Crossed belt sorting trolley assembling method

A cross-belt sorting and assembly method technology, which is applied to assembly machines, metal processing equipment, manufacturing tools, etc., can solve the problems of unfavorable cross-belt sorting system operating efficiency, affecting the stability of trolley operation, and low accuracy of trolley installation and debugging. , to achieve the effect of simplifying the overall connection and installation structure, reducing the difficulty of maintenance and manufacturing costs, and improving the accuracy of assembly and debugging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

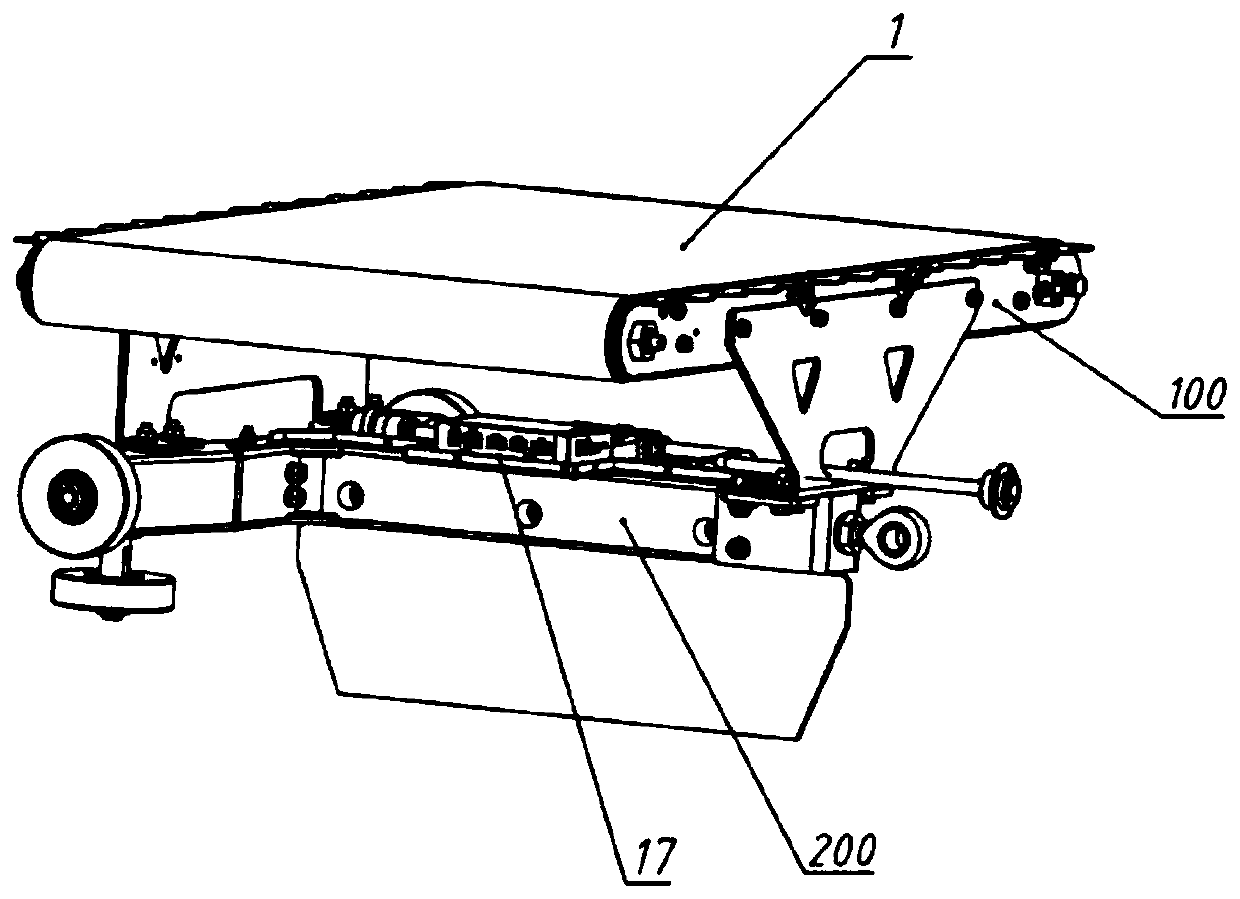

[0036] Example 1, as Figure 1 to Figure 3 As shown, the cross-belt sorting trolley is interconnected by two modular structures to form an integral structure, including an upper conveying unit 100 and a lower frame 200 .

