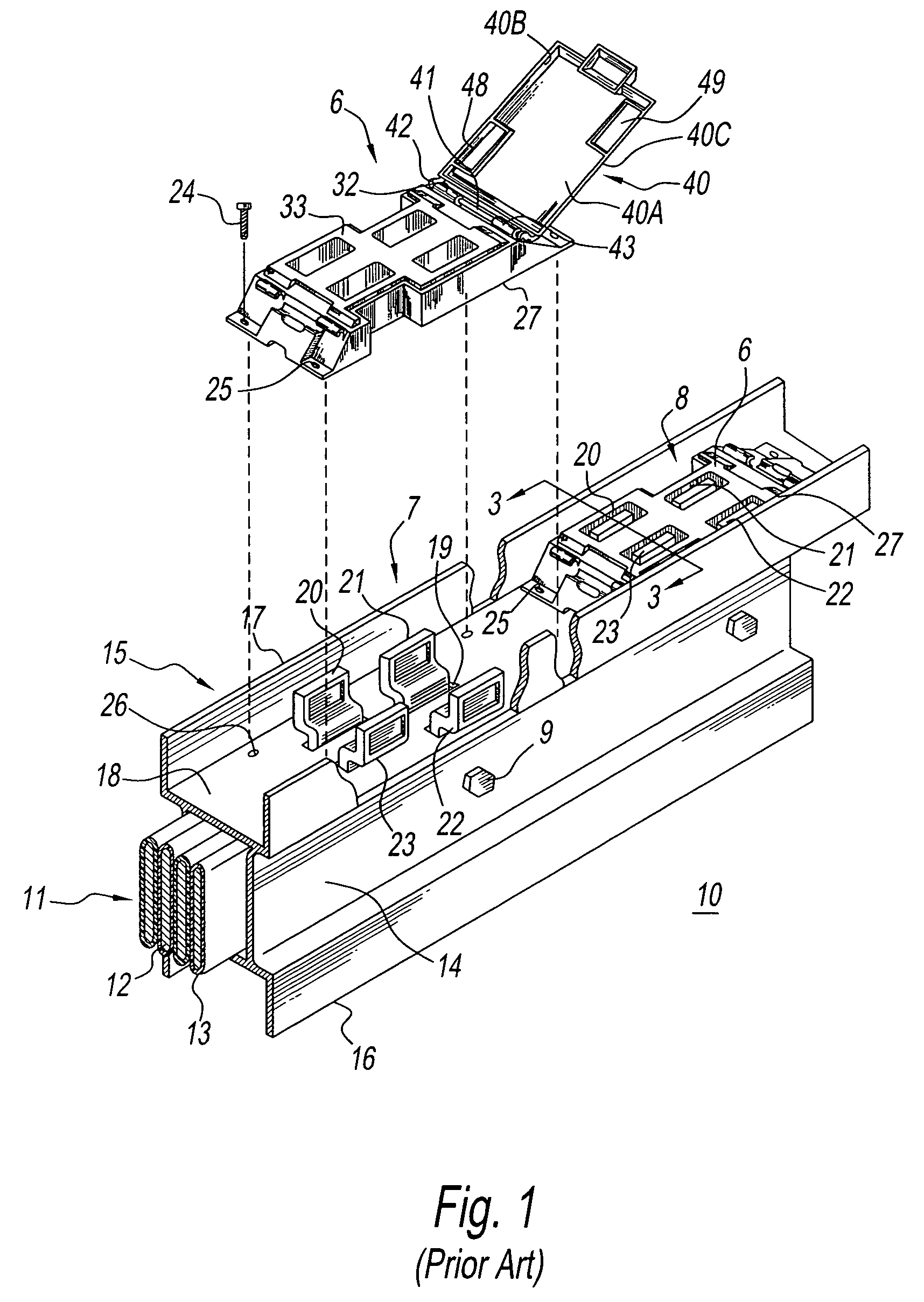

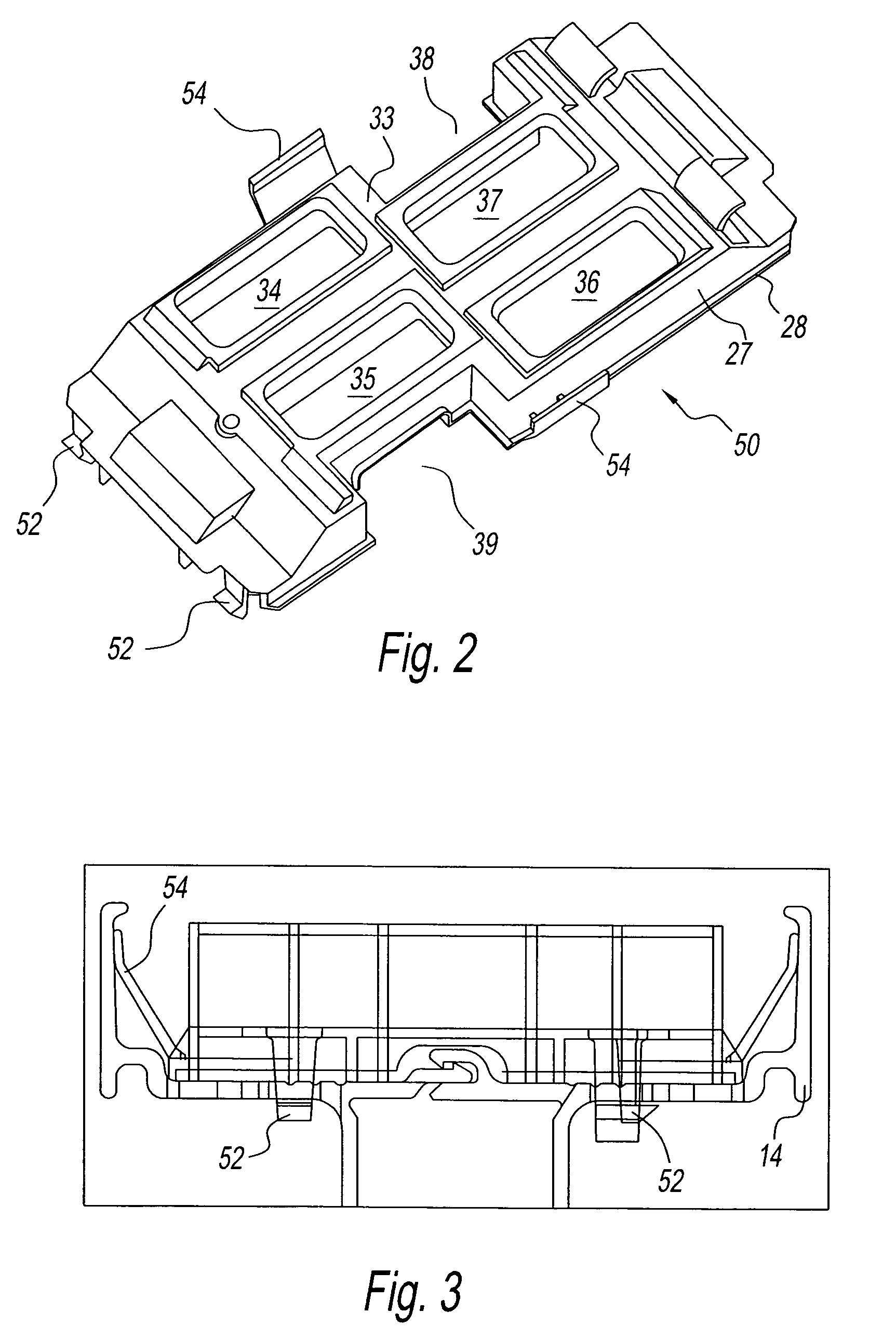

Busway fitting having a stacked bus bar with an extruded support

InactiveUS7091417B1Increase the lengthEliminate needBus-bar/wiring layoutsLaminated bus-barsMechanical engineeringEngineering

A busway fitting bus assembly for a busway fitting, wherein the busway fitting has a housing assembly defining an enclosed space, the housing assembly having a top end, a bottom end, and a sidewall, the sidewall having a side opening, at least one tap bus extending between the side opening and the enclosed space. The busway fitting bus assembly includes a plurality of elongated, main bus members, the main bus members structured to extend the length between the busway fitting housing assembly bottom end and the busway fitting housing assembly top end, and a support assembly having an extruded body structured to enclose and support the plurality of main bus members.

Owner:EATON CORP

Laminated bus bars and methods of manufacture thereof

A method of assembling a multilayer bus bar assembly includes coating a dielectric layer with a molten reactive hot-melt adhesive, placing the dielectric layer between first and second subassemblies, wherein the first and second subassemblies comprise a conductive element, adhering the molten reactive hot-melt adhesive to the subassemblies by applying a pressure of at least about one bar to the multilayer bus bar assembly for at least about one minute prior to the adhesive cooling to room temperature to provide a bonding strength between the dielectric material and a selected one of the first and second subassemblies of at least 1500 Newtons on a 25 millimeter by 25 millimeter sample when tested in accordance with ASTM D-1062.

Owner:ROGERS COMMUNICATIONS

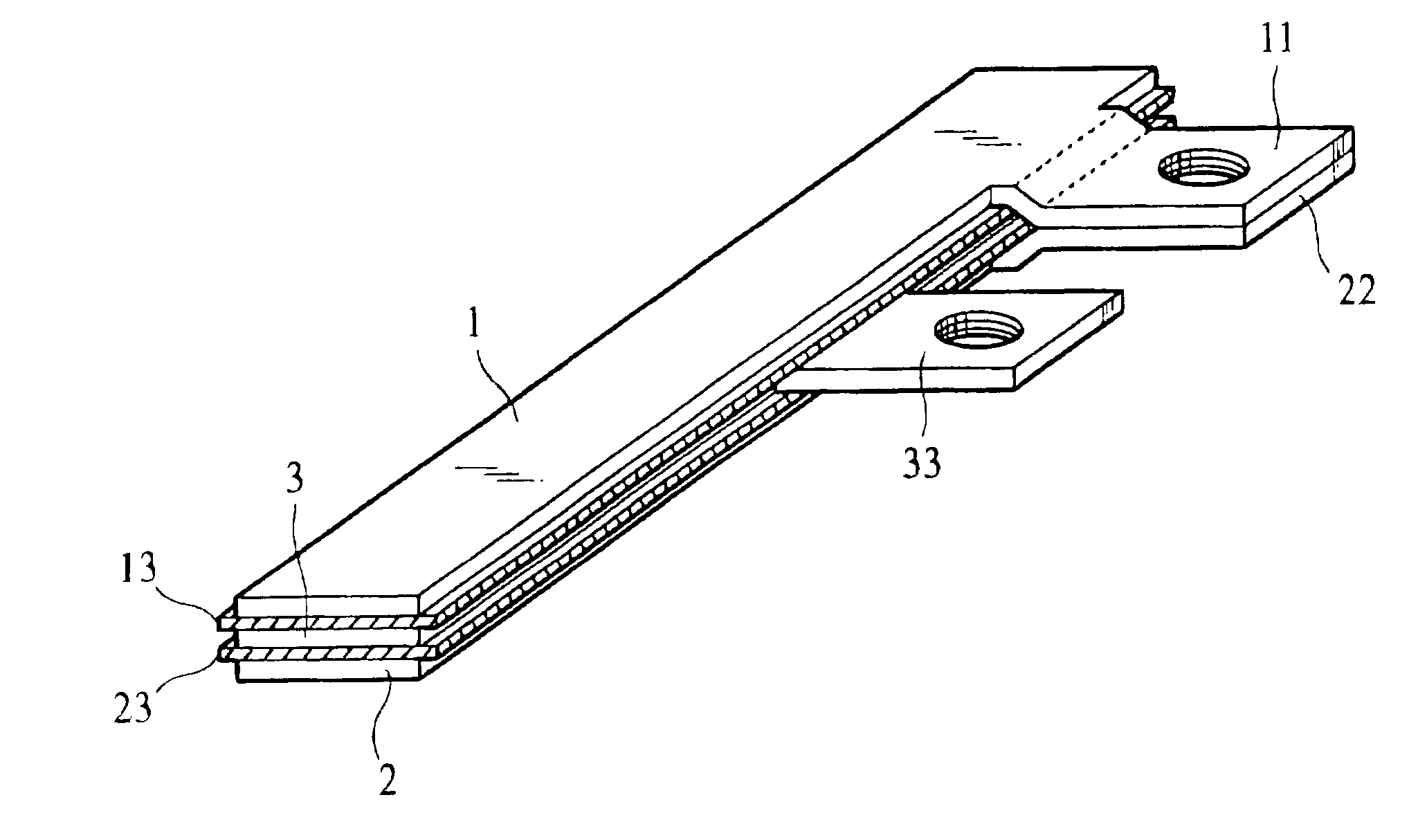

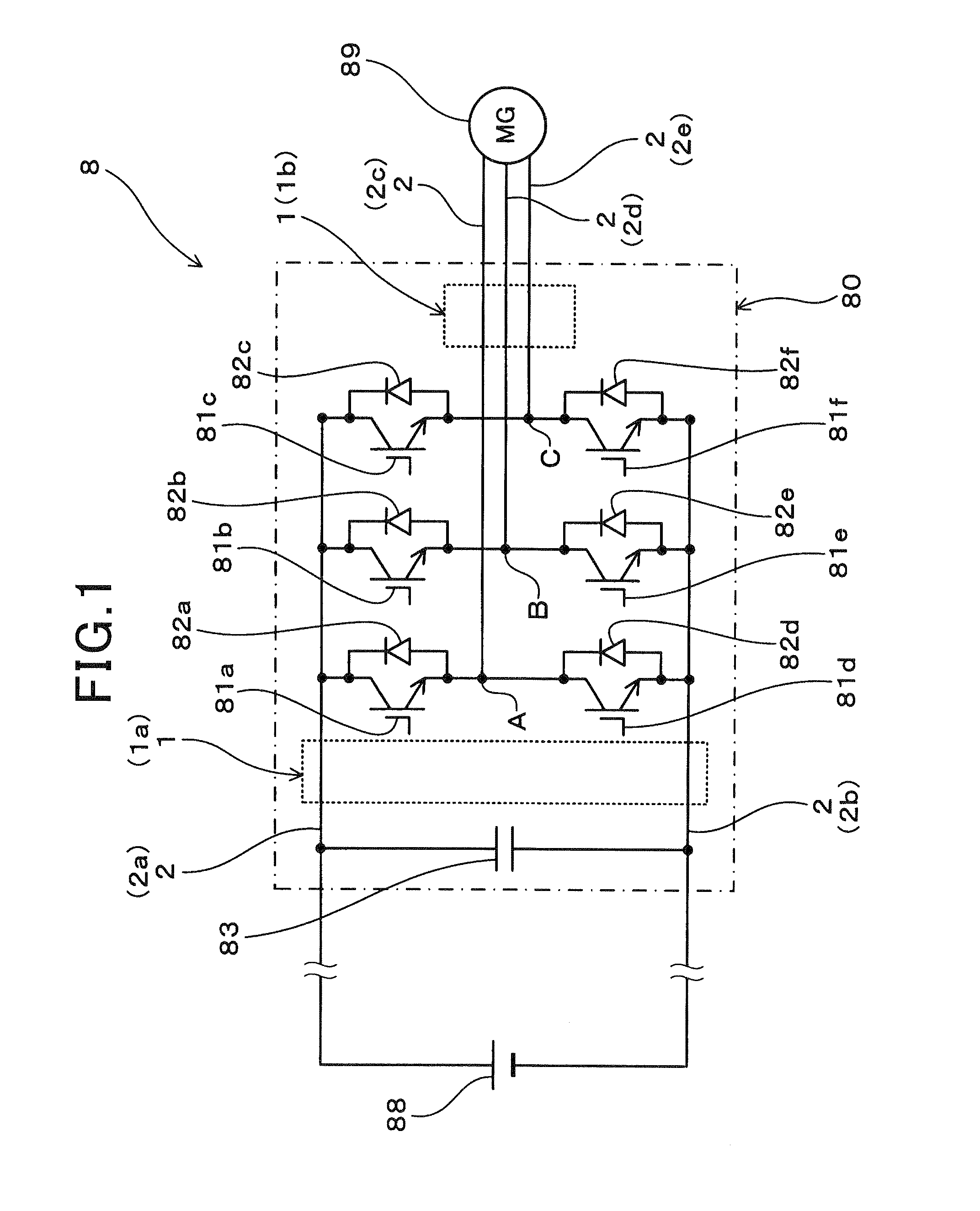

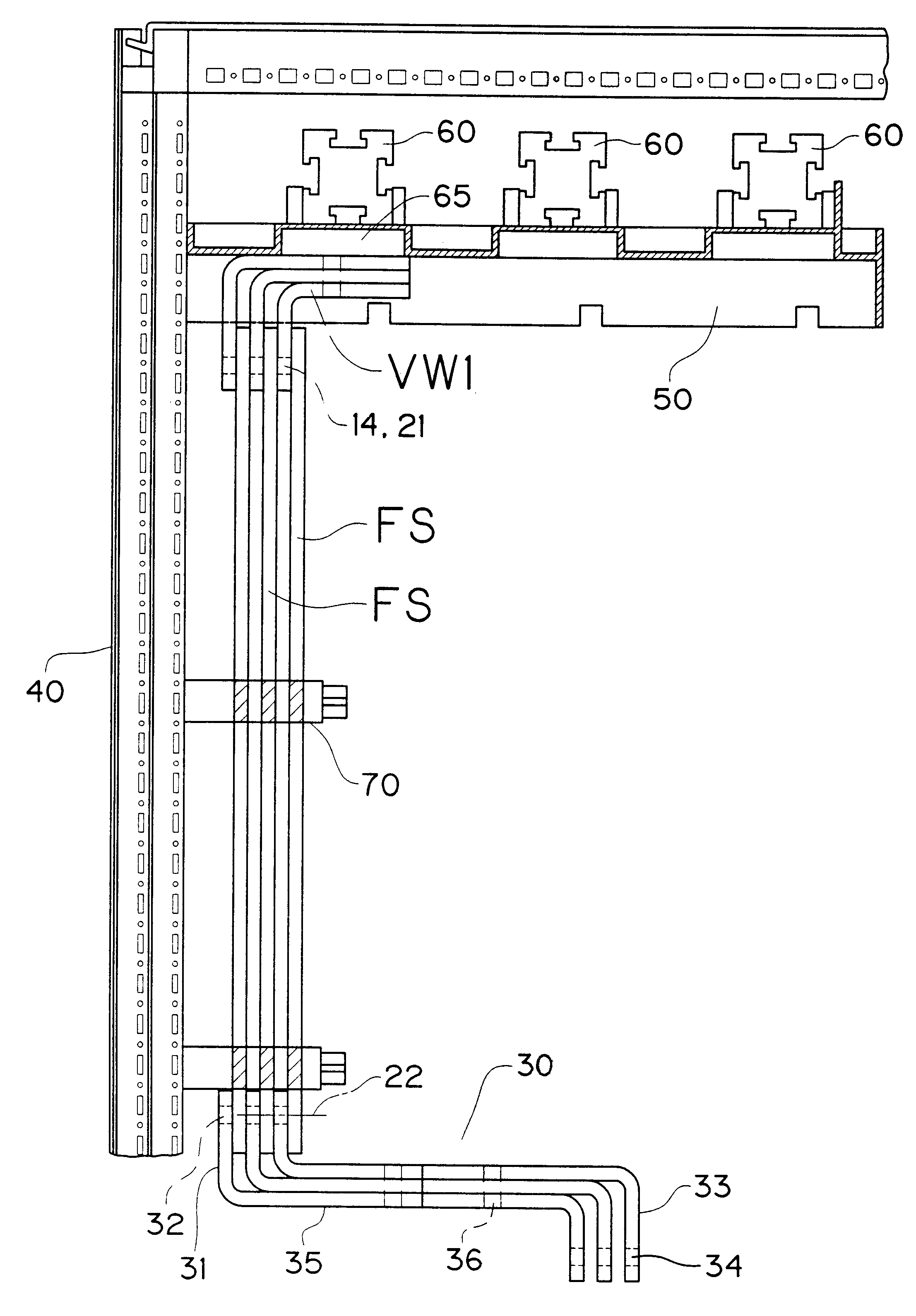

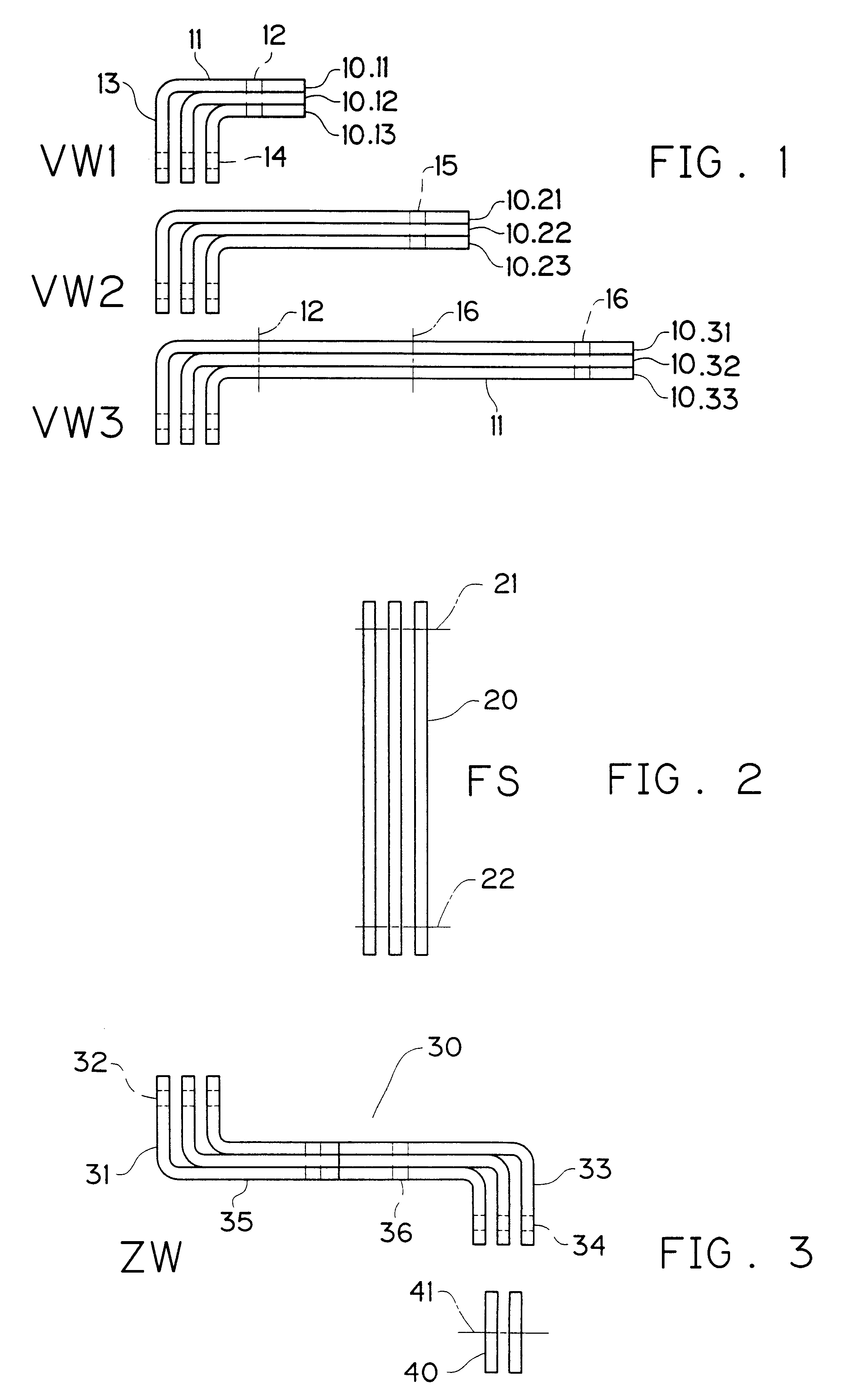

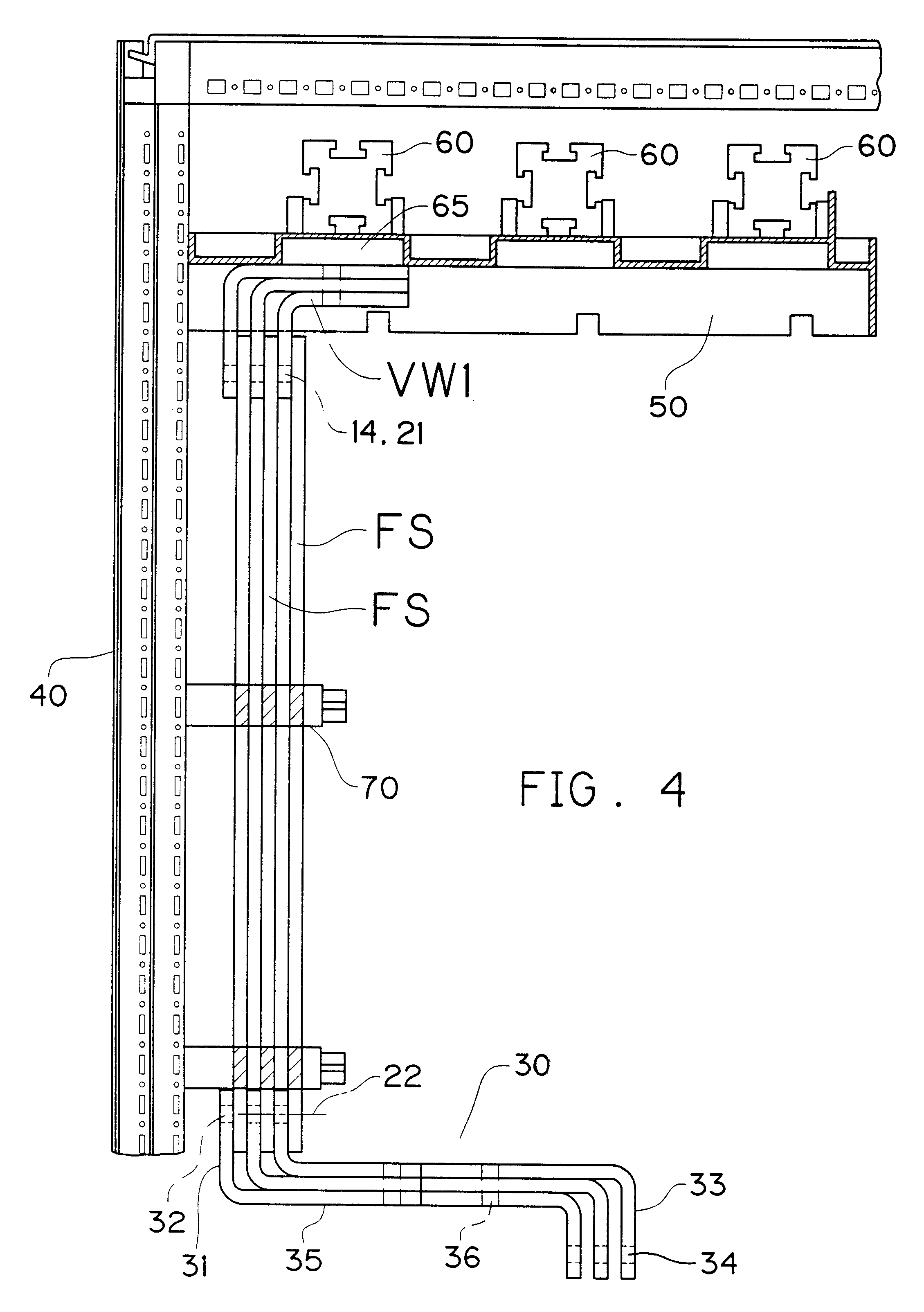

Distribution line structure for electric power supply

ActiveUS7102256B2Increase production capacityBus-bar/wiring layoutsSingle bars/rods/wires/strips conductorsElectrical conductorLine structure

A distribution line structure for electric power supply is provided with a pair of first conductors and a second conductor. Each of the first conductors is provided with a first main portion formed in a flat strip shape and first connection portions, and the second conductor is provided with a second main portion formed in a flat strip shape and second connection portions. The first conductors are connected with each other at the first connection portions. The first and second main portions are layered and separated each other by insulators. The second main portion is put between the first main portions.

