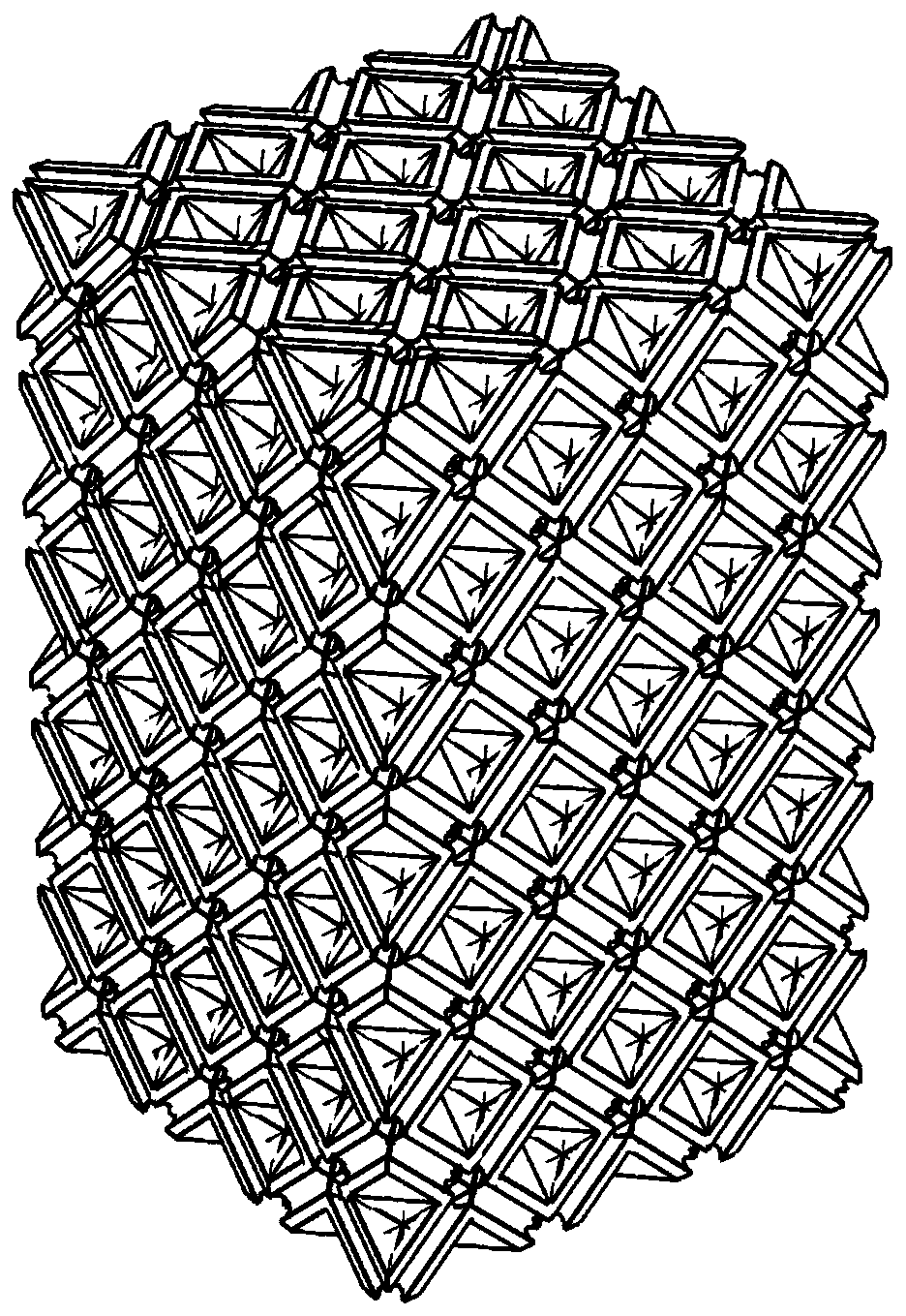

Enhanced superimposed hollow lattice structure and application thereof

A lattice structure, enhanced technology, applied in the direction of elastic shock absorber, spring/shock absorber, shock absorber, etc., to achieve the effect of improving the degree of light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