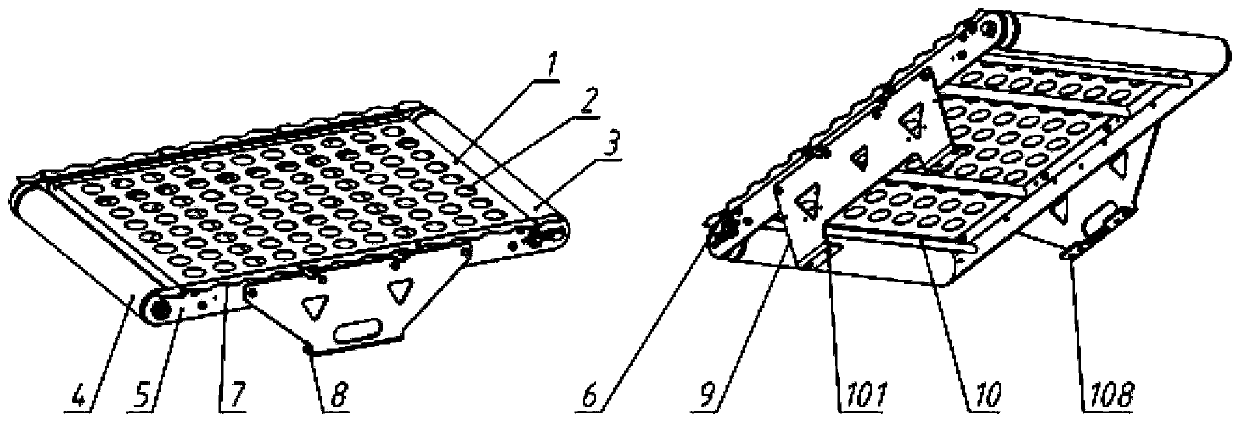

[0037] The upper conveying unit 100 includes a belt support plate 2 and a side plate 5 connected to both sides of the belt support plate 2. The two ends of the side plate 5 are respectively provided with an unpowered roller 3 and a powered roller 4. The belt 1 is wound between the belt support plate 2, the unpowered drum 3 and the power drum 4; the power is transmitted by the power drum 4 to drive the sorting belt 1 to reciprocate on the belt support plate 2 in two directions to implement different sorting action.

[0038] In the lateral direction of each side plate 5, a folded plate 7 is installed horizontally, and a first folded connecting plate 8 or a second folded connecting plate 9 is vertically connected.

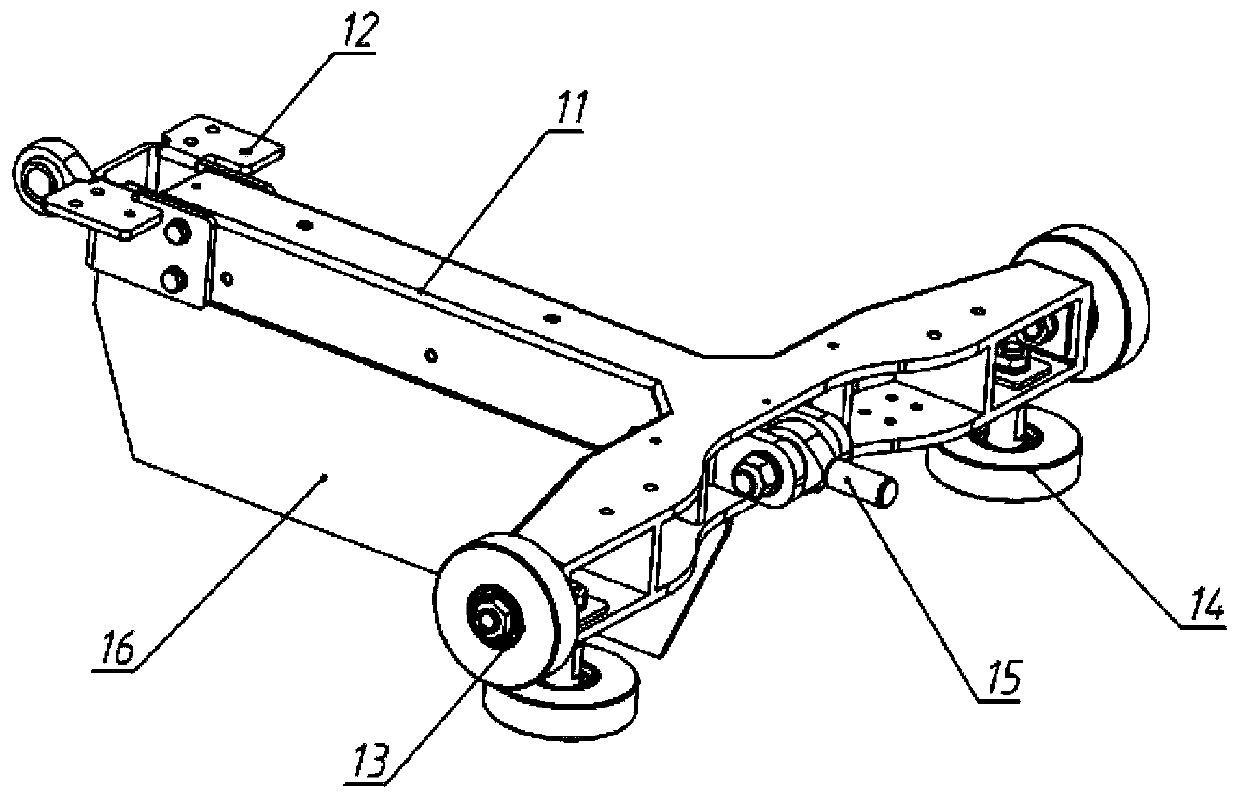

[0039] Specifically, as Figure 4 As shown...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com