Owner:NISSAN MOTOR CO LTD

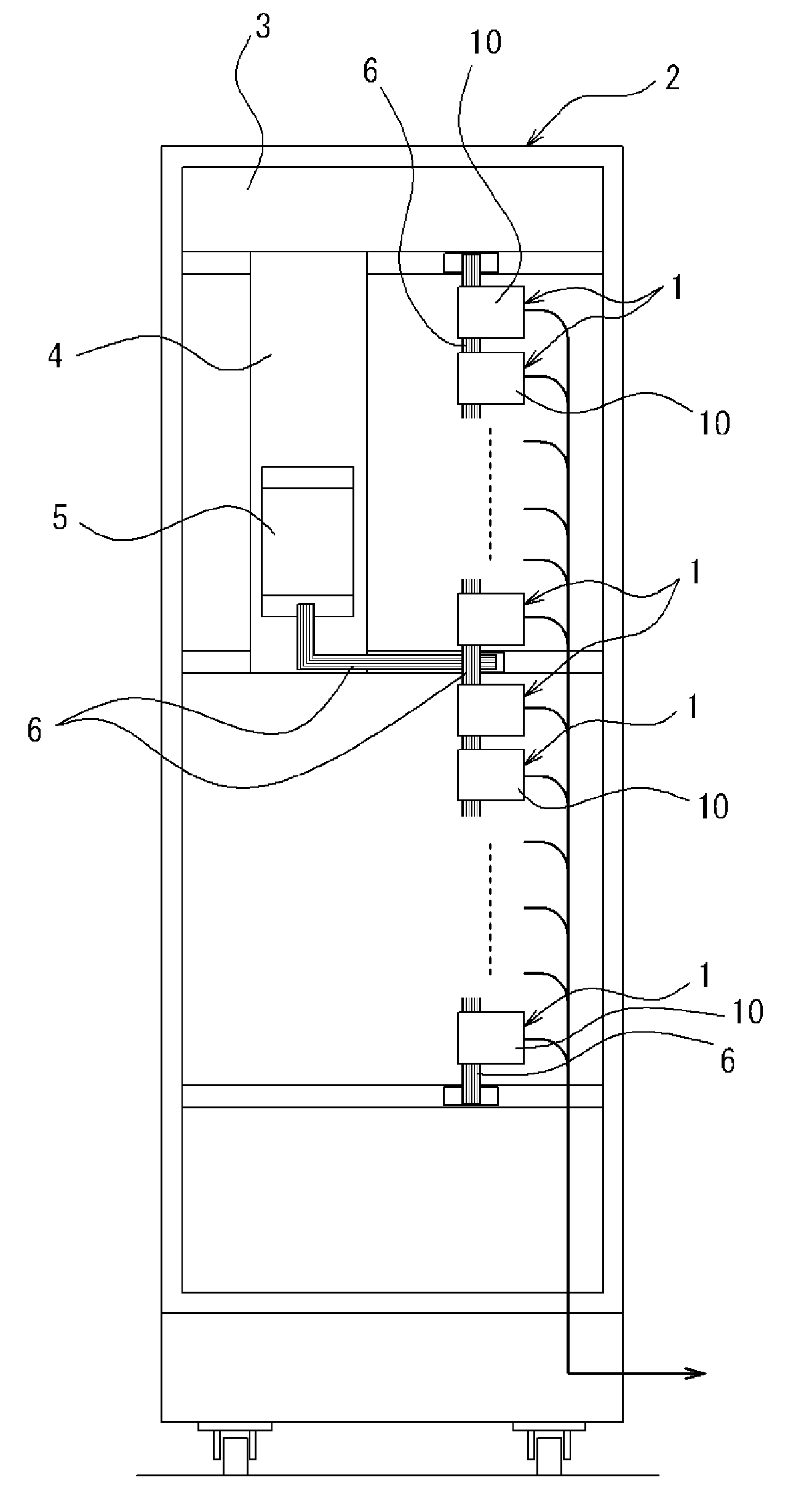

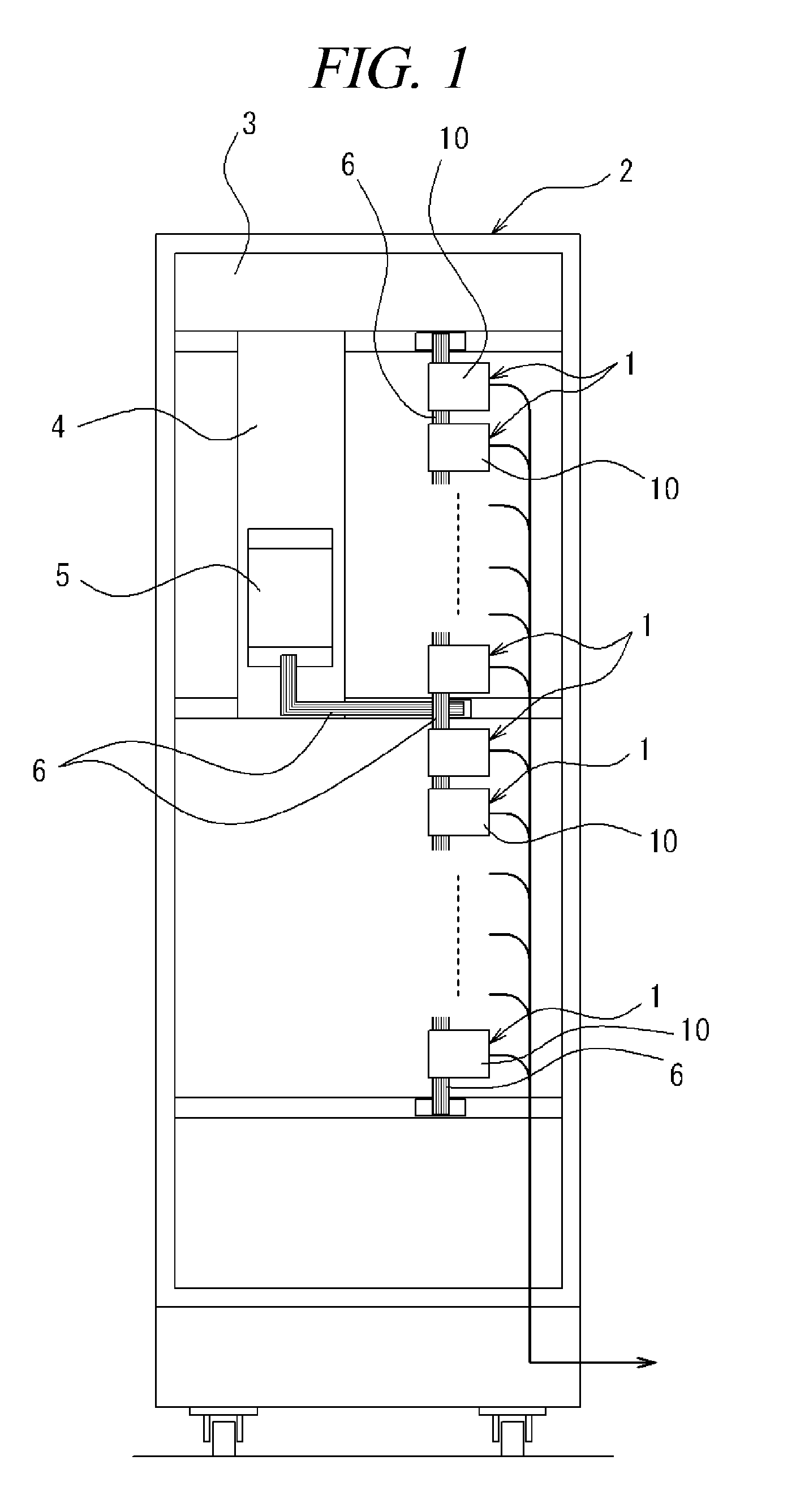

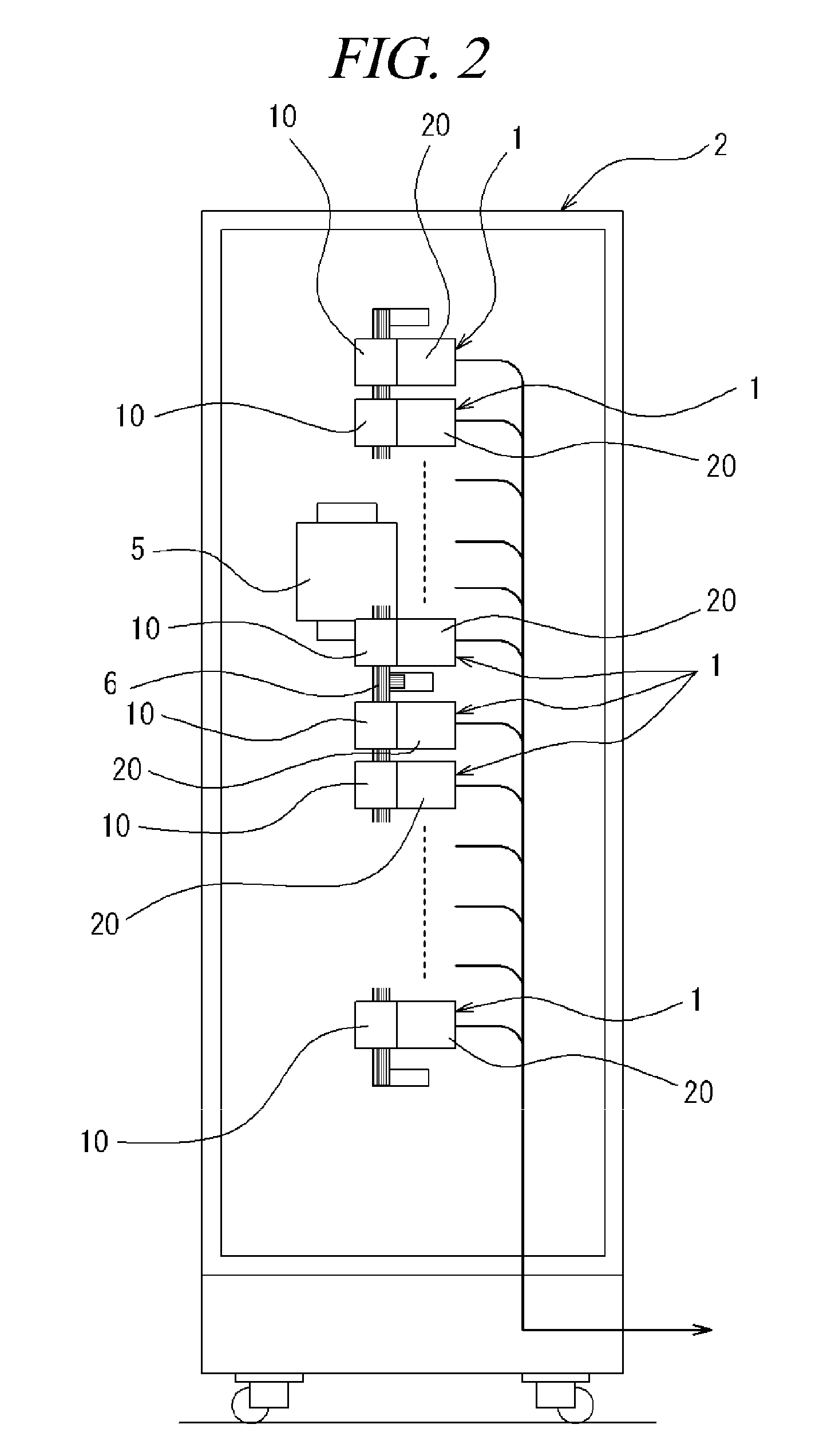

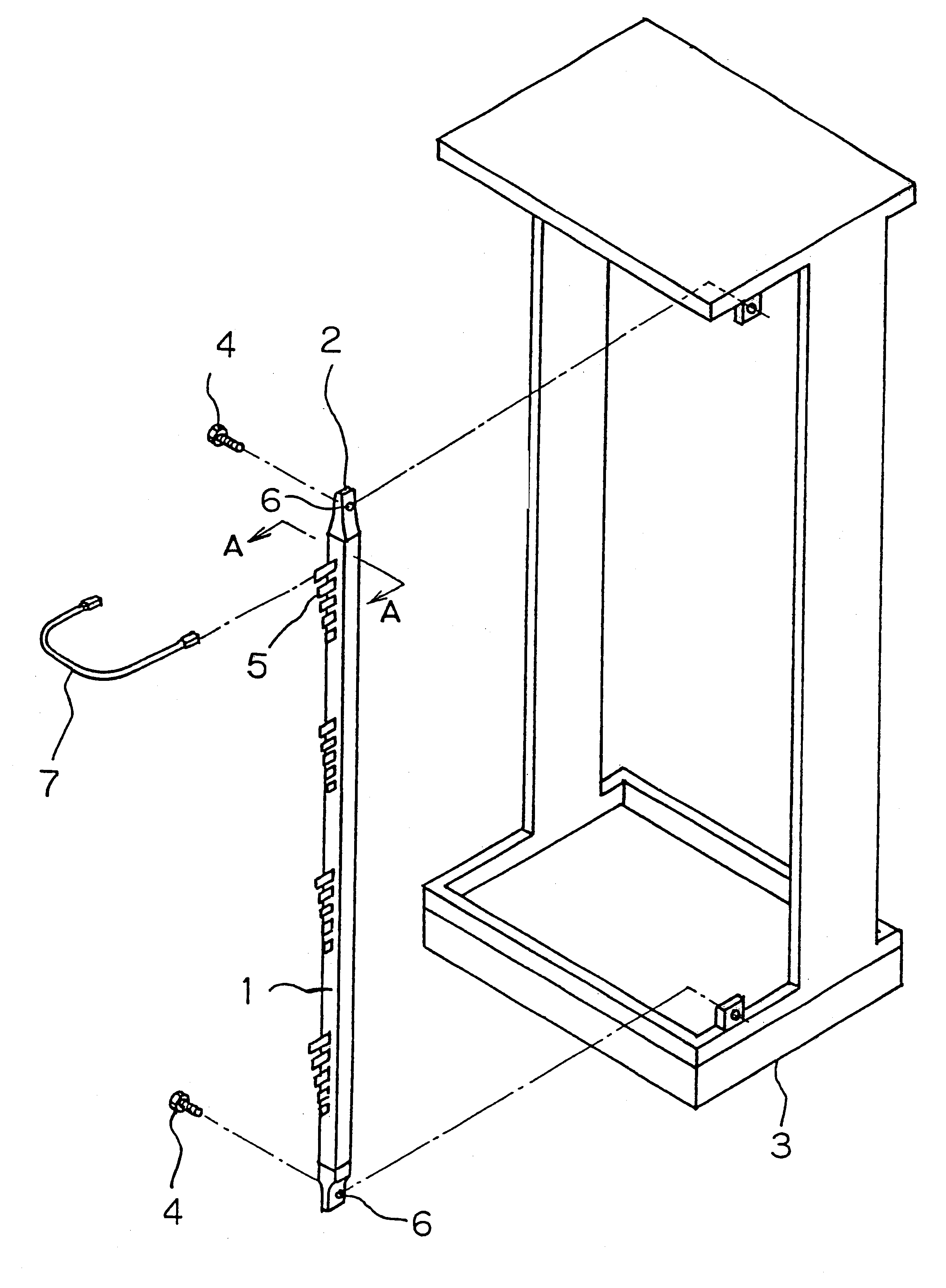

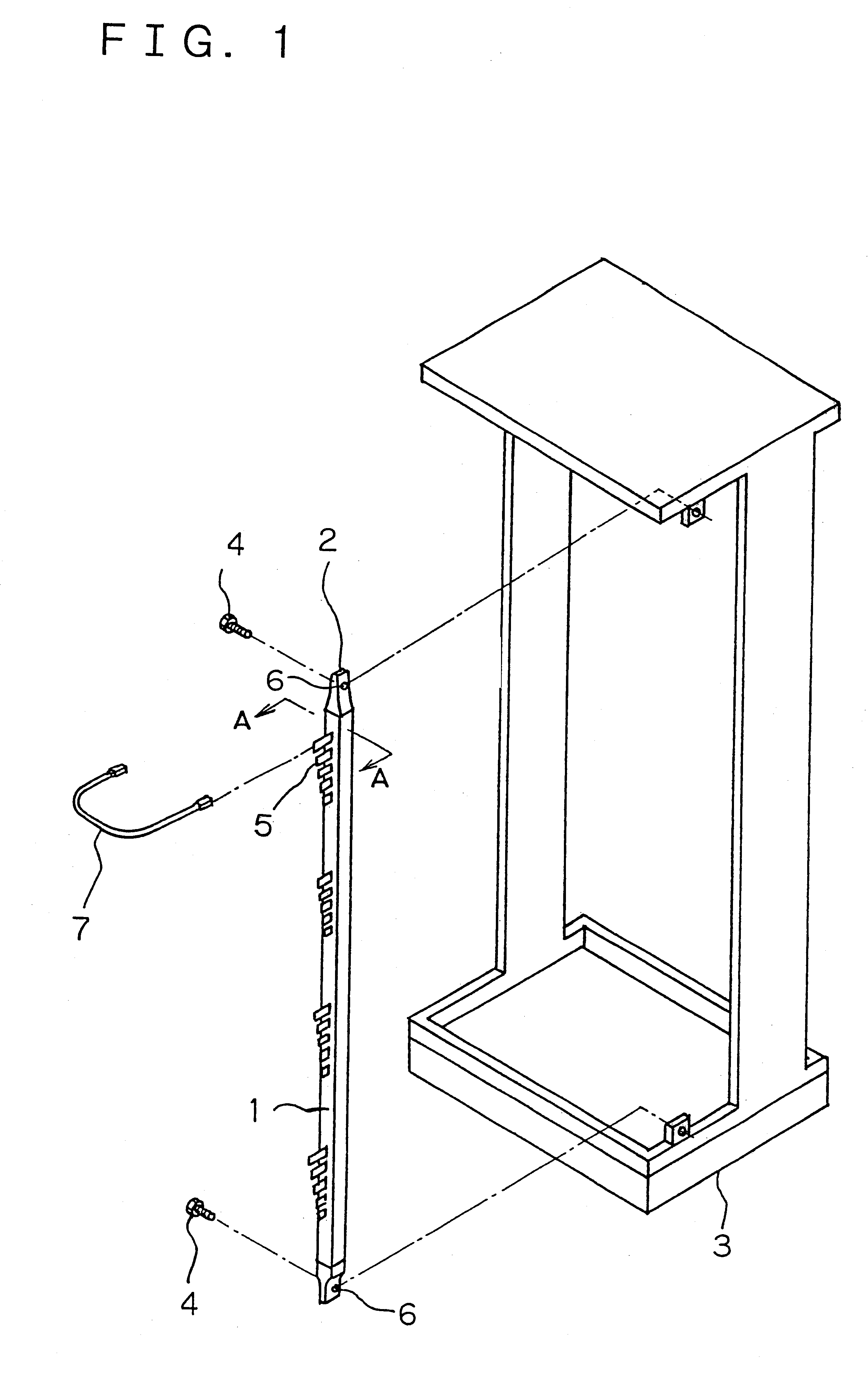

Plug-in unit

ActiveUS20100128417A1Expand the number of processesComplicates installationBus-bar/wiring layoutsElectrically conductive connectionsBusbarJoint surface

A plug-in unit includes a breaker electrically connected with a busbar at a power supply side and an electric device electrically connected with the breaker. Joint surfaces making contact with each other are formed at the breaker and the electric device, respectively. The breaker includes a terminal metal fitting connecting the busbar thereto and a plug-in terminal metal fitting installed at the joint surface of the breaker, and the electric device includes a plug terminal, which is installed at the joint surface thereof and capable of being connected with the plug-in terminal metal fitting. The breaker is detachably joined with the electric device by an engaging member including an engaging unit and an engagement receiving unit. The engaging unit and the engagement receiving unit are installed at the joint surfaces of the breaker and the electric device, respectively, and detachably engaged with each other.

Owner:TOKYO ELECTRON LTD

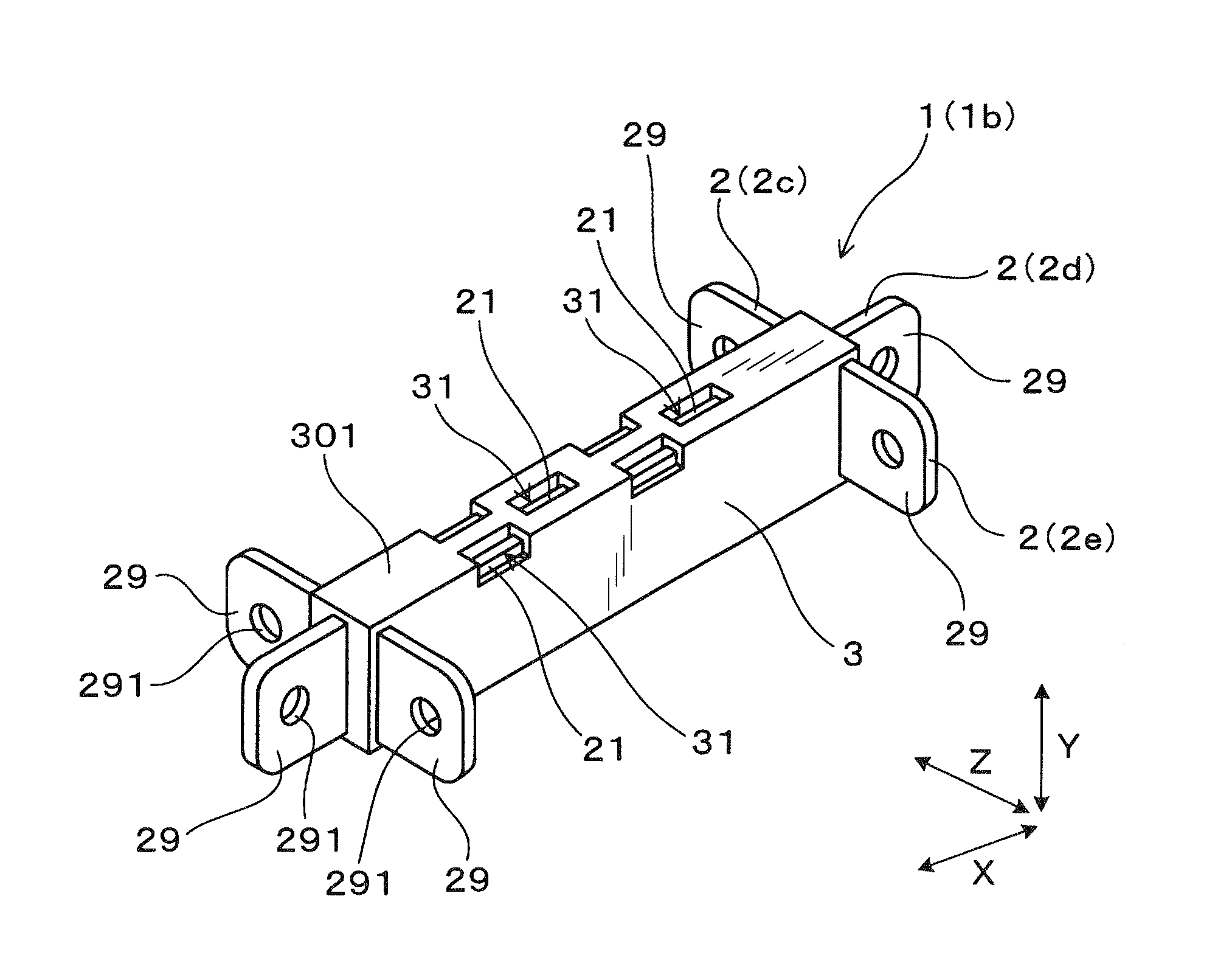

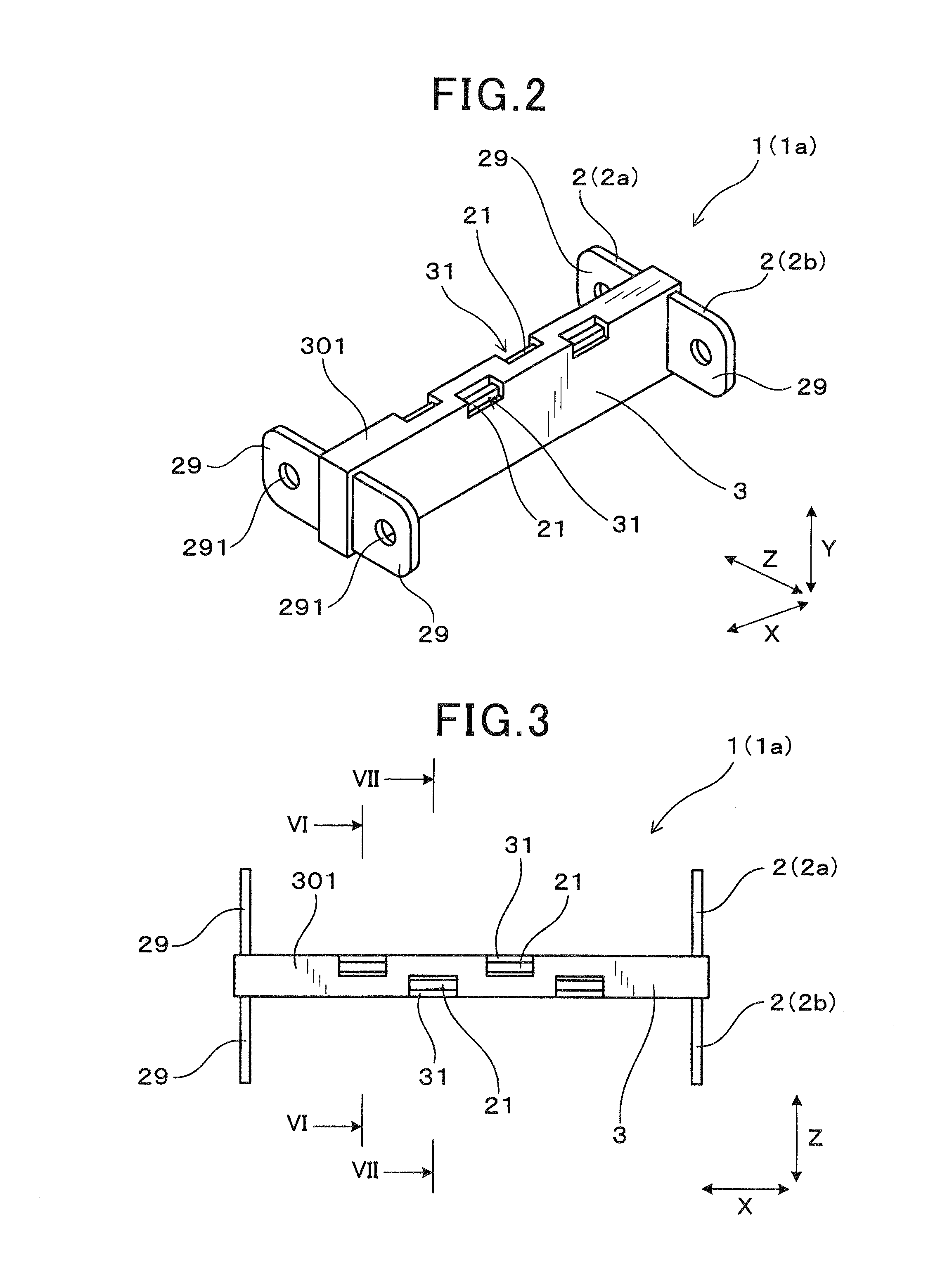

Bus bar assembly and method of manufacturing the same

ActiveUS20140116751A1Precise positioningHelp positioningSingle bars/rods/wires/strips conductorsConversion constructional detailsEngineeringMechanical engineering

A bus bar assembly comprises a plurality of conductive plate-shaped bus bars and a resin mold section in which a plurality of conductive plate-shaped bus bars are partially embedded. In a method for manufacturing the bus bar assembly, firstly a plurality of conductive plate-shaped bus bars are disposed within a cavity formed by a die such as to be stacked in a thickness direction Z with a predetermined amount of space therebetween. Second, a first end and a second end of each bus bar are respectively supported by jigs in the width direction Y. Next, the cavity in the die is filled with the insulating resin and the plurality of bus bars are molded into a single body. After that, jigs are removed from the bus bars and jig placement portions are formed in the resin mold section.

