Controllable multi-layer gap overvoltage protector with high weldability based on graphite-metal coating

A metal coating and solderability technology, applied in the field of controllable multi-layer gap overvoltage protectors, can solve the mutual restriction of AC and DC voltage withstand capability, freewheeling capability and lightning overvoltage protection level, and electrically connect metal electrodes Problems such as poor weldability, to achieve the effect of improving power frequency withstand voltage characteristics and lightning voltage protection level, excellent weldability, and good safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be described in further detail below in conjunction with specific examples, but not as a limitation of the present invention.

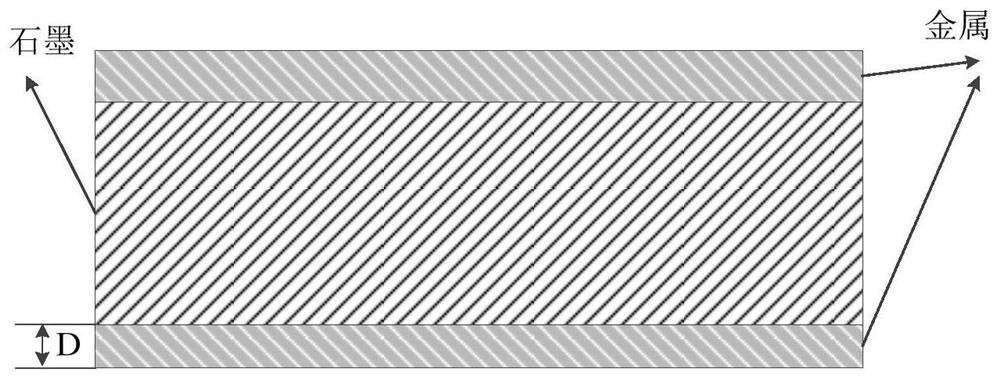

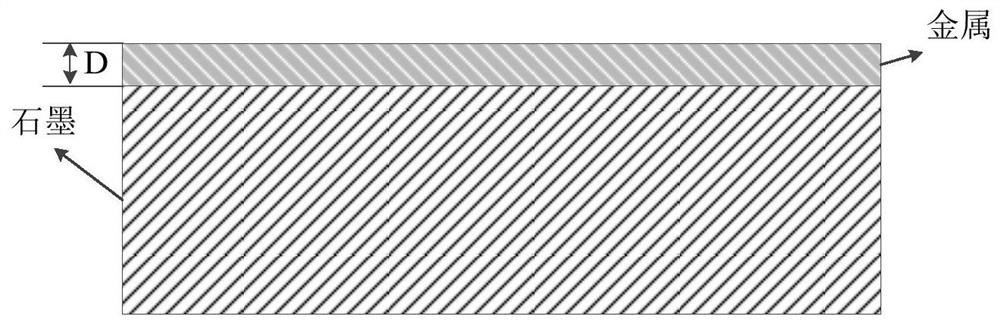

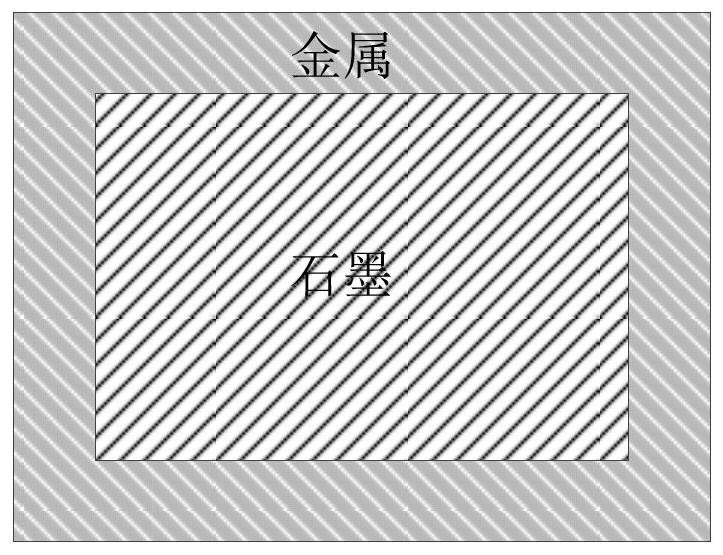

[0039] see Figure 1a-Figure 1d , the present invention is based on graphite-metal coating with high weldability controllable multi-layer gap overvoltage protector, wherein graphite-metal electrode material is made by sputtering metal material on the outer surface of graphite rod, such as Figure 1a and Figure 1b Shown can be a double-side sputtering metal material or a single-side sputtering metal, the graphite rod can be a round rod or a rectangular or square rod, and the rectangular cross-section and circular cross-section of the graphite-metal material are respectively as follows Figure 1c and Figure 1d As shown; the metal material for sputtering can be aluminum, copper or other materials, the thickness D of the metal sputtering layer can be controlled at 8-20mm, and the metal sputtering is realized by arc s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com