Lacquered wire for motor winding

A technology of motor windings and enameled wires, applied in the field of enameled wires, can solve the problems of poor heat resistance of motor windings, reduce the starting speed of the motor, reduce the main magnetic flux of the motor, etc., achieve high heat resistance, stable starting, and improve the effect of the main magnetic flux

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

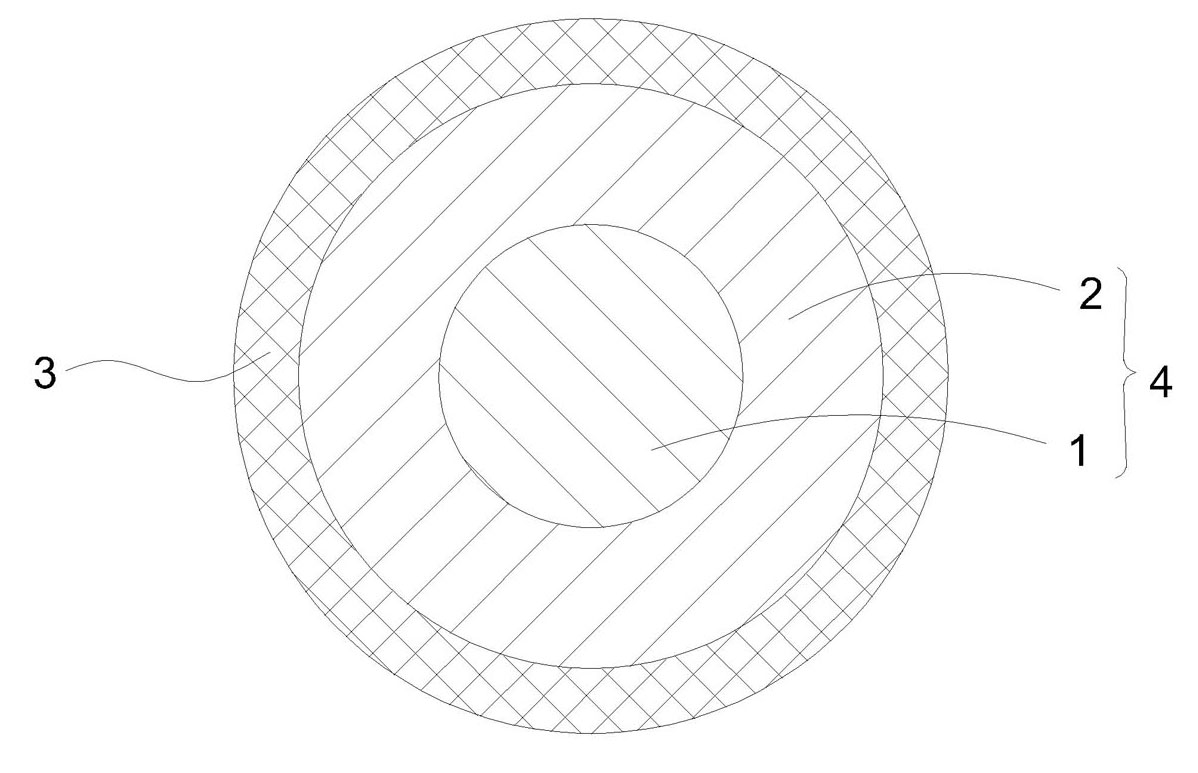

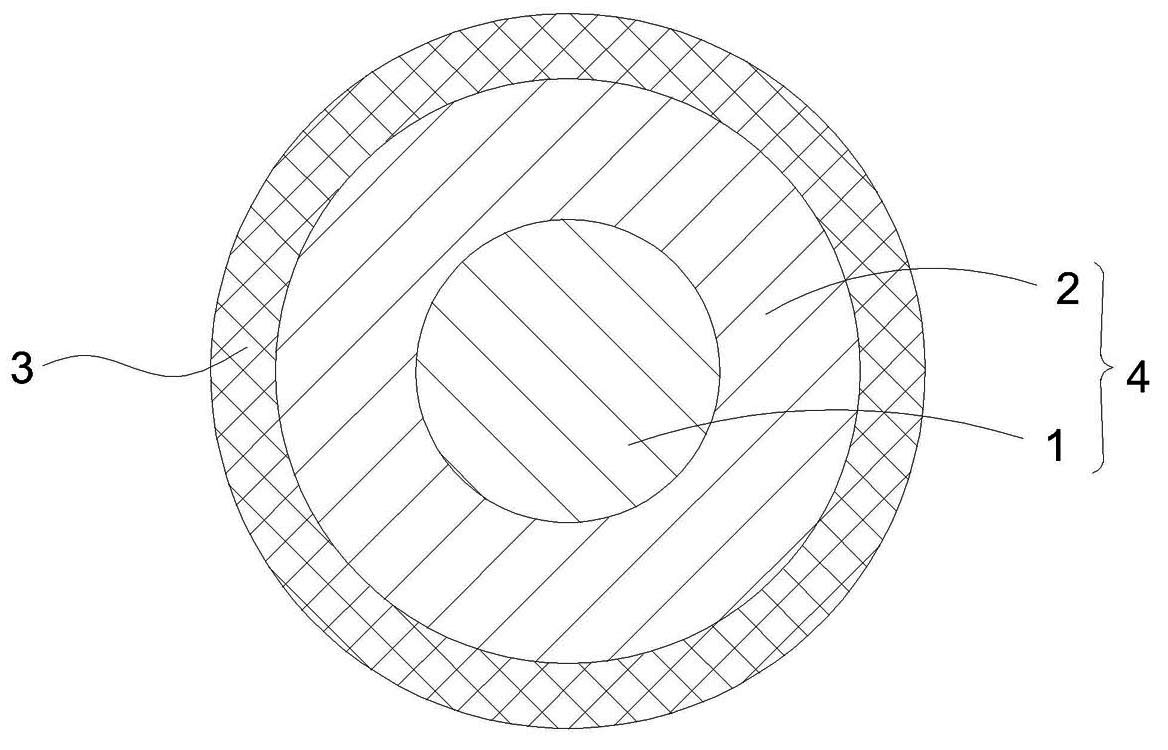

[0016] See attached figure 1 As shown, an enameled wire for a motor winding includes a magnetically permeable core 4 and an insulating layer 3 coated outside the magnetically permeable core 4, and the insulating layer 3 is coated on the outer surface of the copper layer 2 There are polyester or polyurethane or polyimide formed. The magnetic permeable core 4 includes a steel core 1 and a copper layer 2 coated on the outside of the steel core 1 . The copper layer 2 is coated on the outside of the steel core 1 by extrusion. The steel core 1 is preferably Q195 steel with good magnetic permeability. Steel has magnetic properties, so it can play a role in magnetic conductivity, increase the tensile strength of enameled wire and improve the mechanical properties of enameled wire; copper has excellent electrical conductivity and corrosion resistance, so it can improve electrical conductivity and protect the inner layer The role of the steel core.

[0017] The present inventio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com