Honeycomb interlayer structure prepared through added material manufacturing method

A honeycomb interlayer and additive manufacturing technology, applied in the field of additive manufacturing, can solve the problems of inability to meet a wide range of high-performance lightweight structures, poor connection performance between panels and honeycomb stiffeners, and complex forming processes, and achieve fatigue resistance. Good, high forming dimensional accuracy, strong impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the purpose, content and advantages of the present invention clearer, the specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

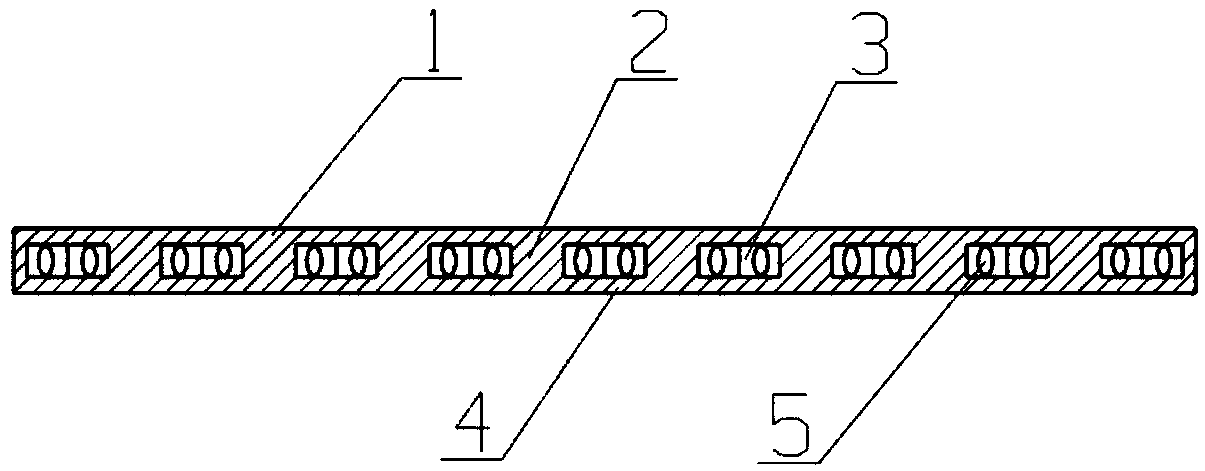

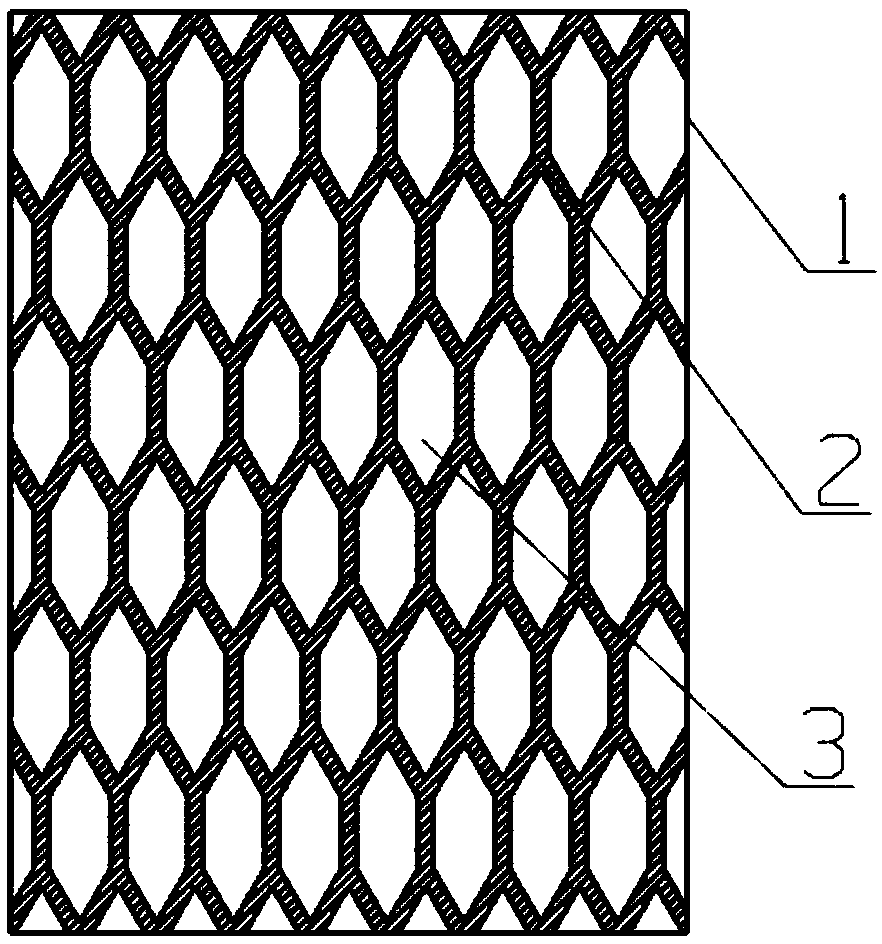

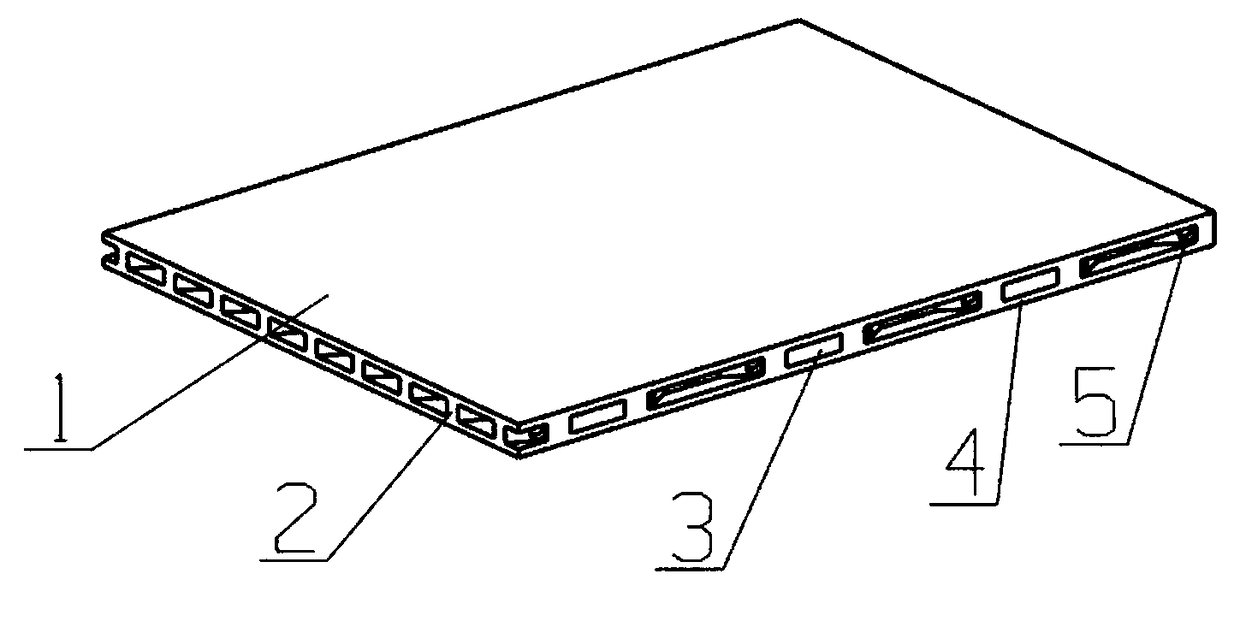

[0023] This example proposes a honeycomb sandwich structure prepared by an additive manufacturing method. The honeycomb sandwich structure is prepared by a laser selective melting additive manufacturing method. Its structure is as follows Figure 1-4 shown. The honeycomb sandwich structure includes a first panel 1 , a honeycomb reinforcing rib 2 , a honeycomb cavity 3 , a second panel 4 and a powder cleaning process hole 5 . Wherein, the honeycomb reinforcing rib 2 is located between the first panel 1 and the second panel 4, and the first panel 1, the second panel 4 and the honeycomb reinforcing rib 2 are metallurgically bonded. The honeycomb reinforcing rib 2 has an irregular hexagonal structure, and a honeycomb cavit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com