Lightweight design method for armor type thin-wall structure

A lightweight design and thin-walled structure technology, applied in design optimization/simulation, geometric CAD, special data processing applications, etc., can solve the problems affecting the overall weight and center of mass estimation of equipment, reduce structural weight, and low efficiency of ribs, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

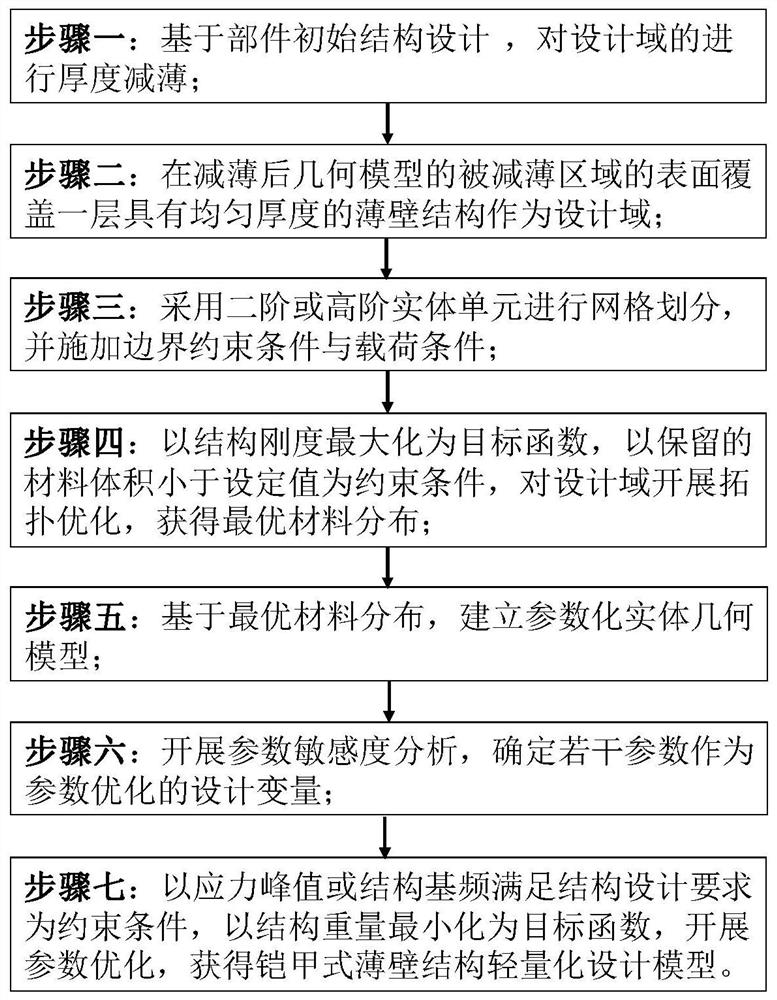

Method used

Image

Examples

Embodiment Construction

[0037] In order to make the technical solutions and advantages of the present invention more clear, the technical solutions in the embodiments of the present invention are clearly and completely described below in conjunction with the drawings in the embodiments of the present invention:

[0038] The characteristics of the armored thin-walled structure are as follows: (1) The designable thin-walled area in the armored thin-walled structure is composed of two areas with different thicknesses. The distribution and shape of the areas with different thicknesses are obtained by the corresponding optimization design process, which can be reasonably The mechanical properties of materials are used to effectively realize the lightweight structure; (2) The structural optimization design process has good integrity, covering the conceptual design stage and the detailed design stage, and both stages introduce applicable structural optimization design technology, so as to ensure that More ef...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com