Processing technology of stainless steel metal wash basin

A processing technology and stainless steel technology, applied in the processing technology field of stainless steel metal washbasin, can solve the problems of low production yield, easy bumping, scratching, high processing cost, improve the surface effect, reduce improper welding, and reduce technical requirements. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Embodiment 1, comprises the following steps:

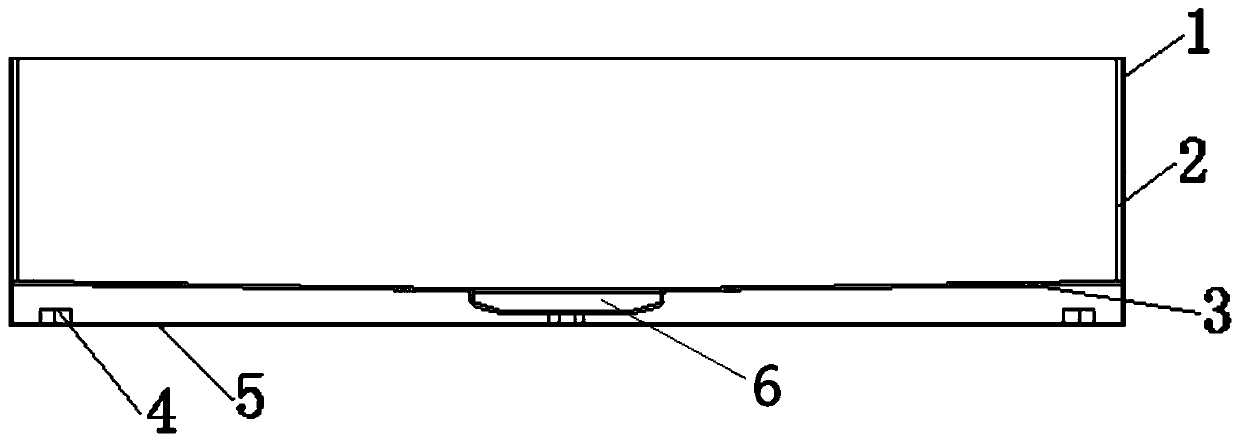

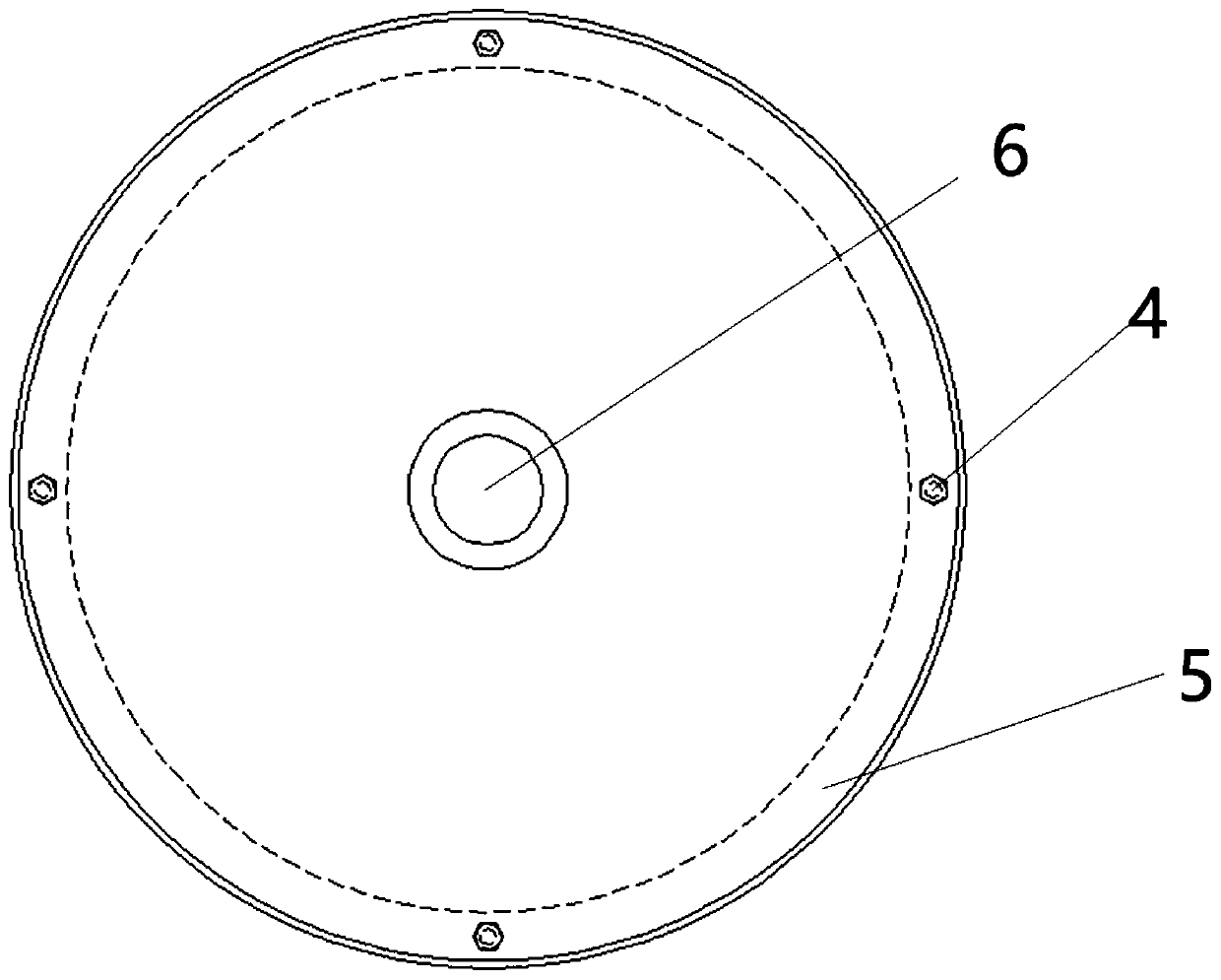

[0022] (1) Firstly, two stainless steel metal sheets with different widths are rolled into inner circle side wall 2 and outer circle side wall 1 with a rolling machine, the narrow one is the inner circle side wall 2, and the wide one is the outer circle side wall 1.

[0023] (2) Then, the bottom end of the inner circular side wall 2 and the basin bottom plate 3 are welded together by argon arc welding to form an inner basin.

[0024] (3) The bottom end of the outer circular side wall 1 and the bottom end of the inner basin are welded together by argon arc welding to form a basin structure.

[0025] (4) Finally, a drain hole 6 is punched out at the bottom plate 3 of the basin body, a support plate 5 is welded with argon arc welding at the other end of the outer circular side wall 1 , and a nut 4 is welded on the support plate 5 .

[0026] Afterwards, the outer circular side wall 1 is polished with weld scars, and after the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com