Owner:DENSO CORP

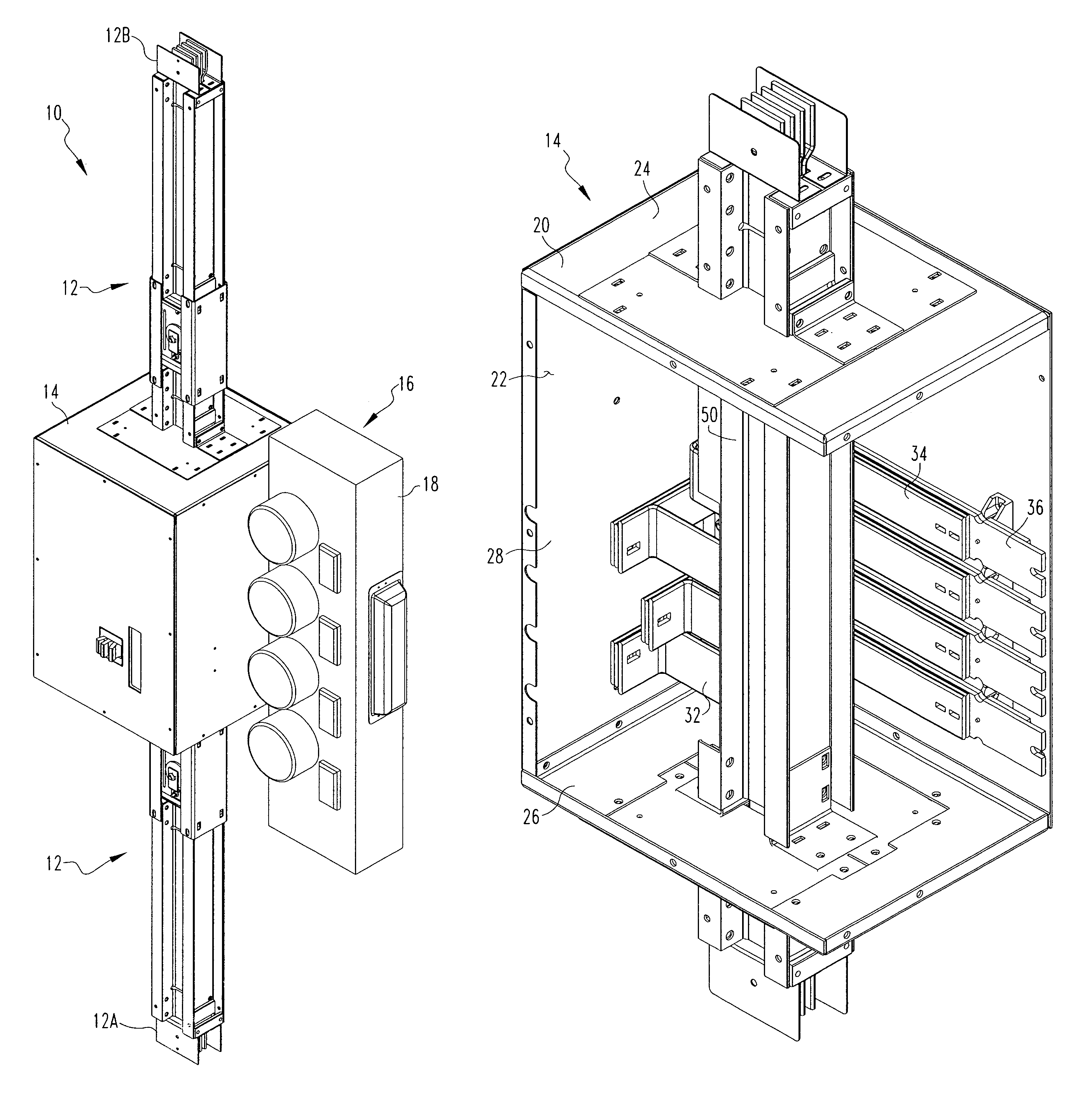

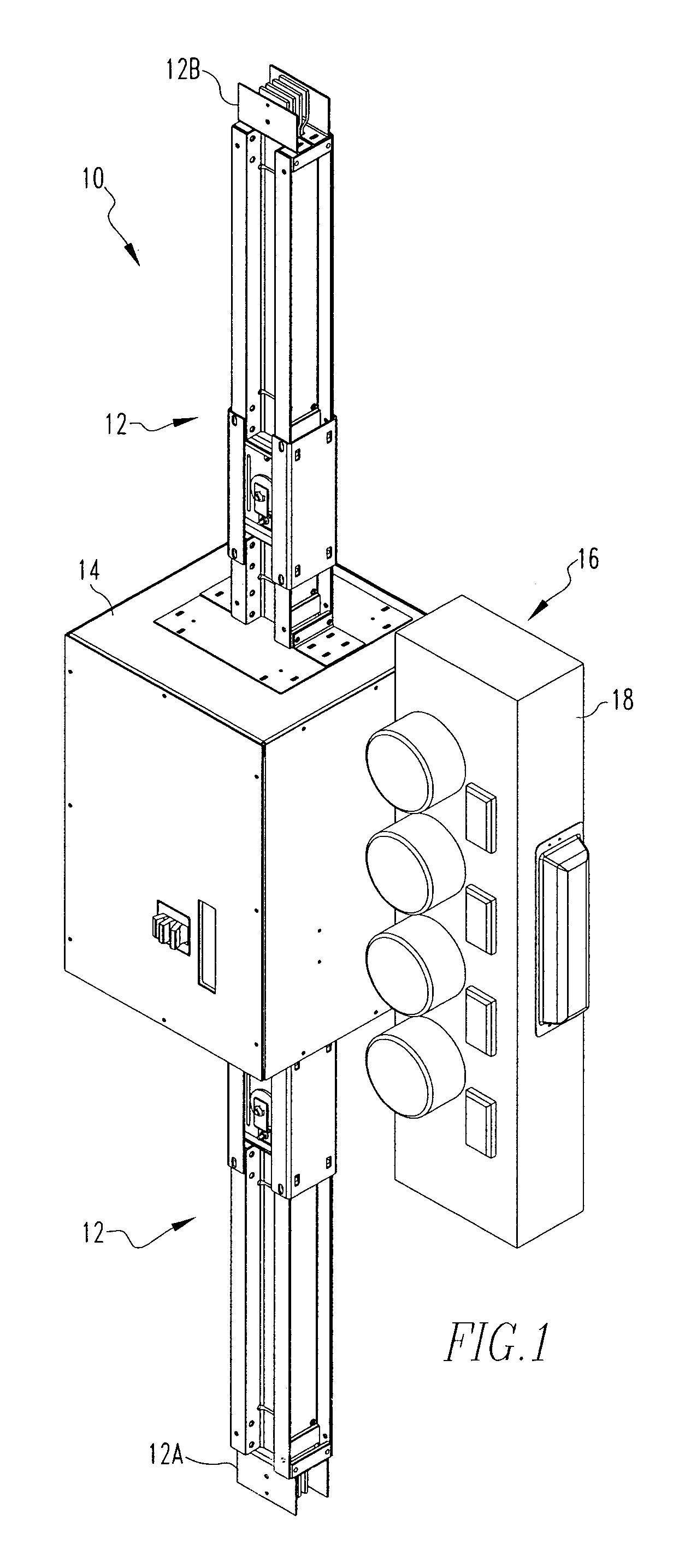

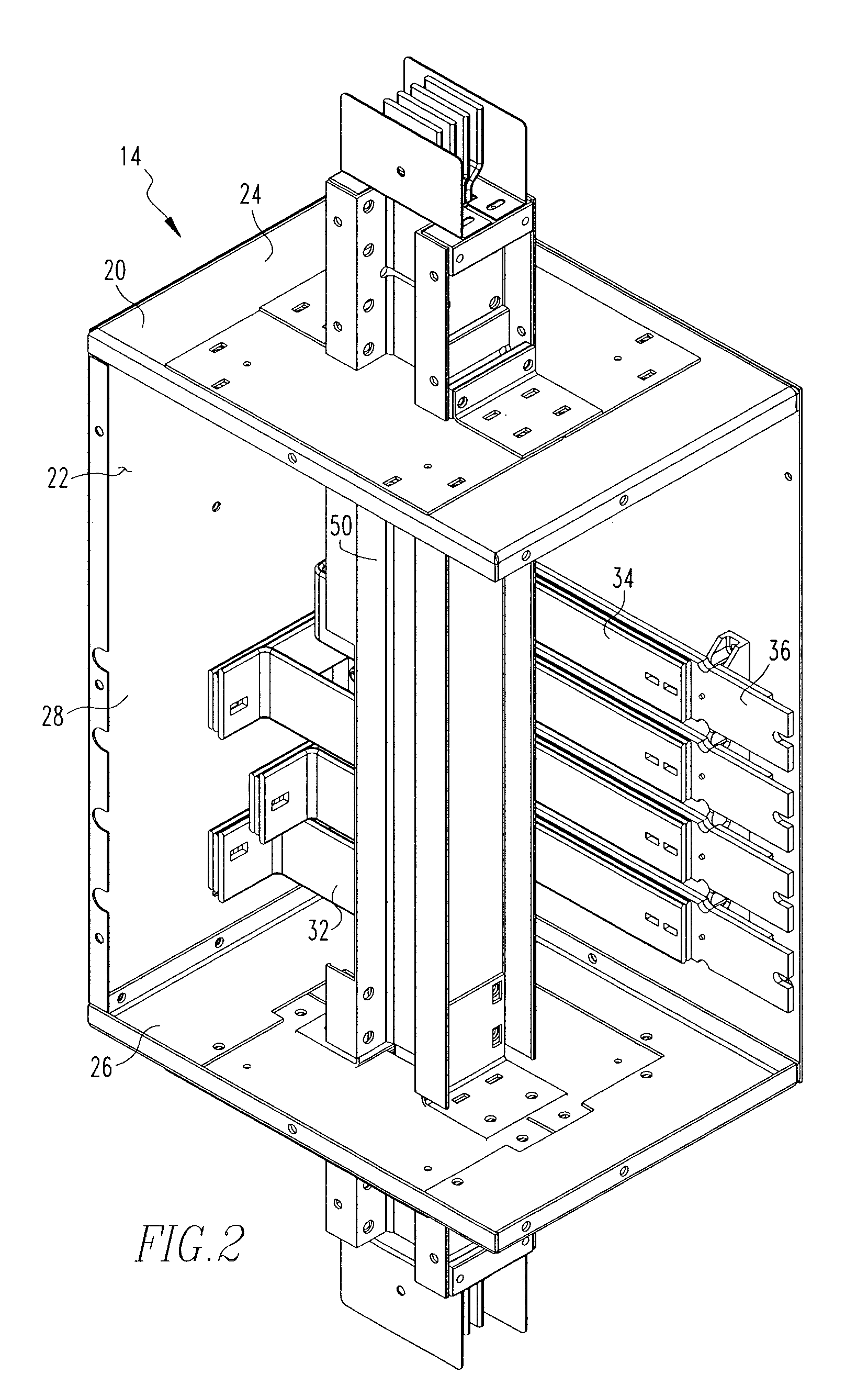

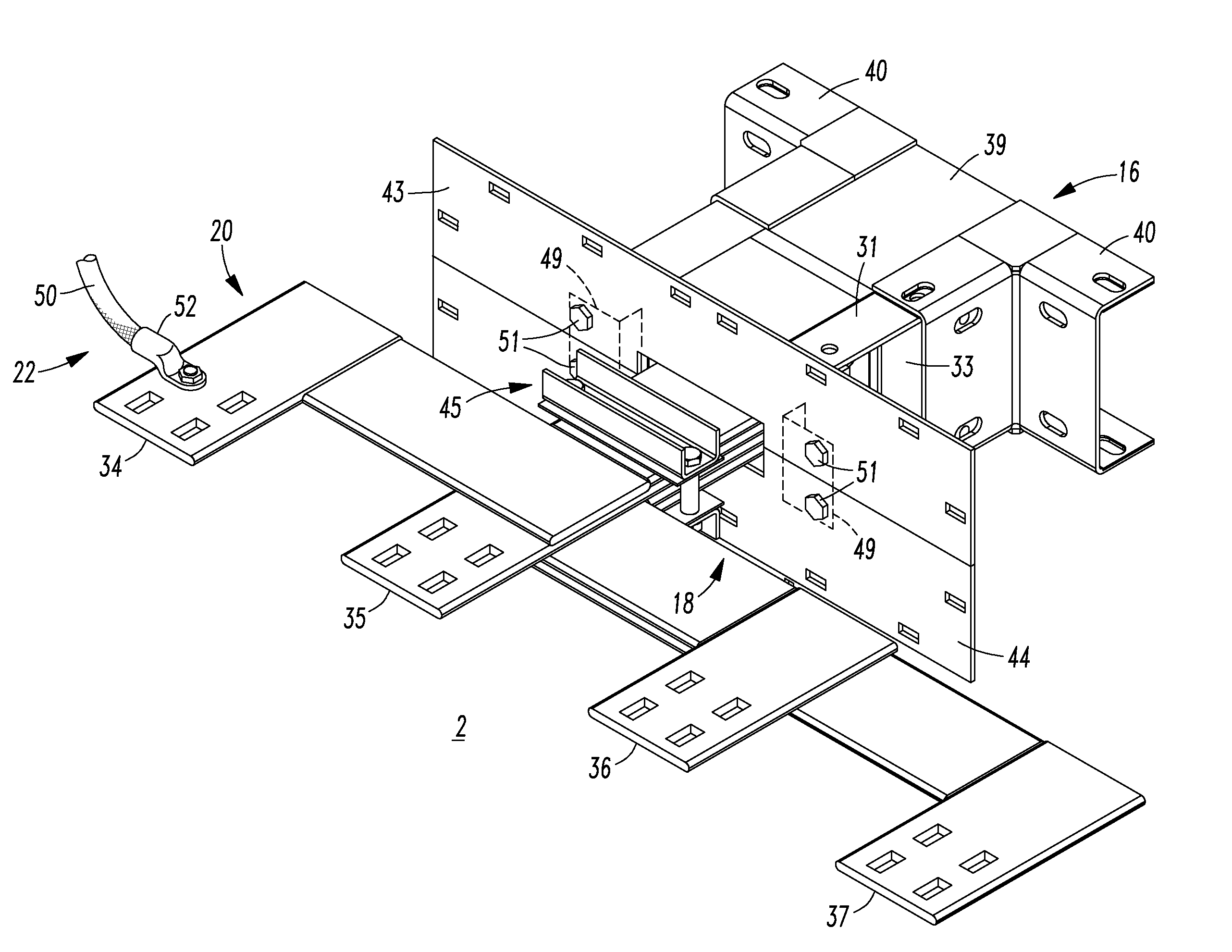

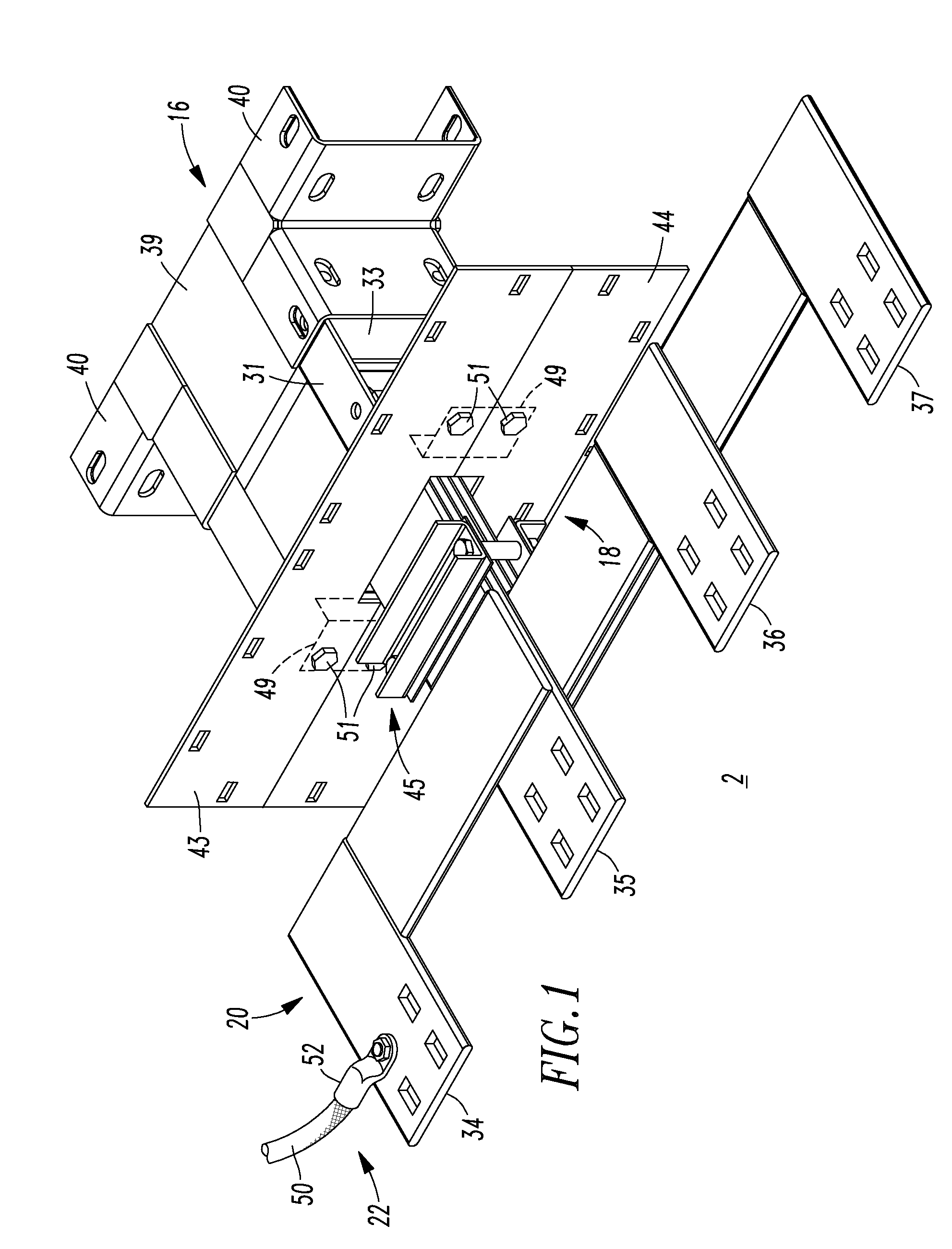

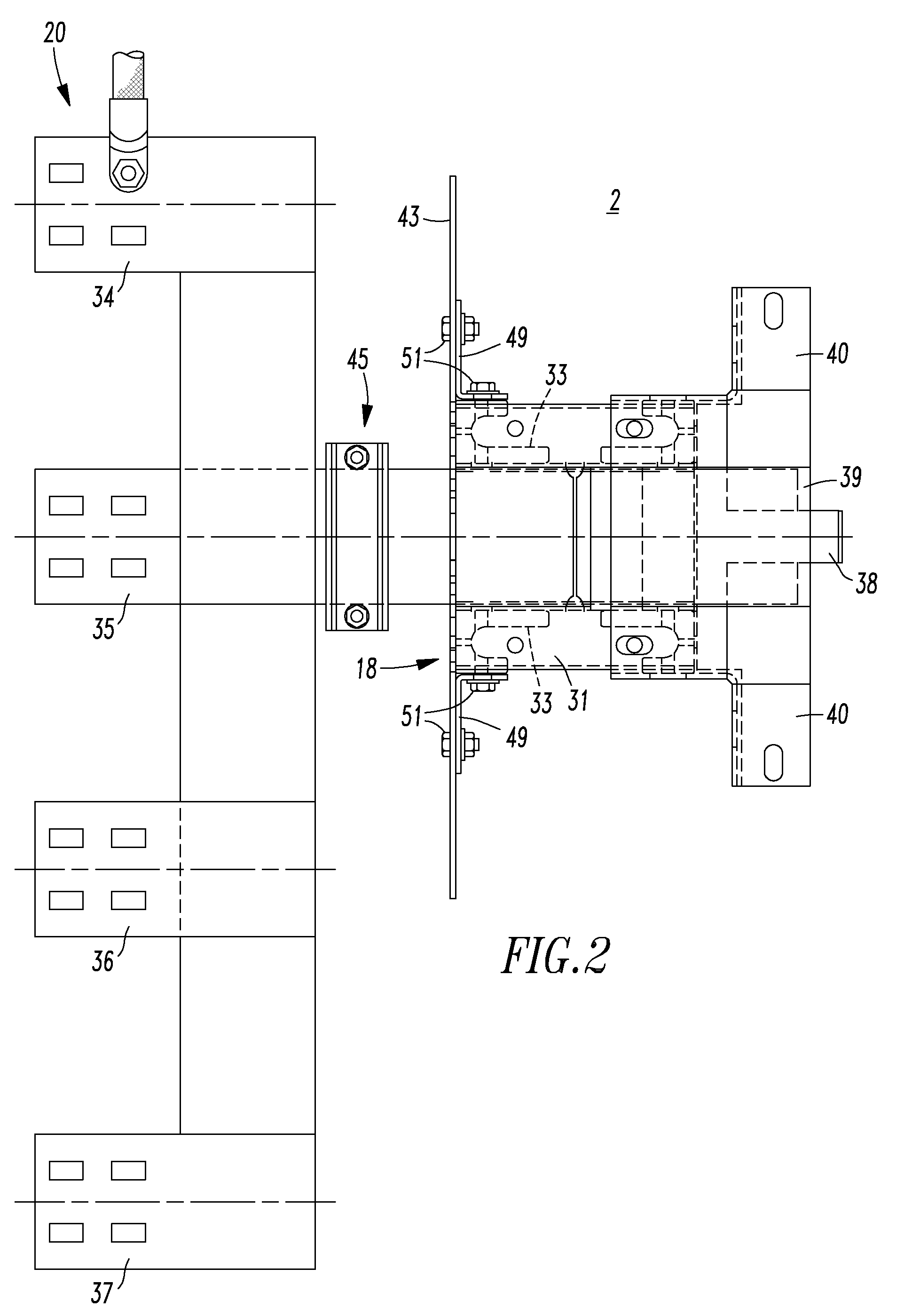

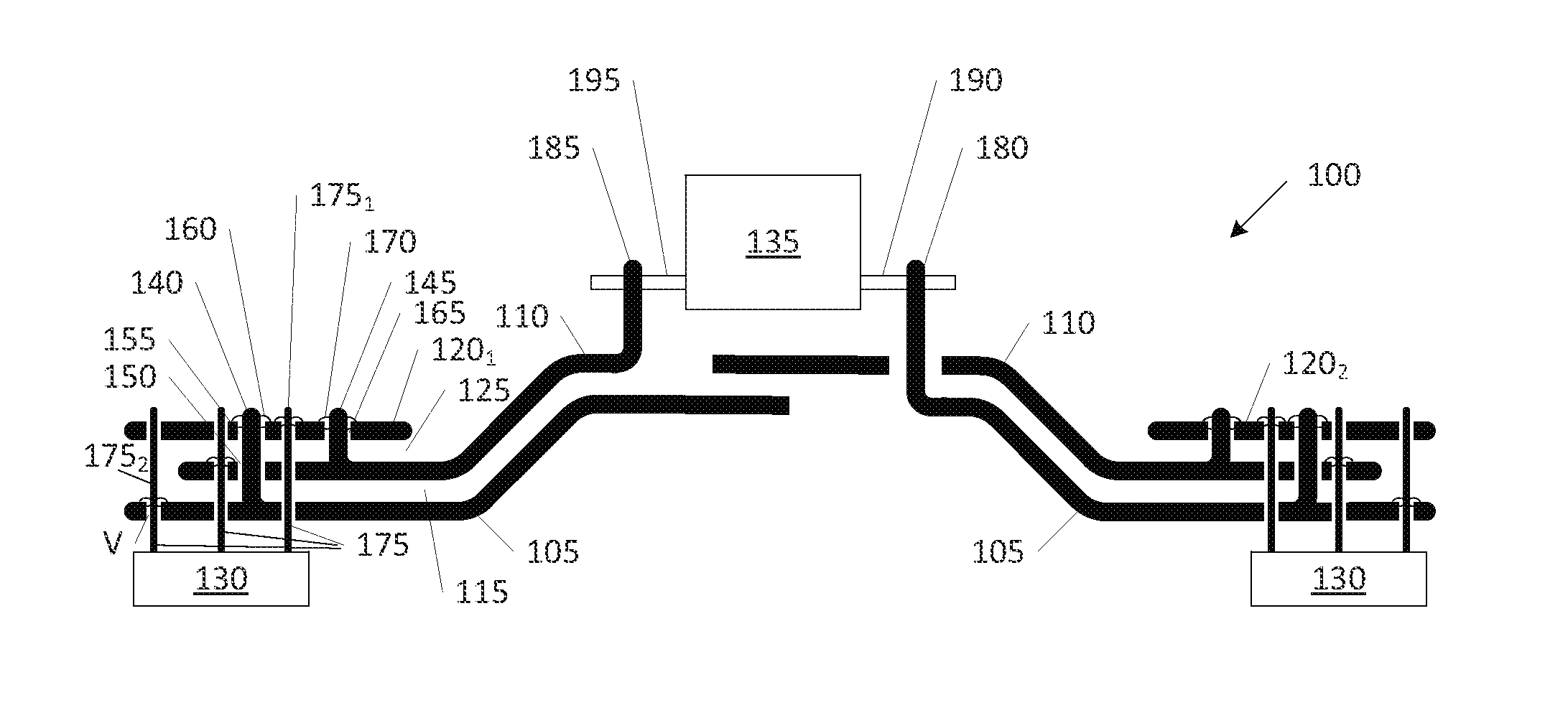

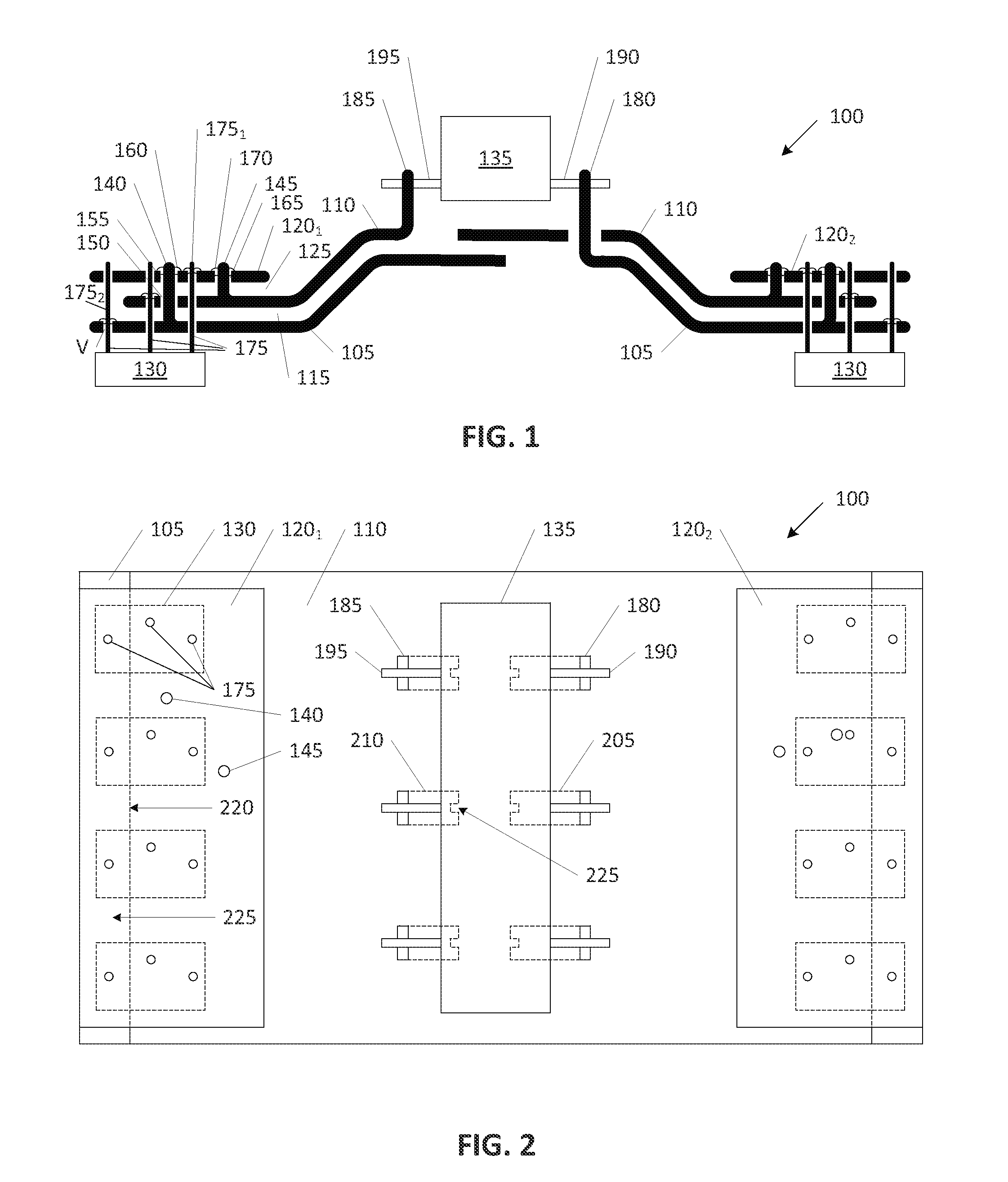

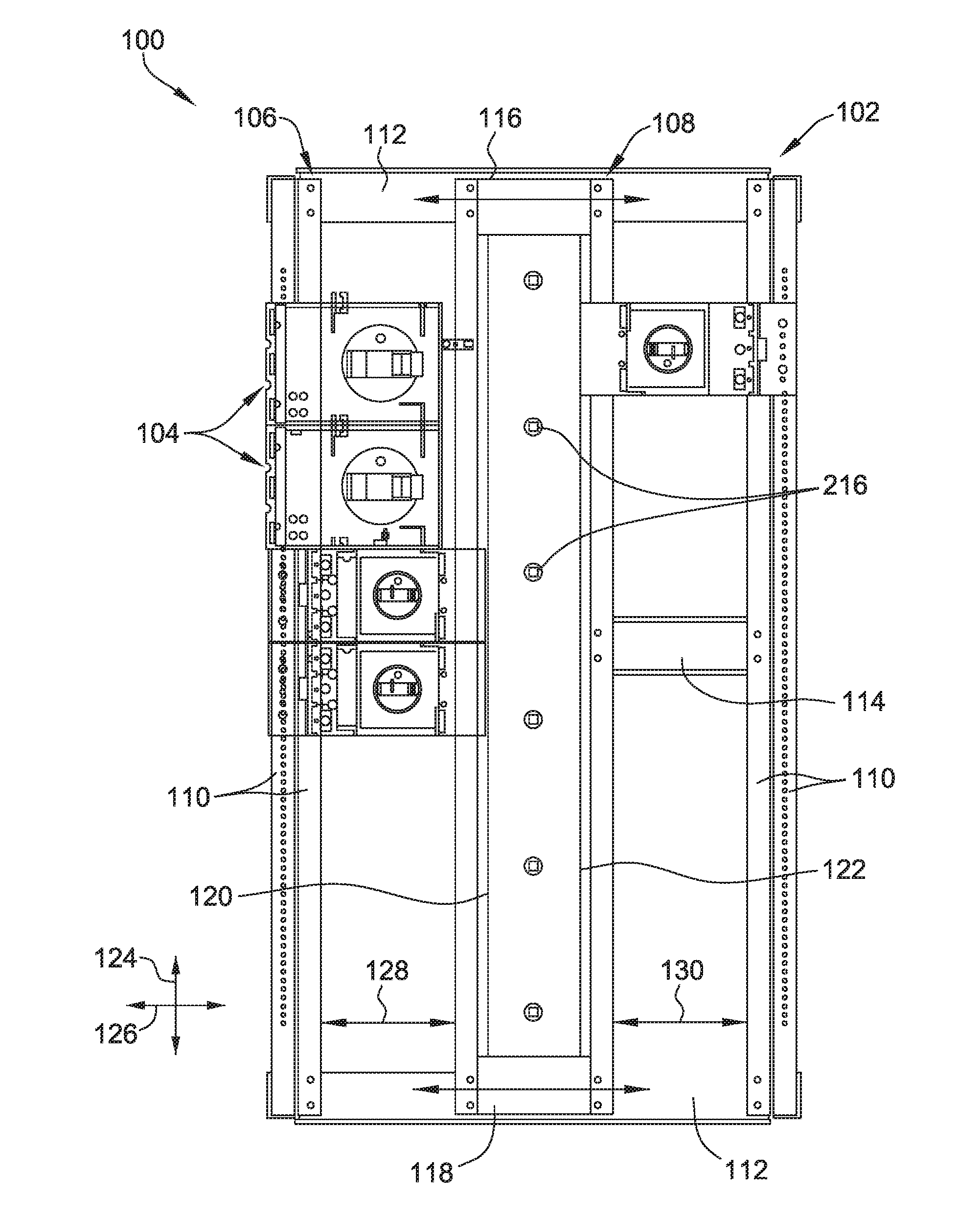

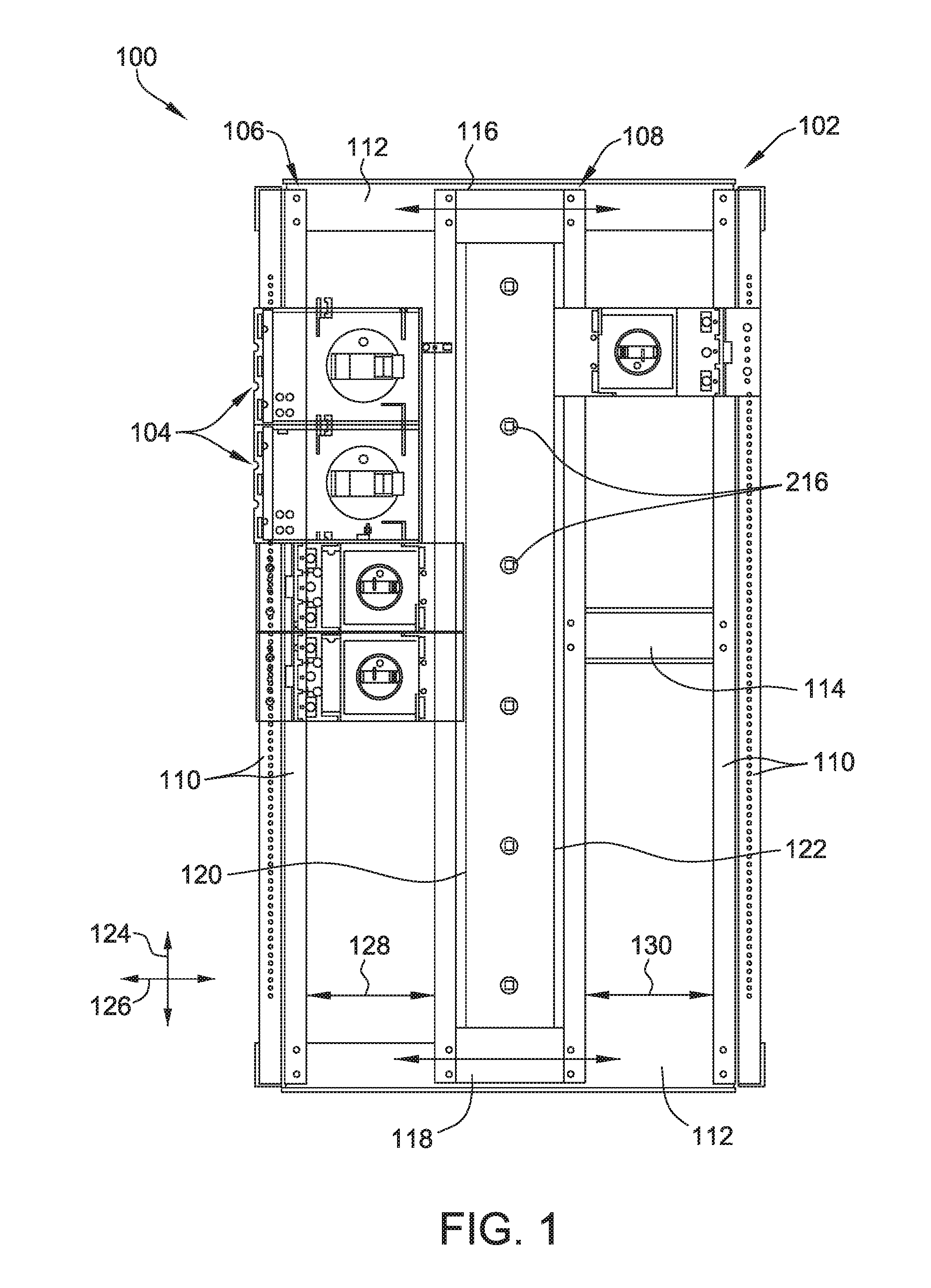

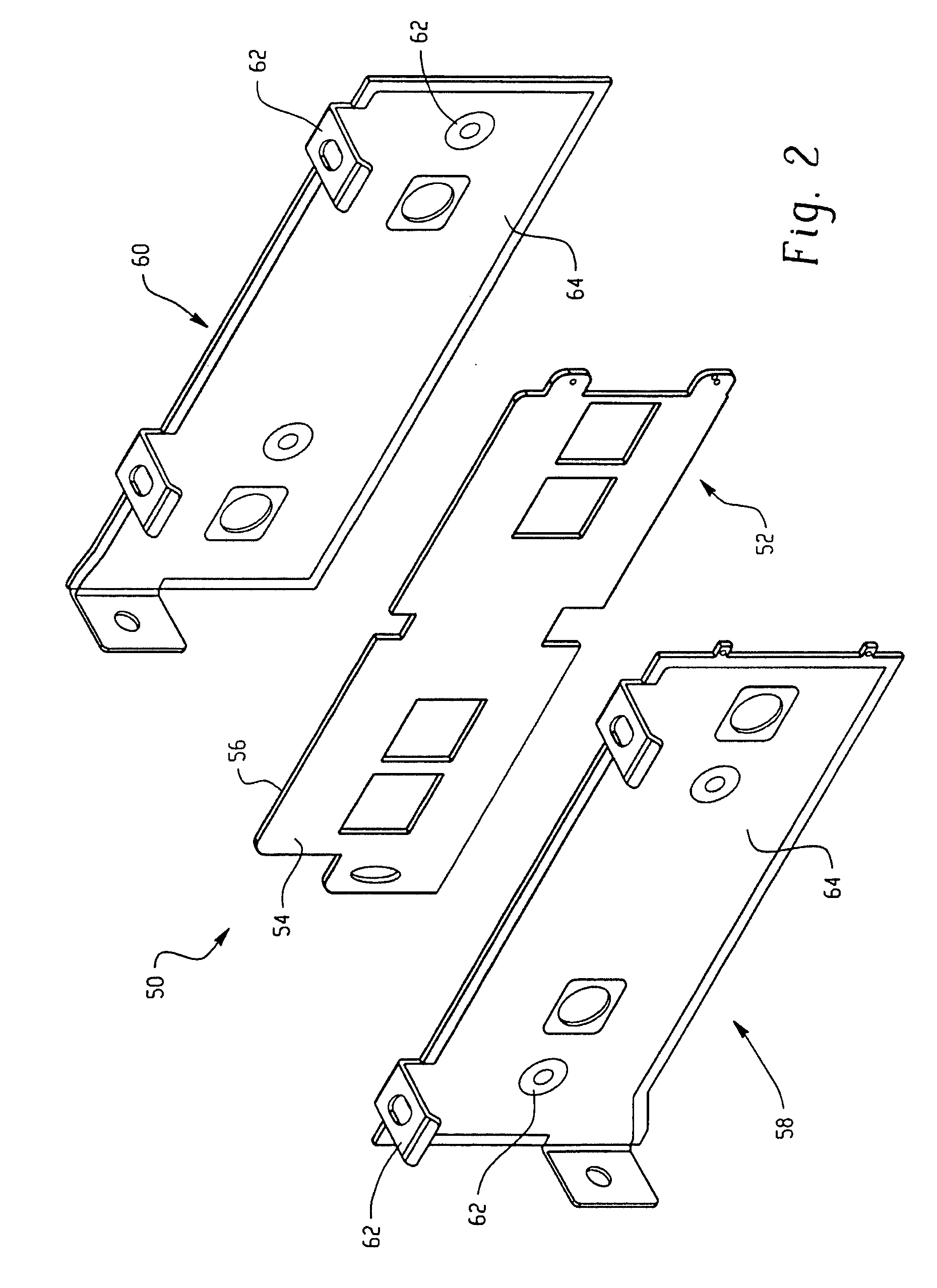

Tap apparatus for electrically interconnecting an electrical busway and switchgear, and system including the same

InactiveUS7830648B2Non-enclosed substationsMaintaining distance between parallel conductorsElectrical devicesEngineering

A system includes an electrical busway, an electrical enclosure enclosing an electrical apparatus, the electrical enclosure including an interior and a mounting portion with an opening therethrough; and a tap apparatus electrically interconnecting the electrical busway and the electrical apparatus. The tap apparatus includes a first