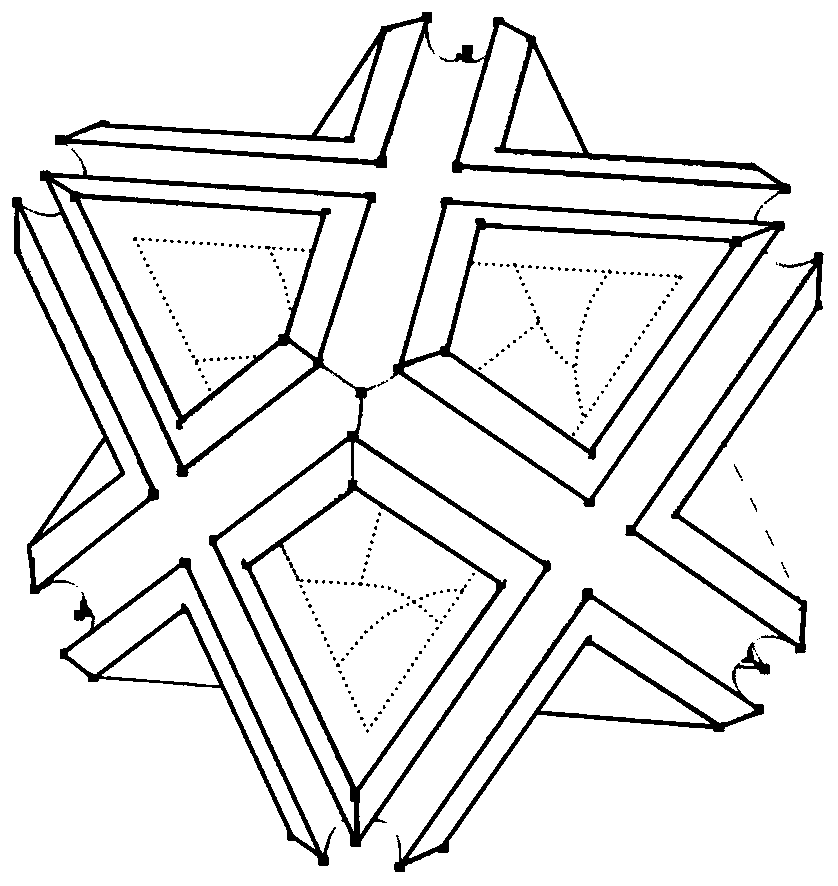

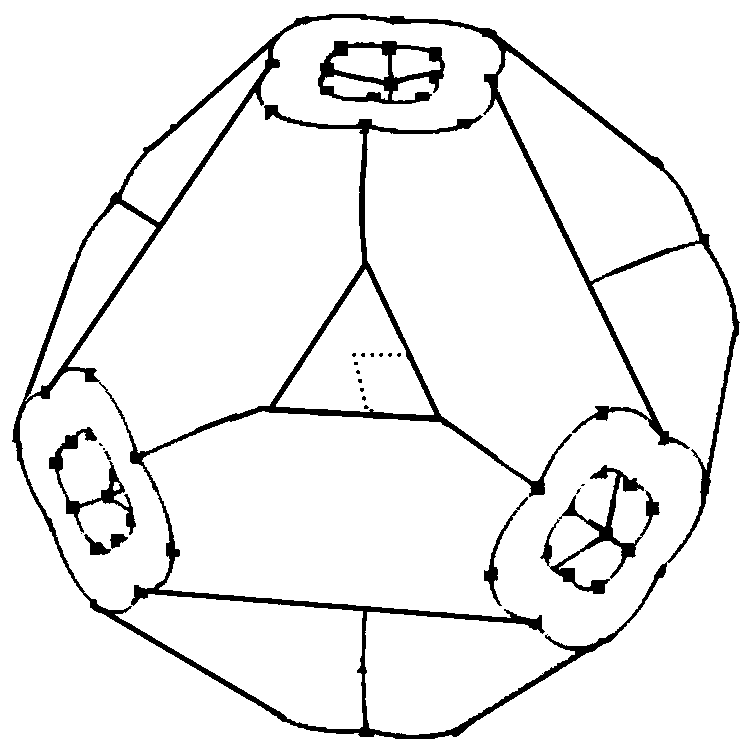

[0032] In order to realize that the strength of the enhanced hollow superimposed lattice structure is higher than the sum of the strengths of the two basic hollow lattice structures implemented separately and greatly reduce the weight to achieve light weight, the diameter of the inner core removed cylinder used in this embodiment is the same as that of the outer cylinder The diameter ratio of the body rod is 1:2, the length of the lattice unit cell is 3 mm, the diameter of the lattice unit cell rod body is 0.8 mm, and the hollow diameter of the internal removal cylinder is 0.4 mm.

[0033] Such as Figure 2 to Figure 4 As shown, they are the peripheral basic hollow unit cell, the inner core support unit cell and the combined enhanced hollow lattice unit cell, which constitute the peripheral basic hollow lattice structure, the inner core support hollow structure, and the reinforced superimposed hollow Lattice structure, through ABAQUS / Explicit to carry out finite element simula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com