Pedestrian overpass

A pedestrian bridge and integrated technology, applied in bridges, bridge parts, bridge construction, etc., can solve the problems of unsuitable durability of steel structures, inconvenient processing of steel structures, inconvenient maintenance and repair, etc., to achieve light weight and improve thermal insulation effect , Easy installation and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

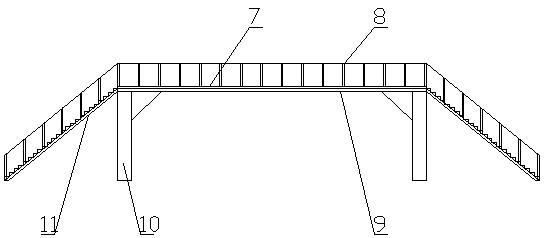

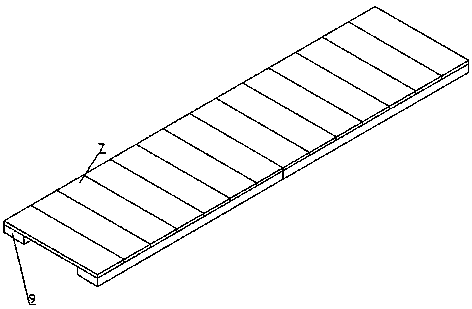

[0049] Such as figure 1 or figure 2 Shown: a pedestrian bridge, including a bridge body, a bridge deck 7 and a guardrail 8 set on the bridge deck 7. The bridge body includes a column 10, a beam 9 and a staircase 11, and the column 10, beam 9, staircase 11 and guardrail 8 are adopted In the traditional steel structure, the bridge deck 7 is joined by a plurality of rectangular composite plates by welding, and the composite plates are fixed on the cross beam 9 by screw connection.

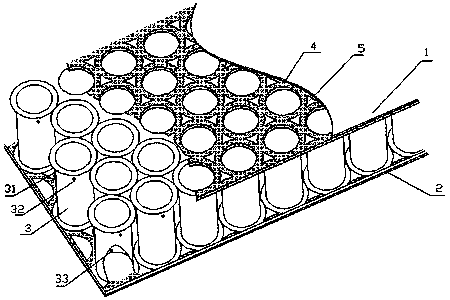

[0050] Such as image 3 Shown: Specifically, the composite board 5 includes an upper panel 1, a lower panel 2, a plurality of round tubes 3 in the middle, and a brazing layer 4 between the round tube 3 and the upper panel 1 and the lower panel 2. The upper and lower ends of the round tube 3 are flanged so that the outer diameter after flanging is larger than the diameter of the round tube; the flanging of the round tube 3 is brazed and connected to the upper panel 1 and the lower panel 2, that is, adjace...

Embodiment 2

[0060] Such as Figure 5 Shown: a pedestrian bridge, including a bridge body, a bridge deck 7, and a guardrail 8 set on the bridge deck 7. The bridge body includes a column 10, a beam 9 and a staircase 11, the column 10 is stacked by multiple composite plates by welding The crossbeam 9 is composed of arc-shaped composite plates spliced by welding; the bridge deck 7 is spliced by multiple composite plates installed on the bridge body by riveting, and the joints between adjacent composite plates Structural glue is injected inside to prevent the bridge deck 7 from leaking; the staircase 11 is formed by overlapping multiple composite boards up and down, and the upper and lower composite boards are connected together by welding.

[0061] Such as Image 6 Specifically, the composite board of this embodiment includes an upper panel 1', a lower panel 2', a number of round tubes 3'in the middle, and a brazing layer 4 between the round tube 3'and the upper panel 1'and the lower panel 2'...

Embodiment 3

[0068] Such as Picture 9 Shown: an arched flyover, which differs from embodiment 1 or embodiment 2 in that it includes a bridge body, a bridge deck 7 and a guardrail 8 arranged on the bridge deck 7. The bridge body includes a column 10, an arched cross beam 9 and The ramp 12 and the column 10 are composed of multiple composite plates stacked by welding; the arched cross beam 9 is composed of multiple arc-shaped composite plates joined by welding; the bridge deck 7 is composed of multiple pieces installed on the bridge by riveting The composite panels on the main body are spliced together, and structural glue is injected into the joints between adjacent composite panels to prevent the bridge deck 7 from leaking; the ramp 12 is composed of multiple pieces connected to the arched beam 9 at one end and fixed at the other end. The composite boards on the ground are spliced together, and the composite boards are connected together by welding.

[0069] Such as Picture 10 Shown: t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com