portion electrically interconnected with the electrical busway through the opening of the mounting portion, a second portion removeably coupled to the mounting portion of the electrical enclosure from the interior of the electrical enclosure, and a third portion including a flexible electrical connection electrically interconnected with the electrical apparatus.

Owner:EATON CORP

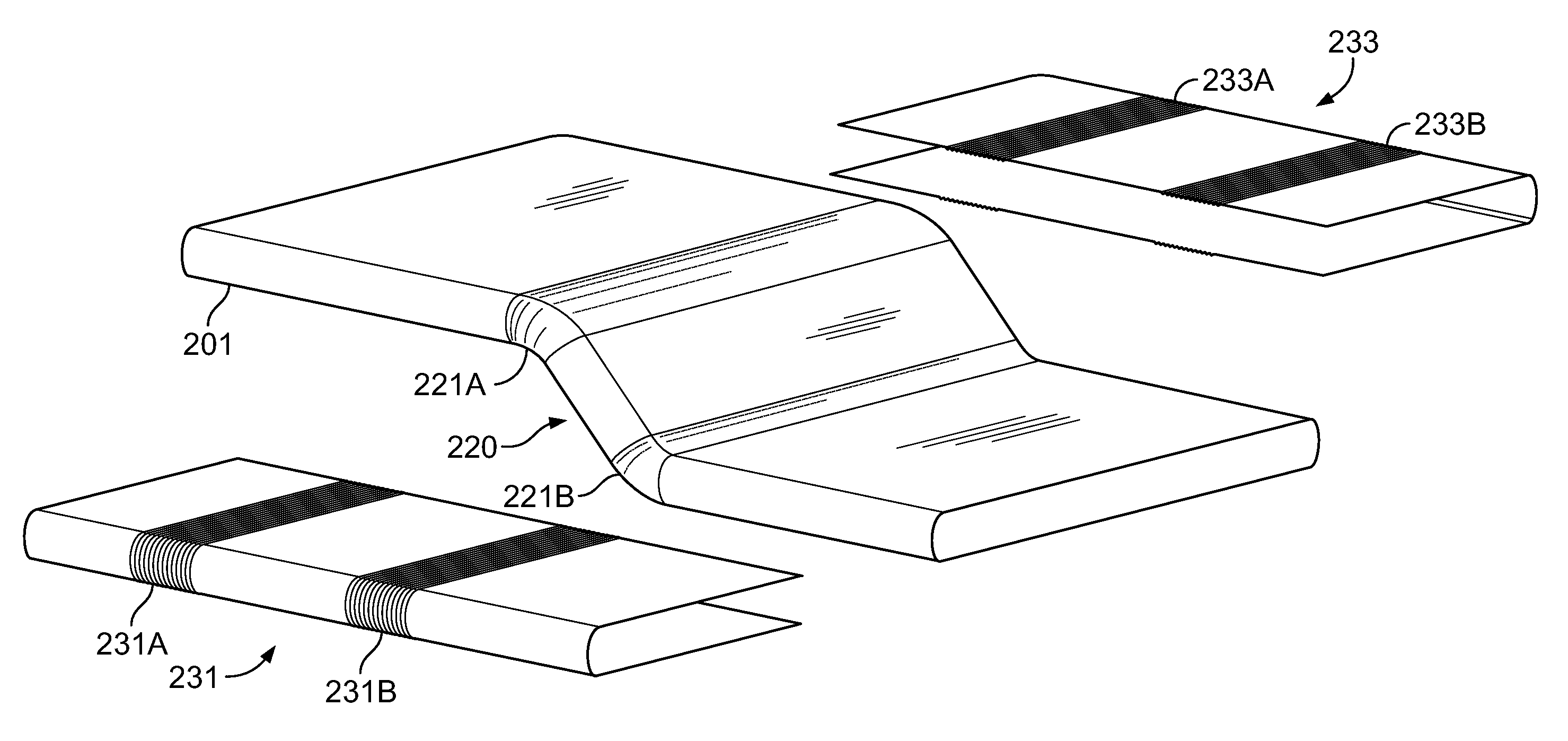

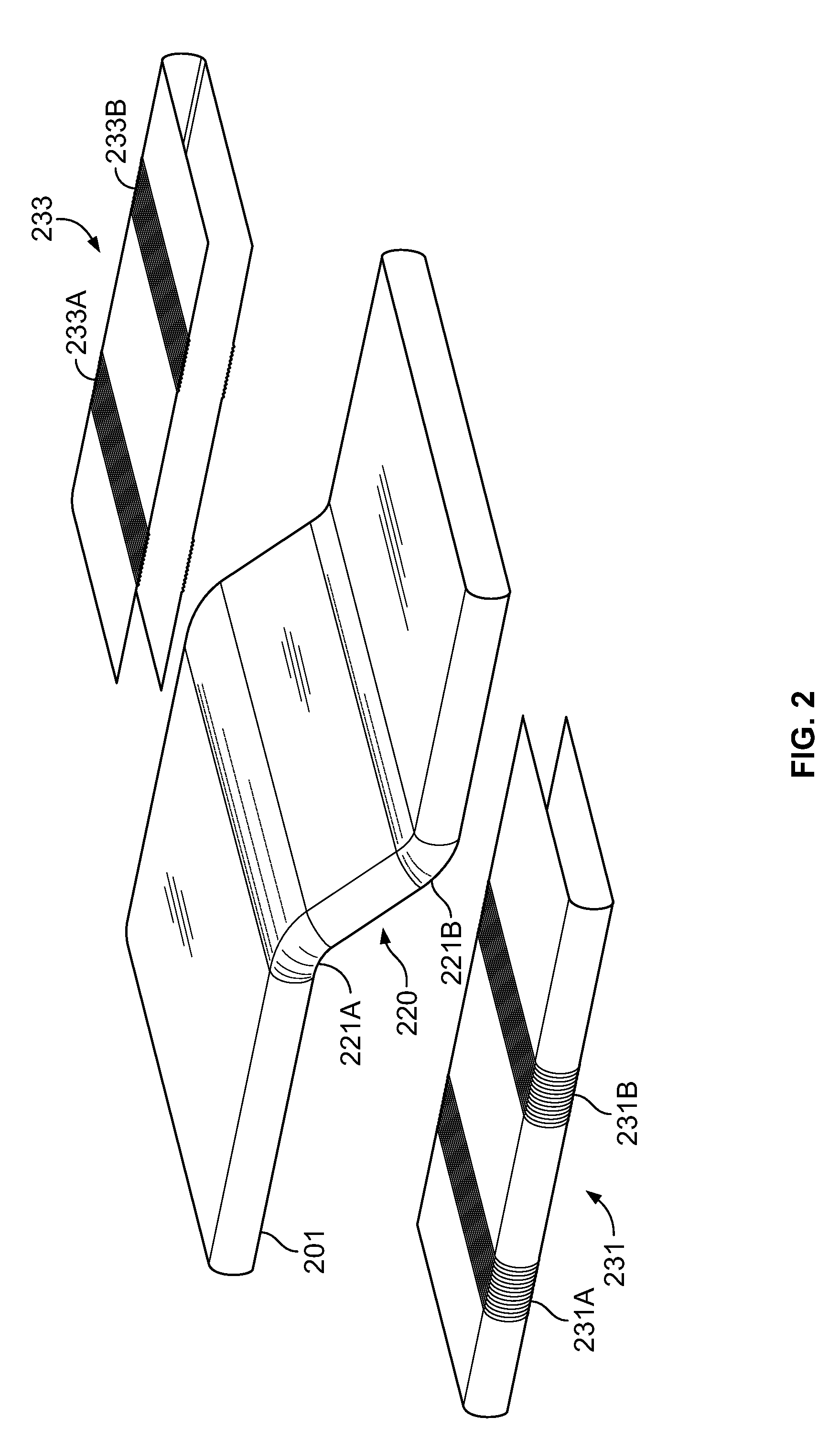

Flexible busbar

ActiveUS20130068495A1Easy to slideIncrease flexibilityCoupling device connectionsLine/current collector detailsElectrical conductorBusbar

A flexible busbar includes a central conductor (generally of rectangular cross section comprising multiple layers of thin aluminum, copper or other alloys with good electrical properties (conductivity)) and a sleeve having a shape on the internal surface to reduce the adhesion between the two conductors and the sleeve when the flexible busbar is bent, folded, or twisted. This increases the flexibility of the flexible busbar.

