Aluminium-in-copper nano mica enamel-covered wire

A nano-mica, enameled wire technology, applied in the direction of transformer/inductor coil/winding/connection, organic insulator, conductor, etc., can solve the problems of waterproof, oil-proof, anti-corona difference, high voltage resistance, thick insulating layer, etc. Achieve anti-corona performance, weight reduction, thin insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

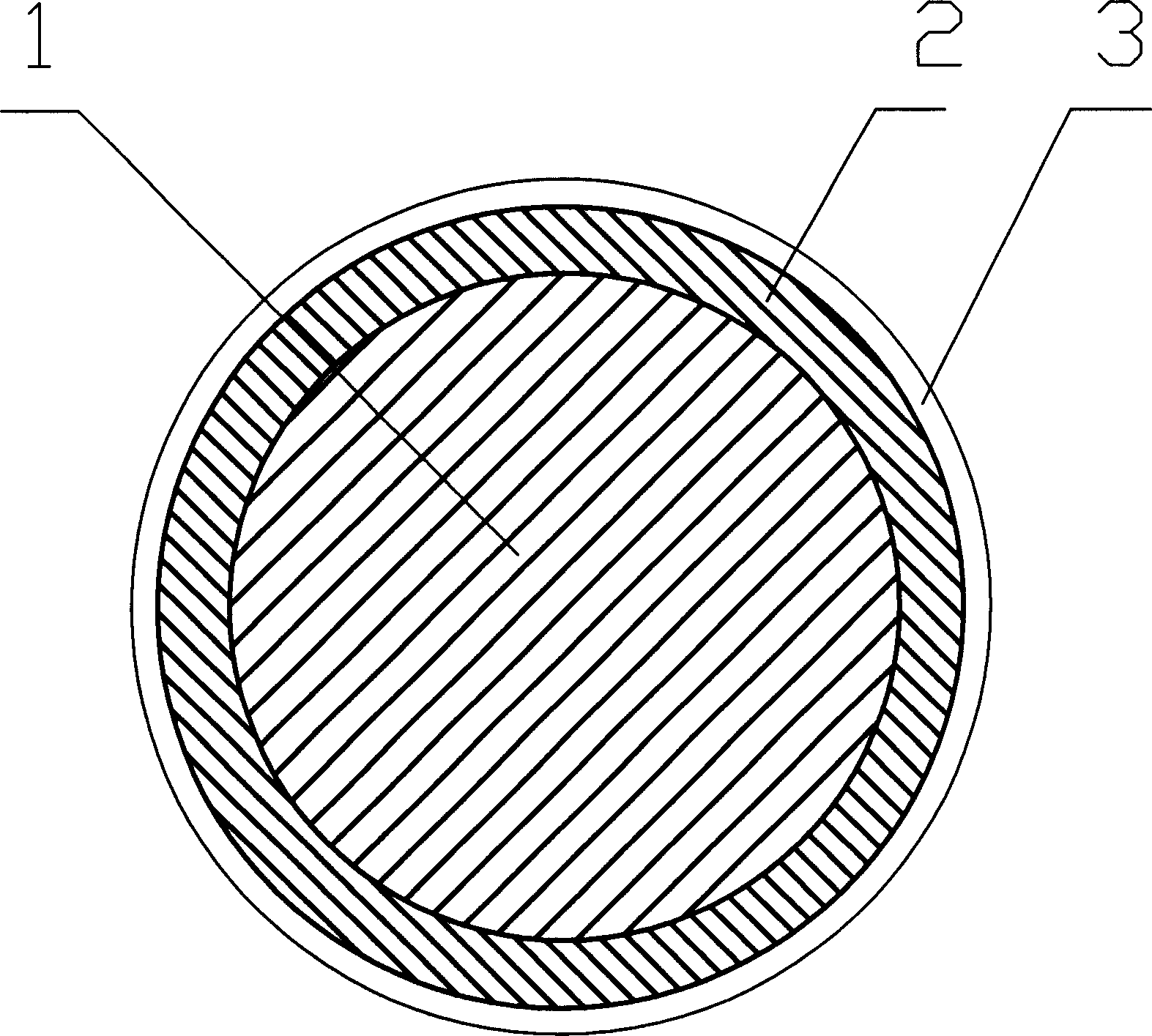

[0008] Referring to the accompanying drawings, the aluminum core 1 is coated with a copper layer 2, and the outer surface of the copper layer 2 is coated with a layer of nano mica insulating varnish 3.

[0009] Due to the "skin effect" of the conductor—that is, the high-frequency current is mainly concentrated on the surface layer of the conductor, that is, the copper layer 2 for transmission. Although the DC resistivity of copper-clad aluminum is equivalent to 1.55 times that of copper, the AC resistivity acting on the operation of motors and transformers tends to be close to that of pure copper wire. Especially in high-frequency signal transmission, due to the skin effect of the conductor, the difference in performance is very small. Therefore, the copper-clad aluminum nano-mica enameled wire can not only realize the purpose of replacing copper with aluminum, reduce costs, and improve benefits; Bimetal is used as the conductor core, which has the advantages of good conducti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com