Copper-clad aluminum-magnesium wire for communication cable and manufacturing method thereof

A copper-clad aluminum-magnesium, communication cable technology, used in cable/conductor manufacturing, communication cables, conductors, etc., can solve the problems that the relevant performance cannot fully meet the functional requirements of communication cables and the high cost of raw materials, save copper resources and reduce raw materials. Cost, reasonable structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

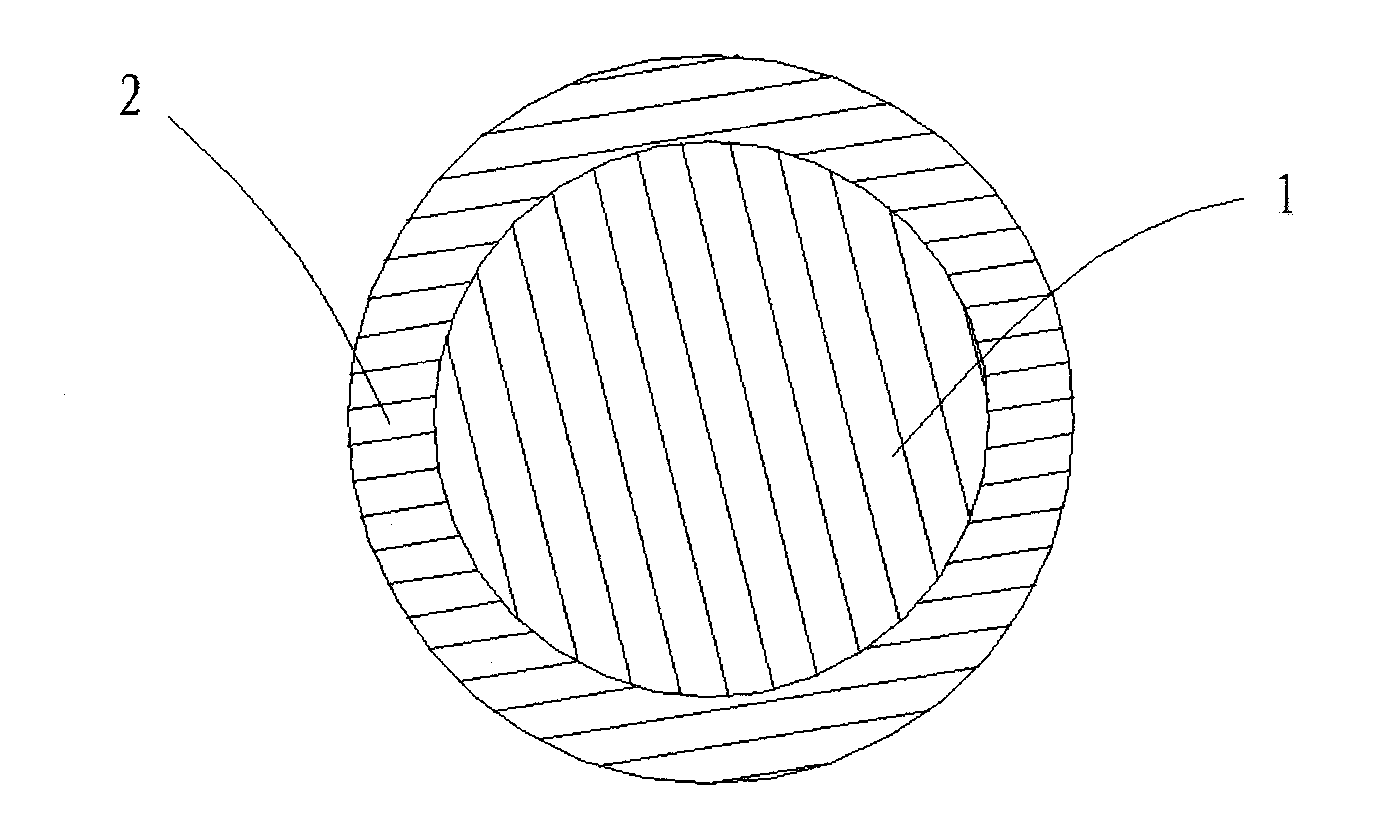

[0051]Embodiment 1: The diameter of the raw material aluminum-magnesium core rod composed of the copper-clad aluminum-magnesium conductor wire for the communication cable is 8.60 mm ± 0.10 mm, according to the volume of the copper-clad aluminum-magnesium conductor wire for the communication cable. For the regulation of 18% to 22%, the thickness of the copper layer is selected to be 0.500mm±0.005mm, and the volume of the copper layer accounts for 19.748% of the volume of the copper-clad aluminum-magnesium conductor wire for communication cables.

Embodiment 2

[0052] Embodiment 2: the diameter of the raw material aluminum-magnesium core rod composed of copper-clad aluminum-magnesium conductor wire for the communication cable is 9.60 mm ± 0.10 mm, according to the volume of the copper layer accounting for the volume of the copper-clad aluminum-magnesium conductor wire for the communication cable For the requirement of 18% to 22%, the thickness of the copper layer is selected to be 0.560 mm ± 0.005 mm, and the volume of the copper layer accounts for 19.804% of the volume of the copper-clad aluminum-magnesium conductor wire for communication cables.

Embodiment 3

[0053] Embodiment 3: the diameter of the raw material aluminum-magnesium core rod composed of the copper-clad aluminum-magnesium conductor wire for the communication cable is 8.60 mm ± 0.10 mm, according to the volume of the copper layer accounted for the volume of the copper-clad aluminum-magnesium conductor wire for the communication cable 18% to 22%, the thickness of the copper layer is selected to be 0.520 mm ± 0.005 mm, and the volume of the copper layer accounts for 20.413% of the volume of the copper-clad aluminum-magnesium conductor wire for communication cables.

[0054] In the technical solution of the present invention, the aluminum content in the aluminum-magnesium core rod is 98.6%-98.8%, the magnesium content is 1.0%-1.4%, and the cadmium content is 0.10%-0.20%.

[0055] In the preferred technical solution of the present invention, the aluminum content in the aluminum-magnesium core rod is 98.65%, the magnesium content is 1.2%, and the cadmium content is 0.15%.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com