Owner:ERICO INT

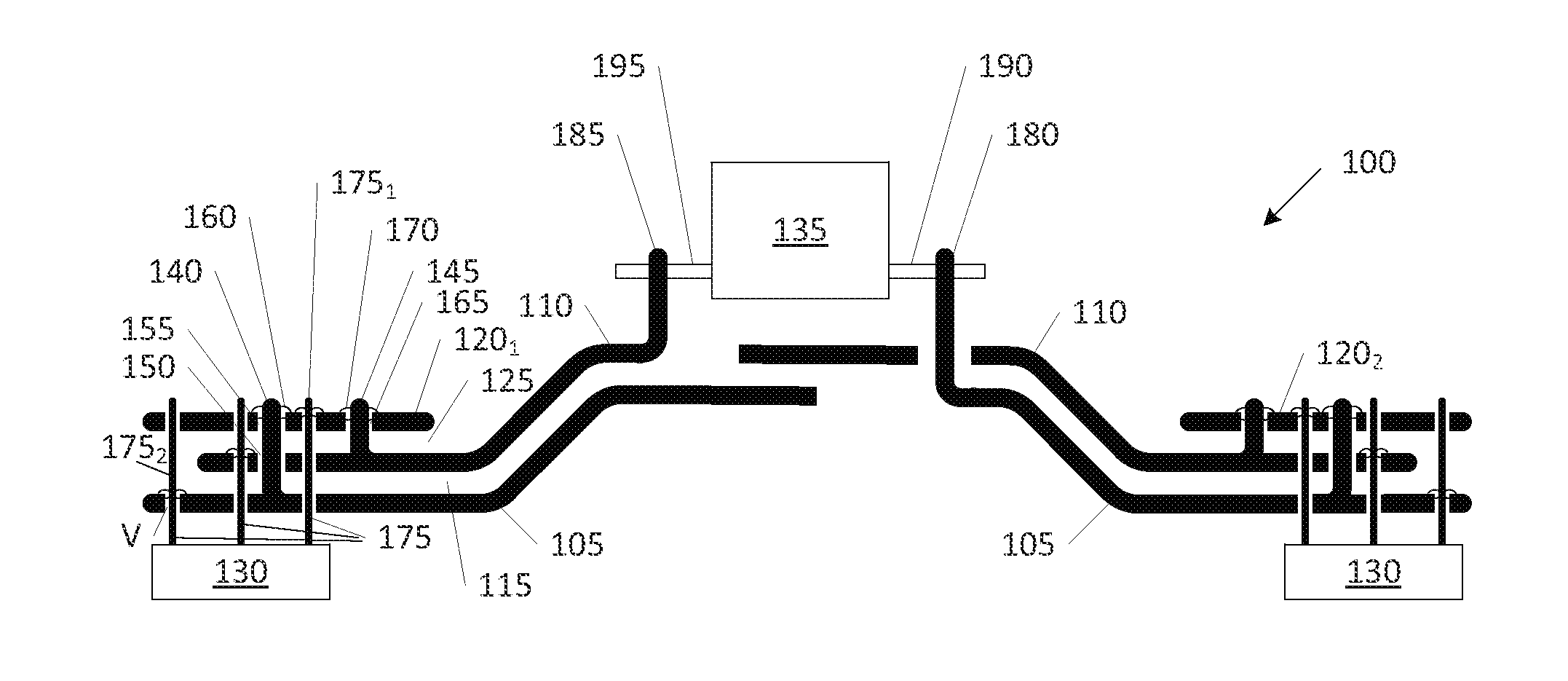

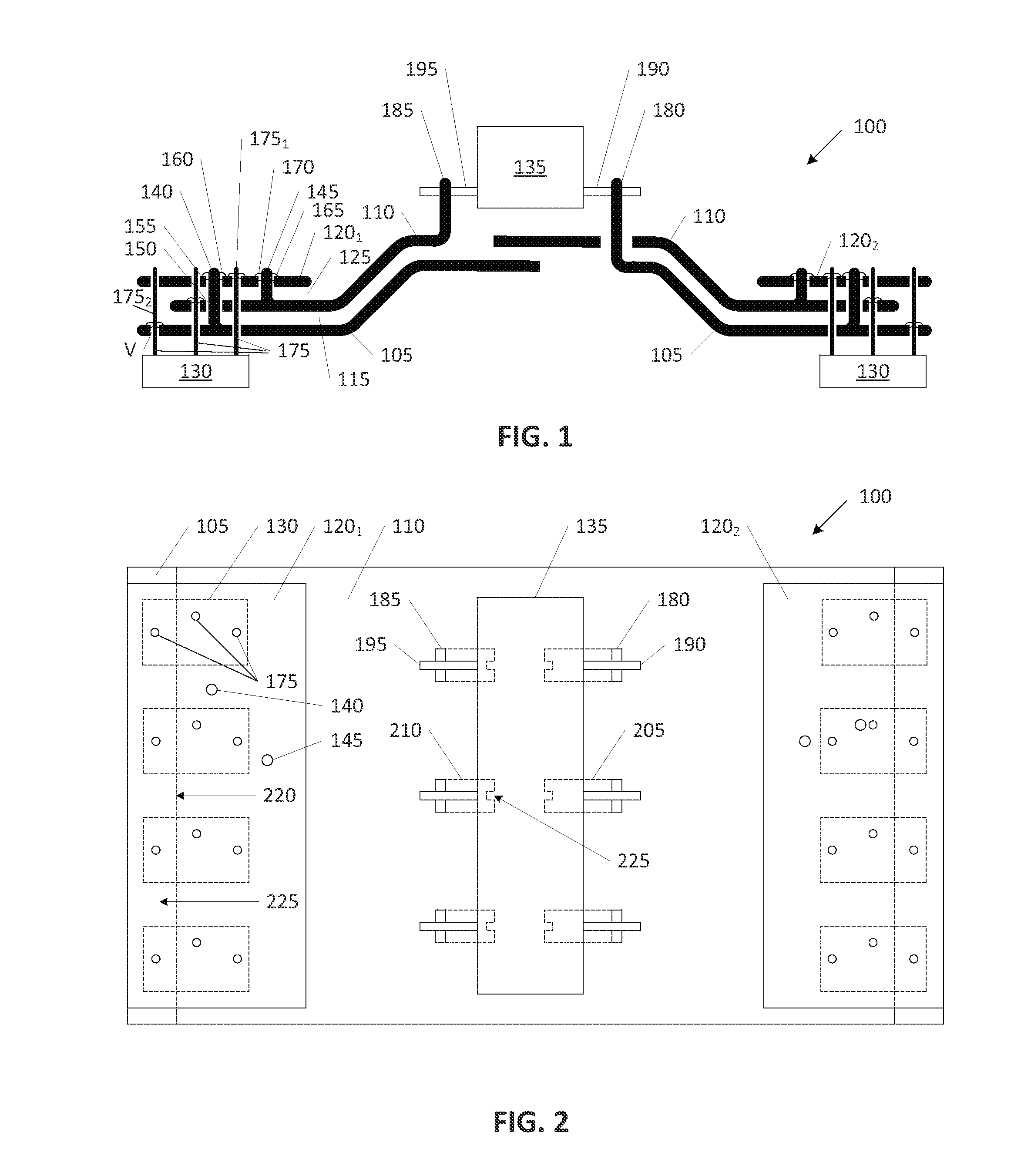

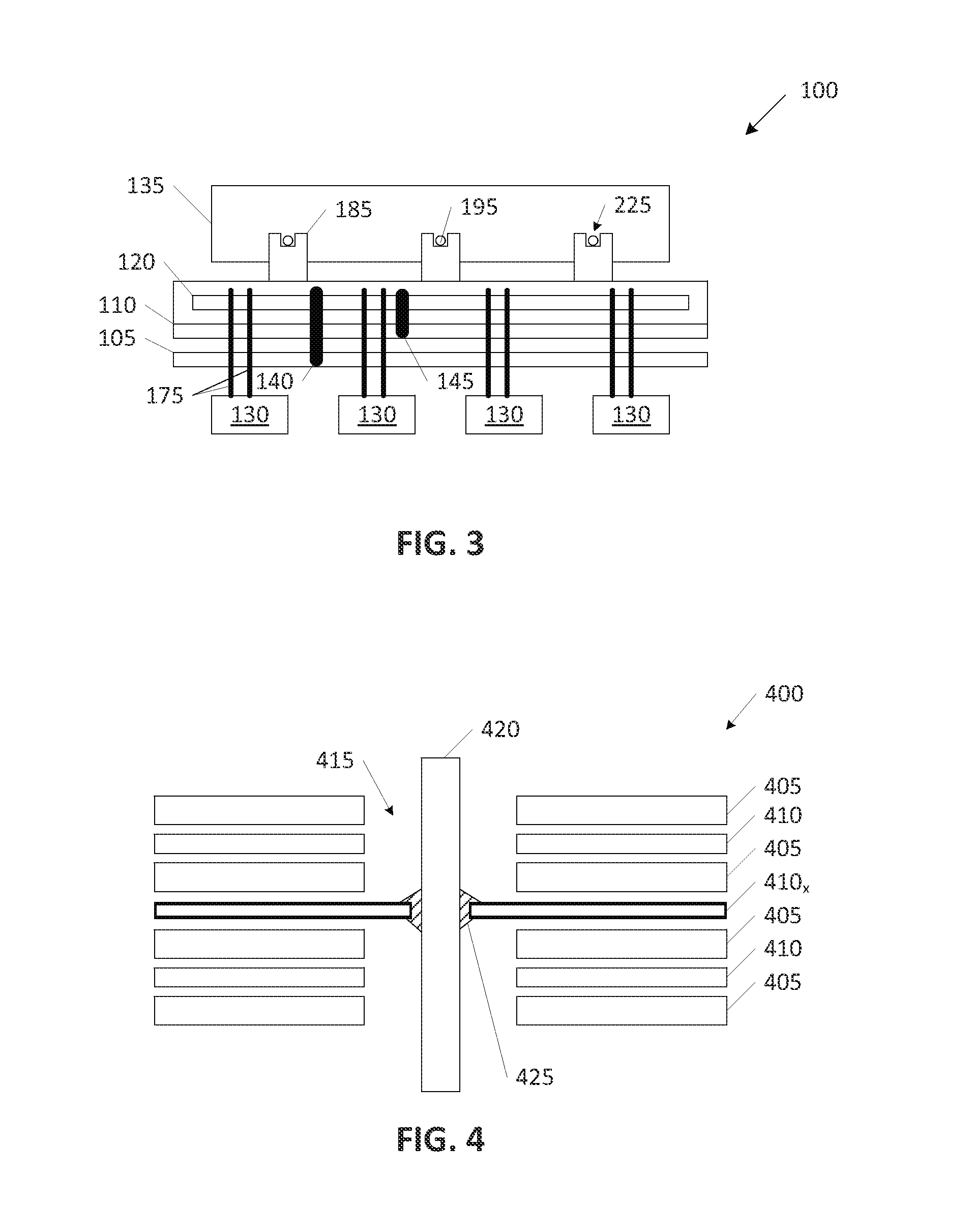

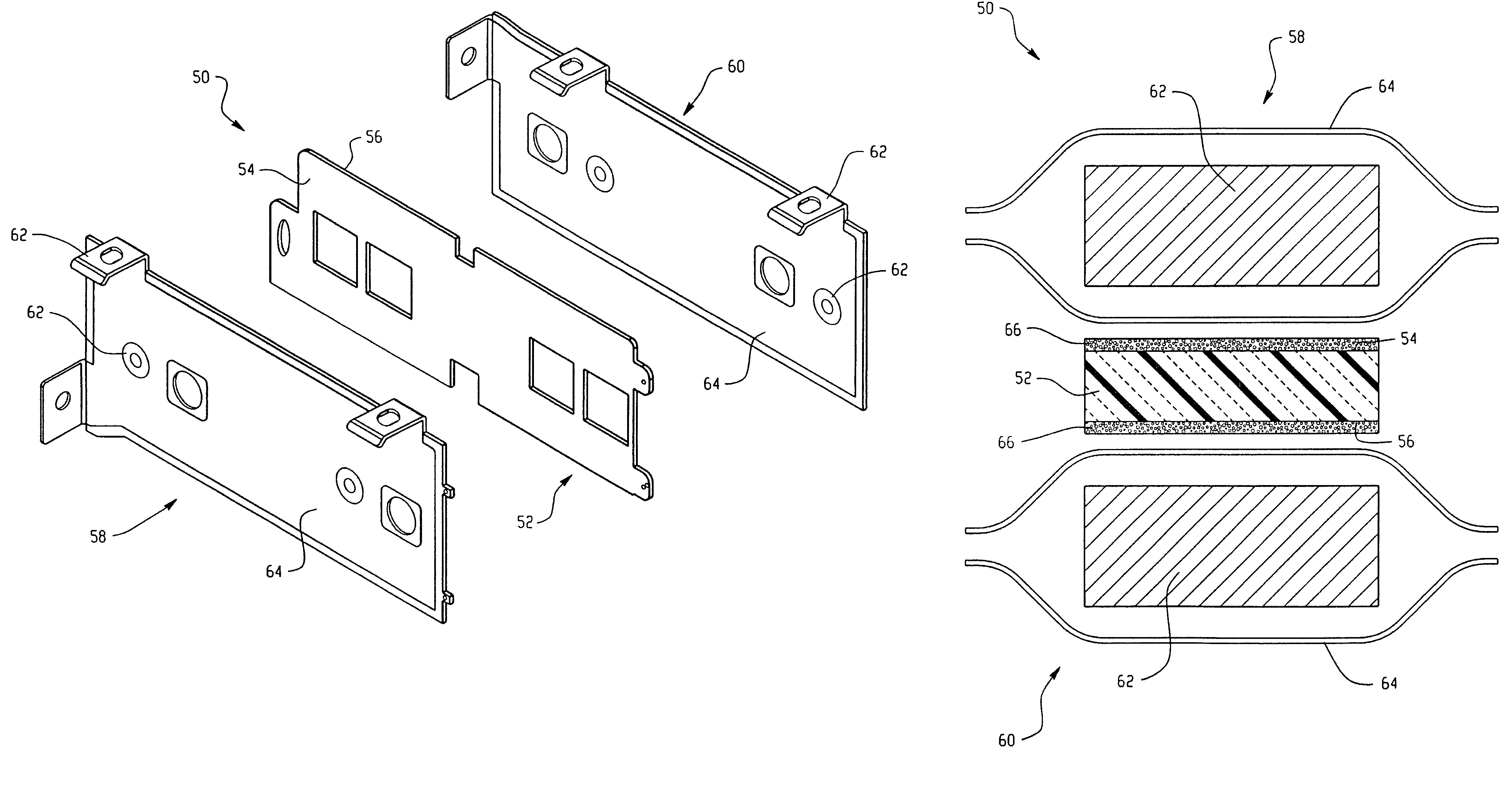

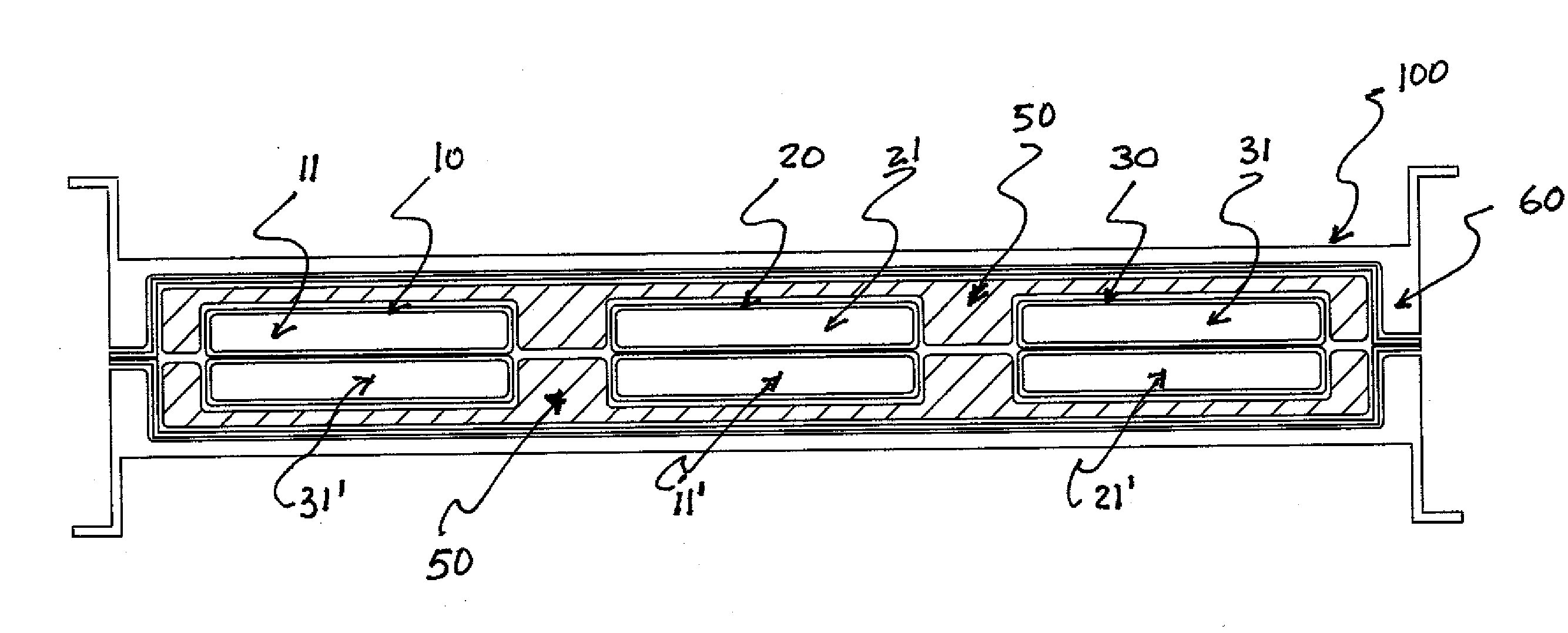

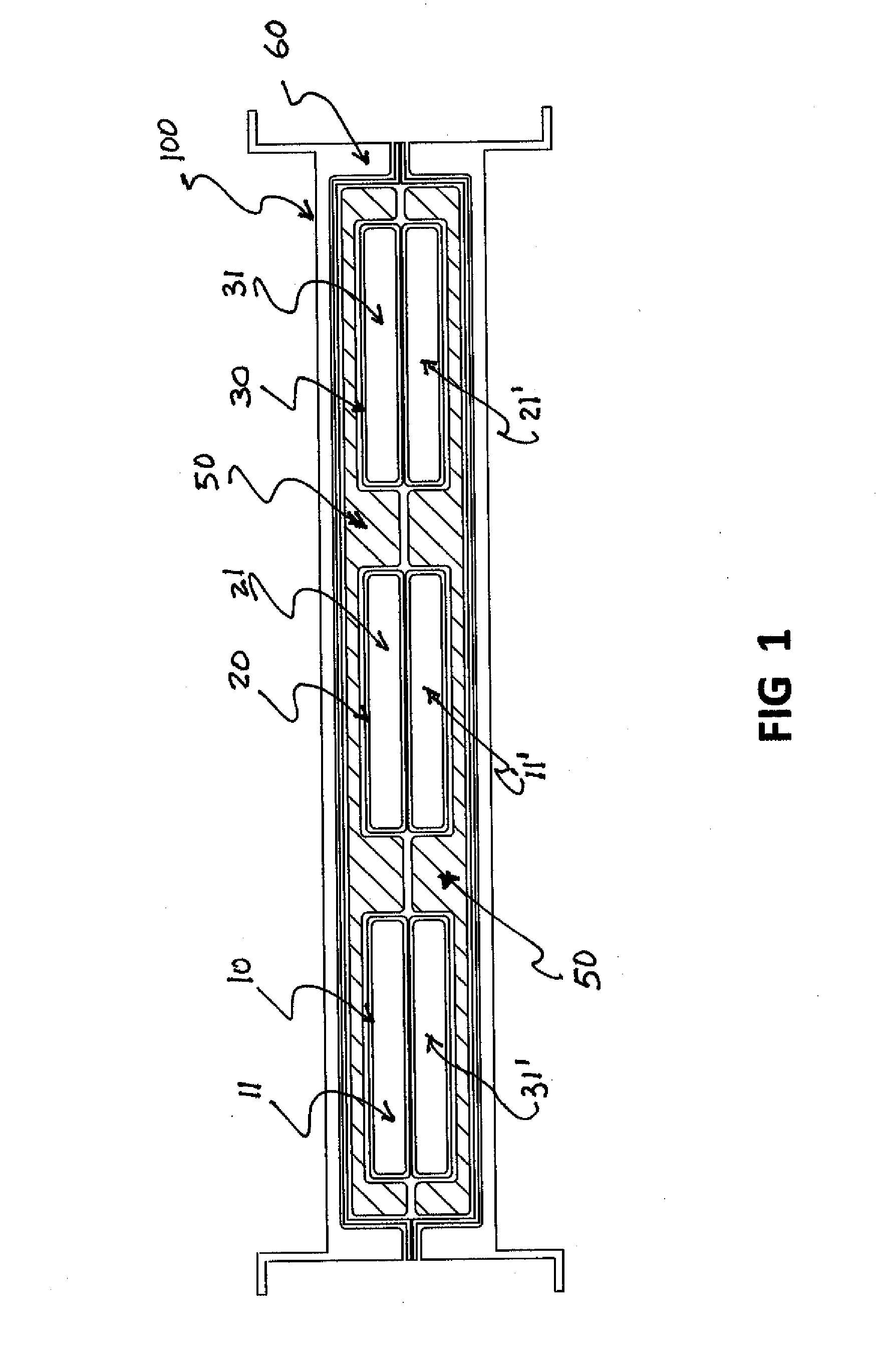

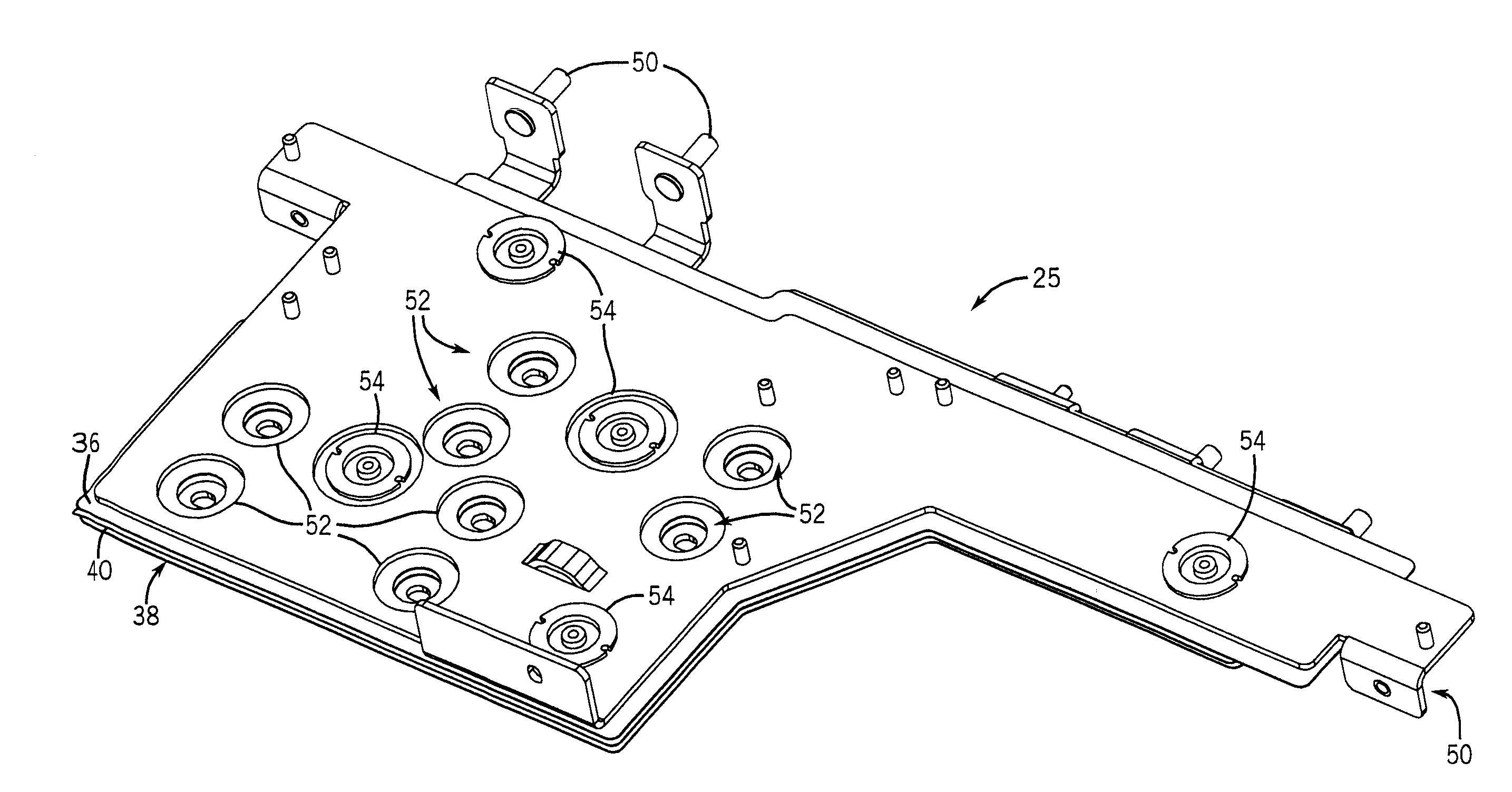

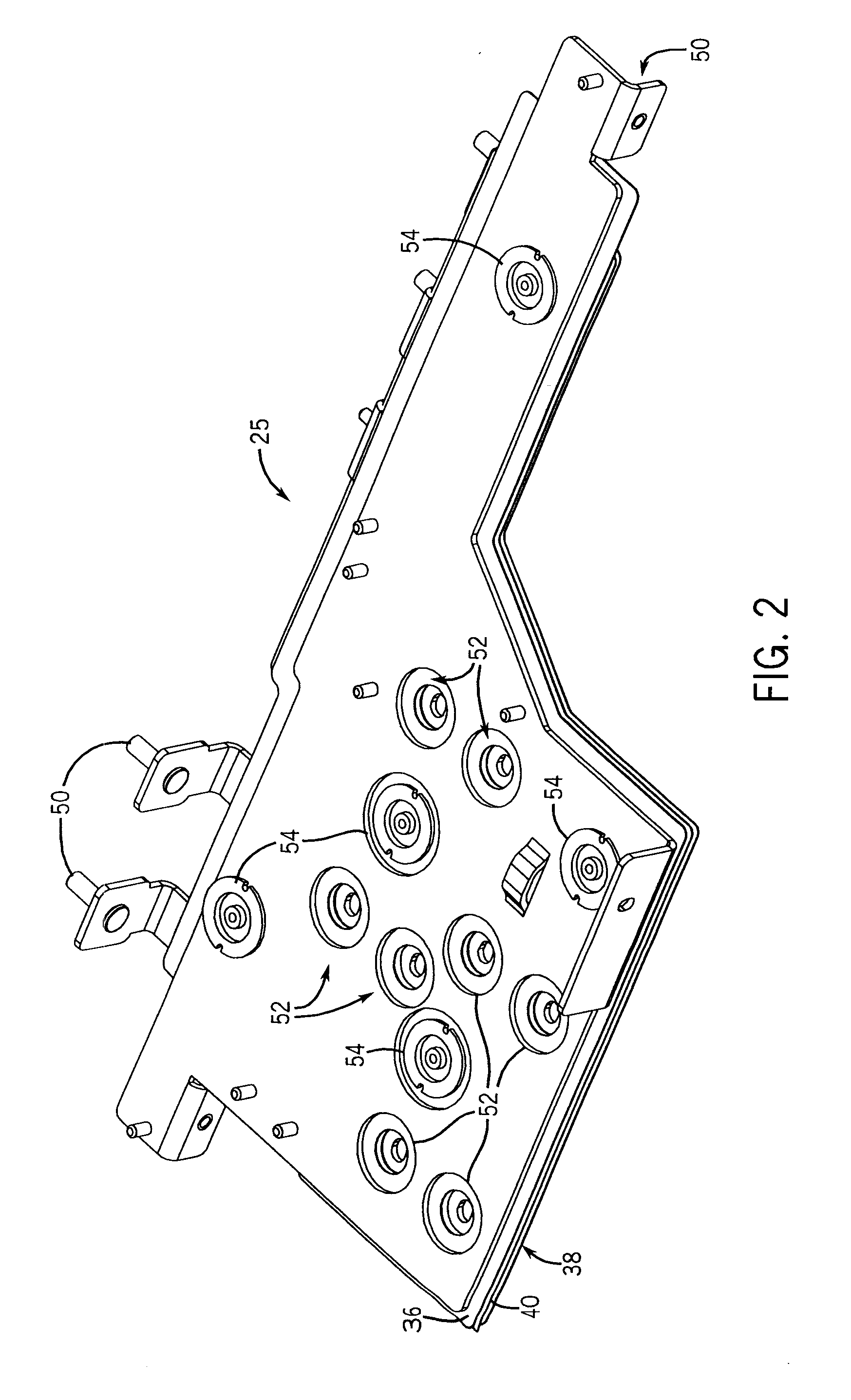

Power electronics interconnection for electric motor drives

ActiveUS8686288B2Improve performanceReduce resistanceLine/current collector detailsElectrolytic capacitorsElectricityElectrical conductor

The bus bar includes a first bus bar layer formed of a first generally uniform thickness of a first bus bar conductor; a first dielectric layer overlying a top surface of the first bus bar layer; and a second bus bar layer formed of a second generally uniform thickness of a second bus bar conductor overlying a top surface of the first dielectric layer and the top surface of the first bus bar layer wherein: the first bus bar layer includes a first via for receipt of a first electrical lead of an electrical component and a second via for receipt of a second electrical lead of the electrical component and wherein: the first dielectric layer and the second bus bar layer each include a via aligned with the first via wherein the first electrical lead is extendable from beneath the first bus bar layer through the first dielectric layer and through the second bus bar layer.

