Lightweight extinction plastic master batch for automotive interior and preparation method of master batch

A technology of automotive interior and plastic masterbatch, applied in the field of automotive interior materials, can solve the problems of uneven dispersion of functional fillers, insufficient light weight, insufficient mechanical properties, etc., and achieve excellent matting performance, excellent light matting, good fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

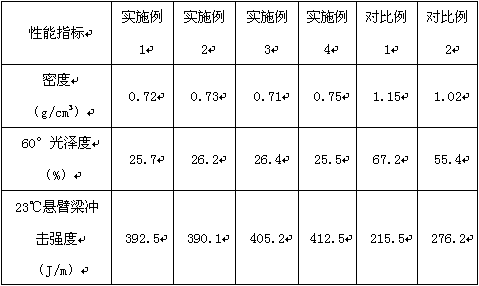

Examples

Embodiment 1

[0030] (1) Mix sodium phosphate and soluble polymer and dissolve in water, then stir to form a uniform mixed solution, then adjust the pH value with acid solution, then add nano mica flakes and soluble calcium salt, and stir evenly to obtain a precursor solution; soluble The polymer is polyethylene glycol, and the soluble calcium salt is calcium chloride; the acid solution is dilute hydrochloric acid, and the pH value is adjusted to 5;

[0031] Each raw material is calculated by weight: 15 parts of sodium phosphate, 2 parts of soluble polymer, 40 parts of water, 13 parts of nano mica flakes, and 15 parts of soluble calcium salt;

[0032] (2) The precursor solution obtained in step (1) is moved into the reactor for microwave hydrothermal reaction, and then centrifuged, washed with deionized water, and then vacuum-dried to generate calcium phosphate on the nano-mica sheet, and assembled into composite loose particles , and the mica sheet with matting effect is loaded inside; the...

Embodiment 2

[0036] (1) Mix sodium phosphate and soluble polymer and dissolve in water, then stir to form a uniform mixed solution, then adjust the pH value with acid solution, then add nano mica flakes and soluble calcium salt, and stir evenly to obtain a precursor solution; soluble The polymer is polyacrylamide, and the soluble calcium salt is calcium nitrate; the acid solution is dilute hydrochloric acid, and the pH value is adjusted to 5;

[0037] Each raw material is in parts by weight, 15 parts of sodium phosphate, 2 parts of soluble polymers, 44 parts of water, 11 parts of nano-mica flakes, and 14 parts of soluble calcium salts;

[0038] (2) The precursor solution obtained in step (1) is moved into the reactor for microwave hydrothermal reaction, and then centrifuged, washed with deionized water, and then vacuum-dried to generate calcium phosphate on the nano-mica sheet, and assembled into composite loose particles , and the mica sheet with extinction effect is loaded inside; the te...

Embodiment 3

[0042] (1) Mix sodium phosphate and soluble polymer and dissolve in water, then stir to form a uniform mixed solution, then adjust the pH value with acid solution, then add nano mica flakes and soluble calcium salt, and stir evenly to obtain a precursor solution; soluble The polymer is polyacrylamide, and the soluble calcium salt is calcium acetate; the acid solution is dilute hydrochloric acid, and the pH value is adjusted to 5;

[0043] The raw materials are, in parts by weight, 16 parts of sodium phosphate, 2.3 parts of soluble polymers, 34 parts of water, 14 parts of nano-mica flakes, and 17 parts of soluble calcium salts;

[0044] (2) The precursor solution obtained in step (1) is moved into the reactor for microwave hydrothermal reaction, and then centrifuged, washed with deionized water, and then vacuum-dried to generate calcium phosphate on the nano-mica sheet, and assembled into composite loose particles , and the mica sheet with extinction effect is loaded inside; th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com