Intensive insulation bus duct

A dense, busway technology, applied in the direction of laminated busbars, fully enclosed busbar devices, etc., can solve problems such as difficulty in meeting fire resistance requirements, and achieve the effect of improving continuous power supply capacity, extending continuous power supply time, and improving fire resistance performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

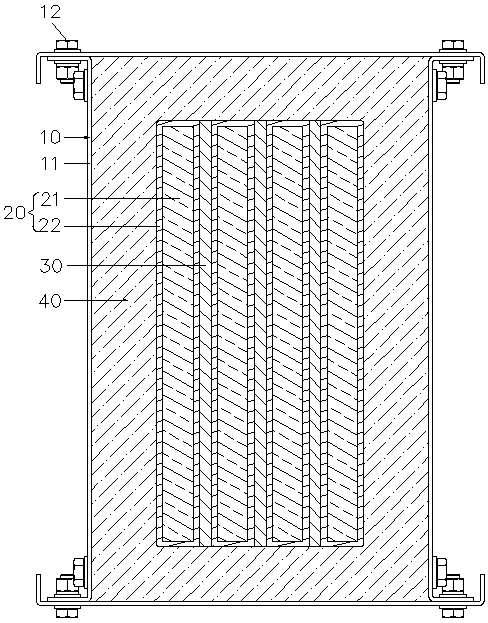

[0026] see figure 1 , the dense insulated busway of the present invention is roughly in the shape of a cuboid, including a busbar protective shell 10 and several busbars 20 arranged in the busbar protective shell 10 .

[0027] The busbar protective shell 10 is a protective shell for intensive insulating bus ducts. It is generally a metal shell, such as a steel or iron shell, which has the function of protecting the internal components of the bus duct. In this embodiment, the busbar protective shell 10 consists of It is surrounded by four metal plates 11, and two adjacent metal plates are fixed together by bolts 12, of course, they can also be fixed by screws.

[0028] The busbar 20 includes a busbar conductor 21 and an insulating layer 22 covering the busbar conductor 21 . The insulating layer 22 mainly plays an insulating role for the busbar conductor 21, and is better able to resist fire. It is preferably a ceramic silicon rubber composite tape, and of course it can also be...

Embodiment 2

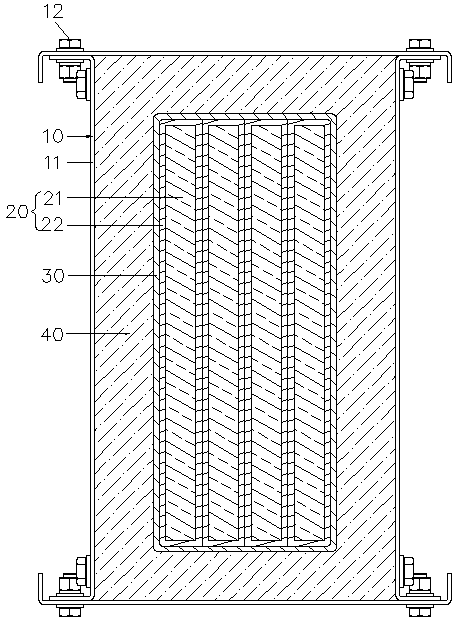

[0038] see figure 2 , which discloses the embodiment 2 of the present invention's intensive insulating busway. Wrapped outside the busbars 20 arranged side by side.

Embodiment 3

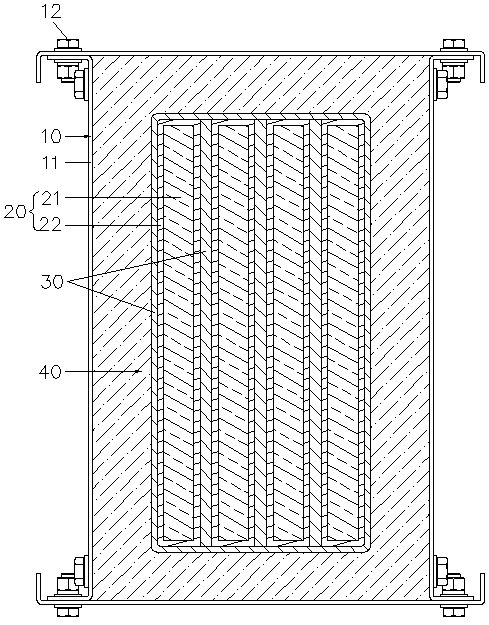

[0040] see image 3 , which discloses Embodiment 3 of the dense insulating bus duct of the present invention. This embodiment is similar to Embodiment 1, and the difference is that the dense insulating bus duct is further coated with an inorganic heat-absorbing material outside the busbars 20 arranged side by side. 30.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com