Owner:TESLA INC

Kit for a bus bar system for connecting bus bars with connectors of an electric installation device

Owner:RITTALWERK RUDOLF LOH GMBH & CO KG

Intensive insulation bus duct

ActiveCN103474929AImprove continuous power supply capabilityExtend continuous power supply timeTotally enclosed bus-bar installationsLaminated bus-barsElectrical conductorWater vapor

The invention discloses an intensive insulation bus duct which comprises a busbar protecting shell and a plurality of busbars arranged in the busbar protecting shell. Each busbar comprises a busbar conductor and an insulating layer which wraps the busbar conductor. The busbars are arranged in parallel side by side. The space between the busbar protecting shell and the busbars which are arranged side by side is filled with fire-resistant materials. Inorganic heat-absorbing materials are arranged in the intensive insulation bus duct. The inorganic heat-absorbing materials in the intensive insulation bus duct can release water vapor when heated to a certain degree; heat is absorbed in the process that the inorganic heat-absorbing materials release the water vapor, and the heat absorption process can play a role in cooling; moreover, the volatilization of the water vapor can take away the heat continuously so as to lower the temperature of the bus duct, therefore, the fire resistance of the bus duct can be improved, the continuous power supply capability of the intensive insulation bus duct in a fire is improved, and the continuous power supply time of the intensive insulation bus duct in the fire is prolonged.

Owner:SHENZHEN WOER HEAT SHRINKABLE MATERIAL +1

Three-phase bus-bar structure having noise-filtering function

InactiveUS6339192B1Lower impedanceReduce noise propagated and radiatedBus-bar/wiring layoutsEarthing arrangementsCapacitanceElectricity

A bus bar in which the noise of an apparatus connected to a bus bar is absorbed by the frame to reduce the noise propagated and radiated from the power feed cable and in which the apparatus may be reduced in size to achieve space saving while being reduced in cost. A plurality of power source layers and a plurality of frame grounding layers are arranged neighboring to one another with dielectric layers in-between, while a plurality of frame grounding layers are arranged neighboring to each other with dielectric layers in-between to provide a multi-layered structure including the frame grounding layers. The frame grounding layers are contacted with a fastener with a casing of a frame apparatus in surface contact to constitute a stable grounding of low impedance, while absorbing the noise proper to the insulating layer by interlayer capacitative coupling.

Owner:NEC CORP

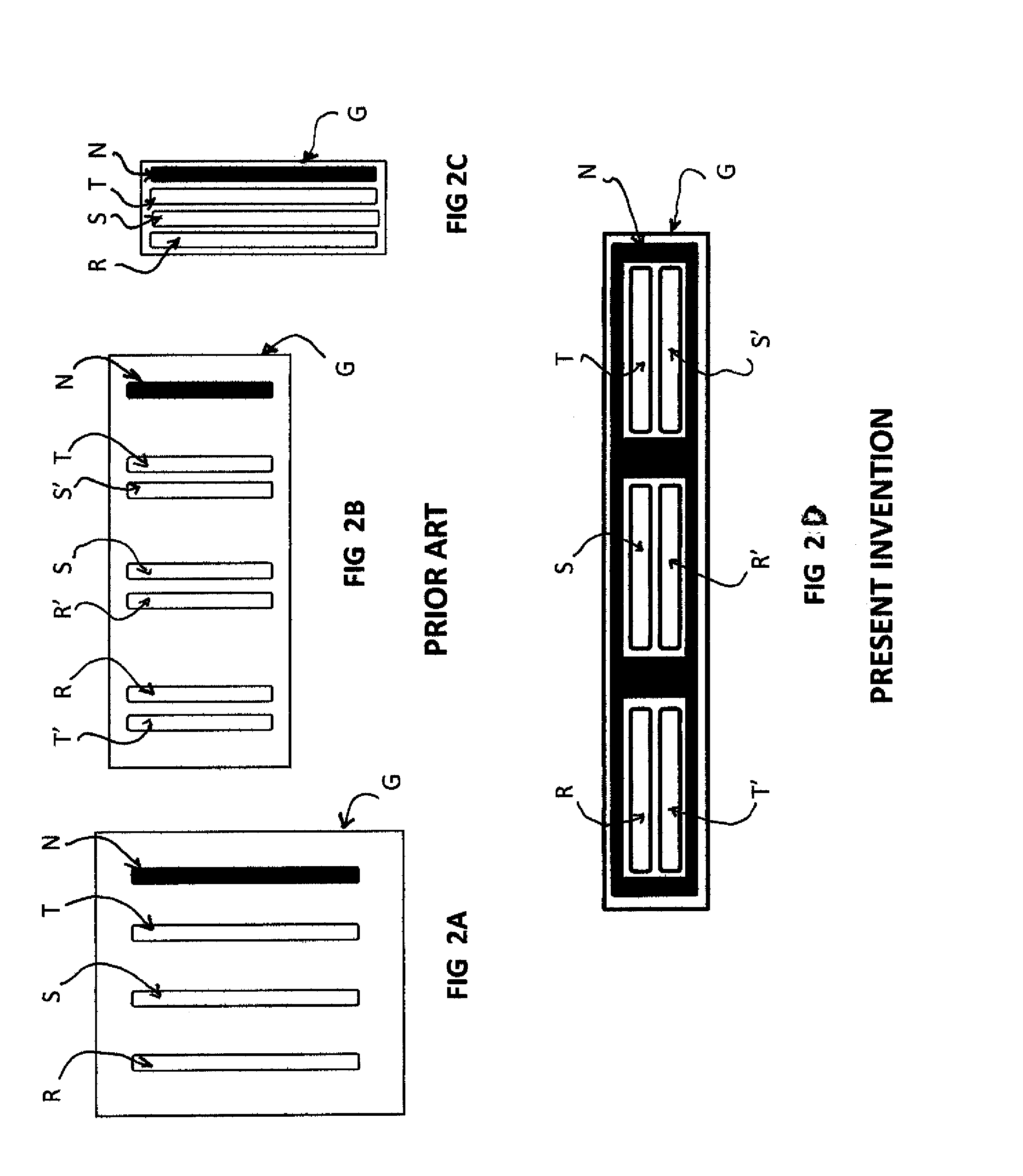

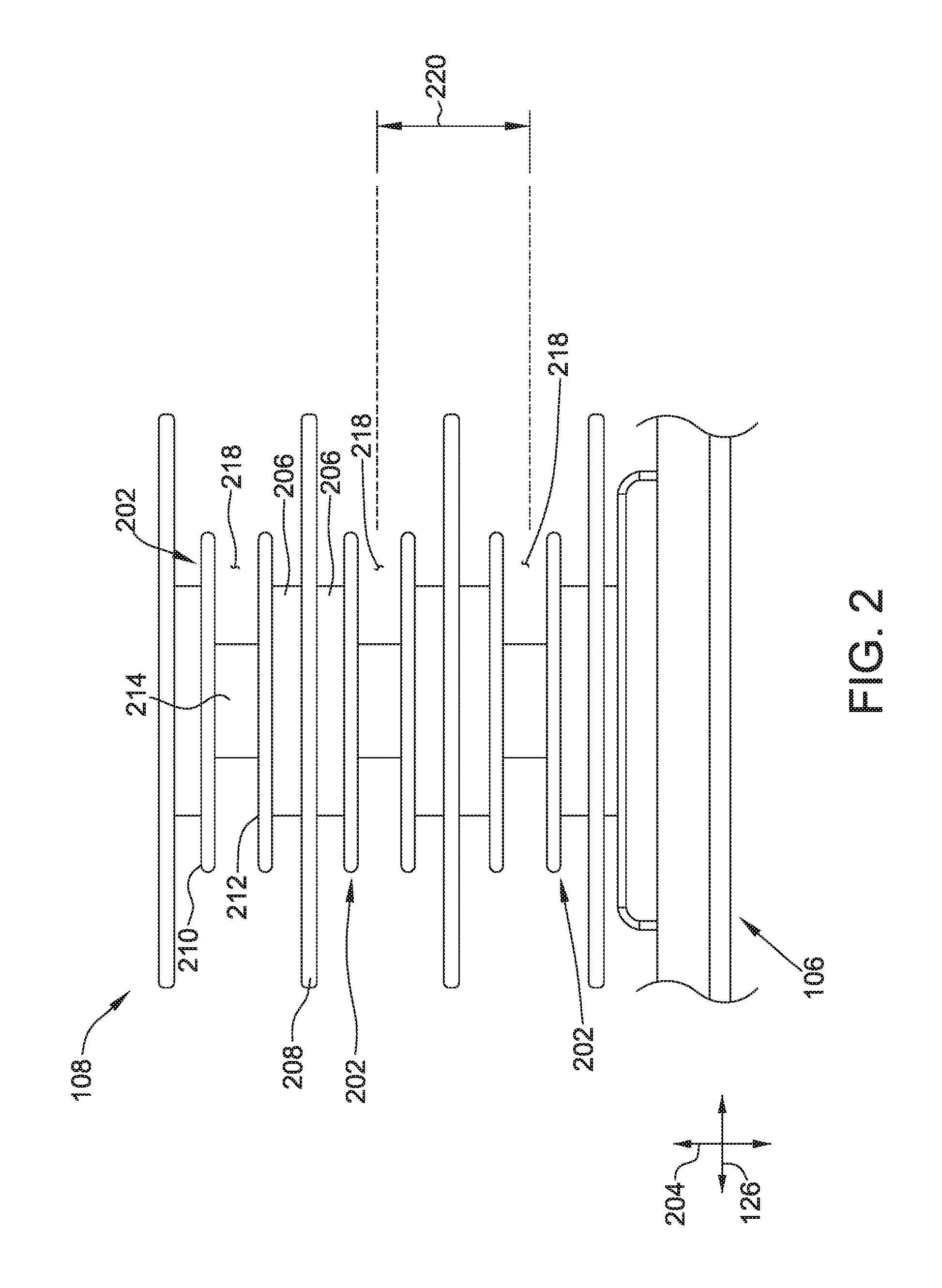

High efficiency paired phases busway system

ActiveUS20090178824A1Maximize efficiencyReduce voltageBus-bar/wiring layoutsTotally enclosed bus-bar installationsInsulation layerThree-phase

A paired phase electrical power distribution bus way system wherein the three phase paired conductors are surrounded and encapsulated by the neutral conductor and packed all together with the housing as a company element to obtain equal separation between the neutral bus bar assembly and the paired phase conductors. The neutral conductor or bus bar assembly consists of two covers that sandwich the three pairs of phase conductors and the insulator layers to achieve minimum and equal distance between them and to reduce and balance the impedance between the neutral and the paired conductors. The housing compresses each pair through the neutral conductor and insulation layer to maintain contact between the conductors, the neutral, and the housing to get efficient heat conduction to the outside.

Owner:BURGUERA ELIO

Flexible conductive tape connection

InactiveUS6319012B1Reduce the overall heightExtended service lifeConductive layers on insulating-supportsCable fittingsElectrical conductorElectrical connection

Owner:ROBERT BOSCH GMBH

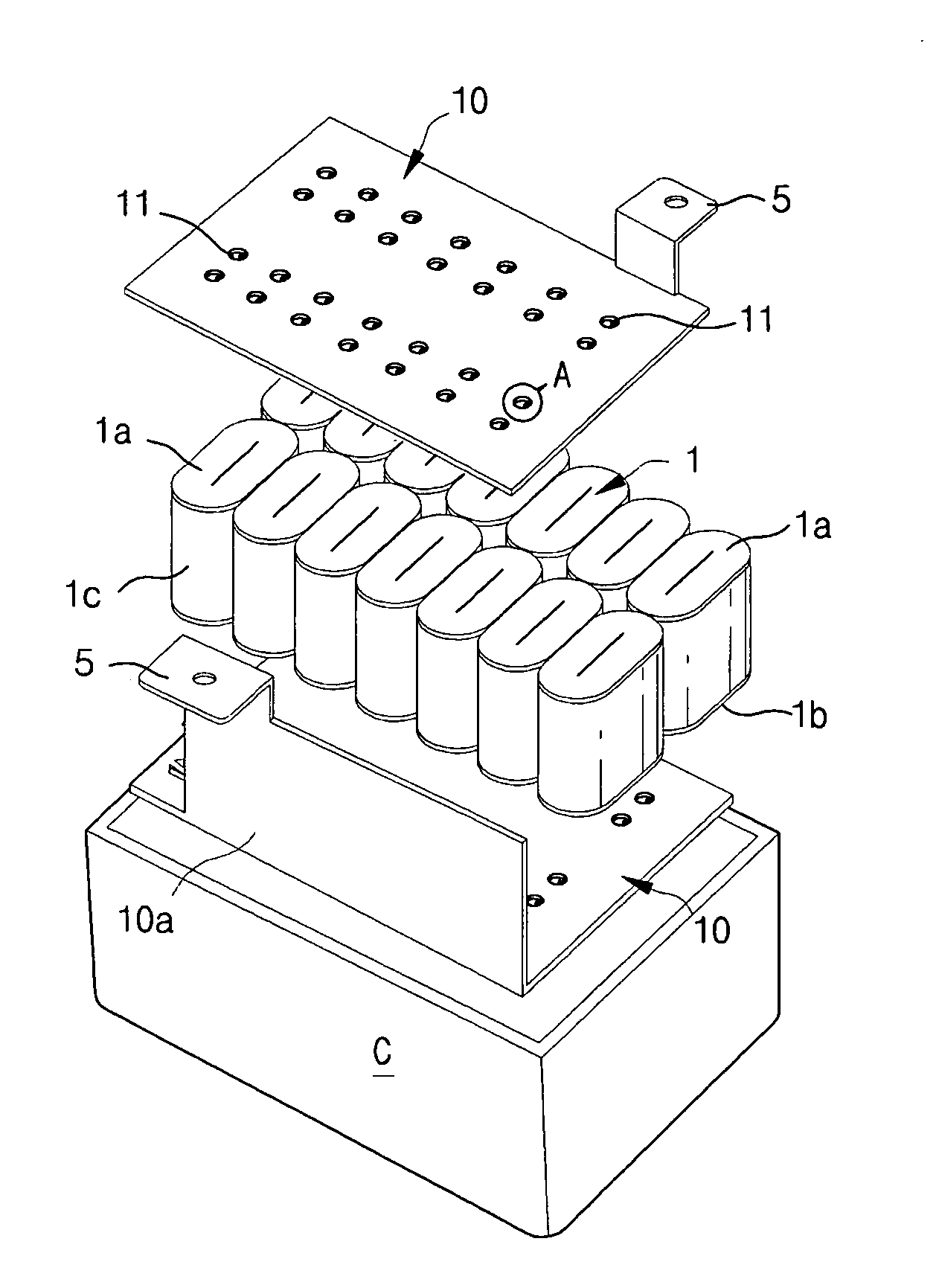

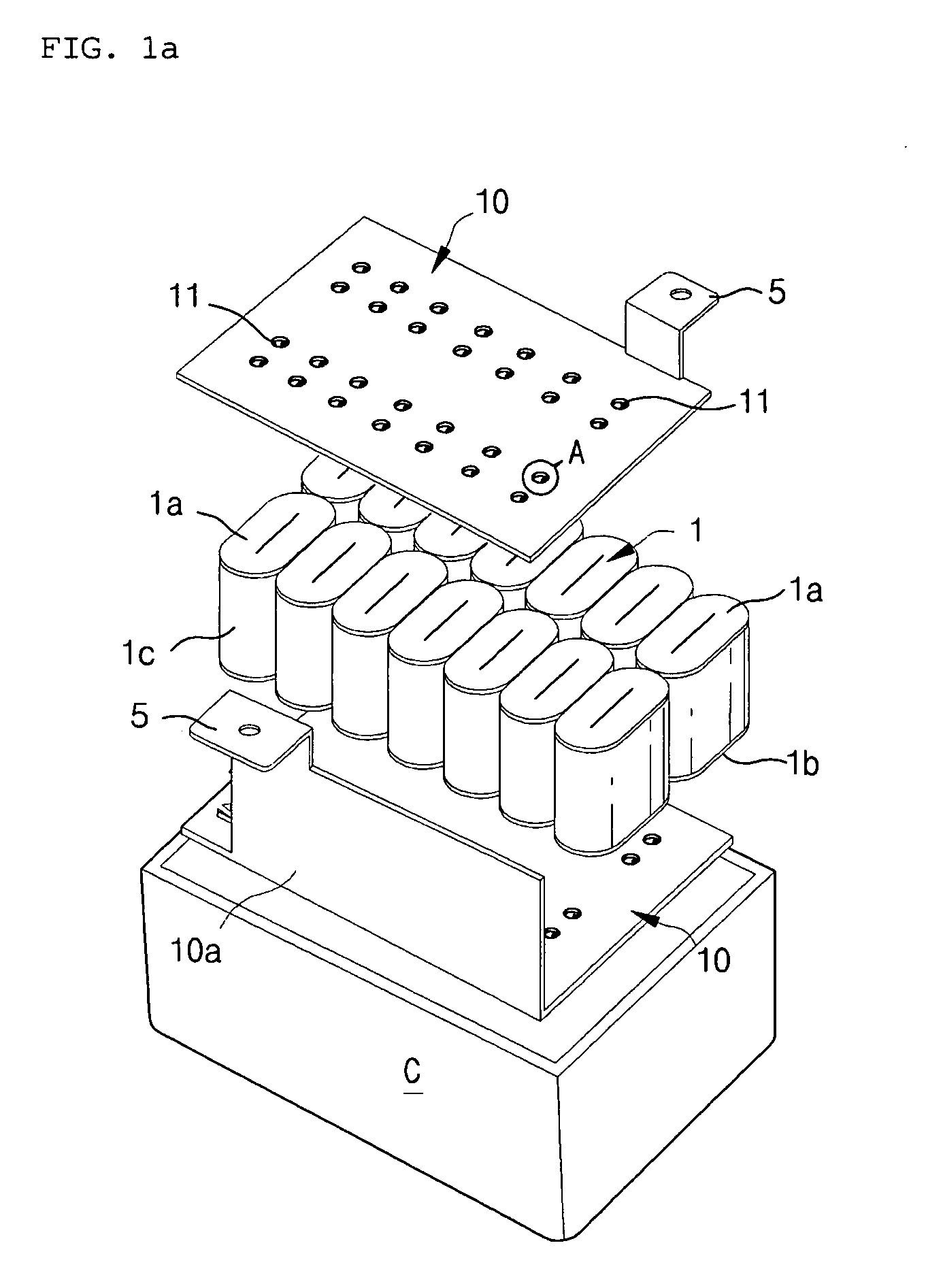

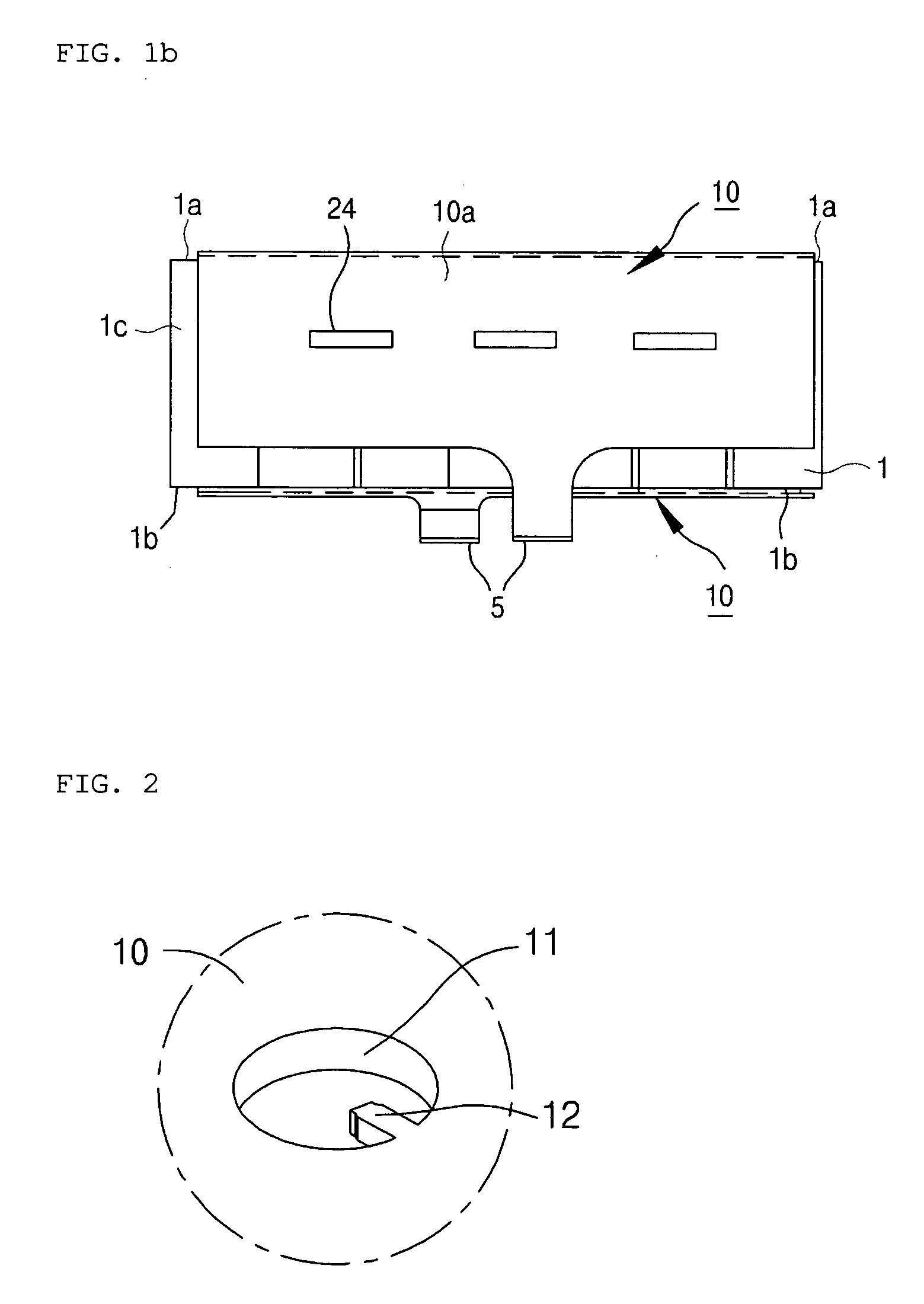

Bus-bar for jointing capacitor

ActiveUS8018712B2Inferiority rate can be reducedImprove welding efficiencyMultiple fixed capacitorsLiquid electrolytic capacitorsEngineeringSoldering

A bus-bar for assembling a capacitor device is disclosed, which is capable of improving the environment of a soldering operation for the bus-bar being soldered to a capacitor device, reducing the inferior rate of the capacitor device while improving the quality of the capacitor device, and reducing the weight of the capacitor module, in soldering the bus-bar to capacitor devices. The lead frame attached to polar plates by soldering is formed thinner than the other parts of the bus-bar, and opening parts having an oval or polygonal shape are formed on a surface of the bus-bar so that two adjoining capacitor devices can be exposed. The lead frame is formed in the opening in order for soldering with the polar plates of the capacitor device.

Owner:NUINTEK

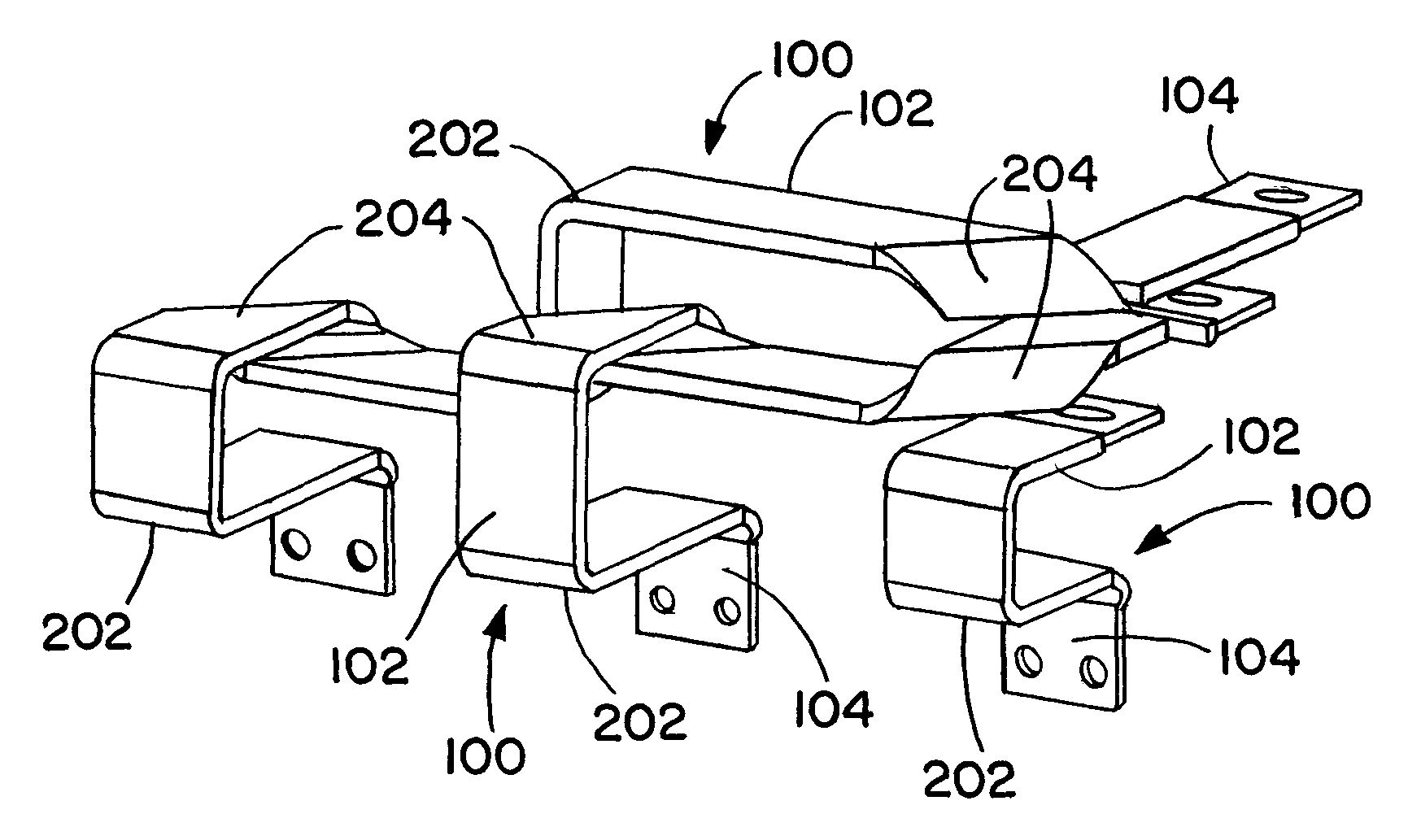

Electrical device, electrical distribution system, and methods of assembling same

ActiveUS20160233649A1Bus-bar/wiring layoutsCoupling device connectionsElectricityDistribution power system

An electrical device having a bus side and a load side is provided. The electrical device includes a plurality of conductive line terminals disposed on the bus side of said electrical device, and a plurality of electrical connectors. Each electrical connector of the plurality of electrical connectors includes a first end coupled to a respective line terminal of the plurality of line terminals, a second end distal from the first end, and a connector clip disposed at the second end. Each connector clip is configured to engage a bus bar to electrically couple the electrical device to the bus bar, and includes a first contact segment and a second contact segment spaced apart from the first contact segment. The first and second contact segments are configured to deflect towards one another from a relaxed position to a depressed position when inserted into a connector channel defined by the bus bar.

