Lightweight fractal gradient gear

A lightweight and gradient technology, applied in belts/chains/gears, components with teeth, portable lifting devices, etc., can solve problems such as reducing the quality of gears, failing to achieve expected results, and achieving improved utilization and excellent comprehensive machinery. Performance, Lightweight Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below through specific embodiments.

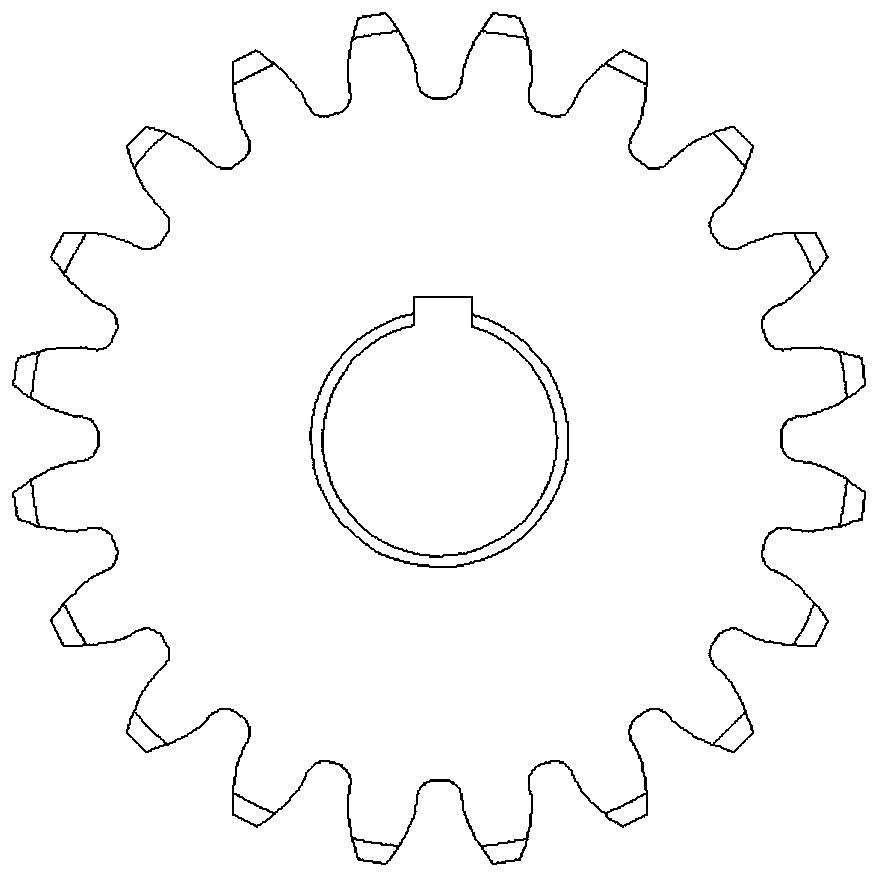

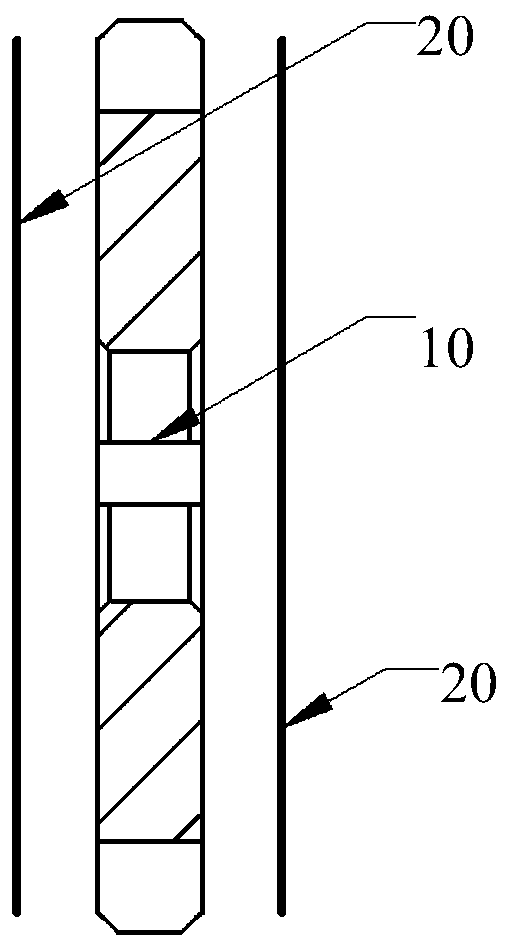

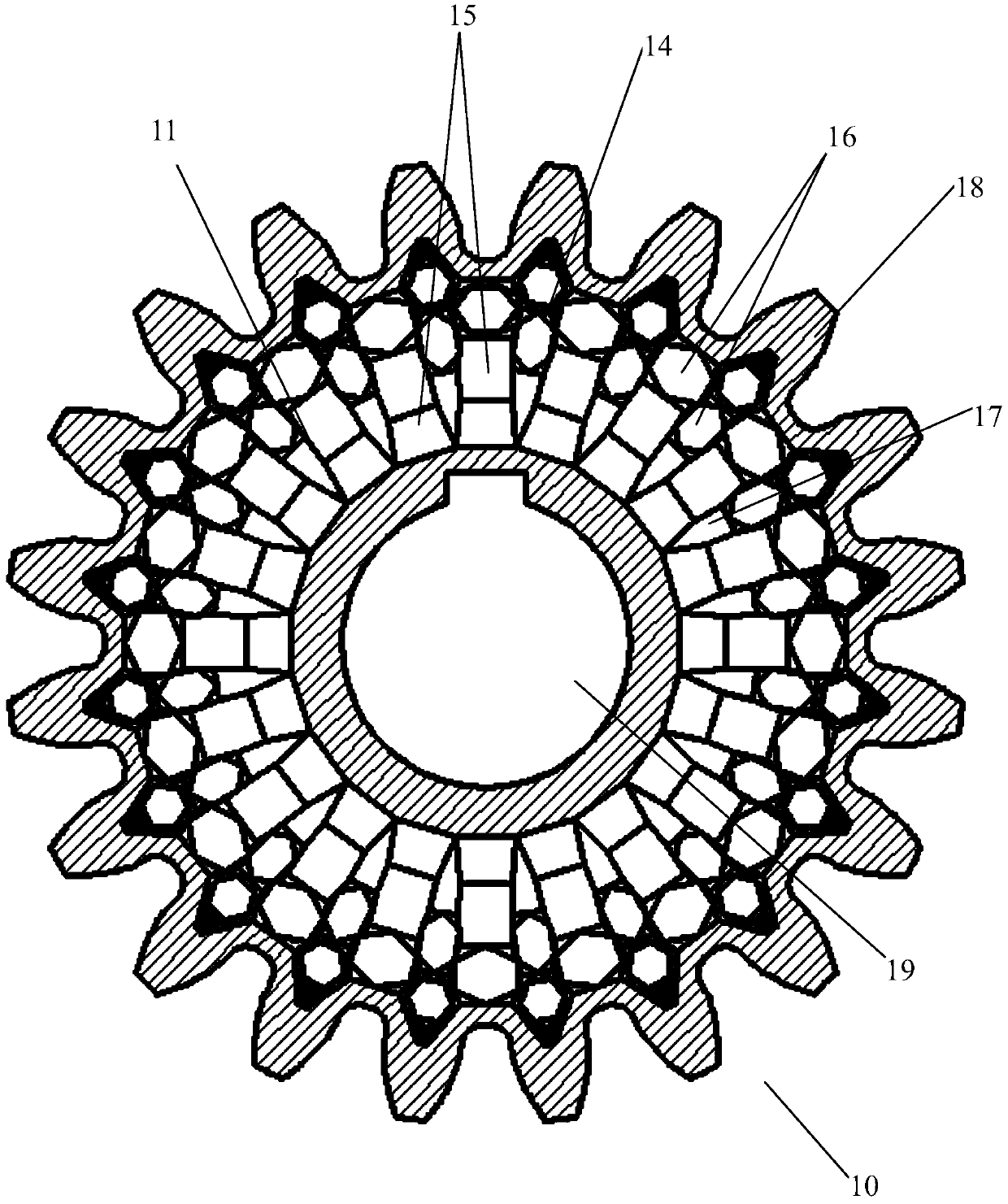

[0033] see Figure 1 to Figure 4 , a lightweight fractal gradient gear, comprising a gear body 10 and two plate bodies 20 , the two plate bodies 20 are fixed on both sides of the gear body 10 . The gear body 10 has a porous lightweight structure 11 and a ring gear. The ring gear is sheathed on the outer periphery of the porous lightweight structure 11 , and bolts can be used to securely socket the ring gear and the porous lightweight structure 11 . The central part of the porous lightweight structure 11 is provided with a shaft hole 19 for connecting a transmission shaft.

[0034] The porous lightweight structure 11 of the present invention at least includes a first-level gradient pore group, a second-level gradient pore group, and a third-level gradient pore group, etc., which are interleaved with each other. Among them, the gradient series of the first-level gradient hole group is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com