Fixing structure of secondary hanger for plating PCB (Printed Circuit Board)

A printed circuit board and fixed structure technology, applied in electrolysis process, electrolysis components, etc., can solve problems such as uneven plating, detachment, copper slag, etc., achieve the effect of improving copper slag problem, improving product quality, and ensuring uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

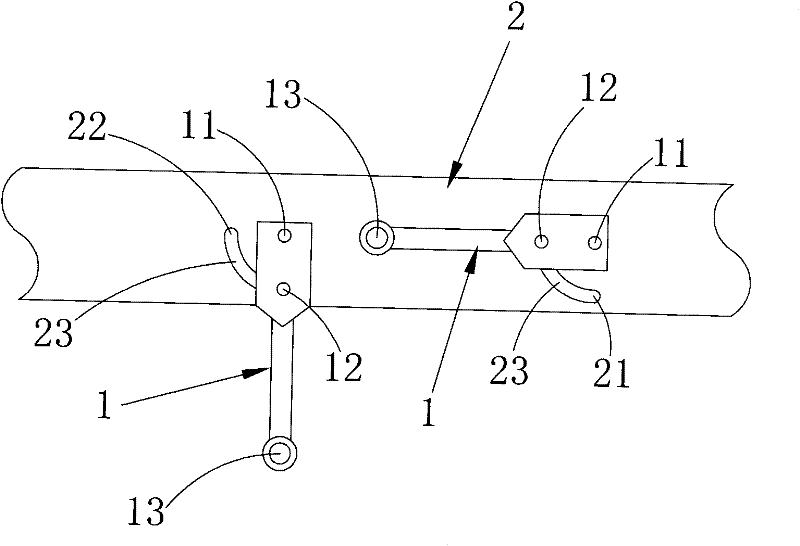

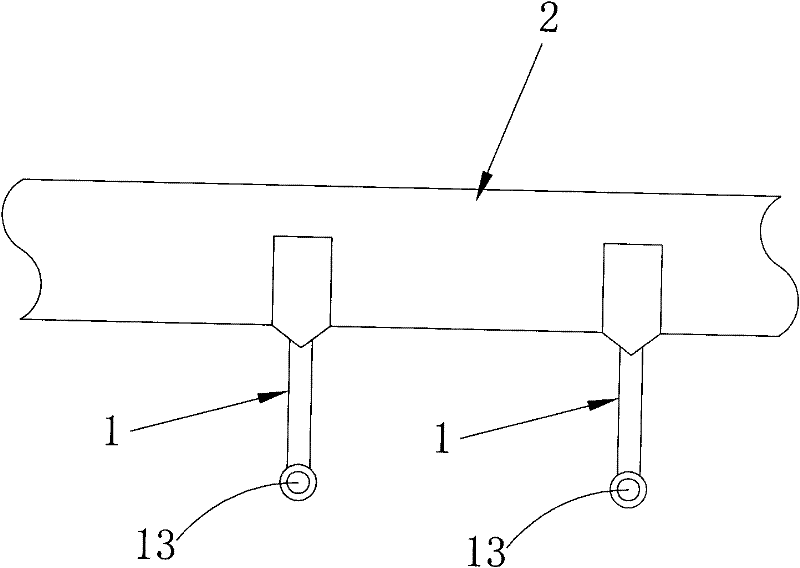

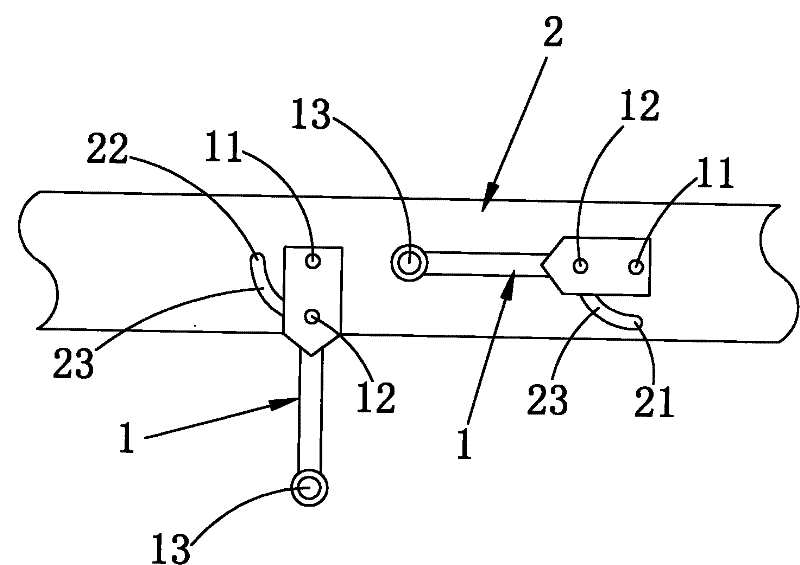

[0013] Embodiment: a fixing structure of a secondary hanger for printed circuit board electroplating, several secondary hangers 1 are fixed on the copper plate 2 at intervals, and one end of the secondary hanger has a fixed point that is fixedly connected with the copper plate. The other end of the secondary hanger has a locking point 13 for fixing the board. One end of the secondary hanger 1 has two fixed points, which are the first and second fixed points 11 and 12. The second hanger is fixed at the first Point 11 is rotatably connected to the bronze medal 2, and the secondary hanger can rotate around the first fixed point. The position on the bronze medal vertically below the first fixed point 11 has a first positioning point 21. The bronze medal The position located in the horizontal direction of the first fixed point and having a horizontal distance from the first fixed point has a second positioning point 22, and the first fixed point 11 is far from the second fixed point...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com