Owner:ABB (SCHWEIZ) AG

Flexible busbar

ActiveUS8859897B2Easy to slideIncrease flexibilityBus-bar/wiring layoutsCoupling device connectionsElectrical conductorBusbar

Owner:ERICO INT

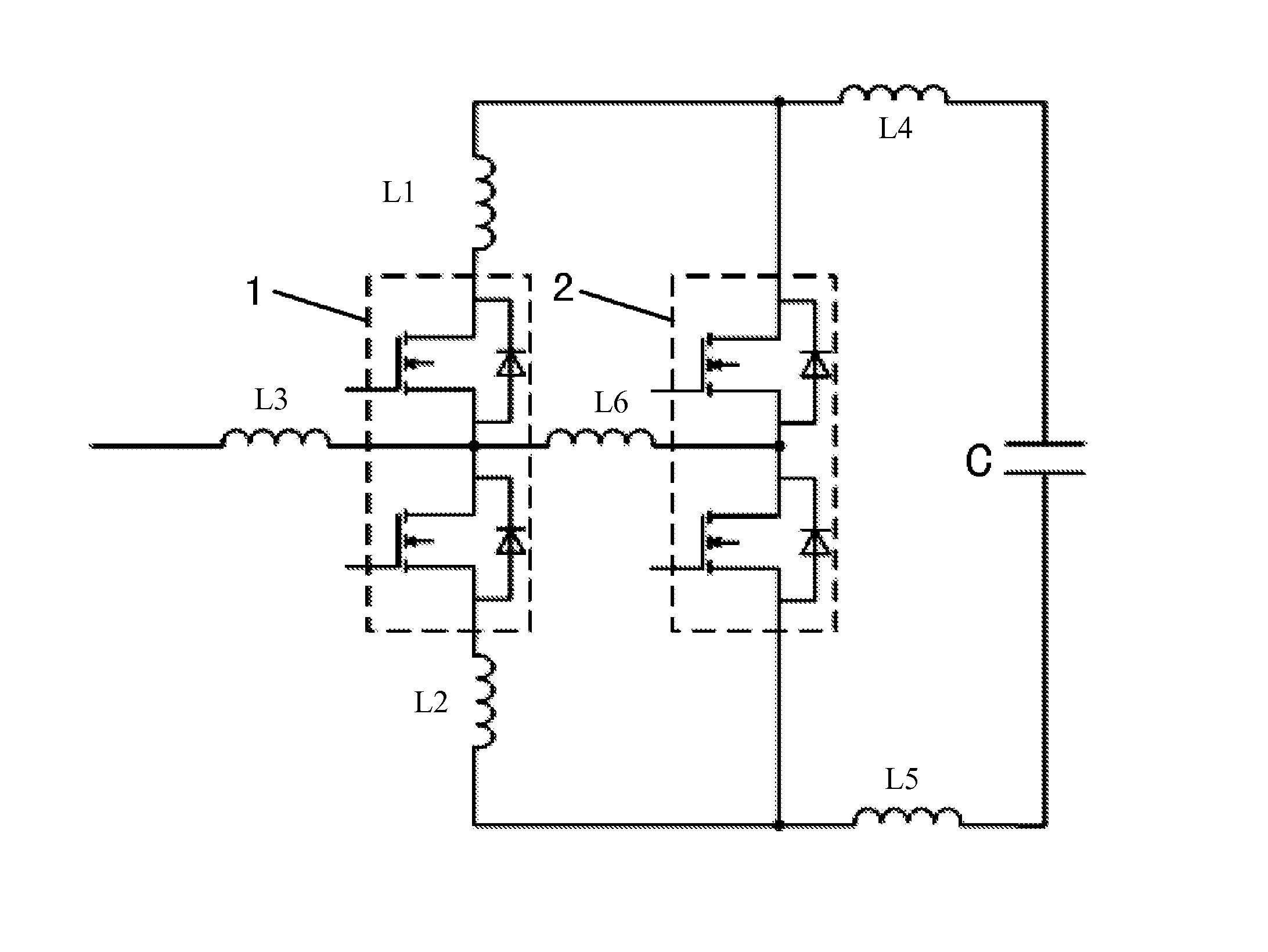

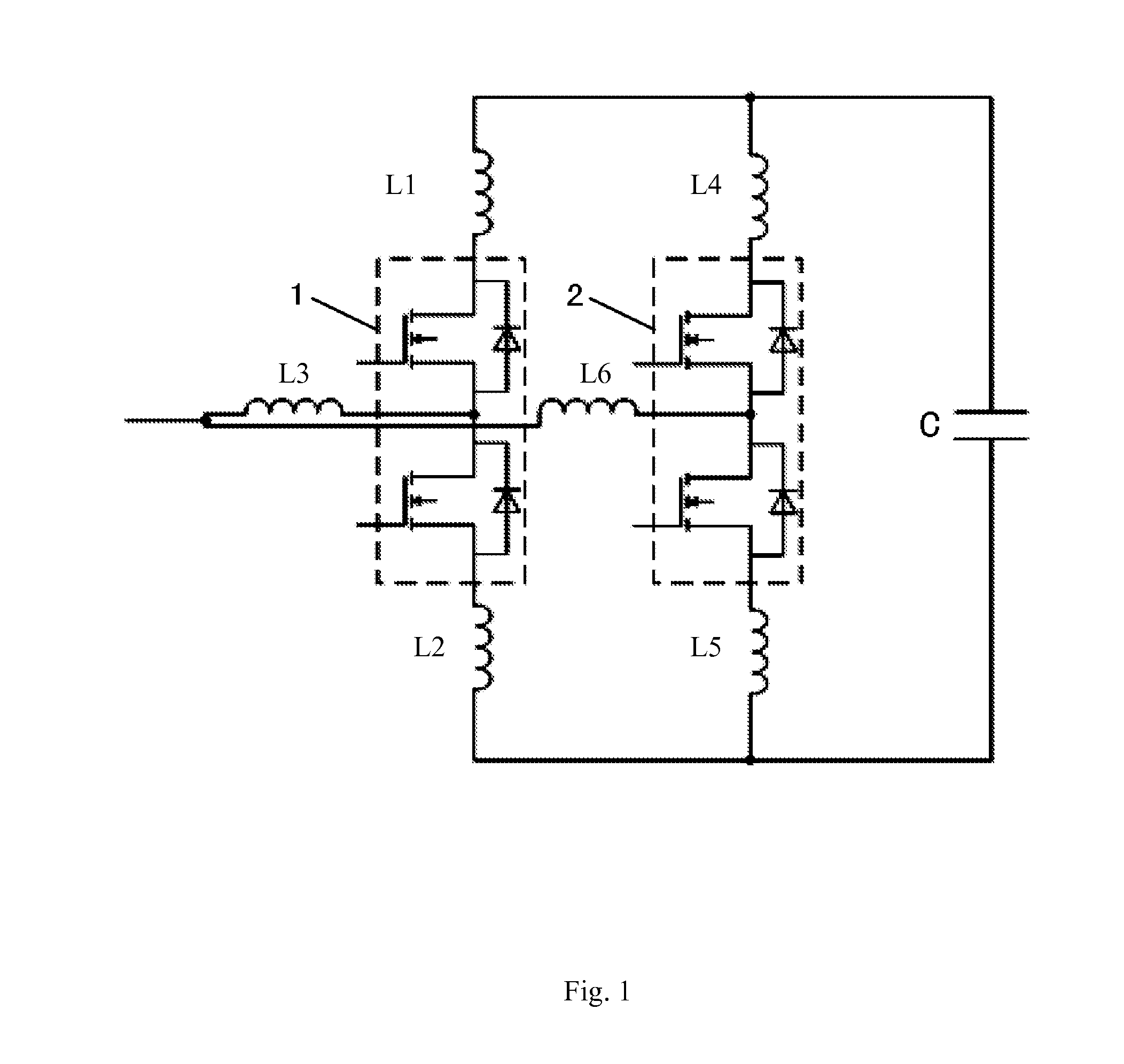

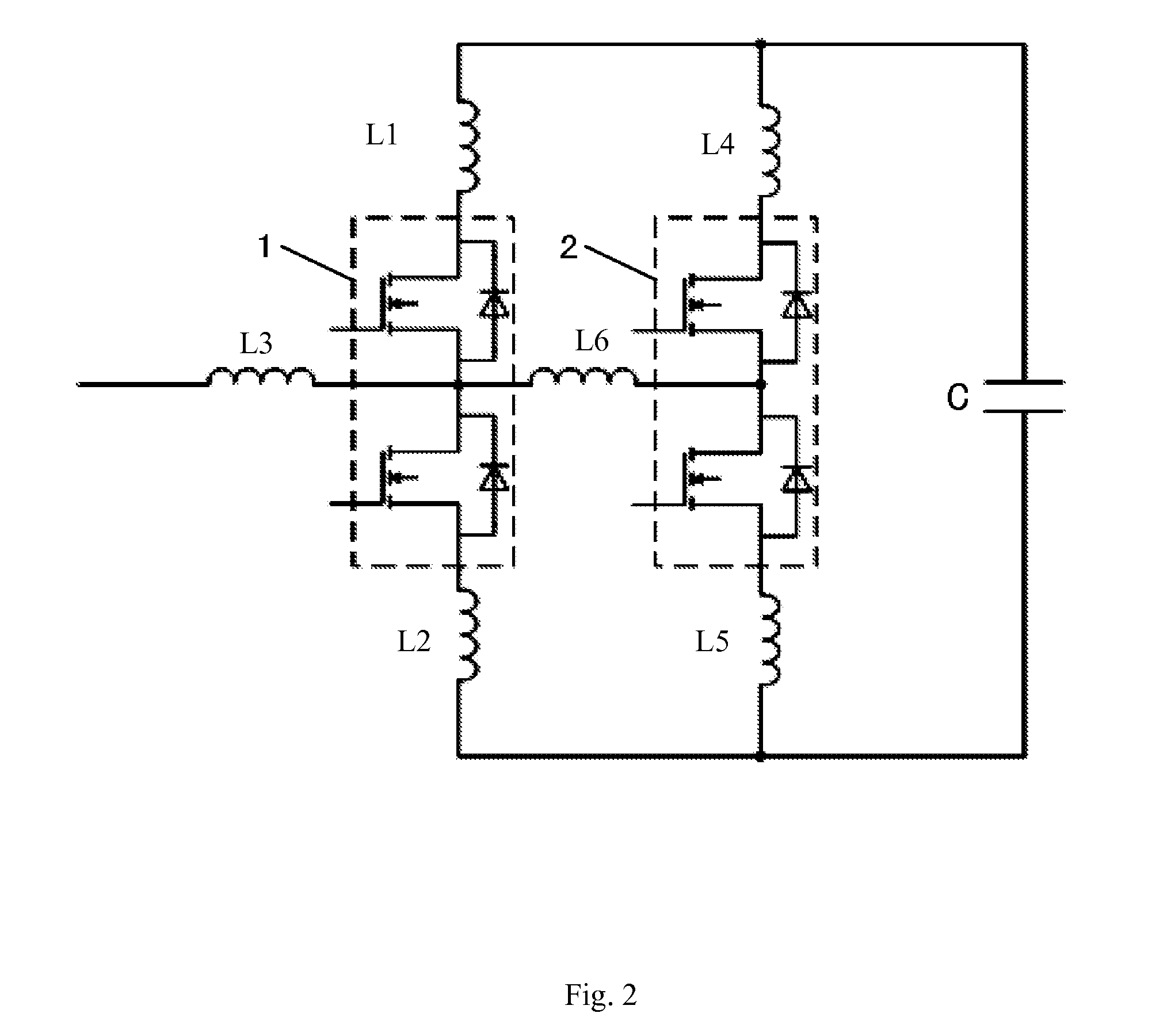

Current equalizing busbar

ActiveUS20140362627A1Simple structureImprove flow uniformitySingle bars/rods/wires/strips conductorsConversion constructional detailsPower flowEngineering

The present application discloses a current equalizing busbar for a converter comprising: a direct current busbar connected to a DC terminal of the converter and positive terminals and negative terminals of respective power modules; and an alternate current busbar connected to AC terminals of the respective power modules and a load; wherein, when the converter operates, a sum of an inductance caused by the DC busbar between the DC terminal and a positive terminal or a negative terminal of a power module and an inductance caused by the AC busbar between the load and an AC terminal of the power module is equal to a sum of an inductance caused by the DC busbar between the DC terminal and positive terminals or negative terminals of other power modules and an inductance caused by the AC busbar between the load and AC terminals of said other power modules.

Owner:DELTA ELECTRONICS INC

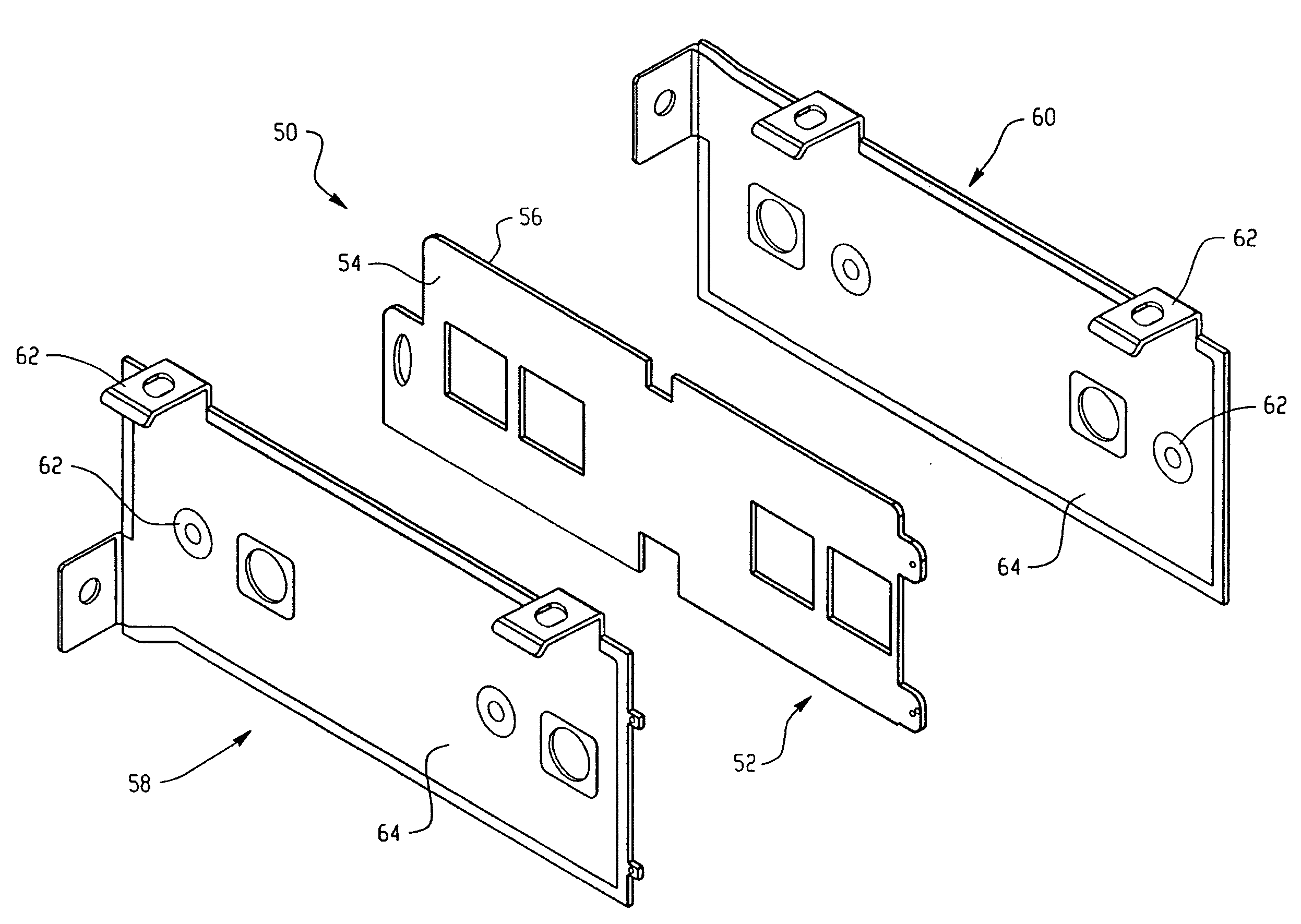

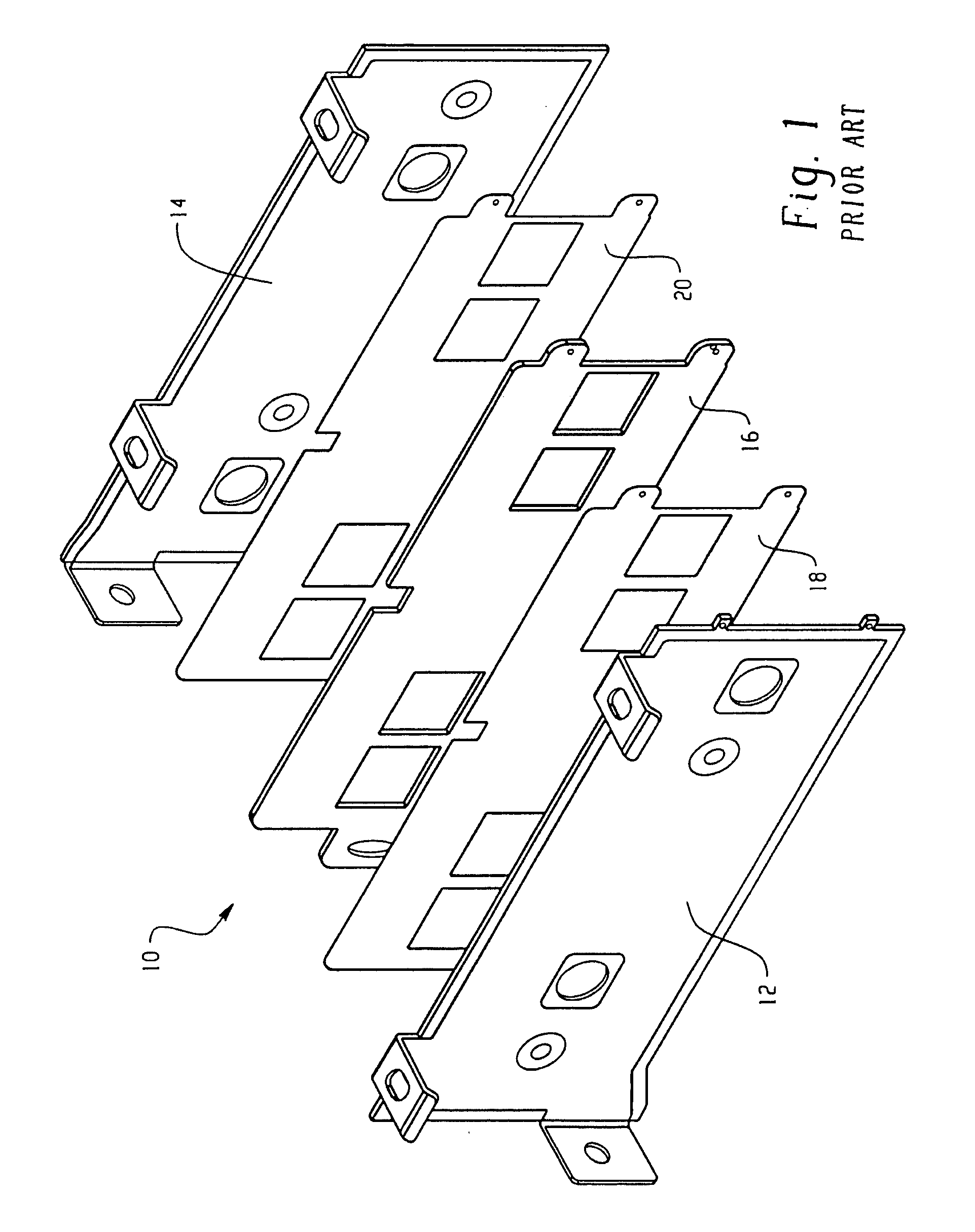

Adhesive-Less DC Bus System and Method for Manufacturing

InactiveUS20080024959A1Bus-bar/wiring layoutsSubstation/switching arrangement cooling/ventilationElectricityDC-BUS

A system and method for manufacturing a power bus assembly is provided. The power bus assembly includes a first conductive sheet configured to receive a positive charge and distribute the positive charge to a plurality of connection points formed thereon. The power bus assembly also includes a second conductive sheet configured to receive a negative charge and distribute the negative charge to a plurality of connection points formed thereon. Additionally, the power bus assembly includes an insulating sheet arranged between the first conductive sheet and the second conductive sheet to electrically isolate the first conductive sheet from the second conductive sheet. A plurality of vice fasteners are included to secure the first conductive sheet, the second conductive sheet, and the insulating sheet together to form the power bus assembly.

