Tin-plated copper-coated brass wire and production method thereof and tin plating device

A production method and brass wire technology, applied in the field of wire and cable, can solve the problems of uneven coating thickness, rough appearance of tinned wire, poor adhesion, etc., and achieve simplified tinning steps, good appearance brightness, and high thickness uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

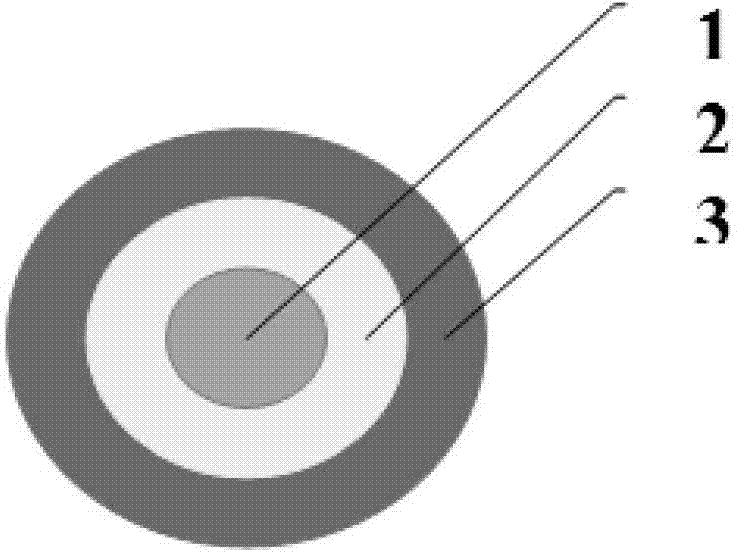

[0029] Such as figure 1 A tinned copper-clad brass wire as shown, which includes a brass wire (1), the brass (1) is coated with a copper layer (2), and the copper layer (2) is coated with The tin layer (3), the brass wire (1) is an alloy containing 68% copper and 32% zinc, and the cross section of the tinned copper-clad brass wire is approximately circular. The copper layer (2) coated on the outside of the brass wire (1) has a copper content of more than 99.98%.

Embodiment 2

[0031] The production method of tinned copper-clad brass wire comprises the following steps:

[0032] (1) Making copper-clad brass rods;

[0033] (2) Draw the above copper-clad copper rod through the wire drawing die of the wire drawing machine to obtain the required copper-clad brass wire. The area reduction rate of the wire drawing die is 10%, and the line speed is 2000 m / min. The compression angle of the mold polycrystalline diamond mold is 12°, the sizing length is 30%, and the formula of the lubricating liquid used in the drawing process is as follows: 10% modified castor oil, 12% modified sunflower oil, 10% sodium petroleum sulfonate, Refined machine oil 54%, isothiazolinone 0.1%, triethanolamine 2.5%, benzotriazole 0.4%, benzene-803%, caustic soda 8%. ;

[0034] (3) Clean the surface of the copper-clad brass wire obtained in step (2) before annealing with a wool-containing 85% felt to remove the drawing lubricant, oil beads, and dust attached to the surfac...

Embodiment 3

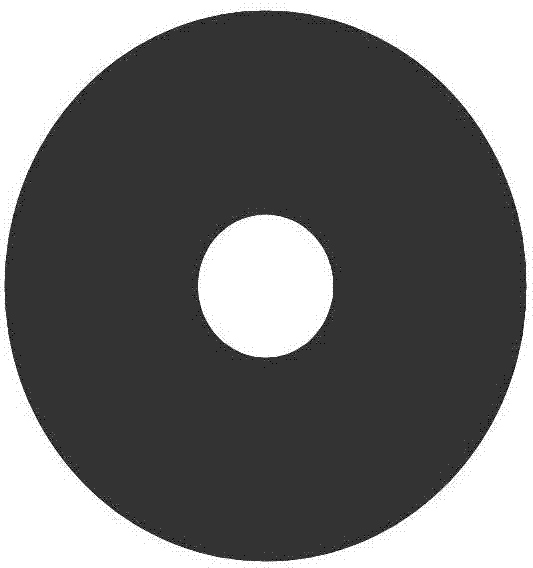

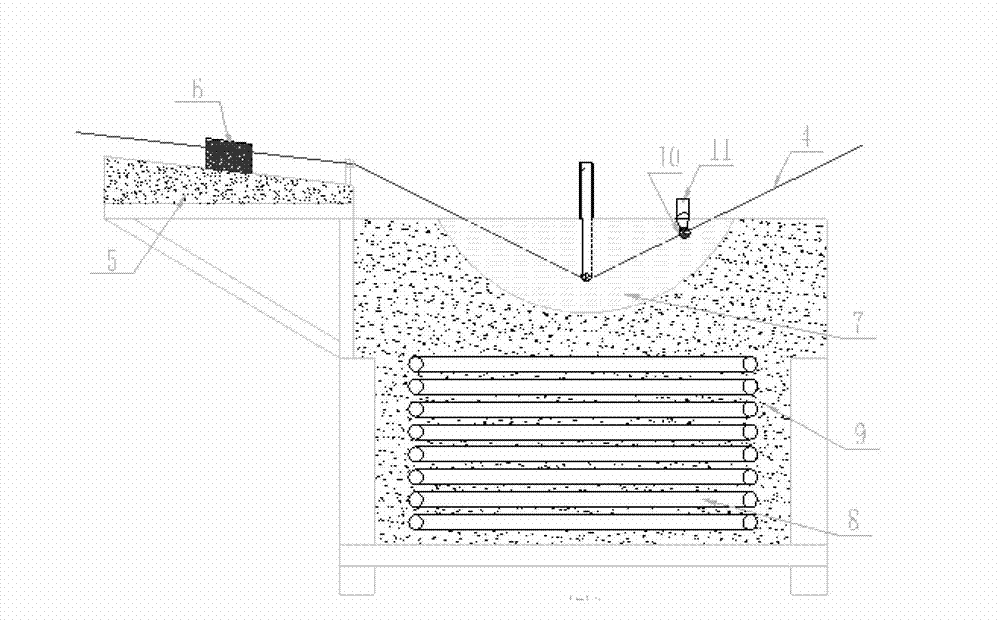

[0038] Such as image 3 As shown, the tinning equipment used in the production process of tinned copper-clad brass wire is hot-dip tinning equipment, which includes a transmission device for transmitting tinned copper-clad brass wire (4), a soldering bath (5), and an auxiliary Welding and clamping tool (6), tin cylinder (7), heating temperature control device (8), heat preservation and temperature-resistant material (9), also includes a tin wiping and sizing mold (10) arranged at the liquid level of the tin liquid And a fixing device (11) for fixing the tin wiping sizing mold (10) at the liquid level of the tin liquid, the fixing mold device can adjust the required angle to meet the required outer diameter of the tinned copper-clad copper wire , to ensure the out-of-roundness of the outer diameter of the tinned copper-clad copper wire and the deviation of the coating. The tin wiping sizing die (10) is composed of a die sleeve and a cylindrical through-hole die core made of di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com