Novel safety protection power strip

A safety protection, plug-in board technology, applied in the direction of contact parts, electrical components, coupling devices, etc., can solve the problems of loose socket holes, hidden dangers, unreasonable design, etc., to avoid easy falling off, good usability, and prevent electric shock. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

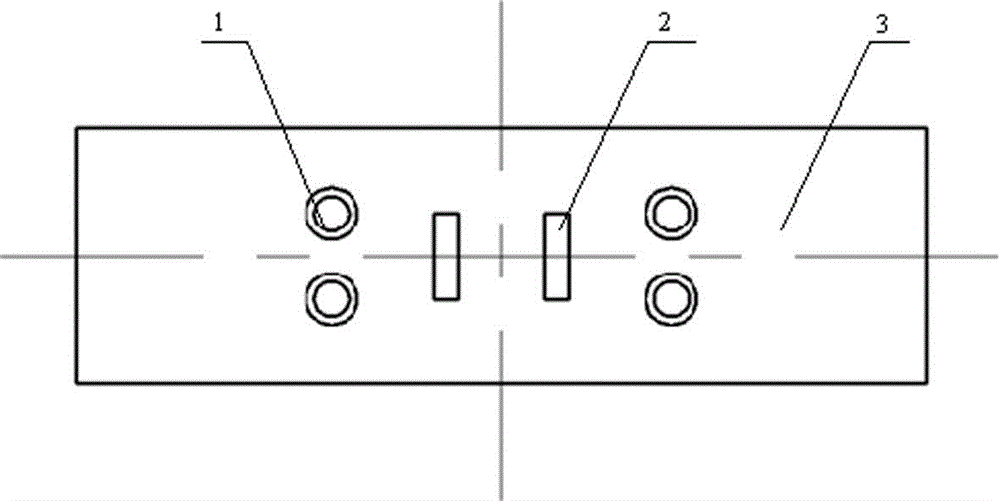

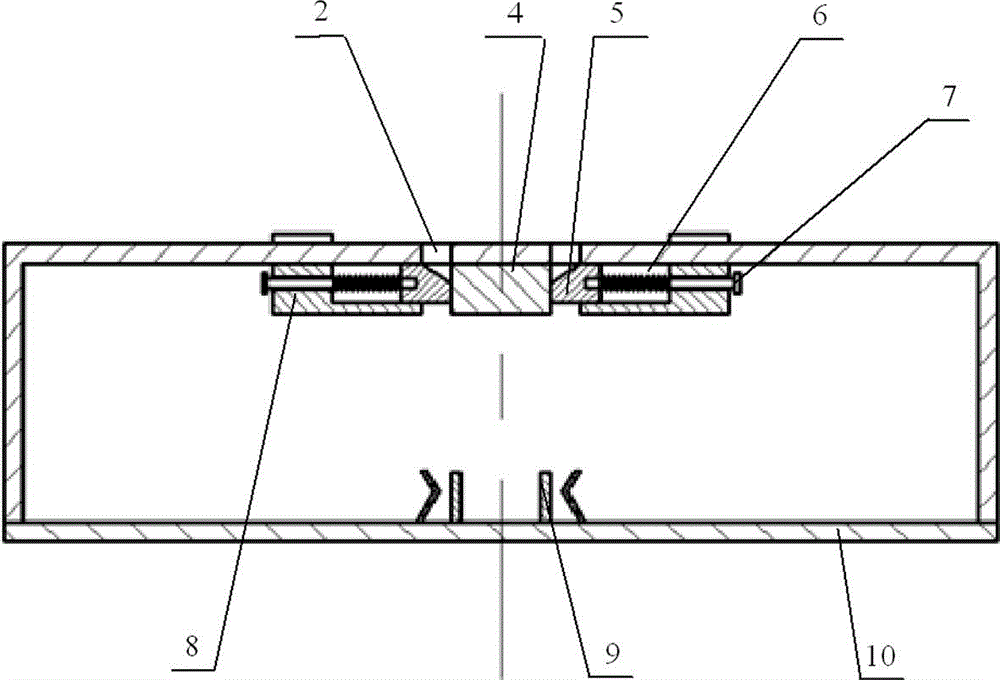

[0012] Such as figure 1 , figure 2 As shown, a new type of safety protection plug-in board includes: a plug-in board case 3 , and a bottom plate 10 is buckled and connected to the bottom of the plug-in board case 3 .

[0013] Jacks 2 are provided on the outer wall of the plug-in board shell 3, and a limit block 4 is fixed on the inner wall of the plug-in board shell 3. The rod 7 is connected with the slide block 5, and the compression spring 6 is sleeved on the slide rod 7.

[0014] Terminal posts 9 are arranged on the inner wall of the base plate 10 .

[0015] The upper part of the slider 5 is provided with a slope.

[0016] The two ends of the compression spring 6 are respectively in contact with the slider 5 and the connecting support block 8,

[0017] And the sliding block 5 is in contact with the limiting block 4 under the elastic force of the compression spring 6 .

[0018] When the power strip is not used, it can prevent electric shock, and when the power strip is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com