Balcony

A balcony and balcony panel technology, which is applied to balconies, building components, buildings, etc., can solve the problems of poor thermal insulation performance and noise isolation ability, and achieve the effect of improving thermal insulation effect, bearing capacity and brazing quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

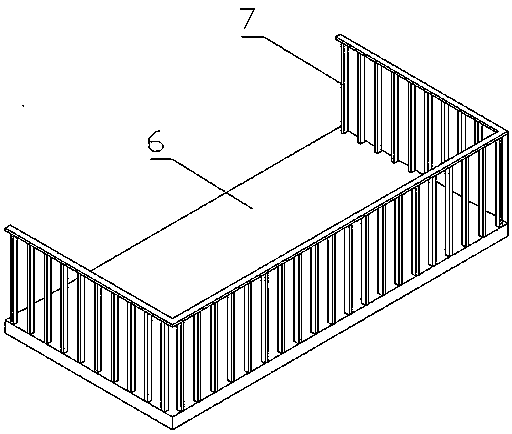

[0046] Such as figure 1 Shown: a kind of balcony, comprises the balcony board 6 that stretches out building and is installed on the guardrail 7 on the balcony board 6, and the balcony board 6 is spliced by several composite boards, and described composite board comprises upper board, lower board, Several pipe bodies in the middle and the brazing layer between the pipe body and the upper panel and the lower panel.

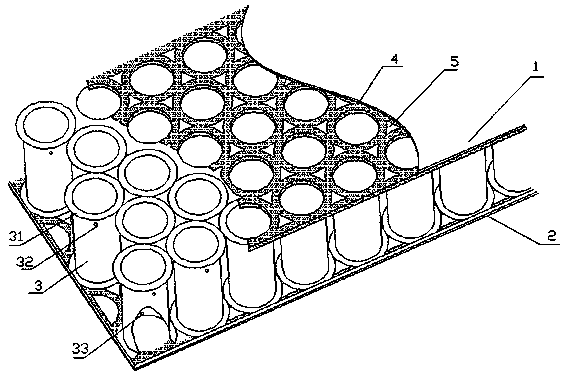

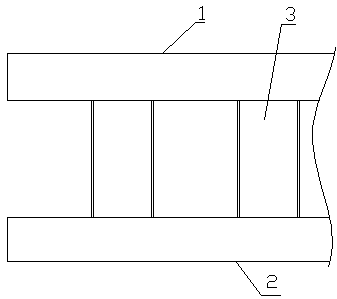

[0047] Such as figure 2 As shown: specifically, the composite board 5 includes an upper panel 1 , a lower panel 2 , several round tubes 3 in the middle, and a brazing layer 4 between the round tubes 3 and the upper panel 1 and lower panel 2 . The upper and lower ends of the round tube 3 are flanged, so that the outer diameter after flanging is larger than the diameter of the round tube; the flanging of the round tube 3 is brazed with the upper panel 1 and the lower panel 2, that is, the adjacent round tubes The flanges of 3 are closely arranged, and after the a...

Embodiment 2

[0057] Such as Figure 4 , Figure 5 Shown: a balcony, including a balcony board 6 protruding from the building and a guardrail 7 installed on the balcony board 6, the balcony board 6 and the guardrail 7 are all spliced by several composite boards, and the composite board includes an upper panel , the lower panel, several tube bodies in the middle and the brazing layer between the tube body and the upper panel and the lower panel.

[0058] Specifically, the composite board includes an upper panel 1', a lower panel 2', several circular tubes 3' in the middle, and a brazing layer 4' between the circular tubes 3', the upper panel 1', and the lower panel 2'. The upper and lower ends of 3' are flanged, so that the outer diameter after flanging is greater than the diameter of the round pipe, and the shape of the flanging is also circular. The flanging 31' of the round tube 3' is brazed with the upper panel 1' and the lower panel 2', and the flanging 31' of the round tube 3' is a...

Embodiment 3

[0065] A balcony with a roof is different from Embodiment 1 or 2 in that a roof is provided above the guardrail, and the roof is spliced by several composite boards.

[0066] Specifically, the composite panel of this embodiment includes an upper panel, a lower panel, several square tubes in the middle, and a brazing layer between the square tubes, the upper panel, and the lower panel. The outer diameter behind the edge is larger than the diameter of the square pipe, and the shape of the flanging is also square. The flanging of the square tube is connected to the upper panel and the lower panel by brazing, the square tubes are arranged at intervals, and after the arrangement, a brazing layer is formed on the flanging by brazing material. The brazing layer is punched and flanged so that the square sleeve is positioned on the flanging of the brazing layer.

[0067] In this embodiment, the brazing material is aluminum brazing material, and the edge of the brazing layer is stren...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com