Colour lamp base of non-binding post on colour lamp string

A technology for colored lamps and lamp sockets, which is applied in connection, incandescent lamps, discharge lamps, etc., and can solve the problems of complex assembly process of colored lamp strings.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

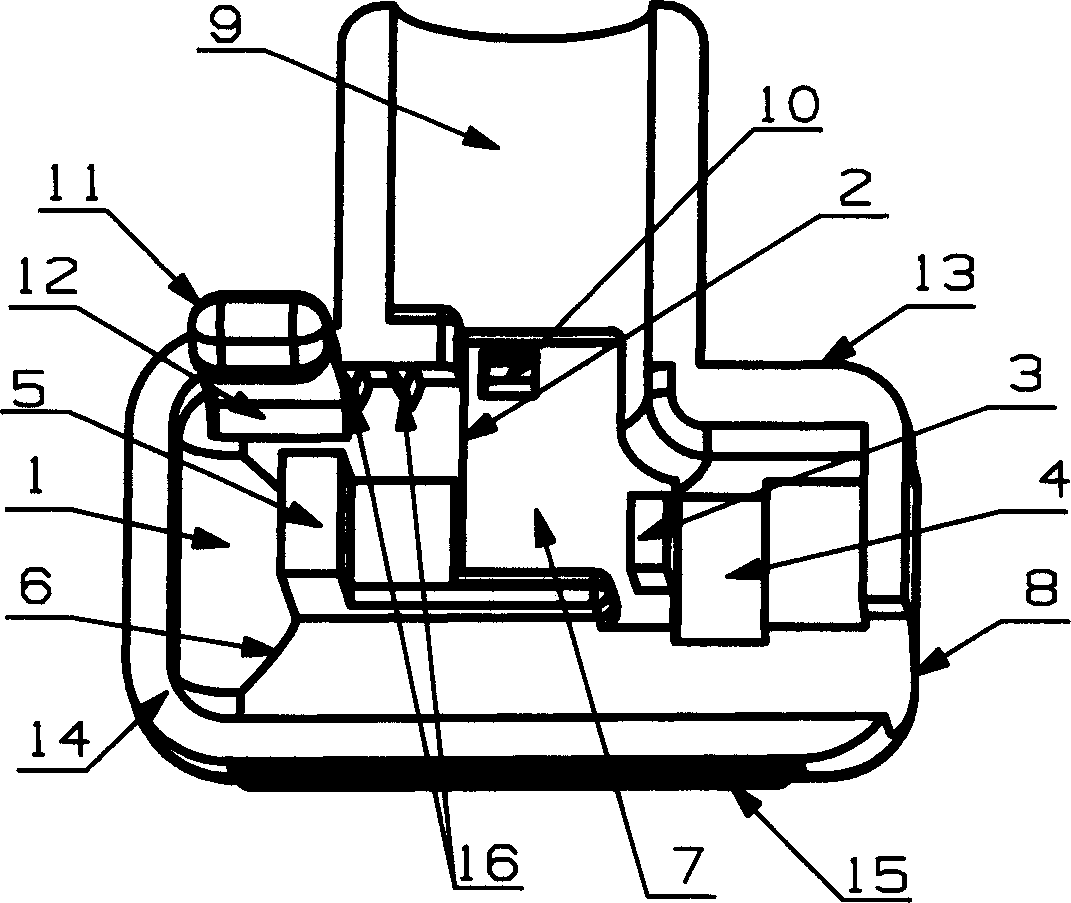

[0016] figure 1 The bottom of the middle groove (1) is a cylindrical surface with the same diameter as the electric wire, the width of the groove (1) is equal to the diameter of the electric wire, and the depth of the groove (1) is equal to or slightly larger than the diameter of the electric wire. The top surface of the plastic sheath of the wire is pushed against the top surface (2) of the groove (1) where the wire is placed. The electric wires are pressed section by section and placed in the upper, left, and lower three-section linear grooves (1). The electric wire is drawn out from the side opening (8) of the groove (1). The inner side junction of the slots (1) where the wires are placed in each section is a right-angled edge (6), and on the outer inner wall of the slot (1) where the wires are placed in the upper section, there are two raised ribs (16) with a height of 0.3 mm. . Rib (6) and rib (16) and the inner wall of each position of groove (1) jointly fix electric ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com