Tooling device used for assembly of rotor and stator in shielding electric motor

A shielded motor and tooling technology, which is applied in the direction of centering/balancing the rotor, etc., can solve the problem of difficult assembly of the shielded motor rotor and stator, achieve the effects of shortening the product manufacturing cycle, facilitating tool disassembly and assembly, and improving the degree of light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

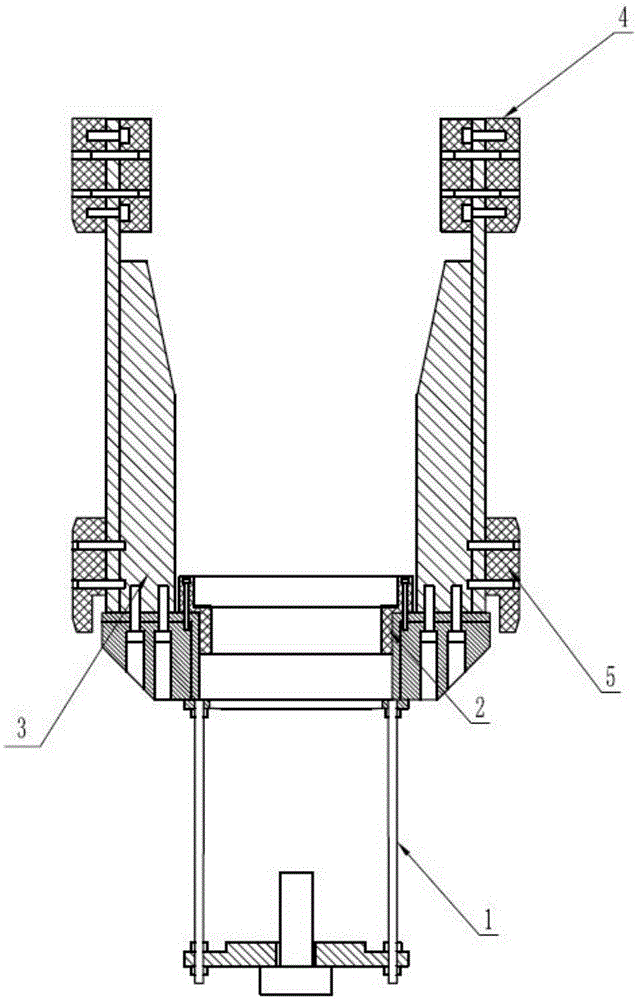

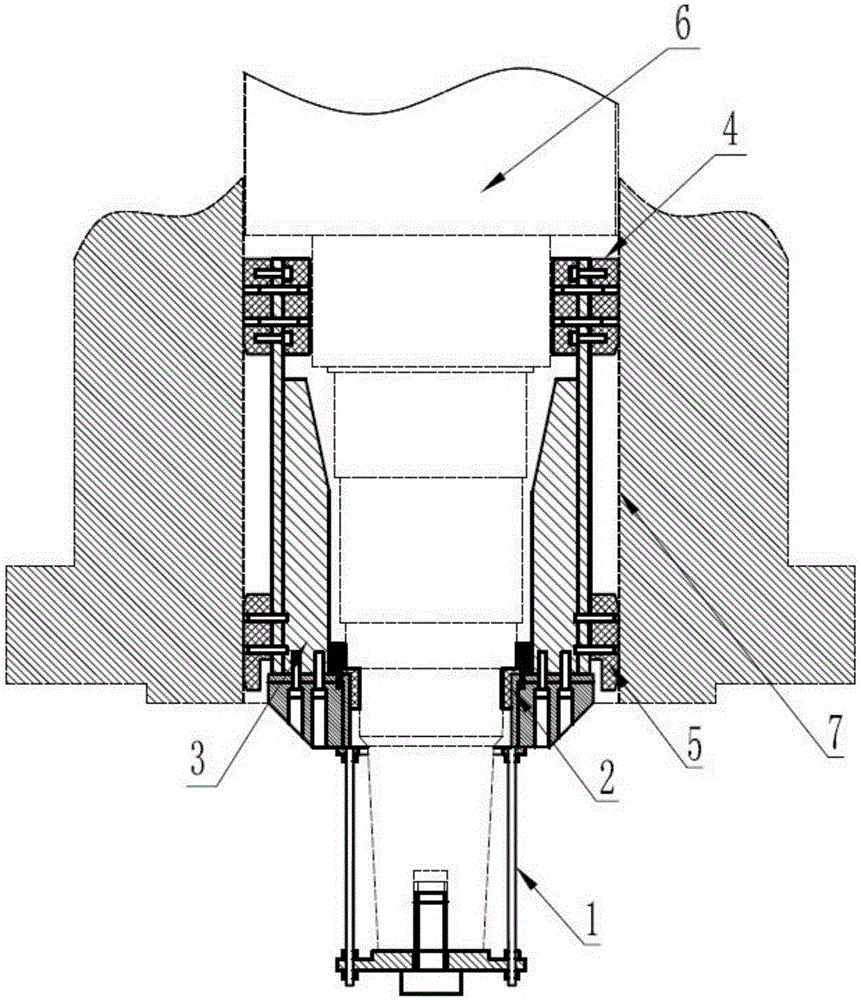

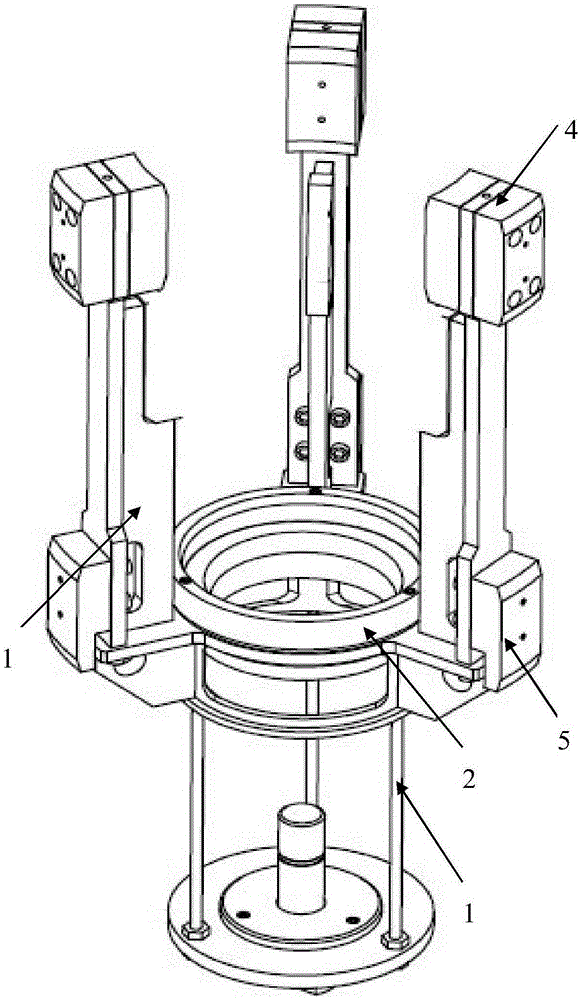

[0023] Such as figure 1 Shown is a tooling device for the assembly between the rotor and the stator of a shielded motor. The tooling bracket 1 is fixed to the rotor 6 through the threaded hole at the shaft end. The outer diameter of the boss of the positioning sleeve 2 is matched with the inner diameter of the tooling bracket 1 and connected by bolts. ,Such as figure 2 As shown, the inner diameter of the positioning sleeve 2 matches the outer diameter of the step of the rotor 6, and there are three aluminum brackets 3, which are evenly distributed on the tooling bracket 1 and connected with bolts; the upper nylon guide block 4 and the lower nylon guide block 5 pass through the cylinder respectively. The pin is positioned with the aluminum bracket 3 and fixed by bolts.

[0024] Such as image 3 As shown, the inner diameter of the upper nylon guide block 4 is matched with the small outer diameter of the rotor 6, the outer diameter of the upper nylon guide block 4 is matched w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com