Owner:ROCKWELL AUTOMATION TECH

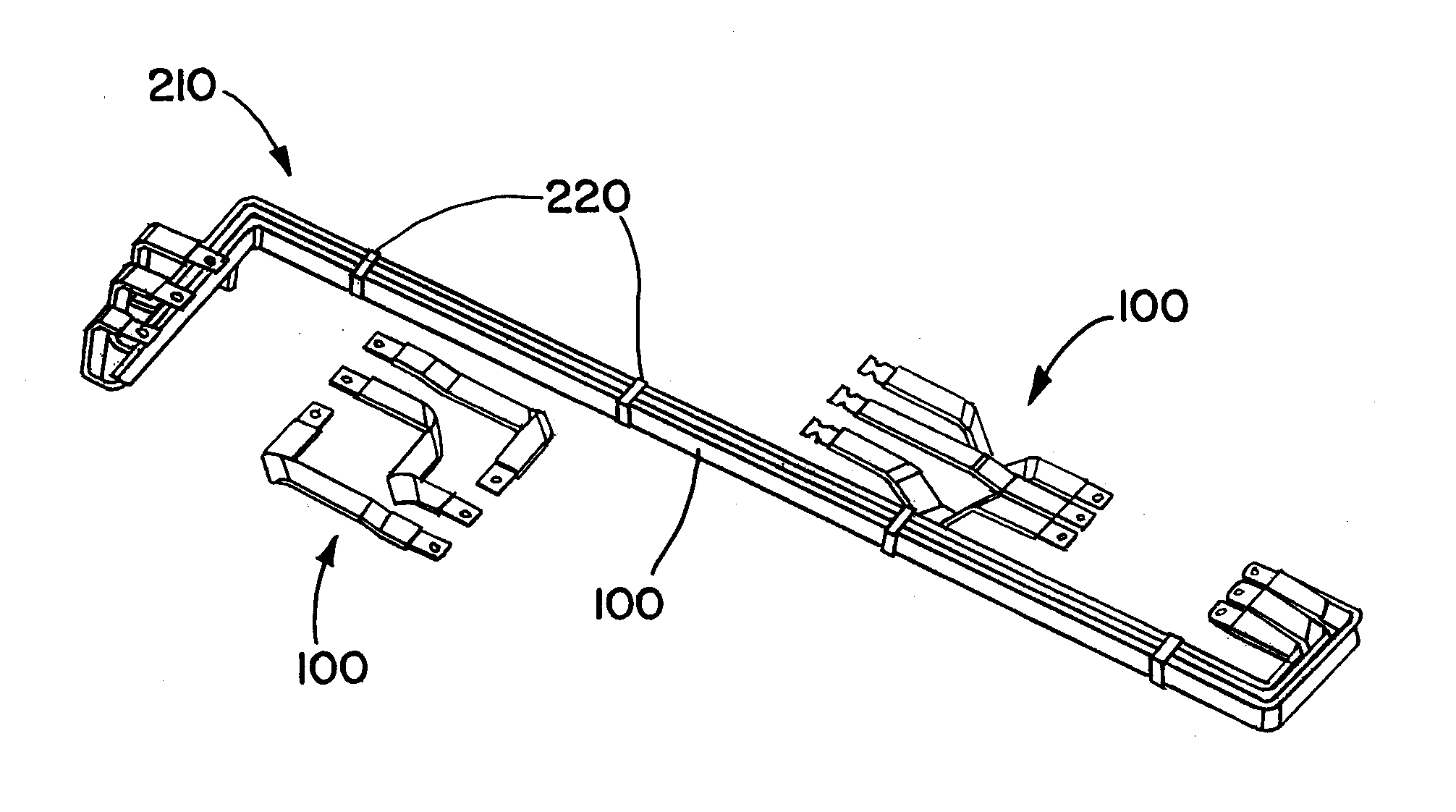

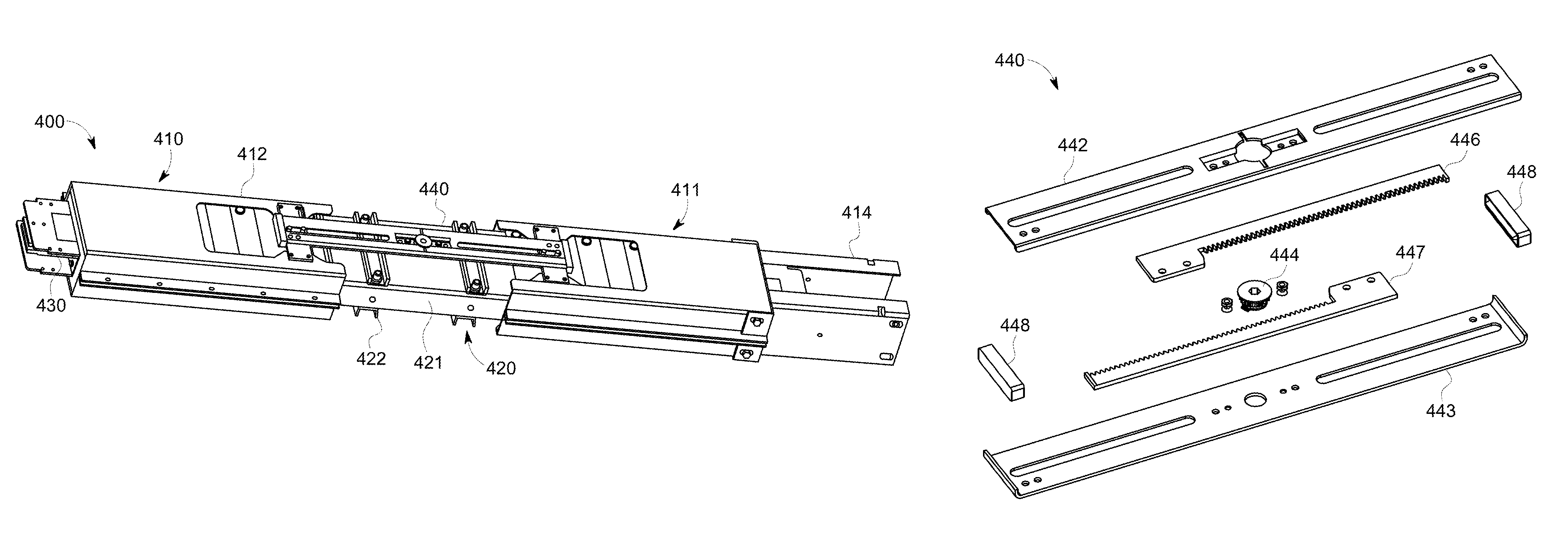

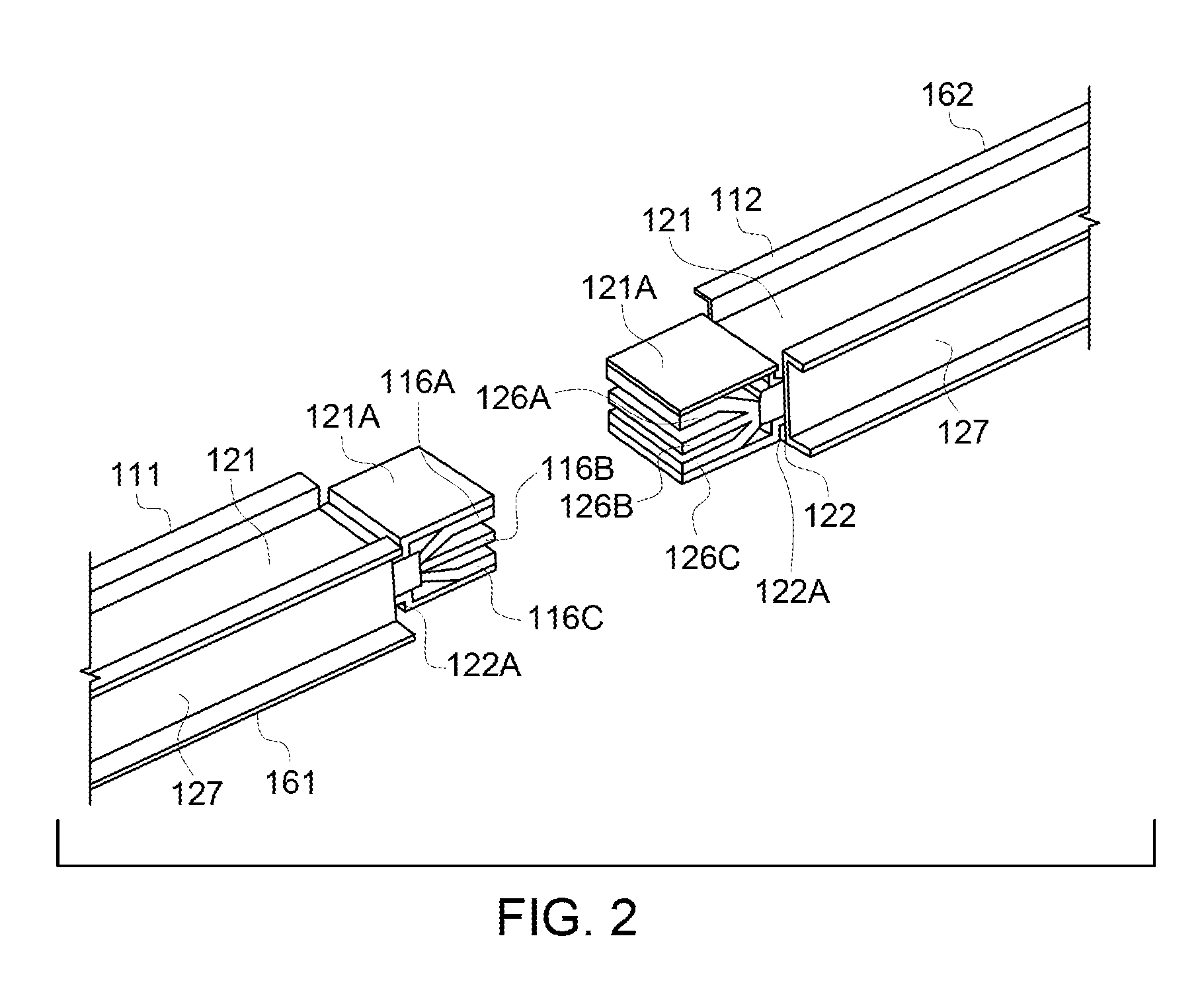

Busway joint coupling having an adjustable assembly for joining two busway sections

A busway system is provided. The busway system includes a first electrical busway section, a second electrical busway section, and a busway joint. The first and second electrical busway sections are disposed longitudinally offset from each other. The busway joint couples the first and second busway sections. The busway joint includes a plurality of busbars, a plurality of splice plates electrically coupled to the busbars, a first assembly coupled to the first electrical busway section, a second assembly coupled to the second electrical busway section, and an adjustment assembly coupled to the first and second assemblies. The splice plates and the busbars electrically couple the first and second electrical busway sections together. The adjustment assembly selectively moves the first and the second assemblies between a contracted position and an expanded position relative to each other.

Owner:ABB (SCHWEIZ) AG

Laminated bus bars and methods of manufacture thereof

A method of assembling a multilayer bus bar assembly includes coating a dielectric layer with a molten reactive hot-melt adhesive, placing the dielectric layer between first and second subassemblies, wherein the first and second subassemblies comprise a conductive element, adhering the molten reactive hot-melt adhesive to the subassemblies by applying a pressure of at least about one bar to the multilayer bus bar assembly for at least about one minute prior to the adhesive cooling to room temperature to provide a bonding strength between the dielectric material and a selected one of the first and second subassemblies of at least 1500 Newtons on a 25 millimeter by 25 millimeter sample when tested in accordance with ASTM D-1062.

Owner:ROGERS COMMUNICATIONS

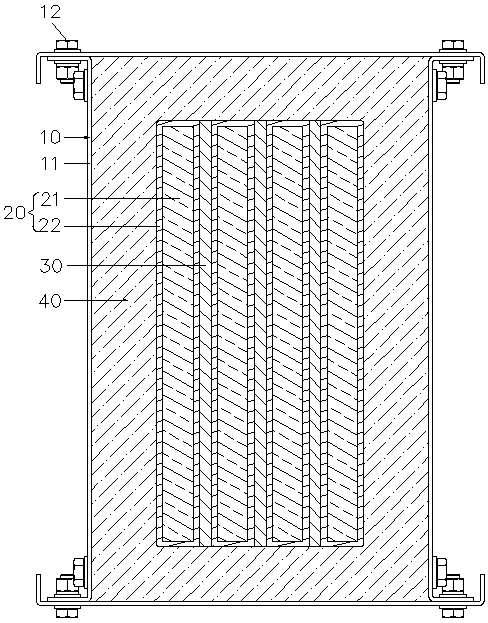

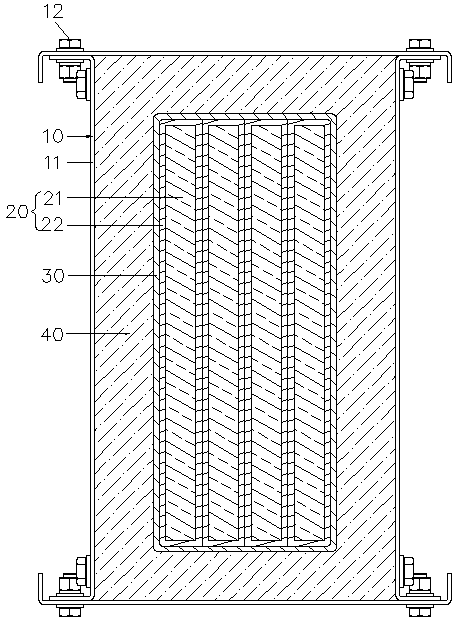

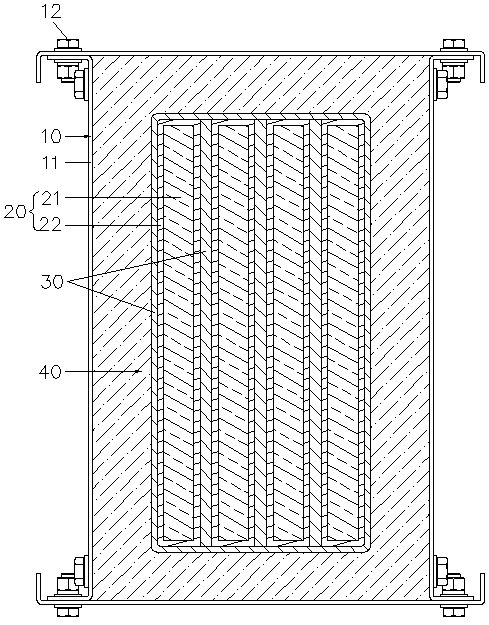

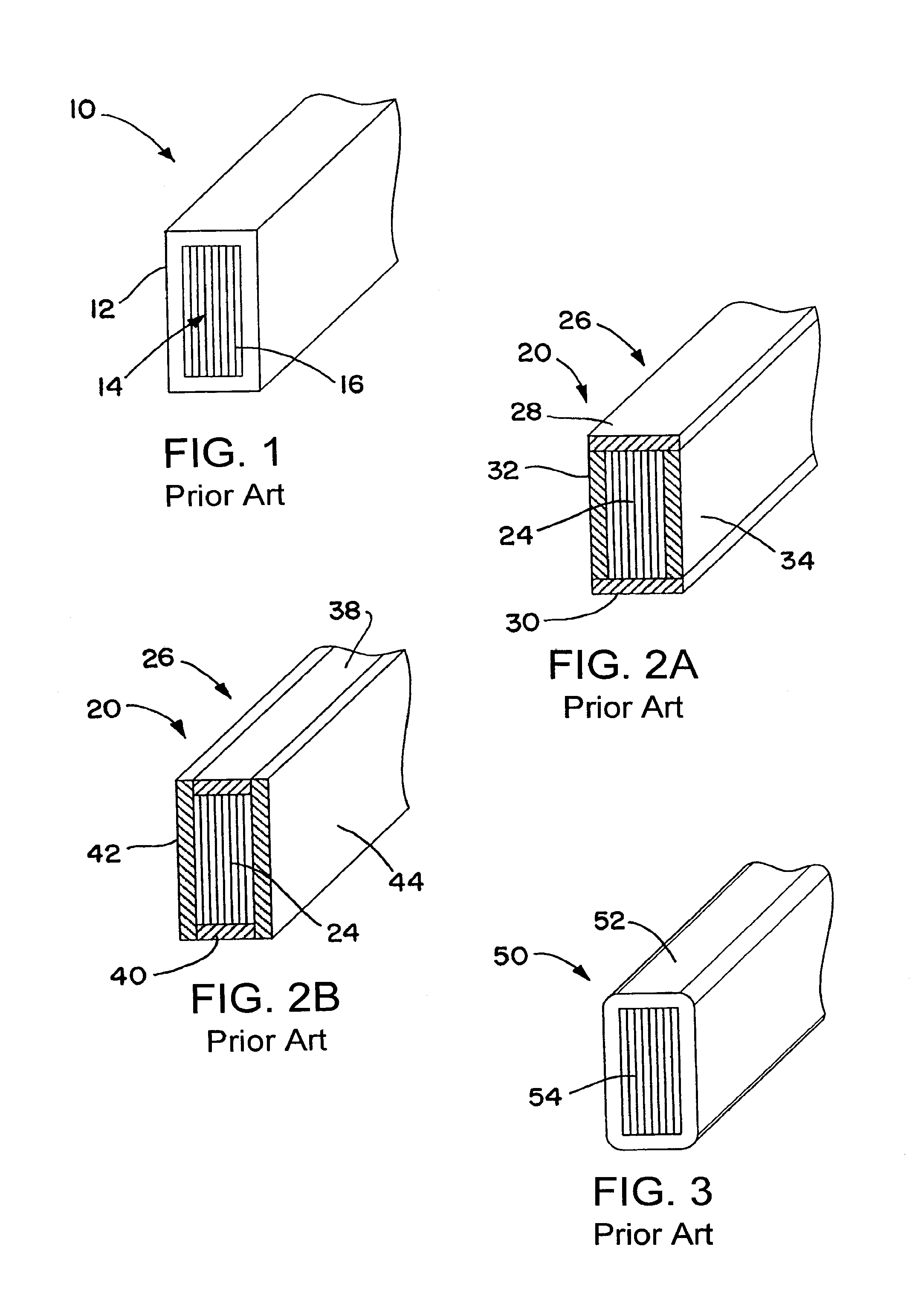

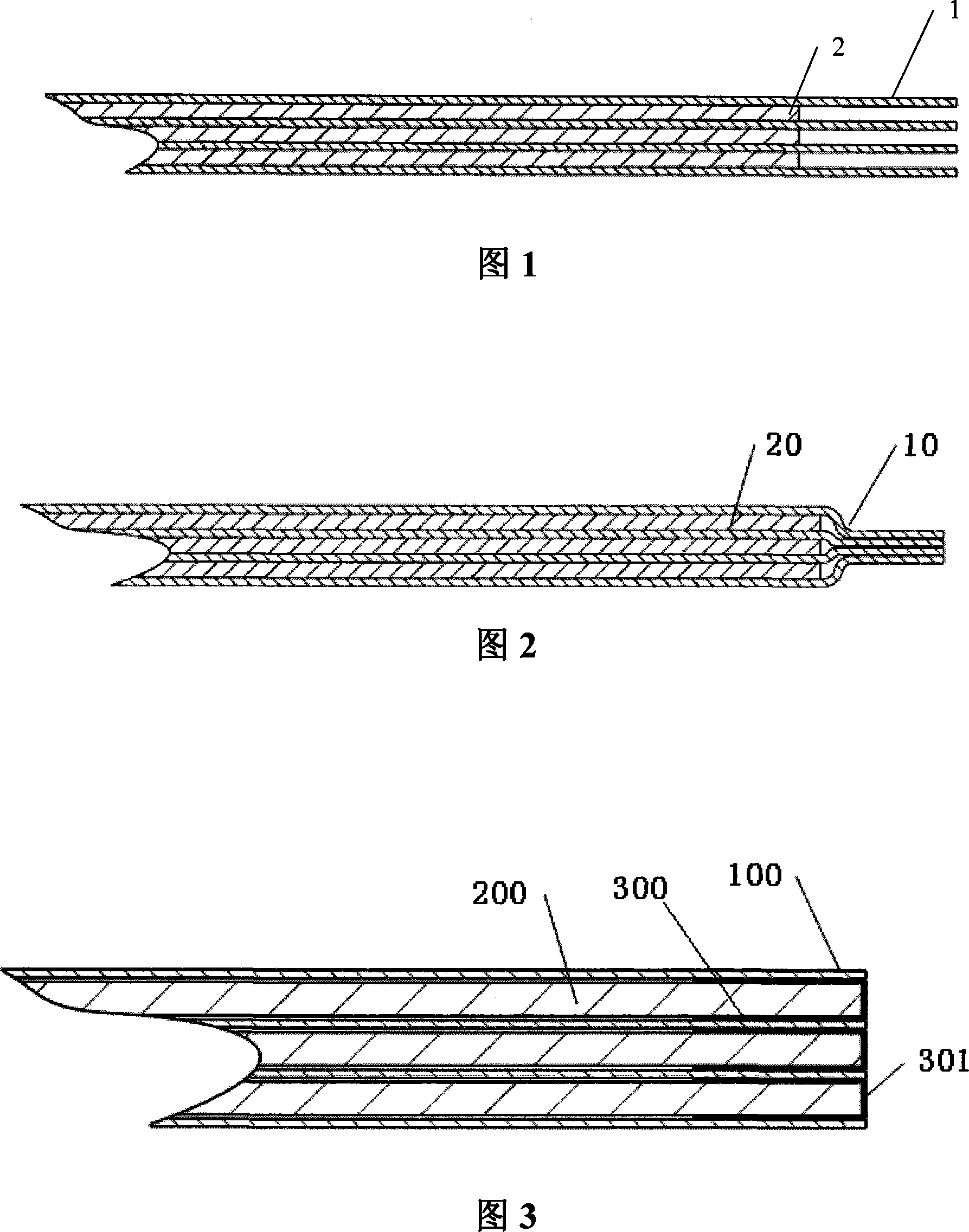

Stack bus bar edge structure

InactiveCN101252257ASave spaceImprove insulation performanceBus-bar/wiring layoutsSingle bars/rods/wires/strips conductorsInsulation layerElectrical conductor

The invention relates to a marginal structure for a laminated busbar, comprising more than one layer of conductor layer(200) and an insulation layer(100) corresponding to the conductor layer(200), wherein the insulation layer(100) is arranged on both sides of the conductor layer(200); moreover, the invention also comprises a coating(300) inserted between the conductor layer(200) and the insulation layer(100), wherein the coating(300) is in sticking contact with the conductor layer(200) and the insulation layer(100) respectively, and has end surfaces(301) of the coating (300) paralleled with edges of the conductor layer(200) and the insulation layer(100); the marginal structure for a laminated busbar has the advantages of saving space due to the adoption of a mode of coating edges of conductors and further ensuring more reliable insulation.

Owner:SHANGHAI STEP ELECTRIC +1

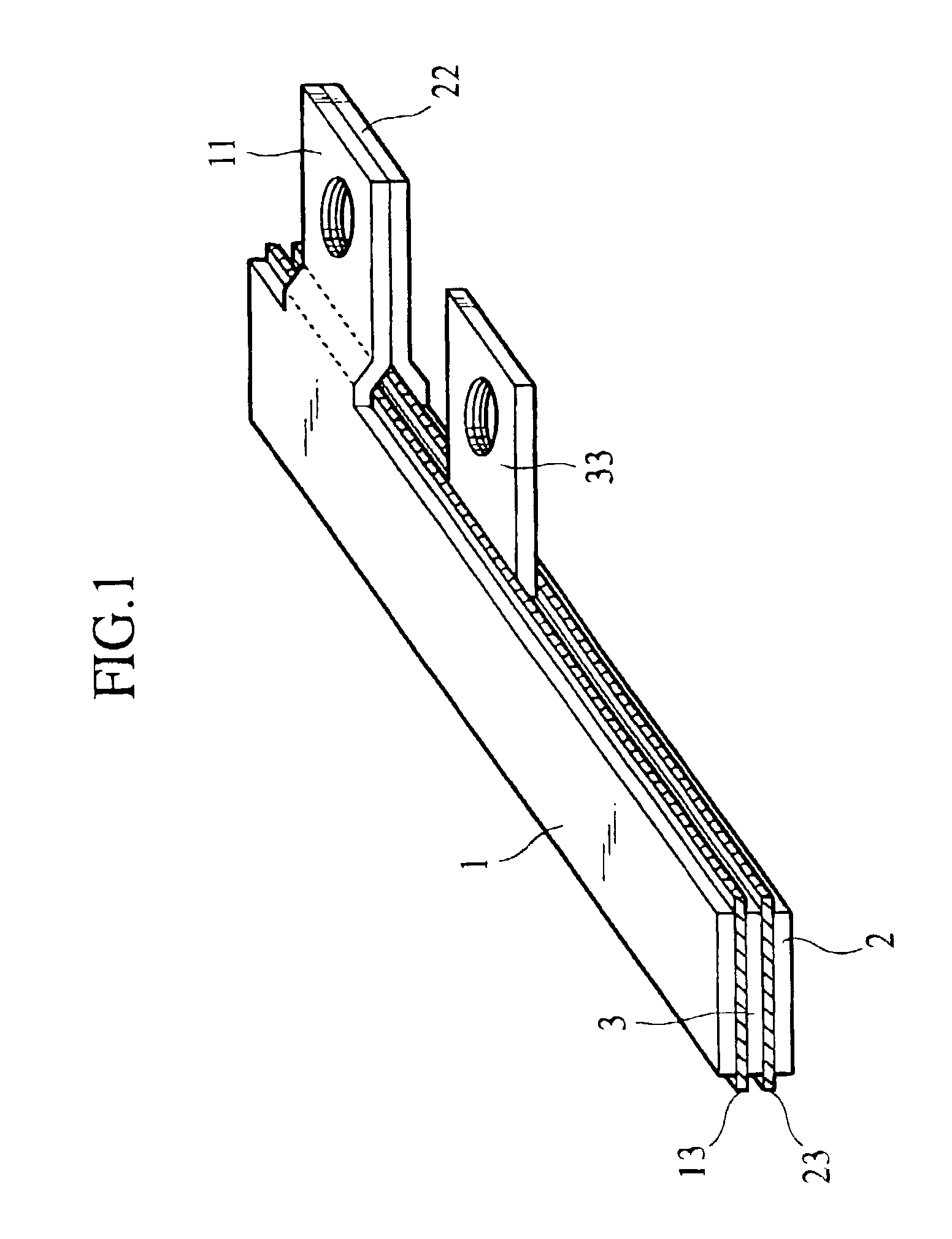

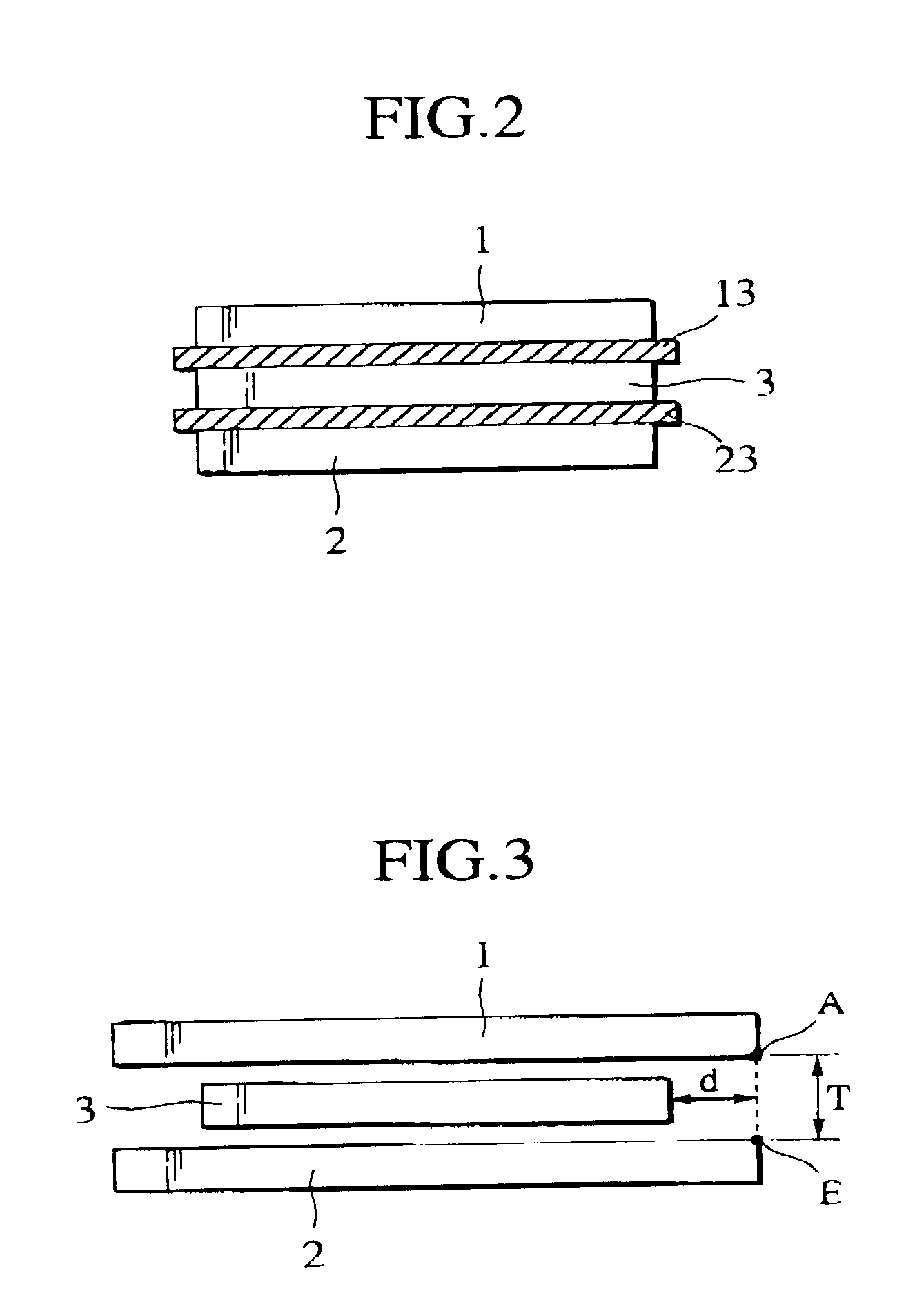

Bus bar wiring plate body for electric coupling box

A bus wiring plate body (20), for an electric coupling box, is arranged in a manner that bus bar members (23, 24) are wired between pre-hardening epoxy resin plates (21, 22) and these pre-hardening epoxy resin plates are subjected to a heat pressing process to thereby integrate the pre-hardening epoxy resin plates (21, 22) and the bus bar members (23, 24) in a laminated state. When hardened epoxy resin plates (25, 26) are disposed outside of the pre- hardening epoxy resin plates (21, 22), respectively, the strength of the bus bar wiring plate body (20) can be improved. Thus, since the bus bar members (23, 24) are sealed in an insulated state, leak current is reduced. Further, the thickness of the bus bar wiring plate body (20) is reduced to a large extent, so that the electric coupling box can be miniaturized and lightweighted.

Owner:YAZAKI CORP

Press fit connection for mounting electrical plug-in outlet insulator to a busway aluminum housing

A molded plastic outlet box for electric busway systems comprising: a molded plastic base comprising a plurality of press-fit tabs for attachment of the base to a housing of the electric busway system disposed about a bottom surface of the base.

Owner:ABB (SCHWEIZ) AG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com